Uncontrolled

Uncontrolled Copy - DTL Connectors

Uncontrolled Copy - DTL Connectors

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Uncontrolled</strong> Copy<br />

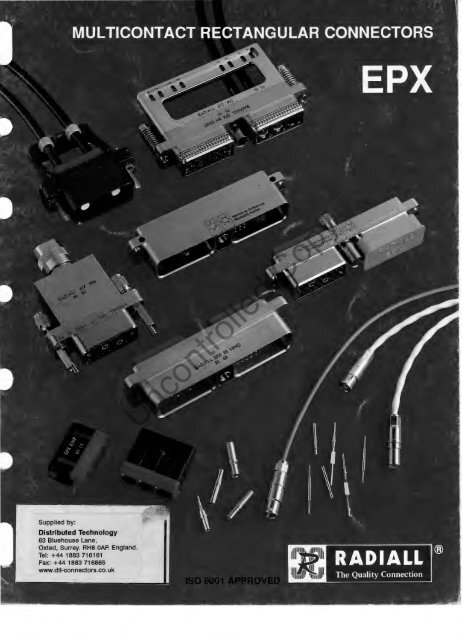

Supplied by:<br />

Distributed Technology<br />

63 Bluehouse Lane,<br />

Oxted , Surrey. RH8 OAP. England.<br />

Tel : +44 1883 716161<br />

Fax: +44 1883 716865<br />

www.dtl-connectors.co.uk<br />

RADIALL<br />

The Quality Connection

Multicontact connectors<br />

EPX series<br />

Introduction .......... .. .. .... ....... .<br />

Features ....... .... . ... .. .. ......... .<br />

Exploded view of size 2 connector .... . .<br />

Technical characteristics .... . ..... .. .. .<br />

Weights . ...... . .... . ... . . . .. . ..... . . .<br />

How to order ........................ .<br />

Insert module dimensions . . ...... ..... .<br />

Contact arrangements ............... .<br />

EPX size 1<br />

Connector mating guide ... ........... .<br />

Receptacle shells . ... .. ....... . .. .. . . .<br />

Plug shells .. .. . .. .. . . . ... ....... . ... .<br />

Fully mated connector dimensions ..... .<br />

Polarization ...... . .... .......... . . . .. .<br />

Backshelis .. .... . ..... .. ........ . . . . .<br />

Panel cut-outs<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8-11<br />

12<br />

13<br />

14-15<br />

16-18<br />

19-21<br />

21<br />

22<br />

22-24<br />

25<br />

EPX size 2<br />

Connector mating guide . . . . . . . . . . . . . . . 26-27<br />

Receptacle shells . . . . . . . . . . . . . . . . . . . . . 28-30<br />

Plug shells . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-33<br />

Fully mated connector dimensions . . . . . . 34<br />

Polarization . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-35<br />

Backshells . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-38<br />

Panel cut-outs 39<br />

EMI/RFI<br />

Shell fitted with grounding spring fingers 40<br />

Filtered version . . . . . . . . . . . . . . . . . . . . . . . 41<br />

Shell for panel conductive seal . . . . . . . . . . 42<br />

Contacts<br />

Crimp contacts . . . . . . . . . . . . . . . . . . . . . . . 43<br />

PC tail termination contacts . . . . . . . . . . . . . 44<br />

Wire wrap contacts . . .. . ... . .. .. ...... . 45<br />

Coaxial contacts . . . . . . . . . . . . . . . . . . . . . . 46-47<br />

Concentric twin ax contacts ......... . .. . 47<br />

Accessories ............ .. .......... . 48<br />

Tooling . .. ..... . ... . ............. .. . . 49<br />

Termination details<br />

Crimp contacts . . . . . . . . . . . . . . . . . . . . . . . 50<br />

Coaxial contacts . . . . . . . . . . . . . . . . . . . . . . 51 -55<br />

Concentric twinax contacts . . . . . . . . . . . . . 56<br />

Tooling and assembly instructions<br />

Mounting of insert module into the shell . . 57<br />

Mounting of size 1 shell onto panel . . . . . . 58<br />

Insertion and removal of contacts . . . . . . . 58<br />

Mounting of size 2 backshell onto shells 59-62<br />

Mounting of size 1 backshell onto shells 62<br />

Modification of polarization code . . . . . . . . 63<br />

Non standard products<br />

Fiber optic application . . . . . . . . . . . . . . . . . 64<br />

Custom design . . . . . . . . . . . . . . . . . . . . . . . 65<br />

<strong>Uncontrolled</strong> Copy<br />

Index of part numbers . . . . . . . . . . . . . . . . . 66<br />

J<br />

_)<br />

l<br />

/

Multicontact connectors<br />

EPX series<br />

The EPX connector is suitable for applications such as civil and military avionics, aircr~fts,<br />

electronic defence systems.<br />

telecommunications and<br />

Suitable for rack and panel, cable to cable or on front panels replacing circular connectors, the EPX range is available in<br />

two shell sizes.<br />

Space saving and lightweight, EPX has been designed to conform to the UTE-C-93425 HE 510 specification.<br />

The shell being manufactured from an aluminium alloy exhibits both strength and good shielding characteristics. To<br />

improve EMI/RFI characteristics the connector can be fitted with EMI grounding spring fingers and insert modules with<br />

filtered contacts.<br />

The insert modules for pin or socket contacts of the EPX can be mounted into either plug or receptacle shells regardless of<br />

gender and are easily removable with the use of a simple tool. This flexibility allows numerous combinations facilitating any<br />

maintenance work, manufacture of prototype equipment, etc ....<br />

Stacking of connectors is possible and optimizes the packing density of the contact. RADIALL can also upon request<br />

realize any configuration of multiple cavity shells, for specific applications.<br />

The modular concept of the EPX, while having good contact packing density offers the option of separating power<br />

transmission from signal transmission and therefore avoiding crosstalk problems.<br />

EPX uses contacts that are similar to those used in MIL-C-81659 B or ARINC 404 and benefits from rack and panel proven<br />

reliability.<br />

EPX is available in environmental and non-environmental styles with a large range of signal, power, coaxial and triaxial<br />

contacts. Termination styles include crimp, PC tail and wire wrap, front release front removable signal contacts are<br />

available.<br />

Space comparison between a circular connector and an EPX connector :<br />

EPX size 2:<br />

80 contacts size 22<br />

or 60 contacts size 20<br />

<strong>Uncontrolled</strong> Copy<br />

MIL-C-38999 size 21 : 79 contacts size 22<br />

or 41 contacts size 20<br />

15 50 +O ,ZO<br />

-0. 10<br />

(614 ~:~~~)<br />

Mating area = connector area = 14 cm2<br />

Plug area = 15 cm2<br />

Receptacle area = 16 cm2 ~- ___ - - -<br />

Mating area = 50 cm2 -------<br />

November 1994 edition<br />

RADIALL ®<br />

The Quality Conn.:-c ti on<br />

-3-

Multicontact connectors<br />

EPX series<br />

• Compact design provides high packing density and space saving.<br />

• High contact density compared with MIL-C-38999 and other rectangular connectors.<br />

• Low weight.<br />

• Interchangeability of pin and socket insert modules between plug and receptacle<br />

shells.<br />

• Ease of assembly and removable insert modules allowing rapid and easy<br />

maintenance.<br />

• Two sizes of shells : with either 1 or 2 insert modules.<br />

• Mounting styles : rack and panel, cable to cable or front panel mounting (alternative to<br />

circular connectors).<br />

• Protection against mismating provided by polarization keys offering up to 12<br />

positions for size 2 connectors and 36 positions for size 1 connectors.<br />

• Facility to separate power contacts from signal contacts.<br />

• Metal shell and EMI grounding fingers offer EMI/RFI protection.<br />

• Matihg and unmating of connectors by the use of jackscrews.<br />

• Large range of contacts either front or rear removable.<br />

• Use of MIL specification tooling.<br />

<strong>Uncontrolled</strong> Copy<br />

• Large range of shells, insert modules, backshells and accessories.<br />

• Choice of environmental or non-environmental with either filtered or fiber optic<br />

capability.<br />

Items in this catalog are covered by French and foreign Patents and/or Patents pending.<br />

