WEST PINTS

PW107

PW107

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PINTS</strong> <strong>WEST</strong><br />

Here comes the science bit ... concentrate<br />

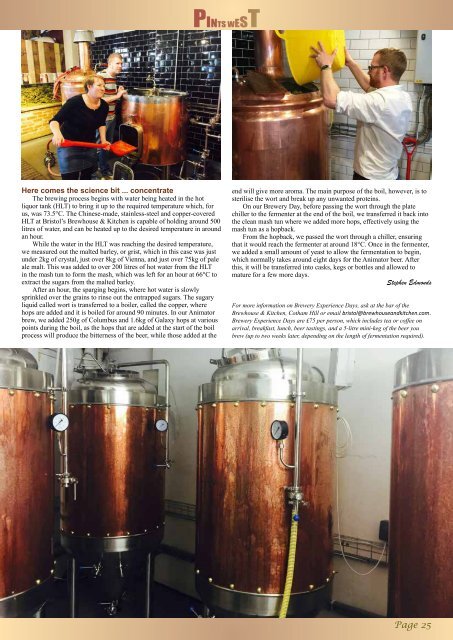

The brewing process begins with water being heated in the hot<br />

liquor tank (HLT) to bring it up to the required temperature which, for<br />

us, was 73.5°C. The Chinese-made, stainless-steel and copper-covered<br />

HLT at Bristol’s Brewhouse & Kitchen is capable of holding around 500<br />

litres of water, and can be heated up to the desired temperature in around<br />

an hour.<br />

While the water in the HLT was reaching the desired temperature,<br />

we measured out the malted barley, or grist, which in this case was just<br />

under 2kg of crystal, just over 8kg of Vienna, and just over 75kg of pale<br />

ale malt. This was added to over 200 litres of hot water from the HLT<br />

in the mash tun to form the mash, which was left for an hour at 66°C to<br />

extract the sugars from the malted barley.<br />

After an hour, the sparging begins, where hot water is slowly<br />

sprinkled over the grains to rinse out the entrapped sugars. The sugary<br />

liquid called wort is transferred to a boiler, called the copper, where<br />

hops are added and it is boiled for around 90 minutes. In our Animator<br />

brew, we added 250g of Columbus and 1.6kg of Galaxy hops at various<br />

points during the boil, as the hops that are added at the start of the boil<br />

process will produce the bitterness of the beer, while those added at the<br />

end will give more aroma. The main purpose of the boil, however, is to<br />

sterilise the wort and break up any unwanted proteins.<br />

On our Brewery Day, before passing the wort through the plate<br />

chiller to the fermenter at the end of the boil, we transferred it back into<br />

the clean mash tun where we added more hops, effectively using the<br />

mash tun as a hopback.<br />

From the hopback, we passed the wort through a chiller, ensuring<br />

that it would reach the fermenter at around 18°C. Once in the fermenter,<br />

we added a small amount of yeast to allow the fermentation to begin,<br />

which normally takes around eight days for the Animator beer. After<br />

this, it will be transferred into casks, kegs or bottles and allowed to<br />

mature for a few more days.<br />

Stephen Edmonds<br />

For more information on Brewery Experience Days, ask at the bar of the<br />

Brewhouse & Kitchen, Cotham Hill or email bristol@brewhouseandkitchen.com.<br />

Brewery Experience Days are £75 per person, which includes tea or coffee on<br />

arrival, breakfast, lunch, beer tastings, and a 5-litre mini-keg of the beer you<br />

brew (up to two weeks later, depending on the length of fermentation required).<br />

Page 25