EVERY WORKER

Download Every Worker/Winter 2013 - Workplace Safety North

Download Every Worker/Winter 2013 - Workplace Safety North

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

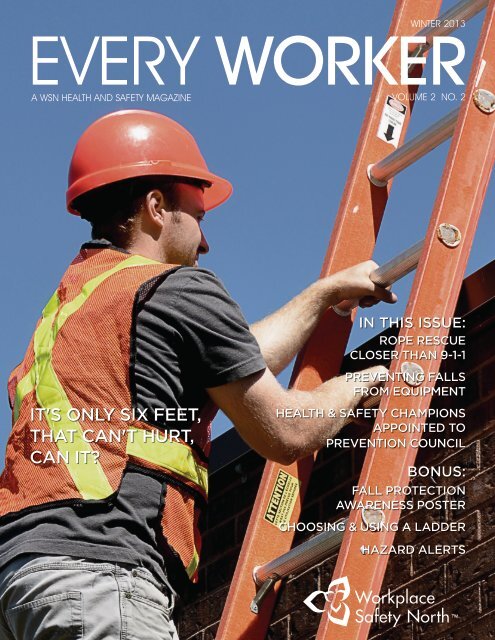

WINTER 2013<br />

<strong>EVERY</strong> <strong>WORKER</strong><br />

A WSN HEALTH AND SAFETY MAGAZINE VOLUME 2 NO. 2<br />

IT'S ONLY SIX FEET,<br />

THAT CAN'T HURT,<br />

CAN IT?<br />

IN THIS ISSUE:<br />

ROPE RESCUE<br />

CLOSER THAN 9-1-1<br />

PREVENTING FALLS<br />

FROM EQUIPMENT<br />

HEALTH & SAFETY CHAMPIONS<br />

APPOINTED TO<br />

PREVENTION COUNCIL<br />

BONUS:<br />

FALL PROTECTION<br />

AWARENESS POSTER<br />

CHOOSING & USING A LADDER<br />

HAZARD ALERTS

<strong>EVERY</strong> <strong>WORKER</strong> MAGAZINE Winter 2013 VOLUME 2 NO. 2<br />

CONTENTS<br />

FEATURES<br />

4 It's Only Six Feet<br />

That Can't Hurt, Can It?<br />

6 Rope Rescue<br />

Closer Than 9-1-1<br />

10 Preventing Falls From Equipment<br />

4<br />

12 Choosing and Using a Ladder<br />

50% Knowledge and 50% Taking Time To Work Safely<br />

14 Health and Safety Champions<br />

Appointed to Prevention Council<br />

PLUS... A FALL PROTECTION POSTER... AND...<br />

6<br />

8 How WSN Can Help<br />

9 Paper, Printing and Converting Sector Hazard Alert<br />

Hidden Hazards Can Trip Workers<br />

11 Mining Sector Hazard Alert<br />

Worker Tumbles from Top of LHD<br />

10<br />

13 Forestry Sector Hazard Alert<br />

Routine Maintenance Ends in Fall from Crane<br />

15 WSN Health and Safety Notes<br />

12<br />

For information and resources on "same level falls", see the Fall 2011 issue of<br />