EUR Patent no 0 183 587 - US Patent no 4 659 162<br />

RADIALL ®<br />

The Quality Connection j<br />

-4-

Multicontact connectors<br />

EPX series<br />

<strong>Uncontrolled</strong> Copy<br />

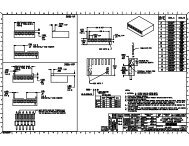

ITJ Shells, male (plug) and female (receptacle)<br />

~ Insert modules environmental or non-environmental<br />

for front or rear removable contacts<br />

[3] Signal contacts size 22, 20, 16, 12. Termination crimp,<br />

PC tail, wire wrap, coaxial size 5, 12 and 15,<br />

concentric twinax size 5 and fiber optic contacts size<br />

12 and 16.<br />

[1) Retention clips for insert module<br />

ffil Jackscrew sleeve with polarising keyway<br />

[QJ Jackscrew<br />

[1] Jacknut with polarising key<br />

[ID Insert module removal tool<br />

RADIALL ®<br />

The Quali ty Connection<br />

-5-

ELECTRICAL CHARACTERISTICS<br />

12<br />

12<br />

14<br />

.075 (1 .9)<br />

.134 (3.4)<br />

23<br />

17<br />

• Insulation resistance (500 V de) :<br />

• Dielectric withstanding voltage at sea level :<br />

> 5000MQ<br />

1500V/50Hz<br />

• EM/ shielding efficiency (page 40) : > 80 dB at 1 GHz<br />

I MECHANICAL CHARACTERISTICS<br />

• Durability: 500 matings<br />

• Shock: 1 shock in each axis<br />

half-sinusoidal I amplitude 50g I duration 11 ms<br />

• Sinusoidal vibration: 10-2000 Hz<br />

acceleration 20 g I 4 H per axis I interruption < 1 fl.S<br />

• Random vibration :<br />

• Salt spray :<br />

1 g 2 /Hz (50/2000Hz) I interruption < 1 fl.S<br />

48, 96 or 500 H depending of shell plating<br />

• Damp heat : 56 days I 95% RH<br />

• Fluid immersion: EN2591 test C15<br />

• Insert module retention :<br />

• Contact retention :<br />

• Mating force :<br />

M/L-T-5624, H-5606, H-7100, L-6081, L-7808<br />

size 22:<br />

size 20:<br />

size 16:<br />

size 12:<br />

size 5:<br />

C-25769, A-8243, COOLANOL 25<br />

shell size 1 :<br />

shell size 2 :<br />

> 40 daN (90 Lbs)<br />

> 4,5 daN (10 Lbs)<br />

> 6,7 daN (15 Lbs)<br />

> 11 daN (25 Lbs)<br />

> 11 daN (25 Lbs)<br />

> 11 daN (25 Lbs)<br />

< 10 daN (22 Lbs)<br />

< 20 daN (42 Lbs)<br />

• Coupling torque (jackscrew): 1.2 Nm (10.4 Lbs/inch)<br />

ENVIRONMENTAL CHARACTERISTICS<br />

• Temperature range : -65 · c to +155 ·c<br />

• Temperature life :<br />

MATERIALS AND PLATING<br />

• Shell:<br />

• Insert module :<br />

• Seal:<br />

• Contact:<br />

• Backshell :<br />

• Screw:<br />

<strong>Uncontrolled</strong> Copy<br />

• Clip·<br />

1000 Hat +155 ·c<br />

aluminum alloy nickel/cadmium<br />

glass filled thermosetting resin<br />

f/uorosilicone elastomer<br />

copper alloy gold over nickel<br />

aluminum alloy nickel/cadmium<br />

stainless steel (48, 96 H salt spray)<br />

aluminum alloy (500 H salt spray)<br />

beryllium copper<br />

RADIALL ®<br />

The Qualit y Connection<br />

-6-

EPX 2 P 17 *<br />

.. REFERENCE<br />

617 900 .·<br />

617911<br />

Open Ty-Rap® backshe/1 (size 2)<br />

617 911 001<br />

617 922 003<br />

<strong>Uncontrolled</strong> Copy<br />

•. 9 (0.32)<br />

16 (0.56)<br />

0<br />

8,4 (0.30)<br />

Size 12<br />

*Polarization and plating to be specified.<br />

RADIALL ®<br />

The Quality Connection<br />

-7-

The modular construction of the<br />

EPX series permits 2 methods of<br />

ordering :<br />

Either by complete part number<br />

(shell, insert modules fitted and<br />

contacts) pages 8 - 9 or by defining<br />

separate components (shell,<br />

insert modules and contacts)<br />

pages 10- 11.<br />

EPX 1 R 11 X1 C<br />

EPX 2 P 17 A N<br />

<strong>Uncontrolled</strong> Copy<br />

-8-

E 40 P Y ························X<br />

E 14 S S E C3 S S X<br />

<strong>Uncontrolled</strong> Copy<br />

The Quahty Conne(' IIOn<br />

-9-

The modular construction of the<br />

EPX series permits 2 methods of<br />

ordering :<br />

Either by complete part number<br />

(shell, insert modules fitted and<br />

contacts) pages 8 - 9 or by defining<br />

separate components (shell,<br />

insert modules and contacts)<br />

pages 10- 11.<br />

EPX 1 R 11 X1 C<br />

EPX 2 P 17 A N<br />

<strong>Uncontrolled</strong> Copy<br />

The Quahfy Connection<br />

-10-

The modular construction of the<br />

EPX series permits 2 methods of<br />

ordering :<br />

Either by complete part number<br />

(shell, :nsert modules fitted and<br />

contacts) pages 8-9 or by defining<br />

separate components (shell,<br />

insert modules and contacts)<br />

pages 10-11 .<br />

EPX E 40 P<br />

*Contact arrangement 0 is available under P/N EPX N 0 (class N without contact type specification)<br />

Contacts (pages 43 to 47), backshells (size 1 page 23 - 24 ; size 2 page 36 to 38) and accessories (page 48)<br />

