RHK-AK - Heizomat

RHK-AK - Heizomat

RHK-AK - Heizomat

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EnErgy in balancE with naturE<br />

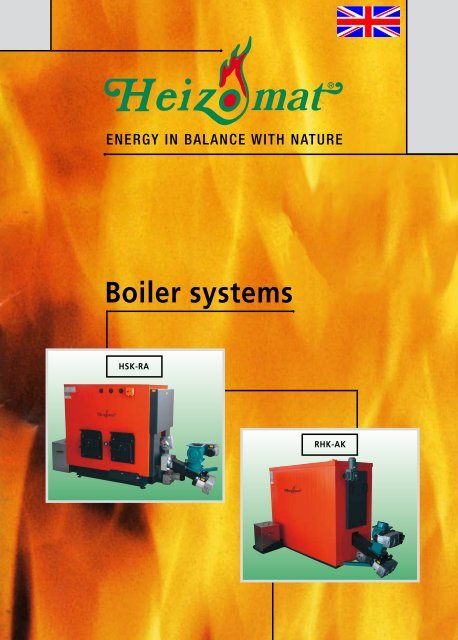

Boiler systems<br />

HSK-RA<br />

<strong>RHK</strong>-<strong>AK</strong>

2<br />

The company<br />

HEIZOMAT is a medium sized company specialising<br />

in the design, development and manufacture of<br />

products that utilise renewable energy sources.<br />

Founded in 1982, by Robert Bloos, HEIZOMAT<br />

has grown from a small company operating from a<br />

garage to one with over 180 highly qualified employees<br />

operating from two sites in Bavaria.<br />

Factory in Heidenheim<br />

Energy in balance with nature...<br />

is our business philosophy.<br />

This has been our guiding principle since the formation<br />

of our company 25 years ago.<br />

Through innovation and design HEIZOMAT have<br />

been able to provide customers with high quality,<br />

reliable and easy to use boiler technology to convert<br />

biomass materials into heat energy. Continual product<br />

development is the key to HEIZOMAT´s success.<br />

<strong>Heizomat</strong> is a pioneer in complete solutions for<br />

biomass energy: harvesting – chipping – preparing –<br />

transporting - storing – heating – we have the solution<br />

for all requirements.<br />

EnErgy in balancE with naturE<br />

solar energy<br />

C + O2 = CO2<br />

H + O2 = H2O<br />

minerals<br />

(ashes)<br />

O2<br />

(oxygen)<br />

decomposition and release of<br />

energy bay combustion<br />

(oxidation)<br />

Factory in Maicha<br />

Both sites are heated exclusively by HEIZOMAT<br />

biomass-fired boilers.<br />

Since its formation, HEIZOMAT has produced over<br />

20,000 biomass heating systems and wood-fuel chippers.<br />

These products have been installed throughout<br />

the world and are known for their quality and reliability.<br />

water (H2O)<br />

CO2<br />

(carbon dioxide)<br />

minerals<br />

+ H2O<br />

assimilation by photosynthesis,<br />

energy storage in wood

Discharger<br />

bunker<br />

heating room<br />

EnErgy in balancE with naturE<br />

bunker<br />

Filling of the bunker<br />

The articulated arm discharger, developed by<br />

HEIZOMAT in 1983, is well proven and of robust<br />

construction enabling fuel to be discharged form the<br />

bunker reliably and without bridging within the fuel<br />

store.<br />

The discharger auger is made from high wear resistant<br />

steel comprising of a solid 50mm diameter shaft and<br />

fully welded flight with a tapered geometry to prevent<br />

jamming ensuring high operating reliability.<br />

The essential part of each HEIZOMAT discharger<br />

system is the conical spur gear gearbox with a transferable<br />

torque of up to 5,000 Nm. The gearbox is<br />

installed inside the fuel bunker and is sealed for life to<br />

prevent the ingress of dirt and dust and also provide<br />

maintenance free operation. The drive motor for the<br />

discharger system is flanged to the discharger channel<br />

outside of the bunker. A dividing floor is not necessary.<br />

Experience has taught us, that the rhombic form of<br />

the discharger channel makes it possible to transport<br />

various biomass fuels of different form, weight and size<br />

(up to G50) without any difficulty.<br />

heating room<br />

bunker<br />

heating<br />

room<br />

HEIZOMAT has developed a range of bunker filling<br />

equipment that can be customised to suit the<br />

requirements of different buildings<br />

and site layouts.<br />

This allows a flexible approach to<br />

the design and location of the fuel<br />

bunkers.<br />

bunker<br />

heating room<br />

3

4<br />

10<br />

6<br />

11<br />

12<br />

EnErgy in balancE with naturE<br />