Every Worker, available at WorkplaceSafetyNorth.ca.<br />

2 WorkplaceSafetyNorth.ca

<strong>EVERY</strong> <strong>WORKER</strong><br />

A WSN HEALTH AND SAFETY MAGAZINE<br />

President’s message<br />

A fall can change everything<br />

Joel Swartz, the director of Metron Construction<br />

Corporation, a Toronto constructor, was fined<br />

$90,000 after pleading guilty to violations of<br />

the Occupational Health and Safety Act (OHSA)<br />

after four workers were killed and another<br />

worker was seriously injured.<br />

On December 24, 2009, six workers were on<br />

a suspended work platform, also known as a<br />

swing stage, at a construction project on Kipling<br />

Avenue in Toronto. The swing stage collapsed<br />

and fell 13 floors, killing four of the workers and<br />

seriously injuring another worker. The only worker properly attached<br />

to fall protection was held by the lifeline and pulled to safety.<br />

A Ministry of Labour investigation found that the deceased workers<br />

had not been properly tied off to a lifeline, and had not been properly<br />

trained in the use of fall protection. The swing stage had been<br />

overloaded and it was later determined to be defective and hazardous.<br />

Swartz pleaded guilty under the Act to failing, as a director, to take all<br />

reasonable care to ensure that:<br />

• workers did not use a defective or hazardous swing stage;<br />

• the swing stage was not loaded in excess of the weight it was<br />

meant to bear;<br />

• workers were adequately trained in the use of fall protection by a<br />

competent person.<br />

Metron Construction Corporation was convicted of criminal negligence<br />

causing death and was fined $200,000 in relation to the same incident.<br />

In honour of the men who died and the one who was injured, please<br />

read the life-saving information on safely working at heights in this<br />

issue of Every Worker. On Page 4 Mike Mitchell shares the devastating<br />

consequences (28-inch incision, 97 staples, 9 six-inch screws) of<br />

falling only six feet off a ladder. On Page 10 we look at how not to fall<br />

off mobile equipment. And on Page 6 we look at what’s critical when<br />

prevention fails – a rescue plan. Do you have one?<br />

We hope you discover some new solutions to old problems in this issue<br />

of Every Worker, and we welcome your feedback. Drop me a line and<br />

let me know what you think.<br />

WORKPLACE SAFETY NORTH<br />

690 McKeown Avenue<br />

P.O. Box 2050, Stn. Main<br />

North Bay, ON P1B 9P1<br />

Toll free: 1-888-730-7821 (Ontario only)<br />

Fax: 705-472-5800<br />

WorkplaceSafetyNorth.ca<br />

The information in this publication is<br />

accurate to the best of our knowledge.<br />

WSN assumes no responsibility or<br />

liability for the accuracy or sufficiency<br />

of this information, nor does it endorse<br />

any product mentioned herein with the<br />

exception of those produced by WSN.<br />

If you would like to receive this<br />

magazine electronically email:<br />

First2Know@workplacesafetynorth.ca<br />

For another copy of Every Worker or for<br />

the French version, call us:<br />

Toll free: 1-888-730-7821 (Ontario)<br />

customercare@workplacesafetynorth.ca<br />

For media inquiries, contact:<br />

media@workplacesafetynorth.ca<br />

To arrange for training or if you have any<br />

questions, please direct your inquiry to<br />

our customer care:<br />

Toll free: 1-888-730-7821 (Ontario)<br />

customercare@workplacesafetynorth.ca<br />

Would you like to be notified of new<br />

WSN products, services and events as<br />

they become available?<br />

Join our mailing list by contacting:<br />

First2Know@workplacesafetynorth.ca<br />

Scan this QR code to<br />

visit our Twitter feed.<br />

Candys Ballanger-Michaud<br />

President & CEO<br />

candysballangermichaud@workplacesafetynorth.ca<br />

<strong>EVERY</strong> <strong>WORKER</strong><br />

3

4 WorkplaceSafetyNorth.ca<br />

BY MIKE MITCHELL

"Six hours, 25 minutes on the operating<br />

table, an incision over 28 inches long, nine<br />

six-inch screws, 97 staples, and generous<br />

amounts of pain later"<br />

It would seem only right to first<br />

apologize for not practising<br />

what I preach, I made the<br />

poorest of poor decisions. At<br />

the same time, let me explain<br />

how easy it was to “talk myself”<br />

into getting where I am now.<br />

The job was to develop a lockout for piping changes<br />

during a mill shutdown. About a dozen valves, some<br />

would be used every five years or so but a couple probably<br />

had never been used since they were installed. In order to<br />

help the lockout go smoothly, I decided to lubricate these<br />

valves before the shutdown.<br />

I chose the easiest one to start with, on a pipe about<br />

eight feet off the ground. Ladders were being furiously<br />

collected at this time for the shutdown and I was left with<br />

the bottom half of a 16-foot extension, a little beat up but<br />

still functional with decent feet.<br />

Because of cable trays and other piping, I could not get<br />

the ladder as vertical as needed – little better than 45<br />

degrees. It looked ugly and I knew it. Worse, there was<br />

no place to tie off the bottom. I examined the options,<br />

walking away, finding a better ladder, waiting for help or<br />

taking a chance.<br />

Being the patient type I am, I looked again at the height<br />

and chose the last one. I figured at best I’d be six feet off<br />

the ground and I could jump if anything happened. How<br />

could I get hurt?<br />

From here my day went downhill.<br />

I bounced on the third rung a couple of times. It did not<br />

move so I decided it was good to go. I’d just got eye level<br />

with the cable tray and was transferring tools when I<br />