are to be ordered separately.<br />

<strong>Uncontrolled</strong> Copy<br />

RADIALL ®<br />

The Qualit y Connec tion<br />

-11 -

INSERT MODULE FOR SOCKET CONTACTS<br />

Non environmental<br />

9030<br />

(. 366)<br />

Environmental<br />

9030<br />

(. 366)<br />

.....---.<br />

.L__.I.<br />

-<br />

POLARIZING KEY<br />

12 (.472)<br />

'<br />

INSERT MODULE FOR PIN CONTACTS<br />

Non environmental<br />

POLARIZING KEY<br />

10060<br />

( .417)<br />

10 50<br />

(.059)<br />

10060<br />

( .417)<br />

rr- --<br />

'-- -<br />

POLARIZING KEY<br />

Environmental<br />

-----n<br />

<strong>Uncontrolled</strong> Copy<br />

12 (.472)<br />

'<br />

15050<br />

( .610)<br />

10 90<br />

( .075)<br />

-<br />

,J--1 I_.,_<br />

,l-1<br />

'-- f-<br />

POLARIZING KEY<br />

15050<br />

( .6 tO)<br />

'<br />

12 (.472)<br />

t<br />

12 (.472)<br />

'<br />

RADIALL ®<br />

The Qua lity Conneclion<br />

- 12 -

PIN INSERT MODULES : MATING FACE<br />

Termination styles available are shown in brackets.<br />

40<br />

40 cavities for size 22 signal contacts<br />

30<br />

700000001<br />

boq,poooo'<br />

~oogoooode<br />

LU000000<br />

30 cavities for size 20 signal contacts<br />

28<br />

22 cavities for size 22 signal contacts<br />

6 cavities for size 16 signal contacts<br />

or size 15 coaxial contacts<br />

or size 16 optical contacts<br />

17 '0 4 0000 1 05<br />

110 70 100 0'<br />

01<br />

17<br />

0 0 O.s ·,.0 0 cJ<br />

14 cavities for size 20 signal contacts<br />

3 cavities for size 12 signal contacts<br />

or size 12 coaxial contacts<br />

or size 12 optical contacts<br />

(S,V,W,Y,YA)<br />

(S)<br />

(S,V,W,Y)<br />

(S)<br />

(S)<br />

(S)<br />

(S)<br />

(S)<br />

6<br />

6 cavities for size 12 signal contacts<br />

or size 12 coaxial contacts<br />

or size 12 optical contacts<br />

c 3 [o·Oo]<br />

3 cavities for size 5 coaxial contacts<br />

or size 5 concentric twinax contacts<br />

with cavity reducer:<br />

size 12 signal contacts<br />

size 12 coaxial contacts<br />

l<br />

[ r====' -""=.<br />

0<br />

blanking insert<br />

<strong>Uncontrolled</strong> Copy<br />

(S)<br />

(S)<br />

(S)<br />

(S)<br />

(S)<br />

(S)<br />

14<br />

14 cavities for size 16 signal contacts<br />

or size 15 coaxial contacts<br />

or size 16 optical contacts<br />

(S)<br />

(S)<br />

RADIALL ®<br />

The Qualil y Connec tio n<br />

- 13-

The various components (backshells, plug shells, receptacle shells)<br />

linked by the same coloured line may be coupled together.<br />

Example: backshell617 907 mounts onto plug shell EPX 1 P 11 *as well<br />

as the receptacle shell EPX 1 R 18 *.<br />

Conversely, this plug shell will not mate with this receptacle shell.<br />

*polarization and plating to be specified.<br />

BACKSHELLS<br />

PLUG SHELLS<br />

RECEPTACLE<br />

SHELLS<br />

EPX 1 P 11 *<br />

<strong>Uncontrolled</strong> Copy<br />

EPX 1 B 12 *<br />

BACKSHELLS<br />

_____ ( ]<br />

00 00<br />

RADIALL<br />

The Quality Conneclion<br />

-14-

0 0 0 0<br />

[_______)<br />

617 921 003/004<br />

EPX 1 P 19 * EPX 1 P 21 *<br />

<strong>Uncontrolled</strong> Copy<br />

Thr Qual ily Connec tion<br />

-15-

18. 30 ±0. 10<br />

(.720±.004)<br />

2. 30 ±0. 10<br />

( . 09 1 ± . 004 )<br />

5 10 +0, 15<br />

0<br />

(. 200 \) 006)<br />

ENVIRONMENTAL :<br />

10 (. 394)<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

M 3 X 0,5 rf.. 3 10 +0, 10<br />

'f.J • 0<br />

l<br />

18.30 ±0. 10<br />

r<br />

{.720±.004)<br />

r33 . 80 ±0,20<br />

(1.330±.008)<br />

+----5-.-10--+~~.~1~5---------- 1~=----.<br />

(. 200 \) 006) -+-----r'-'---Lol..---------------'l....L----'--',<br />

2 HOLES + 004<br />

(rj;. 122 o· l<br />

I Model supplied with hexagonal nut I<br />

Side or front panel mounting<br />

.. ____,_<br />

<strong>Uncontrolled</strong> Copy<br />

i------i<br />

..., 16 +0, 20<br />

-0, 10<br />

(. 630 ~: ~~~)<br />

ENVIRONMENTAL :<br />

10 (. 394)<br />

NON ENVIRONMENTAL<br />

5 {. 197)<br />

M 3 X 0. 5<br />

8. 10 ±0. 50<br />

(. 319± .020)<br />

0<br />

22 -0.30<br />

0<br />

( . 86 ;- . 0 12)<br />

50, 10<br />

Model supplied with hexagonal nut<br />

Front panel mounting<br />

RADIALL ®<br />

The Qualify Connection<br />

-16-

18. 30 ±0. 10<br />

(. 720± .004) M 3 x o. s--++•<br />

f---- 33' 80 ±0' 20<br />

I (1 .330±.008)<br />

16 +0.20<br />

-0 10<br />

0630~.·~~~:<br />

5 10 +0' 15<br />

' 0<br />

(. 200 + 0006)<br />

1<br />

( .827)<br />

ENVIRONMENTAL<br />

10 (. 394)<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

18, 30 ±0. 10<br />

(.720 ±.004)<br />

M 3 X 0 ' 5 ____,-+--_,_.<br />

NON ENVIRONMEN TAL :<br />

5 (. 197)<br />

M 3 X 0, 5<br />

r<br />

33,80<br />

50, 10<br />

( 1. 181<br />

MAX<br />

±0.20 1<br />

(1 .330±.008)<br />

16, 70<br />

( 657)<br />

t<br />

16<br />

•, 70<br />

(. 657)<br />

<strong>Uncontrolled</strong> Copy<br />

r---j-+-----'--'-' 30 ( . 56 3 )<br />

MAX<br />

HEX SOCKET FOR<br />

9/64 ALLEN KEY<br />

~30[5631<br />

12.60 ±0.25 MAX<br />

(.496 ±.0 10)<br />

RADIALL ®<br />

The Qu:dily Conne

18 , 30 ±0 , 10<br />

(. 720±. 004)<br />

MAX PAt~EL<br />

THICKNESS<br />

1. 63 (. 064)<br />

18,70 ±0.20<br />

(.736 ±.008)<br />

5, 10 +~, 1 5<br />

(. 200 + 0006)<br />

ENVIRONMENTAL :<br />

10 (. 394)<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

4 HOLES M 2 x 0,40<br />

C'SUNK go•<br />

------<br />

HEX SOCKET FOR ~.30 1.563)<br />

9/64 ALLEN KEY MAX<br />

<strong>Uncontrolled</strong> Copy<br />

Model supplied with knurled slotted screws<br />

Jackscrew is provided with a hex socket<br />

and slot for tightening with a key or<br />

screwdriver<br />

* Polarization and plating to be specified<br />

RADIALL ®<br />

The Quality Connection<br />

-18-

50. 10 (.ZOO) MAX<br />

* Polarization and plating to be specified<br />

ENVIRONMENTAL :<br />

10 (. 394)<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

¢ 7 --~----+--•<br />

[¢ .Z75)<br />

HEX SOCKET<br />

IT,JO<br />

FOR<br />

9/64 ALLEN KEY<br />

1.563)<br />

ld!bl<br />

MAX<br />

10.65 +~, 10<br />

( . 4 19 \) 004 )<br />

* Polarization and plating<br />

to be specified<br />

ENVIRONMENTAL :<br />

10 (. 394)<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

r--.- 5. 10<br />

10.65 +~.<br />

10<br />

(. 4 19 + 0004)<br />

M 3 X 0, 5<br />

+0 15<br />

( zoo + 0<br />

50 1 0 ( . ZOO) MAX<br />

~:<br />

r JO [1181)d<br />

0· _ --<br />

006)<br />

8 10.<br />

MAX ( .3 19 ±.<br />

h=l If . ~<br />

@I<br />

I<br />

Nl<br />

""'<br />

l<br />

11'-,<br />

I--'<br />

......<br />

M 3 X 0. 5<br />

<strong>Uncontrolled</strong> Copy<br />

=x<br />

..................<br />

16. 70<br />

(.657)<br />

t<br />

0,50<br />

OZO)<br />

( .614<br />

TOTAL PLAY :<br />

¢ 0. 75 ±0. 05<br />

[¢ 030± OOZ)<br />

3~A~ 563)<br />

bJ14.<br />

~-~<br />

'-..."-..<br />

'-JI<br />

~~<br />

"'<br />

"" '"-<br />

PANEL<br />

THICKNESS<br />

15 60 +O.<br />

. -0.<br />

(. 614 + 008)<br />

-.004<br />

0<br />

z -0. 10<br />

(.079 _0004<br />

zo<br />

10<br />

RADIALL ®<br />

The Quality Connectio n<br />

- 19-

* Polarisation and plating to be specified<br />

I Model supplied with hexagonal nut I<br />

Front panel mounting<br />

50. 10 ( .200) MAX<br />

[ill<br />

11 .6541<br />

M 3 X 0. 5<br />

ENVIRONMENTAL :<br />

10 (. 394)<br />

NON ENVIRONMENTAL<br />

5 (. 197) M 3 X 0, 5<br />

5 10 +0. 15<br />

c-- . 0 - -<br />

10.65 +~, 10<br />

(. 4 19 + 6004)<br />

(.ZOO \)006)<br />

* Polarisation and plating to be specified<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

M 3 X 0, 5<br />

5 10 +0. 15<br />

. 0 -<br />

'- ( . zoo + 6<br />

10 65 +O. 10<br />

. 0<br />

( . 4 19 + 6 004)<br />

I<br />

F1<br />

~~<br />

f--..1<br />

r d<br />

30 ( 1 181)<br />

MAX<br />

8.10<br />

I<br />

50. 10 (.ZOO) MAX<br />

~:<br />

J1<br />

!=<br />

0.50<br />

±<br />

(. 319±. 020)<br />

16. 70<br />

(. 657)<br />

t<br />

M 3 X 0. 5<br />

i--30(1.181)l 12,60 ±O,Z5<br />

MAX (.496±. 010)<br />

IU II u 60<br />

<strong>Uncontrolled</strong> Copy<br />

~<br />

006)<br />

tBi n ll<br />

I<br />

1--'<br />

....... !:n:<br />

16 , 70<br />

(.657)<br />

t .._ ........,<br />

~~<br />

•O zo<br />

~ -0.10<br />

( . 6 14 ~ : ~~~)<br />

15<br />

60 +0.20<br />

-0. 10<br />

( 614 ~: ~~~)<br />

RADIALL ®<br />

The Qualify Connection<br />

-20-

4 HOLES M 2 x 0,40<br />

C'SUNK 90'<br />

ENVIRONMENTAL :<br />

10 (. 394)<br />

NON ENV IRONMENTAL<br />

5 (. 197)<br />

50 10 ( . 200) MAX<br />

.•..<br />

.·.· .. ·.· .. · .... ·.· ..<br />

F'~rfNllmb~r ) ·. ····<br />

~~XtB~iH •>·<br />

* Polarization and plating to be specified<br />

Model supplied with knurled slotted screws<br />

Jackscrew is provided with a hex socket and<br />

slot for tightening with a key or screwdriver<br />

14 ,30 (.563)<br />

r--- --r- MAX<br />

10 65 +O, 10<br />

0<br />

(419\)004)<br />

---+--+--- M 3 X 0 ' 5<br />

Visual fully mated "indicator"<br />

<strong>Uncontrolled</strong> Copy<br />

I<br />

t---<br />

23,65 ±0.25<br />

(.931 ±.010)<br />

._______,._.___~J ---'---~<br />

I<br />

I<br />

15 60 +<br />

0· 20<br />

' -0. 10<br />

--r--<br />

(. 614 ~: ~~~<br />

Front panel mounting only<br />

(except variant 31)<br />

RADIALL ®<br />

The Qualil y Conne

The two polarizing keys fitted to extremities of the size 1 shell can each take 6 positions. This enables up to 36 different<br />

codes.<br />

The polarization code corresponds to a letter or a number determined by the indicator on the edge of the polarizing<br />

keys. This code is carried over into the part number of the shell or complete connector in the column "polarization<br />

code".<br />

Example : in the drawing below, the position of the polarizing keys is N2 for the plug shell and N2 for the receptacle<br />

shell. Tt)is polarization code allows these two shells to be mated.<br />

To change the position of the polarizing keys see page 58.<br />

PLUG SHELL<br />

RECEPTACLE SHELL<br />

.------- h:ll<br />

32,50<br />

280:1~<br />

39L r<br />

LJ:<br />

( 1 . 535) 30 2' 50<br />

[0981<br />

2 HOLES<br />

¢ X<br />

~______J~<br />

50<br />

( 1. 969)<br />

¢ 12<br />

(. 472)<br />

2.80<br />

[~ ::J c<br />

<strong>Uncontrolled</strong> Copy<br />

6<br />

( .236)<br />

1 5,60<br />

( .614)<br />

Fitting the backshell, see page 66.<br />

cadmium/nickel under plate 617 907 5.1<br />

® Trade Mark ofThomas & Betts Corp.<br />

For other platings, consult Radiall.<br />

RADIALL ®<br />

The Quality Connection<br />

-22-

13 (. 512)<br />

ON FLATS<br />

50 MAX<br />

( 1. 969)<br />

30<br />

( 1. 18 1)<br />

2 HOLES<br />

¢ X<br />

__l___L_______l _<br />

34 '30<br />

(1 . 350) 2,80<br />

(. 110)<br />

50<br />

( 1. 969 )<br />

35 50<br />

(1 . 398)<br />

2<br />

(.079)<br />

0 0 0<br />

2. 50<br />

( .098 )<br />

______.J=4<br />

_ ¢ 10<br />

(. 394)<br />

5 (. 1 97)<br />

15 . 60<br />

1-4-------t-( . 6 14 )<br />

Fitting the backshell, see page 66.<br />

· < < Partillirriber < x Oia<br />

9~1M iJ fulrisR~ ~ Ji)1erpiCJ.le 61-rs66 3.1<br />

cadmium/nickel underplate 617 908 5.1<br />

For other platings, consult Radiall.<br />

<strong>Uncontrolled</strong> Copy<br />

l<br />

Fitting the backshell, see page 66.<br />

2 HOLES<br />

¢ X<br />

4 1~---<br />

:~<br />

50<br />

( 1. 969)<br />

L=l<br />

.. I<br />

15 . 60<br />

( 614)<br />

42<br />

cadmium olive drab<br />

617 921 003<br />

ci drl1rum/nickel underpiaie. 617 921602<br />

cadmium olive drab 617 921 001<br />

For other platings, consult Radiall.<br />

3.1<br />

5.1<br />

RADIALL ®<br />

The Qualit y Connection<br />

- 23-

34<br />

(1.338) 5(.197)<br />

2<br />

( .079)<br />

0 0 0<br />

34.30 2 80 J<br />

'I<br />

I~ 50 y I<br />

2 HOLES ~II .969)-----2:J<br />

¢ 5. 20(,205)<br />

2 HOLES<br />

M 2 X 0,40<br />

1<br />

16. 10 ( .634) MAX<br />

28,50<br />

(1 .122)<br />

L_<br />

L 49,60_j<br />

S-u-ita-b-le-fo-r -sh-el-l s-ty-le-s-23_ a_n_d -31-. ---,~<br />

48<br />

( 1. 89 0) 4 30<br />

(. 169)<br />

( 1. 953)<br />

11' 35<br />

(. 447)<br />

4 VIS M 2 x<br />

y<br />

4VIS<br />

M 2 X 0, 40<br />

<strong>Uncontrolled</strong> Copy<br />

16 .20 ~<br />

(. 638)<br />

I<br />

- -<br />

I<br />

Plating<br />

'\<br />

l<br />

This model permits attachment of cable braids onto the finger strip of the backshell using heatshrink<br />

