Professional Bulk Handling with Harbour Cranes - Gottwald Port ...

Professional Bulk Handling with Harbour Cranes - Gottwald Port ...

Professional Bulk Handling with Harbour Cranes - Gottwald Port ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

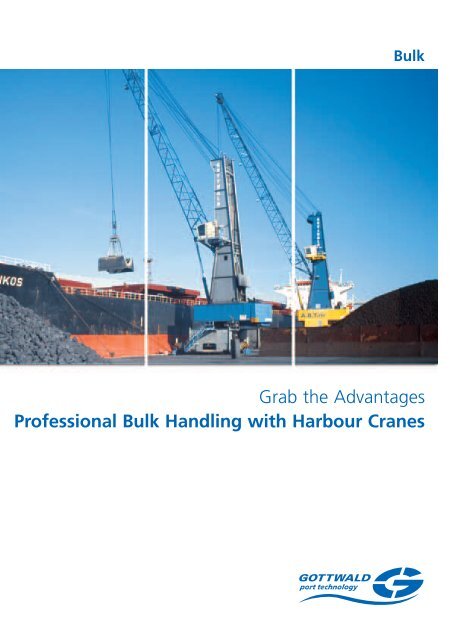

<strong>Bulk</strong><br />

Grab the Advantages<br />

<strong>Professional</strong> <strong>Bulk</strong> <strong>Handling</strong> <strong>with</strong> <strong>Harbour</strong> <strong>Cranes</strong>

2<br />

Goods are Always on the Move<br />

Perfect Logistics Requires Perfect Solutions<br />

<strong>Port</strong>s are interfaces in a complex<br />

chain of logistical stations where not<br />

only containers and general cargo<br />

but also numerous kinds of bulk<br />

goods, like coal and ores, are loaded<br />

and unloaded at maritime and river<br />

terminals, stored and transferred to<br />

power stations, agricultural and<br />

industrial centres using conveyors,<br />

road and rail transport.<br />

Logistics Depends on the<br />

Infrastructure<br />

The multifarious demands made on<br />

ports and terminals make it essential<br />

to have equally flexible handling systems<br />

and machinery at hand, which<br />

make up a highly individual terminal<br />

infrastructure, depending on its geographical<br />

location and the goods it<br />

handles. These facts make it necessary<br />

to take into account a range of<br />

parameters which will influence the<br />

choice of equipment for the handling<br />

systems. After all, the choice of handling<br />

equipment is generally not a<br />

A <strong>Gottwald</strong> HMK 360 EG<br />

4-rope grab crane handling<br />

coal at ABT in Antwerp, Belgium<br />

one-off matter. Quite the contrary,<br />

these machines are integral parts of<br />

a complex handling system, which<br />

includes not merely the ship and the<br />

crane but also such ancillary equipment<br />

as hoppers, conveyor belts and<br />

land-based transport vehicles.<br />

At the same time, downstream<br />

elements of the industrial infrastructure,<br />

such as power generators, steel<br />

mills, gravel quarries and fertiliser factories,<br />

play a part as do value-added<br />

terminal services, such as washing,<br />

blending and bagging bulk goods.<br />

<strong>Professional</strong> <strong>Bulk</strong> <strong>Handling</strong><br />

Within a broad scope of equipment<br />

and services, ranging from Mobile<br />

<strong>Harbour</strong> <strong>Cranes</strong> and <strong>Port</strong>al <strong>Harbour</strong><br />

<strong>Cranes</strong> to Wide Span Gantries,<br />

<strong>Gottwald</strong> <strong>Port</strong> Technology provides<br />

Apart from the worldwide<br />

transport of consumer goods<br />

on container ships …<br />

... transporting raw and process materials on<br />

bulk cargo ships is a central mainstay of international trade<br />

optimised solutions specially designed<br />

for professional bulk handling operations,<br />

such as<br />

■ hard coal<br />

■ ores and scrap<br />

■ gravel and sand<br />

■ raw and process materials, such<br />

as fertilisers, sugar and agribulk.<br />

High-performance, economical handling<br />

equipment made and supplied<br />

by <strong>Gottwald</strong> <strong>Port</strong> Technology can<br />

easily be integrated in existing or<br />

future workflows and infrastructures<br />

for professional bulk handling. As<br />

the world’s market leader in the field<br />

of Mobile <strong>Harbour</strong> <strong>Cranes</strong>, <strong>Gottwald</strong><br />

is a byword for extensive know-how<br />

and well-founded experience in<br />

terminal logistics and in designing<br />

efficient bulk handling facilities.