<strong>RHK</strong>-<strong>AK</strong><br />

2<br />

9<br />

17<br />

8<br />

7

1<br />

There are many biomass materials<br />

that can be used as fuel. The <strong>RHK</strong>-<strong>AK</strong><br />

range of boilers have been specifically<br />

designed and developed to operate<br />

using a broad range of biomass<br />

materials including wood.<br />

The round cyclonic combustion chamber<br />

with a turbulent air supply results<br />

in high combustion efficiency of the<br />

fuel with complete burnout.<br />

The primary air supply is transferred<br />

via the high temperature refractory<br />

lining near the bottom of the combustion<br />

chamber and secondary air via<br />

the refractory lining in the roof.<br />

13<br />

5<br />

EnErgy in balancE with naturE<br />

The new energy system from <strong>Heizomat</strong><br />

- a development for the future -<br />

16<br />

14<br />

15<br />

3<br />

4<br />

The chain grate system slowly conveys<br />

burning fuel through the combustion<br />

chamber ensuring complete burn out<br />

before it deposits ash into the ashbox.<br />

The advantage of this system is<br />

that the operation of the chain<br />

grate can be adjusted to suit the combustion<br />

characteristics of a range of<br />

different biomass materials to ensure<br />

good burnout and ash removal.<br />

1<br />

2<br />

3<br />

Heat exchanger tubes with de-ashing auger<br />

Drive for de-ashing auger<br />

Flue gas blower<br />

4 Ash box<br />

5 Ash cleaning system<br />

6 Rotary valve<br />

7 Combustion chamber<br />

8 Combustion chamber door<br />

9 Secondary combustion blower<br />

10 Feed auger motor<br />

11 Drop in shaft cover<br />

12 Discharger system motor<br />

13 Post combustion/drop out chamber<br />

14 Flue gas temperature sensor<br />

15 Post combustion chamber door<br />

16 Lambda sensor<br />

17 Primary combustion blower<br />

control cabinet with big<br />

touch screen panel<br />

5

6<br />

Triac-Three button<br />

control panel<br />

1 Combustion chamber door<br />

2 Post combustion chamber door<br />

3 Combustion chamber<br />

4 Drive for heat exchanger augers<br />

5 Heat exchanger tubes with de-ashing auger<br />

6 Flue gas blower<br />

7 Lambda sensor<br />

8 Flue gas temperature sensor<br />

9 Ash cleaning system<br />

10 Automatic ignition<br />

11 Primary combustion blower<br />

12 Secondary combustion blower<br />

13 Feed auger motor<br />

14 Drop in shaft cover<br />

15 Motor for rotary valve<br />

16 Rotary valve<br />

17 Stoker motor<br />

EnErgy in balancE with naturE<br />

7<br />

8<br />

6<br />

9<br />

2<br />

5<br />

5<br />

HSK-RA<br />

1<br />

3<br />

4<br />

10<br />

12<br />

11<br />

13<br />

15<br />

16<br />

14<br />

17

The HSK-RA range is still our best-<br />

seller. This range of boilers are completely<br />

enclosed and are renown for<br />

their high efficiency, rugged design,<br />

low flue gas emissions and convenient<br />

operation.<br />

The fuel transfer from the bunker to<br />

the boiler is carried out in the same<br />

way as the <strong>RHK</strong>-<strong>AK</strong> range using<br />

HEIZOMAT’s proven and reliable<br />

discharger technology. Combustion<br />

is controlled by a Lambda sensor.<br />

EnErgy in balancE with naturE<br />

The HSK-RA range is typically used at<br />

locations where wood-chip, sawdust,<br />

wood-shavings and wood-pellets are<br />

available.<br />

The HSK-RA range can be installed<br />

with either HEIZOMAT’s mature Triac-<br />

Three button control panel or the<br />

latest touch screen control panel.<br />

7

8<br />

Rotary valve<br />

The rotary valve has been an integral part of HEIZOMAT´s boiler systems for 20 years. The rotary valve is<br />