solder sleeves (supplied with the backs hells).<br />

For other platings, consult Radial!.<br />

RADIALL ®<br />

The Qualify Connection<br />

- 24-

FIXED MOUNTING ON FRONT OF PANEL (except shell variant 13 and 31)<br />

B<br />

f<br />

30. 10 MIN<br />

~-----.>-----~ A<br />

( 1 . 185 ) 2<br />

+ R.2 MAX<br />

C0 4 7 2 9M~<br />

....._------,.---------.J<br />

14.40 MIN<br />

(. 567) ( 1. 653)<br />

HOLES ¢ 3. 10 ~0 · 10 ( . 122 ~ · 004 )<br />

I fit I ¢ 0' 10 ( . 004) @ I A I B I<br />

FLOAT MOUNTING ON FRONT OF PANEL (shell variant 13 only)<br />

B<br />

t<br />

+----<br />

15 . 30 MIN<br />

(.602 )<br />

31 MIN<br />

( 1 .220)<br />

~----~____,A<br />

R.Z MAX<br />

R. 079 MAX)<br />

42<br />

( 1. 653) _ ___,<br />

SIDE MOUNTING FOR RECEPTACLE SHELL WITHOUT FLANGE (shell variant 12)<br />

*-<br />

-,---t___,___: 2 HOLES ¢ 7 ±0 . 05 ( . 276 ±. 002 )<br />

I fit I ¢ 0' 10 ( . 004) @ I A I B I<br />

32. 50±0. 10 2 HOLES ¢ 3, 10 +0. 10 (. 122 +. 004)<br />

i :, fi_L ZBO±<br />

004<br />

\J[ OR M3 ~ 0, 5 THREA~<br />

-¥.':<br />

'<br />

" '<br />

I 1 1 I<br />

'- .::. -'1 l~o. -'<br />

-+------·-------------"<br />

15.80 MIN<br />

(. 622)<br />

<strong>Uncontrolled</strong> Copy<br />

FIXED MOUNTING ON REAR OF PANEL (shell variant 31 only) :-Consult Radiall<br />

The Quality Connection<br />

-25-

The various components (backshells, plug shells, receptacle shells) linked<br />

by a line may be coupled together.<br />

Example : plug shell EPX 2 P 19 * will only mate with receptacle shell<br />

EPX 2 R 18 *.<br />

*Polarization and plating to be specified.<br />

BACKSHELLS<br />

-<br />

PLUG SHELLS<br />

RECEPTACLE SHELLS<br />

~L----E-PX-~~1-2_*~~<br />

<strong>Uncontrolled</strong> Copy<br />

EPX 2 B 12 *<br />

L-----L....r"\'--__ ?<br />

BACKSHELLS<br />

RADIALL ®<br />

The Quality Connectio n<br />

-26-

I<br />

EPX 2 B 14 * I EPX 2 R 18 *<br />

'L..------,<br />

<strong>Uncontrolled</strong> Copy<br />

(<br />

I<br />

RADIALL<br />

The Quality Connection<br />

-27-

18, 30 ±0, 10<br />

(.720 ± 004)<br />

5. 10 ~0, 15<br />

1,=75 ,80 ±0.20 ~<br />

(2.984 ±.008)<br />

74 ±0, 10<br />

( 2 . 9 13 ± . 004 )<br />

Fixed by two clearance holes<br />

Rack or cable version<br />

2. 55 ±0, 10<br />

( . 100 ± . 004)<br />

NON ENVIRONMENTAL<br />

5 ( 197)<br />

4 HOLES<br />

¢3, 1 ~0 , 10<br />

( ¢ . 1 22 ~ 004 )<br />

················· P~ ifNJM!j;W •••···············<br />

* Polarization and plating to be<br />

specified<br />

18 ,30 ±0. 10<br />

(. 720 ±. 004)<br />

5. lO ;o. 15<br />

-<br />

( . zoo ~. 006)<br />

NON ENVIRONMEN TAL<br />

5 ( 197)<br />

2 HOLES<br />

¢3, 1 ~0, 10<br />

(¢ . 122 ~ 004 )<br />

Part Number<br />

EPX2_B 12 *<br />

~<br />

* Polarization and p lating t? be<br />

specified<br />

I<br />

7 4 ±O · 25 .-------~~ -~ ENVIRONMENTAL<br />

(2.913 ±.010)<br />

13.2281<br />

M 5 X 0,8<br />

r--------- 88 (3 .464) ------~<br />

MAX<br />

r<br />

_______ (75 , 80 ±0' 20 ------~-.ll<br />

2.984 ±.008)<br />

~~<br />

--u;;;;;;;;;;;v \ I<br />

I~ 74 ±0,25 ___ ___,:-.li~ENTAL<br />

~8~ ~ ~ '---" '---"<br />

1\. I<br />

~<br />

00<br />

I<br />

J<br />

10 (. 394)<br />

<strong>Uncontrolled</strong> Copy<br />

---+<br />

16 10 +O,ZO<br />

' -0, 10<br />

( . 6 30 ~ : ~~~)<br />

(2.913 ±.010) 10 (.394)<br />

I<br />

I<br />

13. zz8l<br />

88 (3.464)<br />

MAX<br />

M 5 X 0 8<br />

~~<br />

~<br />

Fixed by two clearance holes<br />

Rack or cable version<br />

I<br />

\<br />

\<br />

.,<br />

1<br />

I<br />

I<br />

0<br />

22 -0 30<br />

0 .<br />

(.866t<br />

-.012)<br />

20<br />

16, 10 ~~·<br />

10<br />

( . 630 ~. 0 08<br />

.004)<br />

RADIALL ®<br />

Th

18,30 ±0, 10<br />

( . 7 20 ± . 004)<br />

5. 10 ~0, 15<br />

-<br />

( .200 ~ 006)<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

2 HOLES<br />

I<br />

______<br />

.--<br />

r<br />

75. 80 ±0. 20 --------~1 Fixed<br />

(2. 984 ± . 008)<br />

I<br />

I~<br />

M 3 X 0, 5<br />

~<br />

~~ '--"<br />

18 , 30 ±0 . 10<br />

(. 720 ± 0 004)<br />

16<br />

(. 630)<br />

t<br />

))}<br />

plating to<br />

5 10 +0, 15<br />

. 0 -<br />

( . 200 ~ . 006)<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

2 HOLES<br />

¢ 3 . 1 ;o. 10<br />

l<br />

~<br />

~~<br />

16=» \ I :=1<br />

I<br />

by 2 threaded holes<br />

Rack or cable version<br />

ENVIRONMENT A L<br />

10 (. 394)<br />

74 ±0. 25 -------~=~1 16 10 •0. zo<br />

(2 .913 ±.010) . -0. 10<br />

I<br />

I<br />

I<br />

~ '--"<br />

I<br />

[][]<br />

13.2281<br />

88 (3 .464)<br />

MAX<br />

------- 75,80 ±0.20<br />

(2 . 984 ± . 008)<br />

1<br />

~~<br />

l==<br />

I<br />

~,<br />

M 5 X 0 8<br />

~~<br />

<strong>Uncontrolled</strong> Copy<br />

74 ~Z5<br />

2 .913 ±.010<br />

-<br />

I<br />

-<br />

I<br />

( 630 +.00 8 l<br />

- .004<br />

E NV IRONMENT AL<br />

10 (. 394)<br />

\ I<br />

I<br />

•<br />

22<br />

( .866t<br />

0<br />

-0.30<br />

0<br />

-.0 12)<br />

N.B. : for a recept acle shell<br />

without flange fix ed by 2<br />

threaded holes, us e the P/N<br />

EPX 2 R 14 *<br />

Cable version<br />

HEX SOCKET FOR<br />

9/64 ALLEN KEY<br />

(¢. 122 ; 004)<br />

* Polarization and plating to be<br />

specified<br />

~------88 (3.464)<br />

MAX<br />

16 10 +<br />

0· 20<br />

. -0, 10<br />

(.630 ~ ~~~)<br />

RADIALL ®<br />

The Qual it y Connecti on<br />

-29-

18, 30 ±0, 10<br />

( . 720 ±. 004)<br />

75.80 ±0.20~<br />

1,=(2.984 ±.008)<br />

7 4 ±0 • 10 * Polarization and plating to be<br />

(2 . 9 13 ±. 004 l specified<br />

5<br />

10 +0 . 15<br />

. 0<br />

~w z. 55 ±0. 10<br />

(. 200 ~. 006) +----r----'rlib~<br />

(. 100 ±.004)<br />

NON ENVIRONMENTAL<br />

5 (. 197)<br />

4 HOLES<br />

¢3, 1 ~0. 10<br />

(¢ . 122 ~.004)<br />

4 HOLES M 2 x 0.40<br />

C'SUNK 90 •<br />

74 ±0,25<br />

~---- (2 . 913 ±.010)<br />

M 5 X 0, 8<br />

88 (3.464) -----~<br />

~------ MAX<br />

ENVIRONMENTAL<br />

10 (. 394)<br />

<strong>Uncontrolled</strong> Copy<br />

\_<br />

•<br />

_j[_<br />

_j)_<br />

J<br />

16 10 +0.20<br />

' -0, 10<br />

( . 6 30 ~ : ~~~)<br />

RADIALL ®<br />

Th£" Qualit y Connection<br />

-30-

Cable version<br />

15 60 +<br />

0· 20<br />

. -0 . 10<br />

[. 6 14 ~ : ~~~}<br />

2 HOLES<br />

¢3. 1 ~0. 10<br />

M 5 X 0.8 [¢. 122 ~ . 004}<br />

NON ENVIRONMENTAL<br />

5 [. 197)<br />

-<br />

r<br />

(.6·lO)<br />

l<br />

+0. 10<br />

10.65 0<br />

{.419 ~.004}<br />

15 60 +<br />

0· 20<br />

. -0. 10<br />

[ . 6 14 ~ : ~~~}<br />

I<br />

NON ENVIRONMENTAL<br />

4. 8 (. 189)<br />

74 +0 - . 25<br />

[2.9 13 ±.010)<br />

•<br />

~<br />

r~J[=¢~<br />

'---<br />

\<br />

* Polarization and plating to be<br />

specified<br />

HEX SOCKET FOR<br />

ENVIRON MENTAL ALLEN KEY 9/64<br />

10 [ .394}<br />

I<br />

5 10 +0, 15<br />

. 0 -<br />

[ . zoo ~ . 006)<br />

~------ 89 (3. 504) --------~<br />

MAX<br />

[][]<br />

13. 228~------.-j<br />

r<br />

<strong>Uncontrolled</strong> Copy<br />

74 +0 - . 25<br />

(2.913 ±.010)<br />

Rack version<br />

Z FLOATING EYELETS<br />

¢ 3 . 1 ~o. 10 (¢. 122 ~ .004)<br />

TOT AL PLAY :<br />

¢ 0.75±0.05 (¢.030± .002<br />

ENVIRONMENTAL<br />

9. 8 {. 386)<br />

