Uncontrolled

Uncontrolled Copy - DTL Connectors

Uncontrolled Copy - DTL Connectors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

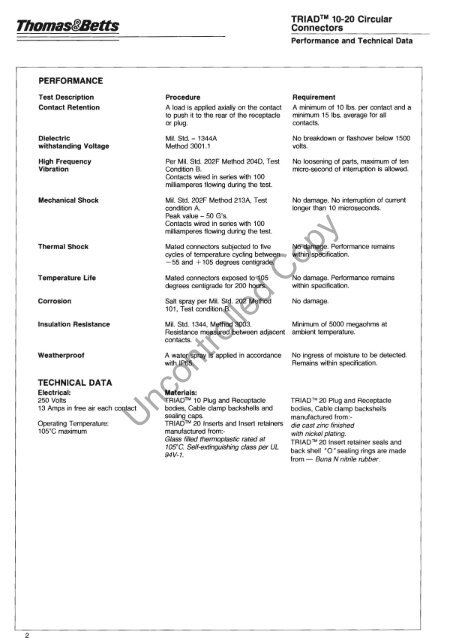

2<br />

Thomas &Betts<br />

TRIAD 10-20 Circular<br />

Connectors<br />

Performance and Technical Data<br />

PERFORMANCE<br />

Test Description<br />

Contact Retention<br />

Dielectric<br />

withstanding Voltage<br />

High Frequency<br />

Vibration<br />

Procedure<br />

A load is applied axially on the contact<br />

to push it to the rear of the receptacle<br />

or plug.<br />

Mil. Std. - 1344A<br />

Method 3001.1<br />

Per Mil. Std. 202F Method 204D, Test<br />

Condition B.<br />

Contacts wired in series with 1 00<br />

milliamperes flowing during the test.<br />

Requirement<br />

A minimum of 1 0 lbs. per contact and a<br />

minimum 15 lbs. average for all<br />

contacts.<br />

No breakdown or flashover below 1500<br />

volts.<br />

No loosening of parts, maximum of ten<br />

micro-second of interruption is allowed.<br />

Mechanical Shock<br />

Thermal Shock<br />

Temperature Life<br />

Corrosion<br />

Insulation Resistance<br />

Weatherproof<br />

TECHNICAL DATA<br />

Electrical:<br />

250 Volts<br />

13 Amps in free air each contact<br />

Operating Temperature:<br />

105°C maximum<br />

Mil. Std. 202F Method 213A, Test<br />

condition A.<br />

Peak value - 50 G's.<br />

Contacts wired in series with 1 00<br />

milliamperes flowing during the test.<br />

Mated connectors subjected to five<br />

cycles of temperature cycling between<br />

-55 and + 105 degrees centigrade.<br />

Mated connectors exposed to 105<br />

degrees centigrade for 200 hours.<br />

Salt spray per Mil. Std. 202 Method<br />

101, Test condition B.<br />

Mil. Std. 1344, Method 3003.<br />

Resistance measured between adjacent<br />

contacts.<br />

A water spray is applied in accordance<br />

with IP65.<br />

Materials:<br />

TRIAD 10 Plug and Receptacle<br />

bodies, Cable clamp backshells and<br />

sealing caps.<br />

TRIAD 20 Inserts and Insert retainers<br />

manufactured from:-<br />

Giass filled thermoplastic rated at<br />

105"C. Self-extinguishing class per UL<br />

94V-1.<br />

No damage. No interruption of current<br />

longer than 1 0 microseconds.<br />

No damage. Performance remains<br />

within specification.<br />

No damage. Performance remains<br />

within specification.<br />

No damage.<br />

Minimum of 5000 megaohms at<br />

ambient temperature.<br />

<strong>Uncontrolled</strong> Copy<br />

No ingress of moisture to be detected.<br />

Remains within specification.<br />

TRIAD 20 Plug and Receptacle<br />

bodies, Cable clamp backshells<br />

manufactured from:-<br />

die cast zinc finished<br />

with nickel plating.<br />

TRIAD 20 Insert retainer seals and<br />

back shell "O"sealing rings are made<br />

from- Buna N nitrile rubber.