The Sky’s the Limit in <strong>Bulk</strong> <strong>Handling</strong><br />

With <strong>Harbour</strong> <strong>Cranes</strong> from <strong>Gottwald</strong> <strong>Port</strong> Technology<br />

As the world’s prime supplier of<br />

Mobile <strong>Harbour</strong> <strong>Cranes</strong>, <strong>Gottwald</strong><br />

<strong>Port</strong> Technology can offer the full<br />

range of performance products <strong>with</strong><br />

lifting capacities of up to 120 tonnes<br />

and radii of up to 56 m and incorporating<br />

a complete range of four-rope<br />

grab cranes for professional bulk<br />

handling – up to 1,500 tph.<br />

Four-Rope Grab <strong>Cranes</strong><br />

On the back of <strong>Gottwald</strong>’s success<br />

as the world’s key supplier of HMK<br />

Mobile <strong>Harbour</strong> <strong>Cranes</strong> for handling<br />

containers comes the four-rope grab<br />

version, which is becoming a common<br />

feature of multipurpose and bulk<br />

terminals the world over for highperformance<br />

handling.<br />

With a view to maximising the<br />

terminal operators’ benefits, the<br />

series is subject to constant review<br />

and upgrading to cater for current<br />

requirements in terms of lifting<br />

capacity, crane classification and<br />

moves per hour.<br />

Also Available as <strong>Port</strong>al <strong>Harbour</strong><br />

<strong>Cranes</strong><br />

<strong>Gottwald</strong>’s answer to modern<br />

demands for high-performance, railbound<br />

bulk-handling cranes was<br />

the development of the HSK <strong>Port</strong>al<br />

<strong>Harbour</strong> Crane <strong>with</strong> a four-rope grab.<br />

A comprehensive range of HSKs<br />

provide the same benefits as those<br />

offered by four-rope HMK grab<br />

cranes – where the HSK portal is<br />

adapted to suit the specific customer’s<br />

requirements.<br />

Diesel-Electric or Fully Electric<br />

Drive<br />

<strong>Gottwald</strong>’s HMK and HSK cranes are<br />

powered by diesel-electric drive systems.<br />

However, they can be designed<br />

from the outset or subsequently<br />

retrofitted to run on an existing<br />

quay-side electric power supply. In<br />

either case, both the diesel-electric<br />

and external power supply alternatives<br />

provide excellent availability and<br />

optimised economy of use.<br />

<strong>Gottwald</strong> <strong>Harbour</strong> <strong>Cranes</strong> are individually adapted to suit the specific workflows of industries close to the terminal – as here at<br />

SAPEC in <strong>Port</strong>ugal, where the ship, HMK 170 EG Mobile <strong>Harbour</strong> Crane, hopper and conveyor belt form a seamlessly integrated unit<br />

3

4<br />

Exploiting the Options <strong>with</strong> <strong>Gottwald</strong> Technologies<br />

The Ideal <strong>Handling</strong> Equipment for Customer-Specific Applications<br />