* Polarization and plating to be<br />

specified<br />

10.50 ±0.25<br />

(.413 ±.010)<br />

-<br />

]<br />

~<br />

r~Jl=¢~<br />

u<br />

\<br />

[<br />

15.95 ±0. 15<br />

( 628 ±. 006)<br />

I \<br />

~<br />

RADIALL ®<br />

The Qua lit y Connecti on<br />

- 31 -

15 60 +<br />

0· 20<br />

' -0, 10<br />

(.614 ~ : ~~~)<br />

1-4--------88 {3 . 464 ) ______ ~<br />

MAX<br />

00<br />

13.2281<br />

r<br />

2 HOLES<br />

¢3, 1 ~0, 10<br />

(¢. 122 ; .004)<br />

Rack version<br />

* Polarization and plating to be<br />

specified<br />

5, 10 ~ 0 , 15<br />

( .ZOO 0006)<br />

-+---+--.--__J__<br />

10, 65 ~ 0 ·<br />

10<br />

(. 419 ~ . 004)<br />

<strong>Uncontrolled</strong> Copy<br />

I .\<br />

If If<br />

Rack version<br />

2 FLOATING DEVICE M 3 x 0, 5<br />

THREAD DEEP:7. 50 (.295)<br />

TOTAL PLAY:<br />

¢ 0,75±0 , 05 {¢ .030±.002)<br />

* Polarization and plating to be<br />

specified<br />

NON ENVIRON MET AL<br />

10 ' 40 (. 409)<br />

74 ±0 . 25<br />

(2 .913 ±.0 10)<br />

ENV IRONMENTAL<br />

15' 40 ( . 606)<br />

COMPR E SSIO~<br />

2. 50 MAX<br />

(. 100 MAX<br />

10,50±0. 25<br />

(.413 ±.0 10)<br />

0, 30 ±0, 10<br />

(.012±.00(<br />

RADIALL ®<br />

T h ~ Quality Connectio n<br />

-32-

15 . 60 ~~ : ~~<br />

( . 6 14 ~ : ~~~)<br />

~------ 88 (3.464)--- -------l<br />

MAX<br />

[][]<br />

13 .228 I M 5 X 0.8<br />

r<br />

NON ENVIRONME N T AL 74 +0 - ' 25<br />

(2 . 9 13 ±. 0 10)<br />

5 (. 197)<br />

5. 10 ;o ' 15<br />

-<br />

...n=n_<br />

06)<br />

(. 200 6 °<br />

10 65 +O ' 10<br />

' 0<br />

(. 419 ; . 004)<br />

5 60 +0,20<br />

' - 0. 10<br />

. 614 ~: ~~~)<br />

-:--<br />

r_L<br />

NtJJ[:6~<br />

R W<br />

B<br />

M 5 X 0, 8<br />

? s<br />

<strong>Uncontrolled</strong> Copy<br />

2 HOLES<br />

¢3. 1 ~0 , 10<br />

004<br />

1¢ . 122 ~ -<br />

)<br />

Cable version<br />

* Polarization and plating to be<br />

specified<br />

ENVIRON MENTAL<br />

10 (. 394)<br />

Q<br />

I<br />

13<br />

(. 512)<br />

2 HOLES<br />

\<br />

L..::..J<br />

¢3 . 1~0. 1 0<br />

1¢ . 122 ~<br />

004 )<br />

4 HOLES M 2 x 0,40<br />

C'SUNK go •<br />

For mounting of 617 922 002<br />

Ty-Rap backshell<br />

74 ±0,25<br />

NON ENVI RONMENT AL F(Z.913 ±.010)<br />

5 (. 197)<br />

.--- -<br />

16<br />

( .630 )<br />

HEX SOCKET FOR<br />

ALLEN KEY 9/.6 4<br />

* Polarization and plating to be<br />

specified<br />

EN VI RONMENTAL<br />

10 (. 39 4)<br />

I<br />

10 65 +O.<br />

' 0<br />

10<br />

D()()()()()()()XX)(l<br />

OCXXXXXXXXXXXXXXXXj<br />

5 10 +0. 15<br />

' 0<br />

( . 4 19 ; . 004) Visual fully mated indicator ( . zoo ~. 006)<br />

RADIALL ®<br />

The Quality Connectio n<br />

-33-

Rear panel mounting<br />

Front panel mounting<br />

13,35 ±0,25<br />

(. 526 ±. 0 10)<br />

L_<br />

The polarization of size 2 shells is realised by a central polarizing key provided with 6 flats.<br />

I<br />

23,65 ±0,25<br />

(.931 ±.010)<br />

_j<br />

The polarizing indicator is a lug on the jacknut and jackscrew sleeve with a keyway. This indicator shows the<br />

polarization co·de .<br />

This code represented by a letter, is marked on the side of the shell.<br />

For the polarization code, the indicator is aligned to the corner of the polarizing Hex (A, B, C, D, E, F codes) or to a<br />

flat (N, R, W, X, Y, Z codes) .<br />

<strong>Uncontrolled</strong> Copy<br />

The code is carried over into the part number of the shell or the complete connector in the column "polarization code".<br />

To change the polarizing position please see page 63.<br />

Polarizing key P/N page 48.<br />

RADIALL ®<br />

The Qua li ty Conneclion I<br />

-34-

Polarization code is marked on the shell.<br />

A, B, C, D, E, F polarization code<br />

The polarizing indicator is aligned to the corner of polarizing hex.<br />

E<br />

polarizing hex.<br />

PLUG SHELL 0<br />

B<br />

A<br />

0<br />

c<br />

This position for polarizing<br />

allows mating of the two shells.<br />

In this example, polarization<br />

position is F.<br />

polarizing indicator<br />

RECEPTACLE 0<br />

SHELL<br />

polarizing indicator<br />

N, R, W, X, Y, Z polarization code<br />

The polarizing indicator is aligned to the flat of polarizing hex.<br />

PLUG SHELL 0<br />

B<br />

B<br />

B polarizing hex.<br />

E<br />

c<br />

D<br />

polarizing hex.<br />

<strong>Uncontrolled</strong> Copy<br />

A<br />

0<br />

0<br />

polarizing indicator<br />

This position for polarizing<br />

allows mating of the two shells.<br />

In this example, polarization<br />

position is N.<br />

0<br />

v<br />

polarizing indicator<br />

I RADIALL ®<br />

The Qualit y Connecti on<br />

- 35-

cl·;----(2-.9-i_3) _-_----------~---JI<br />

34,50 ~~--<br />

0--------~ 0 ~ 1<br />

( 1. 358)<br />

I .t==Lc::-======::::=::::J.....~~rc::=::T"l"""L-=========jj<br />

( .051)<br />

35 MAX<br />

( 1. 378) 26.50<br />

( 1. 043)<br />

r----- 63,50<br />

(2 . 500 ) __ _.-..J<br />

(2.913) 74 _____<br />

6, 50<br />

(. 256)<br />

<strong>Uncontrolled</strong> Copy<br />

15,60<br />

(. 614)<br />

platings, consult Radiall.<br />

6<br />

(. 236)<br />

1' 30<br />

( .051 )<br />

-- 2 CAVITIES FOR<br />

SEPARATION OF CIRCUITS<br />

015, 60<br />

(. 614)<br />

Fitting the backshell , see page 59.<br />

For other pi a r Jngs, consul Radiall.<br />

RADIALL ®<br />

The Qualily Connectio n<br />

-36-

46 MAX<br />

( 1.811)<br />

26.50<br />

( 1.043)<br />

1' 30<br />

( .051)<br />

I<br />

48.5 MAX<br />

¢ 10<br />

(. 394)<br />

74<br />

(2 . 913)<br />

Z CAVITIES FOR<br />

SEPARATION OF CIRCUITS<br />

(Z . 9 13 l .------:.---r--__.__. - - I r-- - - I<br />

26. so I I I I<br />

( 1. 043)<br />

15.60<br />

( .6 14)<br />

Fitting the backs hell, see page 60 .<br />

. . ... ... . -.·.-.-....<br />

.. )< Partnultlbel- >>><br />

>_._ y~df1lilJ&tbi~ k~' ••wF~ e fP 1 •~~~ •••••••••••• < s h. 9o2 •.>•····· ·.<br />

For other platings, consult Radiall.<br />

2,80<br />

(. 110)<br />

F-<br />

<strong>Uncontrolled</strong> Copy<br />

7<br />

(. 276)<br />

¢ 15.60<br />

( 614)<br />

1' 30<br />

(. 051)<br />

¢ 10<br />

(. 394)<br />

Z CAVITIES FOR<br />

'--- SEPARATION OF CIRCUITS<br />

015,60<br />

(. 614)<br />

Fitting the backshell, see page 61.<br />

Plating<br />

Part number<br />

cadmium/nickel underplate 617 903<br />

For other platings, consult Radiall.<br />

RADIALL ®<br />

The Qualily Connection<br />

-37-

t5C<br />

29<br />

( l . 161)<br />

t=J<br />

1. 30<br />

(.051)<br />

16. 10<br />

(. 63 4) MAX<br />

28 .50<br />

(1. 122)<br />

+<br />

-.,.......<br />

0<br />

r--<br />

0 0<br />

"<br />

~ ~<br />

74 00<br />

(2. 913)<br />

2<br />

( .079)<br />

0 0 0 0 0<br />

r-. r-.<br />

L--...J<br />

](Q)[<br />

87 50<br />

4,30 ( 3 .445)<br />

(. 169)<br />

" " " " " " " "<br />

5 (. 1 97)<br />

<strong>Uncontrolled</strong> Copy<br />

~ ~ ~ ~ ~ ~ ~ ~<br />

~<br />

· 0<br />

r---<br />

-<br />

15.60<br />

(. 614)<br />

Fitting the backshell, see page 62.<br />

15,30<br />

(.602) ~-<br />

0<br />

I Suitable for shell styles 22 and 32.<br />

4 VIS M 2 x<br />

This model permits attachment of cable braids onto the finger strip of the backshell using heatshrink<br />