heard/felt the ladder start to slip. Instinctively I grabbed<br />

the ladder tighter (fat lot of use that was!), next I was on<br />

the ground.<br />

That fast.<br />

The plan to jump, you ask?<br />

Not a hope. Not even time to think about it.<br />

So, to return to the question six feet can’t hurt, can it?<br />

Six hours, 25 minutes on the operating table, an incision<br />

over 28-inches long, nine six-inch screws, 97 staples, and<br />

generous amounts of pain later, I can assure you it can!<br />

The picture says a thousand words.<br />

Bottom line, I’m sworn off ladders for life and my thought<br />

process has changed dramatically. (Closing the door on an<br />

empty stable?)<br />

Faced with countless similar choices workers meet<br />

regularly, I hope you would contemplate what happened<br />

to me when making your decisions. This is one example<br />

you don’t want to follow.<br />

Oh, by the way, that valve I was so “gung-ho” to grease? I<br />

later heard it closed like a “piece of cake” without it.<br />

Go figure.<br />

Mike Mitchell, of Sault Ste. Marie, “(eventually) walked<br />

away with no ill effects” and is now retired.<br />

<strong>EVERY</strong> <strong>WORKER</strong><br />

5

Rope Rescue<br />

Closer than 9-1-1<br />

A rescue procedure should<br />

be the final part of any fall<br />

protection plan for working at<br />

heights, and that procedure<br />

should be more than calling 9-1-1<br />

when, in a worst-case scenario,<br />

a worker is suspended at height<br />

and possibly injured.<br />

Shawn Kirwan, an Emergency Services Specialist with<br />

Ontario Mine Rescue, a part of Workplace Safety North,<br />

helps companies prepare for when they need to take<br />

action. Kirwan teaches a variety of emergency response<br />

courses, including a high-angle rope rescue course for<br />

companies that have workers at risk of falling from heights.<br />

6 WorkplaceSafetyNorth.ca

Many of the companies that participate in the course are<br />

mining companies that have operations in locations distant<br />

or remote from emergency services. But not even all modern<br />

urban emergency services have the equipment or the<br />

expertise to do high-angle rope rescue, Kirwan says, and for<br />

those that do, they may not be at the nearest station.<br />

So calling 9-1-1 may not necessarily prompt a rescue,<br />

never mind a timely rescue. Trained volunteer workplace<br />

responders, however, can provide a timely response.<br />

A swift rescue is important because the suspended worker’s<br />

life may be hanging in the balance. The worker may have<br />

fallen because he or she was injured, or may have been injured<br />

in the fall, and in either case requires medical attention.<br />

Delayed response could contribute to the worker panicking.<br />

As well, while suspended, a worker is at risk of suffering<br />

suspension trauma or orthostatic shock, which occurs when<br />

the leg straps of a harness restrict blood circulation, causing<br />

blood to pool in the legs. Suspension trauma can occur<br />

in as little as five minutes, resulting in the worker losing<br />

consciousness and even dying.<br />

Kirwan’s classroom presentation and course materials cover<br />

the basics of rope rescue equipment and techniques, including<br />

rigging configurations, rescue knots and anchorages. But his<br />

two-day course places an emphasis on hands-on activities.<br />

Extensive practical exercises at elevation include the raising<br />

and lowering of personnel, the slinging of stretchers, and the<br />

pick-off maneuver for the rescue of a suspended casualty.<br />

Though Ontario Mine Rescue has access to the Alertec<br />

firefighting training facility in Azilda, near Sudbury to<br />

present the course, Kirwan prefers to offer the course<br />

to companies on-site. That way, he says, the volunteer<br />

responders are not only training in the environment and<br />

the work areas in which they might have to respond, but<br />

the practical exercises can be tailored to the emergency<br />

situations they may encounter.<br />

As well, site-specific issues, such as anchorage locations, can<br />

be examined and addressed in training. Familiarity with their<br />

own facility gives industrial responders an advantage over<br />

equipped and trained municipal services.<br />

The course is developed for use with the GripTech SP2 Rope<br />

Rescue System, a versatile mechanical advantage system<br />

specifically designed for fire departments and industrial<br />

rescue teams, in broad use across Ontario.<br />

The GripTech system allows rescuers to be vertically raised<br />

or lowered from one level to another or for raising victims<br />

to a surface area. It can easily be switched from controlled<br />

lowering to raising, and can be used for any angle – horizontal<br />

to vertical – rescue.<br />

Another attraction of the GripTech is that it and the<br />

half-inch safety rope it uses, is designed to a maximum<br />

two-person load of 600 lbs., Kirwan says, that permits<br />

a rescuer to be raised or lowered with a casualty,<br />

simplifying rescue operations.<br />

However, the emergency services specialist will tailor the<br />

training and practical exercises to whatever rescue rigging<br />

or other emergency equipment that a company uses. The<br />

intent of the course is to help companies be prepared to act,<br />

and provide the final part of their fall protection plan.<br />

<strong>EVERY</strong> <strong>WORKER</strong><br />

7

How WSN can help:<br />

Workplace Safety North offers a range of<br />

products to help workplaces improve their fall<br />

prevention training programs including:<br />

TRAINING<br />

Focus on Falls<br />

People are falling — statistics are not. In Ontario, approximately 80 people<br />