close fitting within its housing giving an airtight seal to prevent burn-back. The valve blades are hardened<br />

and ground and designed to cut trough larger pieces of wood to reduce the potential for jamming. The<br />

rotary valve has its own dedicated drive motor, which enables the valve’s rotational speed to be matched<br />

to the feed rate of the fuel.<br />

Auger (worm)<br />

EnErgy in balancE with naturE<br />

Our existing customers are fully aware of the quality of HEIZOMAT boilers. The operating reliability of the<br />

discharger auger or worm is guaranteed by the choice of material and robust design. The auger shaft is<br />

made from solid steel and is 50 mm in diameter.<br />

The sharp-edged worm flight is made from stainless steel and is fully welded to the shaft providing a<br />

high degree of resistance to corrosion and wear. At the head of the auger are two cutting blades that are<br />

designed to cut through larger pieces helping to reduce the potential for blockages to occur.

Glow bar<br />

automatic ignition<br />

The HEIZOMAT designed glow bar auto-ignition system is unique in its long-life operation. The specially<br />

developed ignition system, only found on HEIZOMAT boilers, provides fast and efficient ignition for both<br />

soft and hard wood.<br />

Lambda sensor<br />

EnErgy in balancE with naturE<br />

The lambda sensor is an integral part of the HEIZOMAT heating system. The sensor monitors the residual<br />

oxygen in the flue gas and transmits the value to the intelligent HEIZOMAT-control system. The control<br />

system then adjusts the amount of combustion air and the amount of fuel to optimise combustion<br />