solder sleeves (supplied with the backs hells}.<br />

For other platings, consult Radial I.<br />

RADIALL ®<br />

The Quality Co nnection<br />

- 38 -

FIXED MOUNTING ON FRONT OF PANEL (except shell variant 13 and 17)<br />

16.40 MIN<br />

(. 646 )<br />

76,20 MIN<br />

~--------~------------~~ A<br />

(3 .000)<br />

2 HOLES¢ 3. 10 ~ 0 . 10 ( . 1 22 ~ · 004)<br />

R . 1 . 8 ( 0 7 1 ) MAX<br />

OR M3 x 0, 5 THREAD<br />

I ~ I ¢ 0' 1 0 ( . 004 ) (@ I A I 8 I<br />

82<br />

(3.228 )<br />

FLOAT MOUNTING ON FRONT OF PANEL (shell variant 13 and 17 only)<br />

77 MIN<br />

A f--..-11-----------------------~<br />

(3. 03 1)<br />

17,20 MIN<br />

(. 677)<br />

R. 1. 8 (. 071) MAX<br />

82<br />

(3 . 228)<br />

2 HOLES ¢ 3, 10 ~0. 10 ( 122; . 004)<br />

OR M3 x 0.5 THREAD FOR<br />

FLOAT MOUNTING ON REAR<br />

OR FRONT PANEL<br />

<strong>Uncontrolled</strong> Copy<br />

2 HOLES ¢ 3, 10 ~0 · 10 (. 122 ~ · 004 )<br />

FOR FLOAT MOUNT ING SPRING<br />

LOADED ON REAR PANEL<br />

I~ I ¢ 0. 10 (@ I A I 8<br />

SIDE MOUNTING FOR RECEPTACLE SHELL WITHOUT FLANGE (shell variant 12 and 32 only)<br />

74±0, 10<br />

(2. 9 13±. 004)<br />

cr- -;- ~ ;<br />

15,80 MIN<br />

(. 622 )<br />

: - . - - - - - - - - - - - .:- - ' I 2 HOLES ¢ 3' 10 ~0' 10 (. 122 ~. 004 )<br />

The Qualit y Connection<br />

-39-

A grounding spring fingers fitted to each plug shell cavity provides excellent EMI/RFI integrity between<br />

mated plugs and receptacles.<br />

This configuration is available for both plug shell sizes and all shell variants.<br />

! 111111 1 1111 1 11 1111 1 1 1 1 111111~ ~"'"""'"···' '"·~lllllllllllllllllllllllllr~~ ~~~~~~~ ~~~~~~~~~~~~~~ ~~~r<br />

fmgers<br />

CHARACTERISTICS<br />

Shielding effectiveness :<br />

Electrical continuity between shell :<br />

Durability :<br />

Grounding spring fingers material :<br />

ATTENUATION CURVE<br />

* Shell variant, polarization and plating to be specified<br />

0<br />

m<br />

-10<br />

~<br />

C/) -20<br />

C/)<br />

w<br />

z<br />

-30<br />

w<br />

> -40<br />

i=<br />

u<br />

w<br />

u.. -50<br />

u..<br />

w -60<br />

C)<br />

z<br />

-70<br />

0<br />

_J<br />

w -80<br />

I<br />

C/)<br />

___ ,..<br />

-90 ~ r-<br />

-100<br />

.5<br />

> 80 dB at 1 GHz<br />

< 1 mQ<br />

500 matings<br />

Beryllium copper, tin over nickel underplate<br />

<strong>Uncontrolled</strong> Copy<br />

____..-"'<br />

v<br />

/\ r., v<br />

_,<br />

FREQUENCY (GHz)<br />

1<br />

10<br />

HOW TO ORDER<br />

Version identified by the letter "H " in the column "shell type" (page 8 or 1 0).<br />

RADIALL ®<br />

The- Quality Connect inn<br />

-40-

Filtered EPX connectors provide a convenient method of preventing transmission of unwanted electromagnetic<br />

interference through input/output cables.<br />

To realise this function, RADIALL use and has a special expertise in two technologies :<br />

- Tubular filters : assembly of inductive/capacitive components on the contact,<br />

- Array filters : assembly of inductive/capacitive components in array.<br />

CHARACTERISTICS<br />

Operating voltage :<br />

Dielectric withstanding voltage :<br />

Insulation resistance :<br />

Temperature range :<br />

Electronic structure :<br />

Tubular<br />

200V<br />

500V<br />

> 10 000 MQ (200 V cc)<br />

-55°C I +125°C<br />

Pi<br />

Others structures available on request. Consult Radiall.<br />

TYPICAL ATTENUATION CURVES FOR DIFFERENT CAPACITANCE VALUES<br />

0<br />

-10<br />

-20! ........_<br />

6 -40<br />

~<br />

~ - 50<br />

w<br />

~ - 60 '<br />

-70 I<br />

-80<br />

1<br />

0<br />

- 10<br />

-20<br />

I<br />

m -30<br />

m - 3o<br />

"'-<br />

"'-<br />

z<br />

0 -40<br />

I<br />

~<br />

::><br />

z -50<br />

w I<br />

~ -60<br />

I<br />

-70;<br />

TUBULAR FILTERS<br />

~ r--- :-.<br />

1'---. 'r--<br />

I<br />

"~<br />

I<br />

I<br />

I<br />

ARRAY FILTERS<br />

I ~ 1--r-<br />

t-<br />

..........<br />

I<br />

r-....<br />

I<br />

I<br />

r---. !'--<br />

r--..... ........_<br />

I' I'<br />

" L 1 0 000 MQ (1 00 V cc)<br />

-55°C I +125°C<br />

Pi<br />

-80<br />

10 100 1000<br />

FREQUENCY (MHz)<br />

HOW TO ORDER<br />

Consult RADIALL.<br />

RADIALL ®<br />

The Quality Connection<br />

-41-

This version accepts a conductive seal fitted into a peripheral groove which provides an environmental<br />

seal and electrical continuity between shell and panel.<br />

GROOVE FOR<br />

CONDUCTIVE 0 'RING<br />

Connector supplied without conductive seal.<br />

Conductive seal:<br />

HOW TO ORDER<br />

574 01 020 shell size 1 (page 49).<br />

574 01 021 shell size 2 (page 49).<br />

Version identified by the letter "G" in the column "shell type" (page 8 or 1 0).<br />

GROOVE FOR<br />

CONDUCTIVE 0 'RING<br />

<strong>Uncontrolled</strong> Copy<br />

RADIALL ®<br />

Thr Qualily Con~c li on<br />

-42-

22<br />

reduced<br />

crimp barrel<br />

28<br />

30<br />

Pin 617 201<br />

Socket 617 301<br />

[j]<br />

,. E{]<br />

rn<br />

[j]<br />

IbM ••<br />

rn<br />

green<br />

green<br />

white<br />

white<br />

40<br />

28<br />

s<br />

16<br />

12<br />

16<br />

18<br />

20<br />

12<br />

14<br />

CABLING TOOLS PART NUMBER<br />

Pin 617 240<br />

Socket 617 340<br />

Pin 617 250<br />

Socket 617 350<br />

[j]<br />

~<br />

[j]<br />

C3DIJ<br />

blue<br />

blue<br />

yellow<br />

yellow<br />

<strong>Uncontrolled</strong> Copy<br />

28<br />

14<br />

17<br />

6<br />

C3*<br />

• with cavity<br />

reducer<br />

Italic : MIL part number - Bold : RADIALL part number<br />

s<br />

s<br />

282 891<br />

282 892<br />

12<br />

M22520/1- 01<br />

282 291<br />

M22520/1-02<br />

282 972<br />

(all plastic)<br />

282 547<br />

(all plastic)<br />

282 547<br />

282 945<br />

Termination of crimp contacts page 50.<br />

Installation and removal of crimp contacts from insert module page 58.<br />

RADIALL ®<br />

The Quahty Connect•o n<br />

- 43 -

REAR REMOVABLE CONTACT*<br />

22<br />

Pin 617 205<br />

==:C:UII==:JI==i<br />

¢o. 635<br />

40 3,2±0,6 282 890<br />

y<br />

X<br />

PLUG SHELL<br />

lr1.15<br />

11_0451<br />

---<br />

~<br />

=<br />

5, 10<br />

(.ZOO)<br />

5.80 ±0,05 10.55<br />

RECEPTACLE SHELL<br />

'"'iT<br />

I, 15<br />

X<br />

18,30 5.80 ±0.05<br />

P.C.<br />

BOARD<br />

SPACER<br />

!.228±.002) (.419) (.720) !.Z28± .002 )<br />

* See also "non standard products" page 66.<br />

Installation and removal of signal PC tail contacts from insert module see page 58.<br />

3<br />

1.100 x<br />

PRINTED CIRCUIT GRID PATTERN<br />

2, 54 X 3 =[[ill ¢ 3. 10 ~0 , 10<br />

~,.-;-w 13 2281 °<br />

=I .Joo ll _ rill~Jtl¢ _122 +.oo4 1<br />

~~ l+l¢0,10 100411<br />

+---+---+-----«~ 0 0 0 0 0 0 0 0 0<br />

~ _ ~o_o~o_o~ _<br />

~ 0 0 0 0 0 0 0 0 0 0 SIZE 1<br />

_.___ ____ ___,00000000~<br />

I ----------¢ 0, 75 MIN<br />

<strong>Uncontrolled</strong> Copy<br />

2. 54 x 9 = 22.86 1¢ .030 MINI<br />

1+1¢ 0 91<br />

¢ 0. 75 MIN<br />

I¢ .030 MIN)<br />

1~1¢ o @I<br />

¢10.5MIN<br />

1¢ .4 13MIN)<br />

¢ 3 10 +0. 10<br />

. 0<br />

1¢ . 1ZZ ; . 004 )<br />

I~ l¢o. 10 Loo4l I<br />

SIZE 2<br />

0 0 0 0 0 0 0 0<br />

2.54x9=l22,86l ~<br />

( . 100x9=[}Q9] )<br />

2. 54x9= lzz. 851<br />

[If]<br />

[ill]<br />

RADIALL ®<br />

The Quality Co nnection<br />

-44-

22 socket 617 303<br />

II<br />

1<br />

ip 0, 60x0, 60<br />

40 11 ,6±0,5<br />

282 948 v<br />

22 Pin 617 204<br />

=tJO:i:=::O• 'i!!I!!EJ!E3-oc{c{<br />

ip 0, 60x0. 60<br />

40 14,15±0,5<br />

282 948 w<br />

PLUG SHELL<br />

H-<br />

4,70 j 5, 10<br />

(. 185) (.ZOO)<br />

X 10, 65<br />

(. 419)<br />

,...--<br />

RECEPTACLE SHELL<br />

--<br />

u-<br />

4, 70<br />

(. 185)<br />

18,30 X<br />

(.720)<br />

Rear removable wire wrap contacts are supplied with a plastic anti-rotation device.<br />