HMK 300 EG Mobile <strong>Harbour</strong> Crane<br />

handling scrap at Pasajes, Spain<br />

HSK 260 EG <strong>Port</strong>al <strong>Harbour</strong> Crane<br />

handling coal at Bordeaux, France<br />

Setting up and expanding quayside<br />

facilities and terminals are long-term,<br />

cost-intensive undertakings influenced<br />

by a number of factors. Of crucial<br />

importance is the choice of the handling<br />

equipment because it is this<br />

aspect that influences the quayside<br />

infrastructure most decisively, as<br />

regards the rail tracks, foundations<br />

and power supply. Depending on<br />

the handling equipment chosen,<br />

savings of up to 15% in infrastructure<br />

overheads are possible. With<br />

existing terminals, it is also essential<br />

to include the track widths, maximum<br />

quay loadings and conveyor<br />

systems in the calculations for the<br />

supply of new handling equipment.<br />

In the case of professional bulk handling,<br />

terminal operators can choose<br />

from a wide range of handling<br />

equipment options. In each specific<br />

case, however, the operator will want<br />

to consider and evaluate all the possible<br />

advantages and disadvantages<br />

of each option. The key factors are<br />

these:<br />

■ the type of bulk goods to be<br />

handled<br />

■ the proportion of total handling<br />

taken up by bulk<br />

■ the required handling performance.<br />

Flexible Solutions <strong>with</strong><br />

Performance Rates of up to<br />

1,500 tph<br />

With its HMK and HSK <strong>Harbour</strong><br />

<strong>Cranes</strong>, <strong>Gottwald</strong> can meet all the<br />

requirements for professional bulk<br />

handling <strong>with</strong> customer-specific<br />

application solutions. Both series are<br />

based on the same proven technology<br />

in use worldwide and are individually<br />

to meet customer-specific requirements<br />

in terms of quayside loadings,<br />

portal dimensions and general local<br />

conditions.<br />

WSG Wide Span Gantry handling coal at the<br />

port in Aschaffenburg, Germany<br />

<strong>Gottwald</strong> manufactures the WSG series of<br />

Wide Span Gantries for the specific requirements<br />

of inland terminals. These cranes are<br />

ideal not merely for loading and unloading<br />

ships but also for intermodal and trimodal<br />

handling between transport modes.<br />

As a four-rope grab crane, the HMKs<br />

and HSKs are designed for highperformance<br />

handling rates of up to<br />

1,500 tph and are, as a result, now<br />

overlapping <strong>with</strong> fields previously<br />

dominated by gantry grab and continuous<br />

ship unloaders. The benefit<br />

to the terminal operator is the comparatively<br />

low investment volume<br />

and the extensive range of benefits<br />

available <strong>with</strong> the crane.<br />

The HSK <strong>Port</strong>al <strong>Harbour</strong> Crane is<br />

always the preferred solution where<br />

an operator is considering replacing a<br />

low-performance double-link luffing<br />

crane which is several decades old.<br />

In these circumstances, <strong>Gottwald</strong><br />

HSK cranes provide numerous advantages<br />

due to their much reduced<br />

dead weight and the more simple<br />

construction of the boom.

The Advantages at a Glance<br />

In view of the high costs of maintaining<br />

a quayside infrastructure,<br />

the need for economical operation<br />

and for flexible, future-orientated<br />

solutions, Mobile <strong>Harbour</strong> Crane<br />

technology made by <strong>Gottwald</strong> is<br />

making significant inroads in the bulk<br />

handling market. Equipped <strong>with</strong> a<br />

wide spectrum of features, <strong>Gottwald</strong><br />

cranes offer numerous advantages,<br />

whether as Mobile HMKs or <strong>Port</strong>al<br />

HSKs, whether as conventional tworope<br />

versions <strong>with</strong> a motor grab or<br />

as four-rope grab versions. These<br />

advantages include:<br />

<strong>Gottwald</strong> Wins Again:<br />

Humber International Terminal<br />

The bulk terminal at the Humber<br />

International Terminal in Immingham,<br />

UK, handles artificial fertilisers and<br />

imported coal on the one hand and<br />

iron ore and scrap on the other.<br />

When the decision was taken in<br />

2000 by the company, an ABP subsidiary,<br />

to extend its bulk terminal<br />

facilities, they also opted for three<br />

<strong>Gottwald</strong> 100-tonne HMK 280 EG<br />

Mobile <strong>Harbour</strong> <strong>Cranes</strong> and three<br />

mobile hoppers.<br />

The customer opted for <strong>Gottwald</strong><br />

Mobile <strong>Harbour</strong> <strong>Cranes</strong> because they<br />

■ provide the required handling<br />

performance<br />

■ reduce overheads for the quayside<br />

infrastructure<br />

■ enable the terminal to cater for<br />

other types of cargo, such as<br />

containers, <strong>with</strong> ease.<br />

HMK 330 EG at Rocha Top<br />

in Paranagua, Brazil<br />

■ high handling rates<br />

■ handling of bulk goods,<br />

containers and general cargo<br />

■ extremely short delivery<br />

and assembly times<br />

■ diesel generator for operation<br />

independently of external power<br />

sources<br />

■ low specific investment<br />

expenditure for handling<br />

equipment and infrastructure<br />

on the quayside<br />

■ high degree of flexibility if the<br />

need arises for a quick change<br />

of cargo type<br />

■ simple procedure for travelling the<br />

crane from one quay to the next.<br />

HMK 280 EG Mobile <strong>Harbour</strong> <strong>Cranes</strong> at the ABP terminal in Immingham, UK – power<br />

generators are supplied from here <strong>with</strong> over 6 million tonnes of hard coal every year<br />

5

6<br />

Four-Rope Grab <strong>Cranes</strong> for<br />

<strong>Professional</strong> <strong>Bulk</strong> <strong>Handling</strong><br />

Success at Full Speed<br />

As a result of their versatility,<br />

<strong>Gottwald</strong> Mobile <strong>Harbour</strong> <strong>Cranes</strong><br />

are the ideal choice for handling all<br />

manner of cargoes. With regard to<br />

the further development of its Mobile<br />

<strong>Harbour</strong> <strong>Cranes</strong>, <strong>Gottwald</strong> has always<br />