efficiency.<br />

9

Technical Specification <strong>RHK</strong>-<strong>AK</strong><br />

10<br />

Heat Load (kW)<br />

Heat exchange surface (m 2 )<br />

Water capacity (l)<br />

max. operating pressure (bar)<br />

Weight (kg)<br />

Length (mm)<br />

Width (mm)<br />

Height (mm)<br />

Boiler shell length (mm)<br />

Boiler shell with (mm)<br />

Boiler shell height (mm)<br />

Flue tube height RRh (mm)<br />

Flue tube height RRh* (mm)<br />

Flue tube Ø (mm)<br />

Heat flow<br />

Heat return<br />

Safety heat flow<br />

Safety heat return<br />

max. boiler temperature (°C)<br />

max. boiler temperature (°C)<br />

with safety cooling system<br />

min. return temperature (°C)<br />

Power supply<br />

Heat Load (kW)<br />

Heat exchange surface (m 2 )<br />

Water capacity (l)<br />

max. operating pressure (bar)<br />

Weight (kg)<br />

Length (mm)<br />

Width (mm)<br />

Height (mm)<br />

Boiler shell length (mm)<br />

Boiler shell with (mm)<br />

Boiler shell height (mm)<br />

Flue tube height RRh (mm)<br />

Flue tube height RRh* (mm)<br />

Flue tube Ø (mm)<br />

Heat flow<br />

Heat return<br />

Safety heat flow<br />

Safety heat return<br />

max. boiler temperature (°C)<br />

max. boiler temperature (°C)<br />

with safety cooling system<br />

min. return temperature (°C)<br />

Power supply<br />

<strong>RHK</strong>-<strong>AK</strong> 30<br />

0 - 36<br />

3,40<br />

165<br />

3,0<br />

900<br />

1700<br />

860<br />

1585<br />

1550<br />

665<br />

1600<br />

1770<br />

1300<br />

200<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 204<br />

0 - 200<br />

18,00<br />

985<br />

3,0<br />

3108<br />

3290<br />

1565<br />

1895<br />

2900<br />

1375<br />

1770<br />

2070<br />

1618<br />

300<br />

DN 80<br />

DN 80<br />

1 1/2“<br />

1 1/2“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

EnErgy in balancE with naturE<br />

<strong>RHK</strong>-<strong>AK</strong> 50<br />

0 - 50<br />

4,50<br />

205<br />

3,0<br />

1000<br />

1900<br />

860<br />

1585<br />

1750<br />

665<br />

1600<br />

1770<br />

1300<br />

200<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 205<br />

0 - 200<br />

18,00<br />

660<br />

3,0<br />

2860<br />

3365<br />

1150<br />

2065<br />

2800<br />

930<br />

1950<br />

NL<br />

1925<br />

300<br />

DN 80<br />

DN 80<br />

1 1/2“<br />

1 1/2“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 60<br />

0 - 60<br />

5,60<br />

250<br />

3,0<br />

1150<br />

2100<br />

860<br />

1585<br />

1950<br />

665<br />

1600<br />

1770<br />

1300<br />

200<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 300<br />

0 - 300<br />

29,70<br />

1258<br />

3,0<br />

5400<br />

3490<br />

1880<br />

2035<br />

3150<br />

1695<br />

1925<br />

2225<br />

1771<br />

300<br />

DN 80<br />

DN 80<br />

1 1/2“<br />

1 1/2“<br />

80<br />

95<br />

>55<br />

400 / 32A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 75<br />

0 - 75<br />

7,20<br />

385<br />

3,0<br />

1400<br />

1950<br />

1085<br />

1700<br />

1550<br />

890<br />

1645<br />

1770<br />

1400<br />

200<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 400<br />

0 - 400<br />

33,75<br />

1580<br />

3,0<br />

6200<br />

3990<br />

1880<br />

2035<br />

3650<br />

1695<br />

1925<br />

2225<br />

1771<br />

350<br />

DN 80<br />

DN 80<br />

1 1/2“<br />

1 1/2“<br />

80<br />

95<br />

>55<br />

400 / 32A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 100<br />

0 - 101<br />

8,90<br />

475<br />

3,0<br />

1500<br />

2200<br />

1085<br />

1700<br />

1800<br />

890<br />

1645<br />

1870<br />

1490<br />

250<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 500<br />

0 - 500<br />

37,10<br />

1805<br />

3,0<br />

6800<br />

4290<br />

1880<br />

2035<br />

3950<br />

1695<br />

1925<br />

2225<br />

1771<br />

350<br />

DN 80<br />

DN 80<br />

1 1/2“<br />

1 1/2“<br />

80<br />

95<br />

>55<br />

400 / 32A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 154<br />

0 - 149<br />

14,10<br />

712<br />

3,0<br />

2570<br />

2790<br />

1565<br />

1895<br />

2400<br />

1375<br />

1770<br />

2070<br />

1618<br />

300<br />

DN 80<br />

DN 80<br />

1 1/2“<br />

1 1/2“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 650<br />

0 - 650<br />

56,00<br />

2680<br />

3,0<br />

8500<br />

4385<br />

2146<br />

2066<br />

3800<br />

1960<br />

1960<br />

2307<br />

NL<br />

400<br />

DN 125<br />

DN 125<br />

DN 80<br />

DN 80<br />

80<br />

95<br />

>55<br />

400 / 32A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 155<br />

0 - 165<br />

13,90<br />

510<br />

3,0<br />

2320<br />

2865<br />

