Process Filtration

Process Filtration

Process Filtration

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

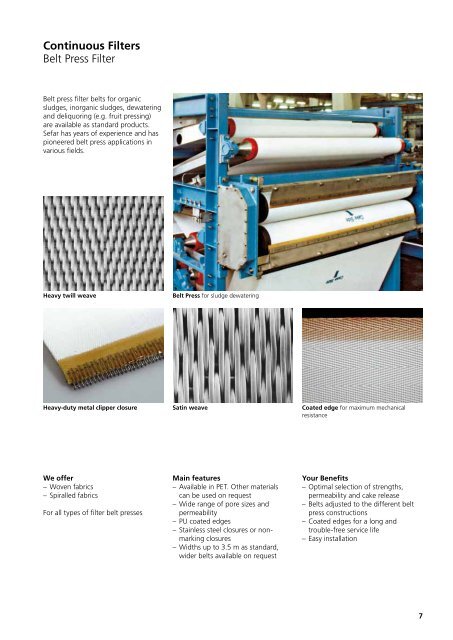

Continuous Filters<br />

Belt Press Filter<br />

Belt press filter belts for organic<br />

sludges, inorganic sludges, dewatering<br />

and deliquoring (e.g. fruit pressing)<br />

are available as standard products.<br />

Sefar has years of experience and has<br />

pioneered belt press applications in<br />

various fields.<br />

Heavy twill weave<br />

Belt Press for sludge dewatering<br />

Heavy-duty metal clipper closure<br />

Satin weave<br />

Coated edge for maximum mechanical<br />

resistance<br />

We offer<br />

– Woven fabrics<br />

– Spiralled fabrics<br />

For all types of filter belt presses<br />

Main features<br />

– Available in PET. Other materials<br />

can be used on request<br />

– Wide range of pore sizes and<br />

permeability<br />

– PU coated edges<br />

– Stainless steel closures or nonmarking<br />

closures<br />

– Widths up to 3.5 m as standard,<br />

wider belts available on request<br />

Your Benefits<br />

– Optimal selection of strengths,<br />

permeability and cake release<br />

– Belts adjusted to the different belt<br />

press constructions<br />

– Coated edges for a long and<br />

trouble-free service life<br />

– Easy installation<br />

7