placed uncompromising emphasis on<br />

meeting the needs of ever larger ships<br />

and barges and all the other factors<br />

influencing terminal operations, in<br />

order to respond to terminal operators’<br />

requirements for special-purpose<br />

applications and higher tonnages.<br />

The further development of the<br />

Mobile <strong>Harbour</strong> Crane to produce<br />

the four-rope grab crane for professional<br />

bulk handling was a rational<br />

step which, once again, is evidence<br />

of <strong>Gottwald</strong>’s unswerving commitment<br />

to retaining its technological<br />

market-leadership.<br />

The steel constructions were strengthened<br />

to meet the requirements of<br />

higher crane classification, a second<br />

hoist was fitted and, where required,<br />

a second slewing gear is fitted, the<br />

roller bearing slew ring assembly and<br />

Two hoists fitted to a<br />

<strong>Gottwald</strong> four-rope grab crane<br />

the rope pulleys were adapted to<br />

meet the higher demands of tough<br />

bulk handling – modifications and<br />

improvements that make <strong>Gottwald</strong>’s<br />

four-rope grab cranes the preferred<br />

choice.<br />

Four-Rope Grab <strong>Cranes</strong> <strong>with</strong> 30%<br />

Improved Performance over<br />

Motor Grabs<br />

The considerably reduced dead<br />

weight of the four-rope grab coupled<br />

<strong>with</strong> the shorter closing times compared<br />

to motor grabs mean that<br />

<strong>Gottwald</strong>’s four-rope grabs manage<br />

a far better payload per move.<br />

Along <strong>with</strong> higher operating speeds,<br />

the overall handling performance<br />

is dramatically improved and these<br />

cranes can out-perform a two-rope<br />

Mobile <strong>Harbour</strong> Crane <strong>with</strong> a motor<br />

grab by up to 30%.<br />

One additional benefit of the fourrope<br />

grab is its rigidity which makes<br />

it far less susceptible to knocks and<br />

damage when used in tough, nonstop<br />

operation. This results in reduced<br />

maintenance requirements and crane<br />

downtimes are reduced to an absolute<br />

minimum.<br />

Even as a Four-Rope Grab Crane,<br />

its Versatility does not Suffer<br />

Even when constructed as four-rope<br />

grab cranes, <strong>Gottwald</strong> Mobile<br />

<strong>Harbour</strong> <strong>Cranes</strong> do not forfeit the<br />

versatility for which <strong>Gottwald</strong> is<br />

renowned and they are not restricted<br />

to bulk handling. When fitted <strong>with</strong><br />

the numerous lifting devices available,<br />

such as spreaders, equalising<br />

spreader beams and magnets, these<br />

cranes can quickly move containers,<br />

semi-finished goods, pallets and all<br />

manner of project cargoes.<br />

HMK 330 EG handling clinker at<br />

Mina Saqr in Ras al Khaimah,<br />

United Arab Emirates<br />

HMK 260 EG four-rope grab in heavy-load lifting<br />

mode at Thessaloniki, Greece

Selection Criteria for <strong>Cranes</strong><br />

The selection of the crane size for<br />

a specific application profile and the<br />

choice between a two-rope and a<br />

four-rope version are determined by<br />

many factors.<br />

Deciding on the Crane Size<br />

Required<br />

The decision as to the size of crane<br />

needed will depend on the maximum<br />

anticipated cargo load and, as regards<br />

the working radius, the width of the<br />

largest vessel to be loaded or<br />

unloaded.<br />

Two-Rope Crane or Four-Rope<br />

Grab Version?<br />

In order to decide whether a two-rope<br />

or four-rope version is most economical,<br />

the following points will need<br />

clarification:<br />

■ the required move speed in<br />

terms of tonnes per hour or<br />

tonnes per year<br />

■ the proportion of total handling<br />

taken up by bulk handling<br />

■ any special requirements resulting<br />

from the type of bulk materials.<br />

Please also refer to the example on<br />

page 8 which illustrates the choice of<br />

crane type and size.<br />

HMK 260 EG crane<br />

handling artificial fertiliser at<br />

Humber International Terminal<br />

in Immingham, UK<br />

HSK 360 EGL <strong>Port</strong>al <strong>Harbour</strong> <strong>Cranes</strong><br />

<strong>with</strong> a custom-made portal<br />

unloading iron ore at<br />

Qinhuangdao, P.R. China<br />

Type Max. handling Lifting capacity [t] / up to max. radius [m]<br />

rate [tph]<br />

Classification according to FEM 1.001<br />

A7 A8<br />

HMK / HSK 170 EG 750 32 / 25 25 / 29<br />

HMK / HSK 260 EG 1,000 40 / 31 34 / 30<br />

HMK / HSK 330 EG 1,200 50 / 31 40 / 32<br />

HMK / HSK 360 EG 1,500 – 50 / 44<br />

Maximum lifting capacity and handling rates in bulk handling are dependent on the<br />

material characteristics, vessel size and terminal layout, amongst others<br />

7

8<br />

Four-Rope Grab or Two-Rope Crane?<br />

A Realistic Assessment <strong>with</strong> a Specific Example<br />

Example<br />

A terminal handles both bulk and<br />

containers and wishes to expand its<br />

capacities. The new machine subject<br />

of the new investment will have to<br />

What is the Most Economical Choice for Each <strong>Bulk</strong> <strong>Handling</strong> Profile?<br />