Installation and removal of signal wire wrap contacts from insert module page 58.<br />

<strong>Uncontrolled</strong> Copy<br />

RADIALL ®<br />

The Quality t:or.nection<br />

-45-

---;<br />

Pin 617102<br />

m [TI[[J<br />

RG142<br />

A<br />

5 RG223 C3 s<br />

page 51<br />

KX23<br />

Socket 617 002<br />

I I<br />

m D<br />

5<br />

12<br />

Pin 617 104 --=3<br />

m [TI[[J<br />

RG178<br />

B<br />

C3 s<br />

KX21 page 52<br />

Socket 617 004<br />

I I<br />

l[] m<br />

Pin 617160 D<br />

[):::::=::::::i<br />

c:::1D==J 6<br />

Semi·rigid 17 c<br />

.085 C3* s<br />

page 53<br />

C1D<br />

D<br />

''With cavity<br />

Socket 617 060 ==Ll reducer<br />

<strong>Uncontrolled</strong> Copy<br />

CABLING TOOL PART NUMBER<br />

Italic : MIL part number - Bold : RADIALL part number<br />

*Consult RADIALL for all other cables.<br />

RADIALL ®<br />

The- Quality Connection<br />

-46-

15<br />

RG178<br />

KX21 s. T.<br />

Pin 617131<br />

Socket 617031<br />

0[] ICJJ=:=3<br />

LOIID<br />

milJD=::=J<br />

i!lc=JI<br />

OJ<br />

28<br />

14<br />

s<br />

02<br />

page 54<br />

15<br />

Semi-rigid<br />

.047<br />

Pin 617135<br />

Socket 617 035<br />

* See also "non standard products" page 66.<br />

CABLING TOOL PART NUMBER<br />

0<br />

<strong>Uncontrolled</strong> Copy<br />

0<br />

28<br />

14<br />

s<br />

03<br />

page 55<br />

Italic : MIL part number - Bold : RADIALL part number<br />

CABLING TOOL PART NUMBER<br />

Italic : MIL part number - Bold : RADIALL part number<br />

Insertion/eXtraction tool<br />

metallic body plastic body<br />

*Consult RADIALL for all other cables.<br />

RADIALL ®<br />

Tht Quality Conneclion<br />

-47-

CAVITY SEALING AND FILLER PLUG<br />

5<br />

5<br />

DUST CAPS<br />

CAVITY REDUCER<br />

pin contact<br />

pin and socket<br />

contact<br />

rear<br />

rear<br />

non environmental White 617 930<br />

environmental Red 925-05-450<br />

CONDUCTIVE SEAL<br />

for shell with panel seal groove<br />

<strong>Uncontrolled</strong> Copy<br />

COD<br />

socket<br />

cavity<br />

617 941<br />

shell size 574-01-021<br />

2<br />

0<br />

POLARIZING KEYS for shell size 2<br />

RADIALL ®<br />

The Quality Connection<br />

-48-

CRIMP TOOLS<br />

M22520/1-01<br />

M22520/2-01<br />

M22520/4-01<br />

M22520/5-01<br />

282 291<br />

282 281<br />

282 292<br />

282 293<br />

POSITIONERS for crimp tools<br />

INSERTION/EXTRACTION TOOL for contacts<br />

M22520/1-02<br />

M22520/2-08<br />

M22520/2-23<br />

282 560<br />

282 572<br />

282 578<br />

282 972<br />

282 971<br />

282 970<br />

DIE SET for crimp tool<br />

M22520/5-05 282 246<br />

282 556<br />

Insert module EXTRACTION TOOL<br />

282 521<br />

METALLIC BODY TOOLS<br />

282 512<br />

282 880<br />

282 881<br />

282 929<br />

282 946<br />

282 945<br />

PLASTIC BODY TOOLS<br />

M81969/1-01 282 885<br />

M81969/1-02 282 886<br />

M81969/1-03 282 546<br />

<strong>Uncontrolled</strong> Copy<br />

282 890<br />

282 891<br />

282 892<br />

282 538<br />

282 948<br />

ALL PLASTIC BODY<br />

282 547<br />

282 548<br />

SPIGOT WRENCH FOR POLARIZING KEYS<br />

SPIGOT WRENCH FOR BACKSHELLS<br />

RADIALL ®<br />

The Quality Connection<br />

-49-

1 See table for correct stripping dimensions.<br />

2 Insert stripped wire into contact crimp barrel.<br />

3 Use correct crimp tool and positioner (see table).<br />

4 Insert contact and wire into positioner.<br />

5 Squeeze tool handles firmly and completely.<br />

RADIALL<br />

22<br />

reduced crimp<br />

barrel<br />

16<br />

12<br />

617 201<br />

617 301<br />

617 240<br />

617 340<br />

617 250<br />

617 350<br />

CABLING TOOL PART NUMBER<br />

28<br />

30<br />

0,093<br />

0,055<br />

1,4<br />

4<br />

3,5<br />

5<br />

16<br />

1,34<br />

18<br />

0,93<br />

2,6<br />

6<br />

20<br />

0,6<br />

12<br />

3,18<br />

8<br />

3,4<br />

6<br />

14<br />

1,91<br />

7<br />

Italic: MIL part number - Bold : RADIALL part number<br />

<strong>Uncontrolled</strong> Copy<br />

20<br />

M22520/2-01<br />

282 281<br />

M22520/2-08<br />

282 971<br />

M81969/1-02<br />

282 886<br />

282 881<br />

M81969/1-02<br />

282 886<br />

282 891<br />

12<br />

M22520/1-01<br />

282 291<br />

M22520/1-02<br />

282 972<br />

(all plastic)<br />

282 547<br />

(all plastic)<br />

282 547<br />

282 945<br />

RADIALL ®<br />

The Qualily Conneclion<br />

-so-

Cables: RG58, RG141, RG142, RG223, KX23<br />

For center contact :<br />

Use crimp tool282 281 (M22520/2-01)<br />

selector 6 : RG58<br />

selector 8: RG141, RG142, RG 223, KX23<br />

Use positioner 282 572<br />

For body:<br />

Use crimp tool 282 293 (M22520/5-01)<br />

Use die set 282 246 (M22520/5-05)<br />

Hex A (5,4 I flats)<br />

For environmental version, slide sealing boot over<br />

cable before stripping<br />

1 Strip cable to dimensions.<br />

2 Slide ferrule A on cable.<br />

Introduce ferrule B under braid(s).<br />

Strip center conductor.<br />

3 Slide center contact onto conductor. Ensure conductor<br />

is visible through side hole.<br />

Crimp contact using correct crimp tool and positioner.<br />

Slide ferrule A over braid until it butts against ferrule B.<br />

4 Push home the cable assembly into body.<br />

Crimp body in the indicated area.<br />

--1---E-fr<br />

I 1<br />

I<br />

5 (.197) ± 0.3 (.012)<br />

,.. ..1<br />

12.5 (.492) ± 0.3 (.012)<br />

<strong>Uncontrolled</strong> Copy<br />

Body<br />

Crimping area<br />

RADIALL ®<br />

The Quality Connection<br />

-51-

Cables: RG174, RG178, RG180, RG316, KX21, KX22<br />

For center contact :<br />

Use crimp tool 282 281 (M22520/2-01)<br />

selector 6 : RG180, RG178, KX21<br />

selector 7: RG174, RG316, KX22<br />

Use positioner 282 572<br />

For body:<br />

Use crimp tool 282 293 (M22520/5-01)<br />

Use die set 282 246 (M22520/5-05)<br />

Hex A (5,4 I flats)<br />

For environmental version, slide sealing boot over<br />

cable before stripping<br />

1 Strip cable.<br />

2 Slide ferrule over braid until it butts against sheath.<br />

Fold braid over ferrule.<br />

Trim braid .<br />

Trim dielectric.<br />

3 Slide rear insulator on dielectric until it butts against<br />

braid.<br />

Slide center contact over conductor until it butts<br />

against rear insulator. Ensure conductor is visible<br />

through side hole.<br />

Crimp contact using correct crimp tool and positioner.<br />

4 Push home the cable assembly into the body.<br />

Crimp body in the indicated area.<br />

1 ~9 (.354) + g ~ 2 01<br />

0<br />

1.3 (. 051) - 02(006) 4.5 (.177)<br />

Side hole<br />

.. ,1 ~ ~ Ferrule<br />

~~ :)<br />

Rear insulator<br />

<strong>Uncontrolled</strong> Copy<br />

+<br />

Crimping area<br />

RADIALL ®<br />

Thr Qual ity Connectio n<br />

- 52-

Semi-rigid cables: .085, .047<br />

For center contact :<br />

Use soldering iron<br />

For body:<br />

Use soldering iron<br />

UT .85 CABLE<br />

1 Strip cable.<br />

2 Slide ferrule over cable.<br />

3 Slide center contact over conductor.<br />

Solder the center contact maintaining dimension<br />

shown.<br />

UT .047 CABLE<br />

FERRULE FOR UT . 08 5 CABLE<br />

FERRULE FOR UT .047 CABLE<br />

<strong>Uncontrolled</strong> Copy<br />

4 Push home the cable assembly into the body.<br />

Slide ferrule fully forward.<br />

Solder the ferrule and cable in the body.<br />

RADIALL ®<br />

The Qualily Connection<br />

-53-

Cables: RG174, RG179, RG316, KX22<br />

For center contact :<br />

Use crimp tool 282 281 (M22520/2-01)<br />

selector 3<br />

Use positioner 282 578<br />

For the ferrule :<br />

Use crimp tool 282 292 (M22520/4-01)<br />

Use positioner 282 556<br />

Use extraction tool 282 512<br />

1 Strip cable.<br />

2 Slide ferrule on cable.<br />

Comb braid(s).<br />

3 Introduce conductor into center contact.<br />

Insert contact into correct crimp tool with positioner<br />

and qimp contact.<br />

4 Push home the assembly into the body.<br />

Press braid(s) over grooved barrel.<br />

Slide ferrule over braid.<br />

Crimp ferrule.<br />

For center contact :<br />

Use crimp tool (M22520/2-01)<br />

selector 1<br />

Use positioner 282 578<br />

1 Strip cable.<br />

2 Slide ferrule on cable.<br />

Comb braid(s) .<br />

3 Introduce conductor into center contact.<br />

Insert contact into correct crimp tool with positioner<br />

and crimp contact.<br />

4 Push home the assembly into the body.<br />

Press braid(s) over grooved barrel.<br />

Slide ferrule over braid.<br />

Crimp ferrule.<br />

t *<br />

Cables : RG178, KX21 S.T., KX 21 D.T.<br />

3.2 (. 126)<br />

~<br />

4.8 (.189) 4 (. 157)<br />

~ -- Jt i4 . Jt i<br />

-t-lOJIDfJ ---t<br />

JC 0.5 (. 020)<br />

For the ferrule :<br />

Use crimp tool 282 292 (M22520/4-01)<br />

Use positioner 282 556<br />

Use extraction tool 282 512<br />