fall at work every day. This half-day course provides participants with<br />

information and guidance and controlling slip, trip and fall hazards in the<br />

workplace. Participants also learn how to develop and implement a fall<br />

prevention program.<br />

Fall Protection Awareness Online<br />

This Internet-based training program provides a valuable one-hour overview of<br />

why fall protection systems are important, what the law requires regarding fall<br />

protection, and how fall hazards in the workplace can be eliminated or prevented.<br />

High Angle/Confined Space Rescue Training<br />

This course, which may be presented on-site if suitable facilities are available,<br />

offers a combination of knowledge and skills development in a competencybased<br />

approach to training with an emphasis on hands-on activities. Classroom<br />

presentations and course material covers legislation imposing rescue<br />

requirements, suspension trauma, and the basics of rope rescue equipment<br />

and techniques, including rigging configurations, rescue knots and anchorages.<br />

Extensive practical exercises at elevation include the raising and lowering of<br />

personnel, the slinging of stretchers, the pick-off maneuver for the rescue of a<br />

suspended casualty, and extrication from confined spaces.<br />

Doing Better,<br />

But More to be Done<br />

When it comes to preventing<br />

falls from heights we’re doing<br />

better, but the improvement is<br />

not keeping pace with the overall<br />

reduction in lost-time injuries.<br />

Statistics show that last year<br />

Workplace Safety North clients<br />

– in the mining, forestry, paper,<br />

printing and converting sectors<br />

– reported a decline of about 52<br />

per cent over the past 10 years in<br />

lost-time injuries due to falls from<br />

heights, but the overall lost-time<br />

injury rate declined by about 68<br />

per cent over the same period.<br />

Falls from heights include<br />

falls down stairs or steps, from<br />

ladders and scaffolding, from<br />

non-moving vehicles, from one<br />

level to a lower level, from roofs,<br />

loading docks and through holes<br />

and various openings.<br />

Across Ontario, falls from<br />

heights account for about a<br />

third of all fall-related injuries.<br />

The remaining two-thirds<br />

are classified as “same level<br />

falls”. (See the Fall 2011 Every<br />

Worker for more on "same level<br />

falls".) Combined falls account<br />

for roughly 20 per cent of all<br />

workplace injuries.<br />

Sprains, strains, soft tissue<br />

tears and bruises are the most<br />

common injuries suffered in falls<br />

from heights, accounting for<br />

more than 50 per cent. Almost 30<br />

per cent result in fractures which<br />

may occur in virtually any bone<br />

in the body.<br />

Falls don't only hurt workers,<br />

they can kill workers. Over the<br />

past 10 years among Workplace<br />

Safety North clients, an average<br />

of one worker a year dies as a<br />

result of injuries suffered in a fall<br />

from heights.<br />

For more information on these courses and products, or for information on other fall protection products,<br />

contact Workplace Safety North at 1-888-730-7821 or visit WorkplaceSafetyNorth.ca.<br />

8 WorkplaceSafetyNorth.ca

HAZARD ALERT!<br />

PAPER, PRINTING AND CONVERTING SECTOR<br />

Hidden Hazards<br />

Can Trip Workers<br />

WHAT HAPPENED?<br />

Each year workers are seriously injured from slips,<br />

trips and falls. Employees working behind a paper<br />

machine on a production-related emergency issue<br />

are in a hurry to get the equipment operational again.<br />

They could be focusing so much of their effort on<br />

those production problems that they fail to see the<br />

hazards, a hose or the slippery material on the floor,<br />

and face injuries ranging from minor scratches all the<br />

way up to fractured arms and legs.<br />

WHY DID IT HAPPEN?<br />

Behind a paper machine are all kinds of slip and fall<br />

hazards – pipes jutting out, hoses all over the floor,<br />

stock and additives leaking onto the floor – that are<br />

normally out of sight and often out of mind.<br />

HOW COULD IT BE PREVENTED?<br />

Workers need to be trained, reminded and encouraged to identify and control<br />

hazards when beginning work assignments.<br />

Good housekeeping practices can make a difference. Workers should take the proper<br />

steps when doing regular clean up, ensure hoses are in their proper spot, and the<br />

floor is clear of stock and fluids.<br />

Better design and regular maintenance can ensure spills are contained and don’t<br />

spread too far into walkways.<br />

Regular equipment inspections and upkeep can limit how much time workers need<br />

to spend in the back of the paper machines.<br />

call us toll free: 1-888-730-7821 (Ontario)<br />

WorkplaceSafetyNorth.ca<br />

This alert is based on an actual incident. If you have an incident you’d like to share, please email customercare@<br />

workplacesafetynorth.ca. The description of circumstances does not reflect legal commentary, nor is it meant to assign<br />

legal responsibility to any person or firm.