(Examples using the HMK 300 E / HMK 330 EG class of crane)<br />

<strong>Handling</strong> rate [tph]<br />

2,000<br />

1,500<br />

1,000<br />

500<br />

Purpose-built equipment<br />

1,200 tph<br />

Four-rope grab crane<br />

600 tph<br />

Two-rope crane<br />

< 60%<br />

Two-rope crane<br />

Rule of thumb for choosing between the two-rope crane and fourrope<br />

grab alternatives. In specific cases, an analysis of the terminal<br />

situation will be carried out.<br />

Transition<br />

zone<br />

0 20 40<br />

60 80 100<br />

Proportion of total taken up by bulk [%]<br />

The proportion of total handling<br />

taken up by bulk handling<br />

60% to 80%<br />

Accurate<br />

analysis of the<br />

situation required<br />

■ load and unload Panamax vessels<br />

■ achieve excellent bulk<br />

performance of at least 850 tph<br />

■ be able to load and unload 40’<br />

containers as far as the 13 th row.<br />

> 80%<br />

Four-rope<br />

grab crane<br />

Given these facts, there are two<br />

options available from <strong>Gottwald</strong>:<br />

the HMK 330 EG and the HMK 300 E.<br />

HMK 330 EG – If <strong>Bulk</strong> <strong>Handling</strong><br />

is the Major Application<br />

If the new crane is to be used for<br />

bulk handling for more than 80% of<br />

the time and only handle containers<br />

at peak times, it makes sense to<br />

invest in a four-rope grab crane. This<br />

model will achieve rates of up to<br />

1,200 tph due to far higher payloads<br />

and improved speeds in contrast <strong>with</strong><br />

the motor grab alternative.<br />

HMK 300 E – If Container <strong>Handling</strong><br />

is the Major Operation<br />

If it is the container handling aspect<br />

that is of key importance, the tworope<br />

crane and motor grab option<br />

will provide the more economical<br />

solution because this crane<br />

■ is fully able to deal <strong>with</strong> the<br />

container handling requirements<br />

■ will achieve the required minimum<br />

of 850 tph <strong>with</strong> the motor grab.

Individual Solutions for Individual Requirements<br />

HSK Series <strong>Port</strong>al <strong>Harbour</strong> <strong>Cranes</strong><br />

HSK 300 E <strong>with</strong> a customer-specific portal<br />

– the proven assemblies from the HMK<br />

Mobile <strong>Harbour</strong> <strong>Cranes</strong> are used from the<br />

slewing ring upwards<br />

Crane Life – A Question of<br />

Crane Classification<br />

The anticipated crane life and the<br />

performance required of the machine<br />

are key criteria determining the<br />

investment in handling equipment.<br />

The lifetime of the crane is determined<br />

by the strength of the steel<br />

construction for a given handling<br />

rate. In order to achieve the lifetime<br />

The HSK series of <strong>Port</strong>al <strong>Harbour</strong><br />

<strong>Cranes</strong>, which use a portal instead of<br />

a rubber-tyred chassis, was developed<br />

specifically <strong>with</strong> operation on narrow<br />

quaysides in mind, and they represent<br />

<strong>Gottwald</strong>’s innovative creativity.<br />

Originally instigated as a result of a<br />

customer’s idea but then consistently<br />

developed to the point where they<br />

stand alongside the HMKs as an<br />

additional product line, these cranes<br />

meet the needs of tough, performance-related<br />

bulk handling.<br />

The portal is designed individually to<br />

take account of any conveyor belts,<br />

train or truck traffic on the site.<br />

Maximum mobility for these cranes,<br />

which are rail-bound in operation, is<br />

provided by retractable travel gear<br />

which allows them to move from<br />

one quay to the next. Stabiliser pads<br />

on the portal also enable them to be<br />

operated on quays <strong>with</strong>out rails.<br />

HSK <strong>Port</strong>al <strong>Harbour</strong> <strong>Cranes</strong> have the<br />

same assemblies as the HMK Mobile<br />

<strong>Harbour</strong> <strong>Cranes</strong> from the slewing<br />

ring upwards. With lifting capacities<br />

of up to 120 t, maximum radii of<br />

56 m and handling rates in four-rope<br />

grab operation of up to 1,500 tph,<br />

these cranes cover the same performance<br />

range as the Mobile <strong>Harbour</strong><br />

<strong>Cranes</strong>.<br />

requirements for a specific application,<br />

<strong>Gottwald</strong> <strong>Port</strong> Technology builds<br />

cranes in crane classifications A6<br />

to A8.<br />

The decision is based on detailed<br />

consulting beforehand which takes<br />

into account the exact requirements<br />

for that specific crane.<br />

HSK 170 EG, equipped <strong>with</strong> special travel gear<br />

and 8 stabiliser pads<br />

While they are normally run on an<br />

external electrical power source<br />

provided on site, the HSK cranes can<br />

be run independently on an optional<br />

on-board diesel-electric generator.<br />

HSK 260 EG handling soya flour<br />

in Bordeaux, France<br />

9

10<br />

Versatility is the Top Priority<br />

<strong>Harbour</strong> <strong>Cranes</strong> for Use in Multipurpose Terminals<br />