<strong>Uncontrolled</strong> Copy<br />

I ~ ,~ +<br />

4.8 (.189) 4.5 (.177)<br />

I~ Jt l 4 ~ I<br />

Single braid ferrule<br />

f=- II<br />

* ::m ==-== . ~ -<br />

Double braid ferrule<br />

~ED : 111 ~ w ~ ----w-~<br />

~0.5(.020)<br />

RADIALL ®<br />

The Quality Connection<br />

-54-

Semi-rigid cable : .047<br />

For center contact :<br />

Use soldering iron<br />

For the ferrule :<br />

Use soldering iron<br />

Use extraction tool 282 512<br />

1 Strip cable.<br />

2 Slide ferrule on cable.<br />

3 Solder center contact.<br />

4 Push home assembly into body.<br />

Slide forward ferrule .<br />

Solder ferrule and cable into body.<br />

<strong>Uncontrolled</strong> Copy<br />

, 4.5. (.177) - ~ 0.5 (.;;;--·------=*<br />

r ~ ( . 0 ~ 2 ) Ferrul~<br />

(C - i£W tlliB= -3<br />

RADIALL<br />

The Quality Connection<br />

- 55-

Cables : PAN 6421, M 17176100002<br />

For center contact :<br />

Use crimp tool282 281 (M22520I2-01)<br />

selector 3<br />

Use positioner 282 560<br />

For the ferrule :<br />

Use crimp tool 282 293 (M22520/5-01)<br />

Use die set 282 246 (M22520/5-05)<br />

Hex B (4,5 I flats)<br />

For body:<br />

Use crimp tool 282 293 (M22520I5-01)<br />

Use die set 282 246 (M22520I5-05)<br />

Hex A (5,4 I flats)<br />

1 Strip the cable.<br />

Comb braids after stripping off the high immunity<br />

shield.<br />

Trim the two conductors.<br />

Twist the braid at the end to reduce entry diameter.<br />

2 Slide ferrule on braid until it butts against sheath .<br />

Fold braid over ferrule.<br />

Trim braid.<br />

Strip the two conductors.<br />

3 Slide the rear insulator on first conductor until it butts<br />

against the braid.<br />

Position the second conductor in the rear insulator<br />

slot.<br />

Slide center contact over the first conductor until it<br />

butts against the rear insulator. The conductor should<br />

be visible through the side hole.<br />

Crimp center contact using the correct crimp tool and<br />

positioner.<br />

4 Slide the ferrule over the rear insulator.<br />

5 Slide cable a·nd crimped center contact into insulator,<br />

then push home the assembly into the intermediate<br />

contact, ensuring that the second conductor is aligned<br />

with the slot.<br />

Introduce the second conductor into the slot and slide<br />

the ferrule over the intermediate contact.<br />

Crimp ferrule ensuring first that the second conductor<br />

is aligned with the flat of the crimp die.<br />

6 Slide intermediatli contact into the insulator, then push<br />

home the assembly into the contact body.<br />

Crimp body.<br />

When crimping, squeeze body slightly in the crimp die<br />

in the indicated area, then push lightly on the cable to<br />

ensure that all the piece parts are fully home complete<br />

crimp.<br />

After assembly inspect dimensions<br />

2 (.079)<br />

- ~"----· ~ ·-<br />

- E -<br />

'<br />

I~<br />

1st conductor (white)<br />

~==~;~~~~~~on the center contact<br />

Rear insulator<br />

Ferrule<br />

<strong>Uncontrolled</strong> Copy<br />

The ferrule and the 2nd conductor<br />

must free the contact shoulder<br />

·& . .<br />

~ + -- ~<br />

- Push the cable I [<br />

1.----t 4.5 ( 177) :!: 0 3 ( 012)<br />

Crimping area<br />

2nd conductor on the<br />

intermediate contact<br />

m i Die'<br />

@<br />

2nd conductor facing<br />

hexagonal flat<br />

Outer contact<br />

RADIALL ®<br />

Th~ Quality Co nneclion<br />

-56-

The insert module is assembled into the rear of the<br />

shell by hand.<br />

Rear shell view<br />

1 Lir.e up the orientation key of the insert module with<br />

the shell cavity keyway.<br />

2 Offer the insert module into the shell cavity.<br />

3 Push the insert module squarely into the shell until the<br />

retention clips engage.<br />

4 Ensure that the insert module is fully retained by<br />

applying slight pressure to the front face.<br />

Shell<br />

Use extraction tool 282 521.<br />

1 Position the tines of the tool into the two grooves of the<br />

insert module.<br />

2 Insert the tool as far as it will go to release retention<br />

clips.<br />

3 From the mating face, push insert module with fingers<br />

un~il insert module moves back slightly.<br />

4 Remove tool from shell, leaving insert module partially<br />

extracted .<br />

5 Push insert module from the mating face completely<br />

out of the rear of the shell.<br />

Rear shell view<br />

<strong>Uncontrolled</strong> Copy<br />

Front shell view<br />

RADIALL ®<br />

The Qual ity Connection<br />

-57-

Use spanner 5.5 across flats.<br />

1 Release the nuts from the two polarizing keys.<br />

2 Remove the polarizing keys.<br />

3 Position the shell in the cut out.<br />

4 Assemble the polarizing keys in the required orientation<br />

(page 22).<br />

Polarizing key<br />

Jy<br />

CRIMP, PCB AND FRONT RELEASE WIRE WRAP CONTACTS<br />

Insertion of contacts into insert modules<br />

1 Position the contact at the extremity of the tool (side<br />

INS for contacts which require mixed tool).<br />

2 Introduce the assembly:<br />

- by rear face of insert module (for rear removable<br />

contacts,<br />

- by front face of insert module (for front removable<br />

contacts.<br />

3 Insert the tool as far as it will go to engage the retention<br />

clips.<br />

4 Remove tool from insert module.<br />

REAR RELEASE WIRE WRAP CONTACTS<br />

Insertion of wrapping contacts into insert modules<br />

1 Engage the contact in the insert module.<br />

2 Push the plastic anti-rotation piece with the INS side<br />

of the tool as far as it will go against the rear face of the<br />

insert module.<br />

Extraction of contacts from insert modules<br />

1 Introduce tool extremity into the insert module (side<br />

EXT for contacts which require mixed tool) by the front<br />

or rear face of insert module (depending on the<br />

contact).<br />

2 Insert the tool as far as it will go to relerase the retention<br />

clip.<br />

3 Release the contact and the tool, the assembly must<br />

slide without difficulty.<br />

Extraction of wrapping contacts from insert modules<br />

<strong>Uncontrolled</strong> Copy<br />

1 With the EXT side of the tool, push the plastic anti-rotation<br />

piece as far as it possible.<br />

2 Extract the contact.<br />

Mixed tool<br />

RADIALL ®<br />

The Quality Connec tion<br />

5 Assemble the washers and nuts and lock with a spanner.<br />

-58-

Use the spigot wrench 282 661.<br />

Rear shell view<br />

Ribbon cable should be fitted with contacts before<br />

moun!ing.<br />

1 If ribbon cable is less than 3. 7 thick, use the reducer. In<br />

the other cases (ribbon cable thickness between 3.7<br />

and 6.5) reducer is not necessary.<br />

Be careful : the backshe/1 can only be mounted one<br />

way round, so ensure that ribbon cable is located in<br />

correct cavity A or B.<br />

2 Engage the ribbon cable in the open side of the backshell<br />

3 Fit the contacts into the insert module.<br />

4 Install the insert module into the shell.<br />

Locking screw<br />

5 Apply some thread lock onto the accessory thread of the connector shell.<br />

Reducer for thin ribbon cable<br />

•<br />

1--Fixing screws of cable clamp<br />

6 Mount the backs hell onto the rear of the connector. Ensure that the locking screw is correctly positioned on the polarizing<br />

key accessory thread.<br />

7 Screw and tighten the locking screw with spigot wrench .<br />

8 Attach the cable clamp using the fixing screws.<br />

9 Push the ribbon cable into the backshell so that there is some slack when the clamp is tightened.<br />

10 Tighten the clamp to trap the ribbon cable.<br />

Use the spigot wrench 282 661.<br />

1 Feed the twisted pair cable through the outlet of the<br />

backshell.<br />

2 Strip and terminate the twisted pair cable.<br />

3 Fit the contacts into the insert module.<br />

4 Install the insert module into the shell.<br />

5 Apply some thread lock onto the accessory thread of<br />

the connector shell.<br />

6 Mount the backshell onto the rear of the connector.<br />

Ensure that the locking screw is correctly positioned<br />

on the polarizing key accessory thread.<br />

7 Screw and tighten the locking screw with the spigot<br />

wrench.<br />

8 Clamp the twisted pair cable with a Ty-Rap® in the slot<br />

of the outlet.<br />

Outlet of the backs hell<br />

<strong>Uncontrolled</strong> Copy<br />

Locking screw<br />

Slot<br />

® Trade Mark of Thomas & Betts Corp.<br />

RADIALL<br />

The Quality Connectio n<br />

-59-

Use the spigot wrench 282 661.<br />

Use a spanner with 13 mm across flats.<br />

Rear shell view<br />

1 Place the braid over the cable.<br />

2 Slide the nuts and braid clamp onto the cable.<br />

Be carreful : the backshe/1 can only be mounted one<br />

way round, so ensure that cable is located in correct<br />