GEARS

6*'4/12.#56+% GEARS - NovaMax Industrial Intl

6*'4/12.#56+% GEARS - NovaMax Industrial Intl

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

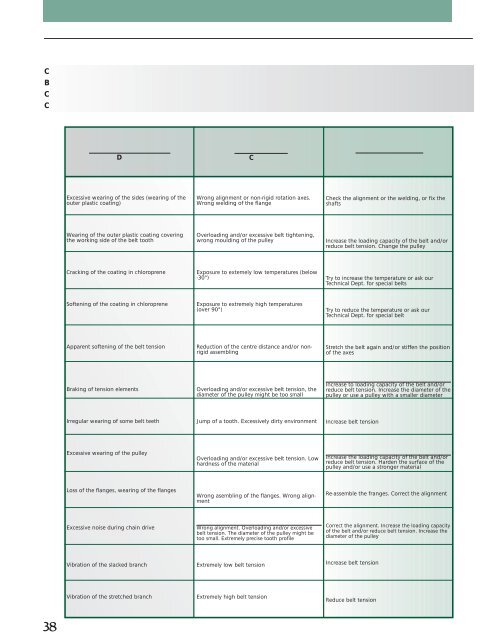

C<br />

B<br />

C<br />

C<br />

D<br />

C<br />

Excessive wearing of the sides (wearing of the<br />

outer plastic coating)<br />

Wrong alignment or non-rigid rotation axes.<br />

Wrong welding of the flange<br />

Check the alignment or the welding, or fix the<br />

shafts<br />

Wearing of the outer plastic coating covering<br />

the working side of the belt tooth<br />

Overloading and/or excessive belt tightening,<br />

wrong moulding of the pulley<br />

Increase the loading capacity of the belt and/or<br />

reduce belt tension. Change the pulley<br />

Cracking of the coating in chloroprene<br />

Exposure to extemely low temperatures (below<br />

-30°)<br />

Try to increase the temperature or ask our<br />

Technical Dept. for special belts<br />

Softening of the coating in chloroprene<br />

Exposure to extremely high temperatures<br />

(over 90°)<br />

Try to reduce the temperature or ask our<br />

Technical Dept. for special belt<br />

Apparent softening of the belt tension<br />

Reduction of the centre distance and/or nonrigid<br />

assembling<br />

Stretch the belt again and/or stiffen the position<br />

of the axes<br />

Braking of tension elements<br />

Overloading and/or excessive belt tension, the<br />

diameter of the pulley might be too small<br />

Increase to loading capacity of the belt and/or<br />

reduce belt tension. Increase the diameter of the<br />

pulley or use a pulley with a smaller diameter<br />

Irregular wearing of some belt teeth<br />

Jump of a tooth. Excessively dirty environment<br />

Increase belt tension<br />

Excessive wearing of the pulley<br />

Overloading and/or excessive belt tension. Low<br />

hardness of the material<br />

Increase the loading capacity of the belt and/or<br />

reduce belt tension. Harden the surface of the<br />

pulley and/or use a stronger material<br />

Loss of the flanges, wearing of the flanges<br />

Wrong asembling of the flanges. Wrong alignment<br />

Re-assemble the franges. Correct the alignment<br />

Excessive noise during chain drive<br />

Wrong alignment. Overloading and/or excessive<br />

belt tension. The diameter of the pulley might be<br />

too small. Extremely precise tooth profile<br />

Correct the alignment. Increase the loading capacity<br />

of the belt and/or reduce belt tension. Increase the<br />

diameter of the pulley<br />

Vibration of the slacked branch<br />

Extremely low belt tension<br />

Increase belt tension<br />

Vibration of the stretched branch<br />

Extremely high belt tension<br />

Reduce belt tension