Besides terminals that specialise in<br />

bulk handling or container handling,<br />

there are numerous maritime and<br />

river ports providing handling services<br />

for all manner of cargoes. It is at<br />

these handling sites in particular that<br />

multiple lifting attachments are in<br />

use for containers, project cargoes<br />

and bulk materials.<br />

<strong>Bulk</strong> <strong>Handling</strong> <strong>with</strong> a Motor Grab<br />

Operators of universal terminals of<br />

this type appreciate machines which<br />

provide economical operation, mobility,<br />

versatility and a high degree of<br />

flexibility in changing the lifting attachments<br />

between jobs.<br />

HMK 260 E handling scrap<br />

at Mardas in Istanbul, Turkey<br />

In this context, <strong>Gottwald</strong>’s Mobile<br />

and <strong>Port</strong>al <strong>Harbour</strong> <strong>Cranes</strong>, built<br />

as conventional two-rope cranes,<br />

are ideally suited to handling a<br />

broad spectrum of goods. Depending<br />

on the type and consistence of the<br />

bulk material, motor grabs such as<br />

scissor grab, dual scoop and orangepeel<br />

grabs are used.<br />

HMK 300 E and HMK 260 E<br />

at the <strong>Port</strong> of Tornio, Finland –<br />

the uncomplicated change of<br />

motor grabs ensures rapid<br />

adaptation of <strong>Gottwald</strong> cranes to<br />

a wide range of bulk materials<br />

External Power Supply Provides<br />

Improved Efficiency<br />

<strong>Gottwald</strong> <strong>Port</strong> Technology is the only<br />

supplier worldwide of diesel-electric<br />

Mobile <strong>Harbour</strong> <strong>Cranes</strong>, which provides<br />

customers <strong>with</strong> the benefits of<br />

low operating and maintenance costs.<br />

To enable terminal operators to<br />

achieve even greater savings in running<br />

costs, <strong>Gottwald</strong> Mobile <strong>Harbour</strong><br />

<strong>Cranes</strong> can be connected to the<br />

shore power supply and run on this<br />

external source. In this way, the crane<br />

drives are supplied direct <strong>with</strong> electri-<br />

Where the power demands are<br />

very high, for instance when handling<br />

scrap <strong>with</strong> orange-peel grabs,<br />

<strong>Gottwald</strong> cranes can be fitted <strong>with</strong><br />

a second cable reel.<br />

cal energy from<br />

the terminal<br />

mains supply.<br />

For the external<br />

power feed, the<br />

crane has to be<br />

equipped <strong>with</strong> a<br />

cable reel and is<br />

then connected to an appropriate<br />

power outlet located in the terminal.

Container and General Cargo<br />

<strong>Handling</strong> Using a Variety of<br />

Lifting Attachments<br />

To enable efficient container handling,<br />

the two-rope versions of <strong>Gottwald</strong><br />

Mobile and <strong>Port</strong>al <strong>Harbour</strong> <strong>Cranes</strong><br />

can be used <strong>with</strong> all readily available<br />

spreaders including twin-lift spreaders.<br />

<strong>Gottwald</strong> Mobile <strong>Harbour</strong> <strong>Cranes</strong><br />

load and unload coils, steel slabs<br />

and other semi-finished materials<br />

and pallets using magnets, hooks<br />

and a wide selection of attachments<br />

purpose-built for specific applications.<br />

Equipped <strong>with</strong> numerous different<br />

lifting attachments, <strong>Gottwald</strong>’s<br />

two-rope cranes can cope <strong>with</strong> any<br />

type of cargo<br />

Maximum lifting capacity and handling rates in bulk handling are dependent on the<br />

material characteristics, vessel size and terminal layout, amongst others<br />

Type Max. handling Lifting capacity [t] / up to max. radius [m]<br />

rate [tph]<br />

Classification according to FEM 1.001<br />

A7 A8<br />

HMK / HSK 170 E 650 32 / 25 25 / 29<br />

HMK / HSK 260 E 800 40 / 31 34 / 30<br />

HMK / HSK 300 E 850 50 / 31 40 / 32<br />

HMK / HSK 360 E 900 50 / 44 –<br />

11

12<br />

<strong>Handling</strong> <strong>Bulk</strong> at Inland <strong>Port</strong>s<br />

Wide Span Gantries for <strong>Port</strong>, Stack and Intermodal <strong>Handling</strong><br />