PREVENTING FALLS<br />

FROM EQUIPMENT<br />

If workers stopped jumping off mobile<br />

equipment, there would be a drop of about<br />

five per cent in the number of lost-time<br />

injuries due to falls from mobile equipment<br />

among Workplace Safety North clients.<br />

That’s not a bad start to reducing claims, but it’s not<br />

nearly enough to reduce or stop the pain and suffering<br />

workers experience when injured in falls from mobile<br />

equipment, or the costs to employers when valuable<br />

employees are off work for weeks or months at a time.<br />

Though fatal falls from mobile equipment are uncommon<br />

– none have been recorded among WSN clients in the last<br />

10 years – almost all workers experience soft tissue injuries<br />

such as cuts, bruises and abrasions, sprains, strains, and<br />

muscle tears, and a significant number, more than 25 per<br />

cent, suffer serious hard tissue injuries like dislocations<br />

and fractures to their feet, legs, back, neck and head.<br />

In each sector WSN serves – mining, forestry, paper,<br />

printing and converting – workers are injured in falls<br />

from equipment in roughly equal numbers. They are hurt<br />

falling off mobile equipment of every type, from small<br />

forklifts to huge off-road haul trucks. They fall mounting or<br />

dismounting, maintaining or servicing vehicles, checking<br />

or securing loads, and, yes, several times a year because<br />

they jump or don’t use the ladders or steps provided.<br />

Employers should develop and regularly review a<br />

comprehensive fall prevention plan for mobile equipment<br />

that goes beyond worker awareness of fall hazards and<br />

training in appropriate procedures. The plan could begin<br />

by examining fall protection measures other sectors use<br />

and considering whether those measures can be used or<br />

adapted to their own operations.<br />

Those may include fixed horizontal lifelines on mobile<br />

equipment or in service/maintenance facilities that permit<br />

the use of fall restraint or fall arrest; temporary or portable<br />

anchorage systems that can be attached to equipment or<br />

located next to equipment in operational areas; collapsible<br />

or temporary guardrails on equipment, as well as<br />

temporary ladders or access platforms or other devices.<br />

Since it’s not just operators who fall from mobile<br />

equipment while mounting or dismounting, the plan<br />

should review the specific fall hazards each piece of mobile<br />

equipment poses to different workers, such as mechanics<br />

or maintenance staff, who come into contact with the<br />

equipment, and determine what control measures –<br />

additional fall prevention features, modifications, training,<br />

and procedures – may be appropriate.<br />

For example, recently a worker was working in an<br />

underground shop on the top of an LHD (Load-Haul-<br />

Dump). While on his knees, the worker placed a hand<br />

on a rubber wheel fender which flexed under his weight<br />

causing him to fall (See the Mining Hazard Alert on Pg.<br />

11). Prior modifications to the equipment or different<br />

procedures may have prevented the incident.<br />

Of course, it’s better not to have to modify equipment, so<br />

prior to purchasing new mobile equipment it should be<br />

assessed for the risk of falls. Discussions can be held with the<br />

manufacturer or dealer on additional fall prevention features<br />

they may add, or that can be added during commissioning.<br />

Employer concerns about fall prevention features need to<br />

passed along to manufacturers and dealers, so that they<br />

can jump on the fall prevention bandwagon.<br />

When designing or purchasing equipment note:<br />

• Stairs are preferable to vertical steps<br />

• Continuous hand rails are preferable to individual<br />

grab handles<br />

• Mounting steps should be designed not to collect<br />

dirt (mud, snow or ice)<br />

• Anti-slip paint is preferable to tape<br />

• Access points (stairs and handles) should be<br />

painted a different colour so workers know where<br />

to step and what to grab<br />

• As much servicing as possible is done at ground level<br />

• Lighting for access points, especially for equipment<br />

used in low or poor light situations<br />

10 WorkplaceSafetyNorth.ca

HAZARD ALERT!<br />

MINING SECTOR<br />

Worker Tumbles<br />

From Top of LHD<br />

WHAT HAPPENED?<br />

A worker was working in an underground shop on the top of a nine-yard LHD (Load-<br />

