Containment

Technical Buyer's Guide - PFPA

Technical Buyer's Guide - PFPA

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

This fire test method when applied to wall and ceiling<br />

linings is being made redundant in the Building Code<br />

of Australia and is being replaced by ISO9705 and/or<br />

AS/NZS3837 fire test data.<br />

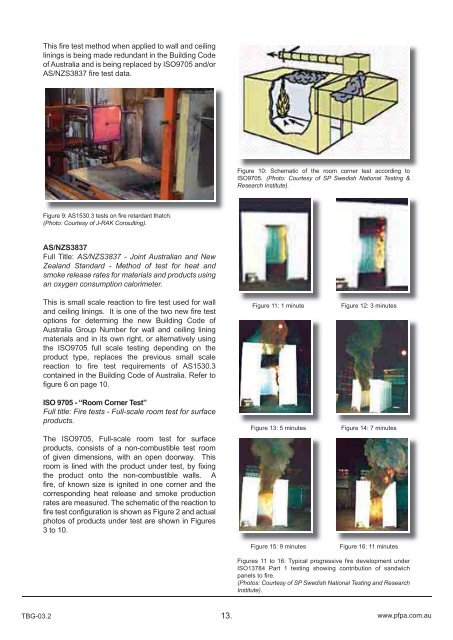

Figure 10: Schematic of the room corner test according to<br />

ISO9705. (Photo: Courtesy of SP Swedish National Testing &<br />

Research Institute).<br />

Figure 9: AS1530.3 tests on fire retardant thatch.<br />

(Photo: Courtesy of J-RAK Consulting).<br />

AS/NZS3837<br />

Full Title: AS/NZS3837 - Joint Australian and New<br />

Zealand Standard - Method of test for heat and<br />

smoke release rates for materials and products using<br />

an oxygen consumption calorimeter.<br />

This is small scale reaction to fire test used for wall<br />

and ceiling linings. It is one of the two new fire test<br />

options for determing the new Building Code of<br />

Australia Group Number for wall and ceiling lining<br />

materials and in its own right, or alternatively using<br />

the ISO9705 full scale testing depending on the<br />

product type, replaces the previous small scale<br />

reaction to fire test requirements of AS1530.3<br />

contained in the Building Code of Australia. Refer to<br />

figure 6 on page 10.<br />

ISO 9705 - “Room Corner Test”<br />

Full title: Fire tests - Full-scale room test for surface<br />

products.<br />

The ISO9705, Full-scale room test for surface<br />

products, consists of a non-combustible test room<br />

of given dimensions, with an open doorway. This<br />

room is lined with the product under test, by fixing<br />

the product onto the non-combustible walls. A<br />

fire, of known size is ignited in one corner and the<br />

corresponding heat release and smoke production<br />

rates are measured. The schematic of the reaction to<br />

fire test configuration is shown as Figure 2 and actual<br />

photos of products under test are shown in Figures<br />

3 to 10.<br />

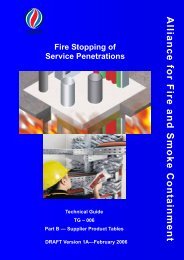

Figure 11: 1 minute<br />

Figure 13: 5 minutes<br />

Figure 15: 9 minutes<br />

Figure 12: 3 minutes<br />

Figure 14: 7 minutes<br />

Figure 16: 11 minutes<br />

Figures 11 to 16: Typical progressive fi re development under<br />

ISO13784 Part 1 testing showing contribution of sandwich<br />

panels to fi re.<br />

(Photos: Courtesy of SP Swedish National Testing and Research<br />

Institute).<br />

TBG-03.2<br />

13.<br />

www.pfpa.com.au