Coal, ores, raw and process materials<br />

are transported from numerous<br />

sources around the world to transcontinental<br />

hubs on board ocean-going<br />

vessels. From here, the goods are<br />

distributed to power generators and<br />

industrial enterprises via a complex<br />

infrastructure.<br />

WSG Wide Span Gantries<br />

While <strong>Gottwald</strong> Mobile and <strong>Port</strong>al<br />

<strong>Harbour</strong> <strong>Cranes</strong> are in use at both<br />

specialised and multiple-cargo terminals<br />

for handling cargoes from all<br />

sizes of vessels, a new range of Wide<br />

Span Gantries (WSG) has been available<br />

from <strong>Gottwald</strong> since the beginning<br />

of 2003 which provide improved<br />

efficiency in handling bulk materials<br />

at inland terminals, in particular.<br />

For the Most Diverse Applications<br />

A feature of WSG Wide Span Gantries<br />

is their wide scope of applications.<br />

They are used not only for loading<br />

and unloading vessels but are ideally<br />

suited to transshipment from one<br />

mode of transport to another. In<br />

detail, their suitabilities are as follows:<br />

■ loading and unloading ships<br />

■ intermodal handling between<br />

rail and road<br />

■ trimodal handling in ports<br />

between ship, freight train and<br />

road truck.<br />

WSGs are also the ideal choice as<br />

dedicated storage cranes for organising<br />

storage yards. These newcomers<br />

to the <strong>Gottwald</strong> family<br />

demonstrate their flexibility best,<br />

WSG Wide Span Gantry at the river terminal in Aschaffenburg, Germany:<br />

Originally used for unloading coal and simultaneously managing the storage yard, …<br />

however, in ports where they are also<br />

used for managing storage areas<br />

close to the quay. It is possible, for<br />

example, in the case of coal terminals<br />

located close to a power station, to<br />

unload the coal from a vessel, store<br />

different types of coal on a yard where<br />

they are blended and fed direct to<br />

the coal hopper.<br />

Customer-Orientated Constructions<br />

Each individual portal is built to meet<br />

the specific requirements of each<br />

customer. Cantilevers of up to 40 m<br />

on the waterside enable all the usual<br />

vessel sizes to be serviced not only in<br />

inland terminals but also at smaller<br />

maritime terminals. In addition, total<br />

spans of 80 m provide maximum<br />

flexibility.

WSG Wide Span Gantry<br />

handling intermodal cargo<br />

between ships and rail<br />

at Orsoy, Germany<br />

<strong>Handling</strong> <strong>Bulk</strong> Material <strong>with</strong><br />

Motor and Four-Rope Grabs<br />

For bulk handling purposes, <strong>Gottwald</strong><br />

supplies its WSGs <strong>with</strong> motor grabs.<br />

If the WSG is operated in a specialised<br />

bulk terminal, the trolley can be<br />

equipped <strong>with</strong> four-rope grab technology<br />

to maximise bulk handling<br />

performance.<br />

... this WSG is now used for handling<br />

and stacking containers due to a<br />

change in the service requirements<br />

at the Aschaffenburg terminal<br />

A second hoist guarantees maximum<br />

availability of the crane during<br />

motor grab operation<br />

Excellent Availability<br />

WSG Wide Span Gantries are generally<br />

equipped <strong>with</strong> a pair of two-rope<br />

hoists. The broad rope spread reduces<br />

the typical swinging effect known<br />

from handling containers and long<br />

goods.<br />

Where bulk handling only uses a<br />

single hoist, the second, redundant<br />

hoist contributes to excellent crane<br />

availability since, in the event of a<br />

failure of one, there is no effect on<br />

performance.<br />

Many Fields of Application<br />

<strong>Gottwald</strong> WSG Wide Span Gantries<br />

are not restricted to use in bulk<br />

handling terminals. They are, in fact,<br />

ideally suited to handling containers<br />

and a wide range of general cargoes.<br />

Superordinate stock management<br />

systems also enable the cranes to<br />

be seamlessly integrated in complex<br />

logistical workflows.<br />

Mobile <strong>Harbour</strong> <strong>Cranes</strong> at Inland<br />

Terminals<br />

<strong>Gottwald</strong> also offers a range of Mobile<br />

<strong>Harbour</strong> <strong>Cranes</strong> for bulk handling at inland<br />

terminals and smaller maritime terminals.<br />

These are the 20-tonne HMK 60 HG and<br />

the 44-tonne HMK 130 HG – both available<br />

as four-rope grab cranes.<br />

An HMK 60 HG loading sand at the terminal<br />

in Plymouth, UK<br />

13

14<br />

Special-Purpose Equipment<br />

Added Value for <strong>Professional</strong> <strong>Bulk</strong> <strong>Handling</strong><br />