Haul-Dump) picking up tools and materials. While on his knees, the worker placed<br />

a hand on a rubber wheel fender which flexed under his weight causing him to lose<br />

balance and fall to the concrete floor. The worker suffered minor injuries that could<br />

have been much more serious.<br />

WHY DID IT HAPPEN?<br />

The worker was not wearing a fall arrest/travel restraint device.<br />

There were no fall prevention guardrails on the top of the LHD.<br />

The rubber fender was not designed to bear the weight of a human, and the worker<br />

was not aware or alert to this fact.<br />

HOW COULD IT BE PREVENTED?<br />

Mobile equipment manufacturers and mining companies should consider providing<br />

anchor points to allow for fall arrest/travel restraint.<br />

Collapsible or temporary fall prevention (guardrails) devices may be installed on the<br />

top of the LHD.<br />

All accessible surfaces should consist of a rigid material capable of supporting the<br />

weight of a worker.<br />

In a shop area, fall arrest anchorages may be installed for workers who access the<br />

top of mobile equipment. This may consist of an adjustable and/or removable, wellmarked<br />

lifeline across the shop.<br />

call us toll free: 1-888-730-7821 (Ontario)<br />

WorkplaceSafetyNorth.ca<br />

This alert is based on an actual incident. If you have an incident you’d like to share, please email customercare@<br />

workplacesafetynorth.ca. The description of circumstances does not reflect legal commentary, nor is it meant to assign<br />

legal responsibility to any person or firm.