1150<br />

2065<br />

2300<br />

930<br />

1950<br />

NL<br />

1925<br />

300<br />

DN 80<br />

DN 80<br />

1 1/2“<br />

1 1/2“<br />

80<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

<strong>RHK</strong>-<strong>AK</strong> 850<br />

0 - 850<br />

74,00<br />

3940<br />

3,0<br />

9900<br />

5086<br />

2146<br />

2066<br />

4500<br />

1960<br />

1960<br />

2307<br />

NL<br />

400<br />

DN 125<br />

DN 125<br />

DN 80<br />

DN 80<br />

80<br />

95<br />

>55<br />

400 / 32A<br />

5-polig

Heat Load (kW)<br />

Heat exchange surface (m 2 )<br />

Water capacity (l)<br />

max. operating pressure (bar)<br />

Weight (kg)<br />

Length (mm)<br />

Width (mm)<br />

Height (mm)<br />

Boiler shell length (mm)<br />

Boiler shell with (mm)<br />

Boiler shell height (mm)<br />

Flue tube height RRh (mm)<br />

Flue tube height RRh* (mm)<br />

Flue tube Ø (mm)<br />

Heat flow<br />

Heat return<br />

Safety heat flow<br />

Safety heat return<br />

max. boiler temperature (°C)<br />

min. return temperature (°C)<br />

Power supply<br />

Heat Load (kW)<br />

Heat exchange surface (m 2 )<br />

Water capacity (l)<br />

max. operating pressure (bar)<br />

Weight (kg)<br />

Length (mm)<br />

Width (mm)<br />

Height (mm)<br />

Boiler shell length (mm)<br />

Boiler shell with (mm)<br />

Boiler shell height (mm)<br />

Flue tube height RRh (mm)<br />

Flue tube height RRh* (mm)<br />

Flue tube Ø (mm)<br />

Heat flow<br />

Heat return<br />

Safety heat flow<br />

Safety heat return<br />

max. boiler temperature (°C)<br />

min. return temperature (°C)<br />

Power supply<br />

EnErgy in balancE with naturE<br />

HSK-RA 30<br />

0 - 33<br />

3,80<br />

188<br />

3,0<br />

770<br />

935<br />

740<br />

1440<br />

1067<br />

775<br />

1392<br />

1250<br />

1560<br />

200<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

HSK-RA 100<br />

0 - 96<br />

10,50<br />

360<br />

3,0<br />

1470<br />

1635<br />

890<br />

1550<br />

1767<br />

925<br />

1486<br />

1300<br />

1660<br />

250<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

HSK-RA 50<br />

0 - 44,5<br />

4,90<br />

210<br />

3,0<br />

860<br />

1135<br />

740<br />

1440<br />

1267<br />

775<br />

1392<br />

1250<br />

1560<br />

200<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

HSK-RA 150<br />

0 - 150<br />

15,70<br />

625<br />

3,0<br />

2140<br />

1635<br />

930<br />

1980<br />

1695<br />

975<br />

1922<br />

1960<br />

2150<br />

300<br />

2“<br />

2“<br />

1 1/4“<br />

1 1/4“<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

HSK-RA 60<br />

0 - 60<br />

5,90<br />

255<br />

3,0<br />

950<br />

1335<br />

740<br />

1440<br />

1467<br />

775<br />

1392<br />

1250<br />

1560<br />

200<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

HSK-RA 200<br />

0 - 200<br />

20,90<br />

810<br />

3,0<br />

2660<br />

2135<br />

930<br />

1980<br />

2195<br />

975<br />

1922<br />

1960<br />

2150<br />

300<br />

2“<br />

2“<br />

1 1/4“<br />

1 1/4“<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

HSK-RA 75<br />

0 - 75<br />

8,10<br />

280<br />

3,0<br />

1300<br />

1335<br />

890<br />

1550<br />

1467<br />

925<br />

1486<br />

1300<br />

1660<br />

200<br />

1 1/2“<br />

1 1/2“<br />

1“<br />

1“<br />

95<br />

>55<br />

400 / 16A<br />

5-polig<br />

Technical Specification HSK-RA<br />

11

Some references:<br />

One-family house, Meyer Wilfried<br />

91719 Hechlingen a. See, Mittelfranken<br />

Deutschland<br />

HSK-RA 30<br />

Nürminger Handwerk & Design Zentrum<br />

91595 Burgoberbach, Mittelfranken<br />

Deutschland<br />

<strong>RHK</strong>-<strong>AK</strong> 200<br />

<br />

Windsbach<br />

B446<br />

Gunzenhausen<br />

Dinkelsbühl<br />

Maicha<br />

B446<br />

B13 B2<br />

Weißenburg<br />

Wassertrüdingen Heidenheim<br />

EnErgy in balancE with naturE<br />

Wellness-farm Weihersmühle<br />

Inh. Bernd Hückl<br />

97650 Fladungen, Unterfranken<br />

Deutschland, HSK-RA 100<br />

Schoolcenter Petersaurach<br />

91580 Petersaurach, Mittelfranken<br />

Deutschland<br />

<strong>RHK</strong>-<strong>AK</strong> 300<br />

B2<br />

Agricultural estate<br />

Fam. Palleta, 86684 Holzheim<br />

Schwaben, Deutschland<br />

<strong>RHK</strong>-<strong>AK</strong> 150<br />

Capernwray Hall, Carnforth<br />

Lancashire<br />

United Kingdom<br />

<strong>RHK</strong>-<strong>AK</strong> 500<br />

<strong>Heizomat</strong><br />

Gerätebau - Energiesysteme GmbH<br />

Maicha 21<br />

D-91710 Gunzenhausen<br />

Tel. 0049 98 36 / 97 97- 0<br />

Fax 0049 98 36 / 97 97- 97<br />

info@heizomat.de<br />

www.heizomat.de<br />

Our partner<br />

Stand 09-2009 Art.-Nr. 88-022-010