For the experts at <strong>Gottwald</strong>, just<br />

delivering one of many types of<br />

standard crane would simply not<br />

be in keeping <strong>with</strong> the company’s<br />

philosophy. <strong>Gottwald</strong> makes every<br />

effort to adapt its cranes on site<br />

to meet the local conditions by,<br />

for example, fitting dust-protection<br />

systems and grab models designed<br />

specifically for a particular application.<br />

HMK 300 EG <strong>with</strong> an active dust-protection<br />

system at Ership, Huelva, Spain<br />

Dust-Protection Systems for<br />

Machines and Equipment<br />

<strong>Handling</strong> bulk materials automatically<br />

involves the creation of large amounts<br />

of dust. These represent not only a<br />

loss of valuable materials but also<br />

a source of potential damage to the<br />

cranes and equipment if fine dust is<br />

allowed to penetrate them and interfere<br />

<strong>with</strong> their operation.<br />

To minimise these effects, <strong>Gottwald</strong><br />

installs both passive and active dustprotection<br />

systems to prevent damage<br />

of this kind.<br />

Where the dust emissions at the<br />

terminal are minimal, a passive<br />

dust-protection system will suffice.<br />

On <strong>Gottwald</strong> cranes, this involves<br />

sealing off the machine room as far<br />

as is practicable. This includes the<br />

simple expedient of ensuring access<br />

to the superstructure through a door.<br />

Active Dust-Protection System for<br />

Improved Safety<br />

Terminals producing a high level of<br />

dust emissions are advised to ensure<br />

their cranes and equipment are well<br />

protected by installing high-performance<br />

dust-protection systems. This<br />

involves fresh air, free of dust, being<br />

sucked in through a pipe at the tip<br />

of the tower before it is passed down<br />

to the machine room through a filter.<br />

This produces a slight overpressure<br />

in the machine room to ensure that<br />

no outside air and no dust can enter<br />

the area.<br />

<strong>Gottwald</strong> will<br />

supply the<br />

right grab for<br />

the application<br />

The Type of <strong>Bulk</strong> Material will<br />

Determine the Type of Grab<br />

Whether a dual scoop, scissor grab<br />

or orange-peel grab is required will<br />

depend on the consistence of the<br />

bulk material, be it coal, ore or<br />

artificial fertiliser, and must also<br />

be matched to the crane.<br />

To achieve maximum performance<br />

and speed from a crane, it is crucial<br />

to consider both the density of the<br />

bulk material and the lifting capacity<br />

of the crane when selecting the size<br />

of grab.<br />

<strong>Gottwald</strong> can provide customers<br />

<strong>with</strong> all available kinds of grabs and<br />

makes a point of assisting customers<br />

<strong>with</strong> the selection of the ideal size<br />

and type combination – especially<br />

where different kinds of bulk are to<br />

be handled.

Reliable Service<br />

Around the World, Around the Clock<br />

Against a background of increasing<br />

pressure to reduce costs in shipping<br />

generally and cargo handling specifically<br />

and the simultaneous need for<br />

maximum availability, <strong>Gottwald</strong> <strong>Port</strong><br />

Technology’s after-sales service plays<br />

a crucial role.<br />

Our reputation for providing customer<br />

support efficiently, flexibly and fast is<br />

based on our comprehensive range<br />

of services which is constantly being<br />

reviewed and expanded to meet<br />

market needs. The spectrum ranges<br />

from individual one-off solutions<br />

through to the supply of complete<br />

support packages as full-service<br />

maintenance agreements.<br />

Worldwide Network of Service<br />

Experts<br />

As an internationally active enterprise,<br />

<strong>Gottwald</strong> <strong>Port</strong> Technology<br />

maintains a globally interlinked network<br />

of permanent service partners.<br />

These partners have excellent knowledge<br />

of the products and can ensure<br />

easy communication in the language<br />

of the customer.<br />

support@gottwald.com<br />

Comprehensive Range of Services<br />

<strong>Gottwald</strong> <strong>Port</strong> Technology’s service<br />

portfolio includes:<br />

■ 24-hour service stand-by<br />

■ technical support<br />

■ spare parts from centralised<br />

warehouses and worldwide depots<br />

■ spare parts packages for first-time<br />

supply<br />

■ service contracts<br />

■ assembly and commissioning<br />

■ upgrading and retrofitting<br />

■ teleservice<br />

■ crane inspection and overhaul<br />

■ crane transport<br />

■ customer training and<br />

documentation.<br />

In this way, <strong>Gottwald</strong> is synonymous<br />

<strong>with</strong> service and support, guaranteeing<br />

economical, trouble-free operations<br />

throughout the world and in<br />

any field of application.<br />

Transport, assembly and<br />

commissioning of cranes worldwide<br />

Training crane operators at<br />

<strong>Gottwald</strong> <strong>Port</strong> Technology<br />

Rapid supply of spares<br />

including supply from local depots<br />

15

<strong>Gottwald</strong> <strong>Port</strong> Technology GmbH • Postfach 18 03 43 • 40570 Düsseldorf, Germany<br />

Phone: +49 211 7102-0 • Fax: +49 211 7102-3651 • info@gottwald.com • www.gottwald.com<br />

<strong>Bulk</strong> 02/07.04 UK S+S<br />

Subject to change <strong>with</strong>out notice