Choosing & Using a Ladder<br />

Proper ladder usage is 50% knowledge<br />

and 50% taking the time to work safely.<br />

With the variety of ladders in workplaces for different uses,<br />

decisions should be made on the appropriate use of fixed,<br />

portable, step, and extension ladders. Ladders should only be<br />

used as a means of access and not as work platforms.<br />

Only choose ladders with the UL seal from Underwriter's<br />

Laboratory. Ladders commonly come in three materials:<br />

aluminum, wood, or fiberglass. Aluminum is the most<br />

durable, but will conduct electricity, making it dangerous for<br />

use around electricity. Wood may rot. Fiberglass is the best<br />

combination of durability and non-conductivity, but is also the<br />

most expensive.<br />

The Canadian Standards Association has established three<br />

portable ladder grades, rated for weight capacity. The weight<br />

capacity includes the weight of the person and the equipment<br />

on the ladder:<br />

• Grade 1 – Construction and Industrial: heavy-duty with a<br />

load capacity not more than 250 pounds.<br />

• Grade 2 – Tradesman and Farm: medium-duty with a load<br />

capacity not more than 225 pounds.<br />

• Grade 3 – Household: light-duty with a load capacity of<br />

200 pounds.<br />

When using a Ladder<br />

• Make sure the ladder is suited for the type of job you plan to do.<br />

• Use extension ladders as a unit. Do not separate them.<br />

• Before using a ladder, especially a ladder that has been<br />

stored for a time, inspect it for cracks or broken joints.<br />

Discard defective ladders. Get help when moving heavy or<br />

long ladders.<br />

• Assess the work area and surroundings in advance, and<br />

check for overhead hazards.<br />

• If using outside, do not work in windy or inclement weather.<br />

• Wear appropriate shoes to avoid slipping, and ensure the<br />

soles are free of grease, oil or water.<br />

• Place the ladder on a stable, even, flat surface. Never place a<br />

ladder on top of another object.<br />

• Use the 1:4 ratio to ensure a stable working platform. Place<br />

the base of the ladder one foot away of whatever it leans<br />

against for every four feet of height to the point where the<br />

ladder contacts at the top.<br />

• Make sure that only one person at a time is on the ladder.<br />

• When using an A-frame stepladder, make sure the brace is<br />

locked in place.<br />

• If climbing onto another surface, make sure the ladder<br />

extends at least three feet past the platform you're climbing<br />

onto.<br />

• Secure tall ladders by lashing or fastening the ladder to<br />

prevent movement, especially if it will be a regular means of<br />

access.<br />

• Always face the ladder when climbing or descending.<br />

• Keep both feet on the ladder – never put one foot on a rung<br />

and the other foot on a different surface.<br />

• Do not climb higher than the second rung on stepladders or<br />

the third rung on straight or extension ladders.<br />

• Never stand on the top or the paint shelf of a stepladder.<br />

• Maintain three-point contact when climbing or working<br />

from a ladder. Wear a tool belt or pull equipment up with a<br />

rope after climbing the ladder.<br />

• Never over-reach to get at something off to the side. The<br />

climber’s hips should remain between the ladder’s two side<br />

rails. Always re-position the ladder.<br />

Other hazards associated with ladders include:<br />

• Being struck by materials falling from ladders or falling<br />

ladders<br />

• Tripping over ladders (erect or lying on floor)<br />

• Lifting heavy ladders<br />

• Striking persons or objects when carrying ladders<br />

• Contact with electrical equipment<br />

12 WorkplaceSafetyNorth.ca

HAZARD ALERT!<br />

FORESTRY SECTOR<br />

Routine Maintenance<br />

Ends in Fall from Crane<br />

WHAT HAPPENED?<br />

A worker was on top of a log-loading crane performing routine maintenance – adding<br />

hydraulic oil and checking the swing gear box level. While adding oil, a small amount<br />

spilled onto the engine cover which he inadvertently stepped in.<br />

Next he checked the swing gear box, which required him to sit on the engine cover, lean<br />

forward and pull out the dipstick. While rising to a standing position after completing<br />

the task, his foot slipped and he fell off the machine, a distance of about eight feet.<br />

The worker suffered minor injuries that required modified duties.<br />

WHY DID IT HAPPEN?<br />

There were no fall prevention guardrails or barriers on the top of the crane.<br />

Spilled oil created a slip hazard.<br />

The location of the swing gear box is difficult to reach.<br />

HOW COULD IT BE PREVENTED?<br />

Guardrails and barriers can be erected around the top of the machine.<br />

The maintenance procedure to add hydraulic oil should be revised to reduce the risk<br />

of an oil spill, possibly through the use of a hand or electric pump.<br />

Equipment design should be reviewed to improve ease of access to the swing gear<br />

box dipstick.<br />

Supervisors should periodically review workplace fall hazards and fall protection<br />

measures with workers, and continue to monitor and enforce these requirements on<br />

a daily basis.<br />

call us toll free: 1-888-730-7821 (Ontario)<br />

WorkplaceSafetyNorth.ca<br />

This alert is based on an actual incident. If you have an incident you’d like to share, please email customercare@<br />

workplacesafetynorth.ca. The description of circumstances does not reflect legal commentary, nor is it meant to assign<br />

legal responsibility to any person or firm.

Workplace Safety North (WSN)<br />

health and safety champions<br />

appointed to new Prevention Council<br />

Nancy Hutchison and Roy Slack, now former members<br />

of WSN’s Mining Advisory Committee, have joined the<br />

11-member council comprised of health and safety experts<br />

from a broad range of backgrounds. The role of the council<br />

is to support the efforts of the Chief Prevention Officer<br />

George Gritziotis, and to advise the Minister of Labour on<br />

health and safety issues.<br />

Hutchison, the secretary treasurer of the Ontario<br />

Federation of Labour, is one of four labour representatives<br />

on the council. She worked in the mining industry in Red<br />

Lake for 19 years, beginning underground at Campbell<br />

Red Lake Gold Mine and later the Dickenson Gold Mine,<br />

before joining the staff of United Steelworkers in 1995 and<br />

pursuing her interest in health and safety.<br />

Hutchison’s involvement in health and safety includes<br />

positions on the boards of the Workers Health and Safety<br />

Centre, the Occupational Health Clinics for Ontario<br />

Workers, the Council of Governors for the Canadian<br />

Centre for Occupational Health and Safety, the Workplace<br />

Safety and Insurance Board’s Labour and Injured Worker<br />

Advisory Group, as well as with WSN and various health<br />

and safety positions with the United Steelworkers.<br />

Roy Slack, the president of Cementation Canada Inc.,<br />

is one of four employer representatives on the council.<br />

He established Cementation in 2002, building the<br />

company into one of Canada’s largest mine contracting<br />

and engineering firms with a safety-based, people-first<br />

approach, including a declared target of “Zero Harm”.<br />

“My appointment to the Prevention Council is a great<br />

honour for me and a chance to represent both Northern<br />

Ontario and the mining industry and make a difference in<br />

the lives of Ontario workers and their families,” Slack said.<br />

In addition to his involvement with WSN, Slack as served<br />

as a director of the Ontario Mine Contractor’s Safety<br />

Association, and a member of the Conference Board of<br />

Canada’s CEO Health and Safety Leadership Charter. The<br />

North Bay-based company with more than 1,500 employees<br />

and international operations has won numerous accolades<br />

as one of Canada’s top employers.<br />

“I think the mining industry has a lot to offer but of course<br />

we still have work to do as well, so I am eager to contribute<br />

and also interested in learning from other industries,” Slack<br />

said. “From our first meeting it was clear that all the council<br />

members have a common goal, to make Ontario a safer<br />

place to work.”<br />

The council was created in response to recommendations<br />

of the Expert Advisory Panel on Occupational Health<br />

and Safety, which reviewed Ontario’s prevention system<br />

following the deaths of four workers when their scaffolding<br />

on a Toronto high-rise collapsed in December 2009.<br />

14 WorkplaceSafetyNorth.ca

Free ‘Home’ Delivery Available<br />

If your print copy of Every Worker gets delayed in the<br />

mail, lost in the interoffice delivery system, or irretrievably<br />

“borrowed” by safety-inquisitive colleagues, it’s time to sign<br />

on to Workplace Safety North’s free ‘home’ delivery service.<br />

Each and every issue of Every Worker can be delivered to<br />

your email address to read and share with colleagues at<br />

your convenience, and ensuring you will not miss out on<br />

this important health and safety resource.<br />

Simply drop an email to First2Know@workplacesafetynorth.ca.<br />

Your email will add you to Workplace Safety North’s Every<br />

Worker subscriber list and ensure electronic delivery of the<br />

magazine and other WSN publications.<br />

Subscribe today!<br />

Upcoming Events<br />

January/February 2013<br />

Ministry of Labour Safety Blitz - Mining sector<br />

Ventilation hazards<br />

February/March 2013<br />

Ministry of Labour Safety Blitz - Forestry, paper, printing,<br />

converting sectors<br />

Slips, Trips and Falls (Ladder safety and fall protection hazards)<br />

April 10 & 11, 2013<br />

HSO Partners in Prevention Conference, Sault Ste. Marie<br />

April 16 – 18, 2013<br />

WSN's Mining Health & Safety Conference, Sudbury<br />

April 28, 2013<br />

National Day of Mourning<br />

Commemorating workers killed or injured in the workplace<br />

April 30 – May 1, 2013<br />

HSO Partners in Prevention Conference, Mississauga<br />

May 5 – 11, 2013<br />

NAOSH (North American Occupational Health & Safety) Week<br />

Check out WSN Events page on our website –<br />

WorkplaceSafetyNorth.ca – for webinars, workshops and<br />

other special safety-focused events for the mining, forestry,<br />

paper, printing and converting sectors.<br />

WSN and Ontario Mine Rescue<br />

prep for international conference<br />

Workplace Safety North, Ontario Mine Rescue and<br />

its mine rescue counterparts from across Canada will<br />

host the sixth biennial conference of the International<br />

Mines Rescue Body in Niagara Falls, Oct. 5 to 10, 2013.<br />

Planning for the conference is well underway with the<br />

theme of "Sharing Vision, Sharing Knowledge."<br />

Previous IMRB conferences around the world<br />

have discussed breathing apparatus, emergency<br />

preparedness, heat stress, training methods, legislation<br />

affecting mine rescue, specific mine emergencies, as<br />

well as differing national approaches to mine rescue,<br />

and more.<br />

More than 40 papers were presented at the 2011<br />

conference in Beijing, attended by approximately 600<br />

delegates from 22 nations, including the United States,<br />

South Africa, Australia, Germany and India.<br />

A call for papers has been issued and registration is<br />

now open. Further information on IMRB 2013 can be<br />

found on the event's website – www.imrb2013.ca.<br />

The IMRB was created in 2001 to promote mine rescue<br />

at an international level and to improve mine rescue<br />

knowledge and practices by supporting innovation and<br />

global cooperation.<br />

<strong>EVERY</strong> <strong>WORKER</strong><br />

15

Circle These Dates on Your Calendar<br />

Workplace Safety North's acclaimed Mining Health and Safety Conference will<br />

be held April 16-18, 2013, in Sudbury.<br />

The annual conference for employers, managers, Joint Health & Safety Committee<br />

members, health and safety personnel and anyone interested in safety will feature<br />

a range of speakers, knowledgeable on mining and health and safety topics,<br />

networking opportunities, as well as a trade show and other attractions.<br />

Plan to join us at our 2013 Mining Health and Safety conference, and watch our<br />

website for additional details as they become available.<br />

For more information contact Megan Waqué at (705) 474-7233 ext. 250 or<br />

meganwaque@workplacesafetynorth.ca<br />

WorkplaceSafetyNorth.ca<br />

toll free: 1-888-730-7821 (Ontario)