SHAFT HOISTING AND ROPE- HANDLING TECHNOLOGY

TI_36_Impala_en.pdf - SIEMAG TECBERG

TI_36_Impala_en.pdf - SIEMAG TECBERG

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNICAL INFORMATION<br />

<strong>SHAFT</strong> <strong>HOISTING</strong> <strong>AND</strong> <strong>ROPE</strong>-<br />

H<strong>AND</strong>LING <strong>TECHNOLOGY</strong><br />

(IMPALA PLATINUM LIMITED, ILLOVO, SOUTH AFRICA)<br />

WWW.SIEMAG-TECBERG.COM

TECHNICAL INFORMATION<br />

<strong>SHAFT</strong> <strong>HOISTING</strong> <strong>AND</strong> <strong>ROPE</strong>-<br />

H<strong>AND</strong>LING <strong>TECHNOLOGY</strong><br />

As mining in the platinum belt at Rustenburg in South Africa<br />

progresses, the workings have to push forward to everincreasing<br />

depths. Impala Platinum Limited is no exception<br />

and in 2007 the company decided to construct shaft number<br />

17 to extract ore from a depth of around 2,000 metres.<br />

The sinking of the main shaft had to be started as quickly as<br />

possible, but there was no winder of the required capacity<br />

available at the time. The construction and delivery of a<br />

new winder would have taken too long and wrecked the<br />

customer‘s tight schedule.<br />

At this time, the customer was discussing with SIEMAG<br />

TECBERG the possibility of finding a suitable winder for the<br />

new shaft among the machinery decommissioned following<br />

the phasing-out of coal mining in Germany. The Koepe<br />

winder installed at the Goettelborn mine seemed to meet<br />

the requirements for mining ore at Shaft 17. Since a second<br />

hoisting system with a second Koepe winder was planned<br />

for transporting material and personnel, the solution was<br />

adopted of using the two winders for the final mine in order<br />

to sink the main shaft.<br />

SKIP TRANSPORT DURING SINKING OPERATIONS<br />

The twin-drum machines normally used for shaft sinking have<br />

a resetting (clutch) device to allow two skips to be hoisted<br />

and lowered alternately and to load and unload them at the<br />

same time as the distance to the foot of the shaft steadily<br />

increases. Koepe winders are unsuitable for operations of<br />

this kind, but when suitably converted, can work with one<br />

skip. It was therefore decided to dismantle the machine at<br />

the Goettelborn shaft and transport it to South Africa. It<br />

was also decided to replace the electrical control system<br />

at the same time and construct a new drum locally to cope<br />

with both the shaft-sinking operations and the subsequent<br />

mining operations. The high constricting pressures from the<br />

five-layer coiling of the loaded rope made drums with extrathick<br />

sheet casing necessary for both machines.<br />

In the case of Impala 17, single-kibble operation was<br />

sufficient in the initial shaft-sinking phase and the converted<br />

Goettelborn winder proved suitable for the purpose. This<br />

allowed work on the shaft to be started early and the second<br />

kibble went into operation when the service winder was<br />

completed to allow enough material to be hoisted as the<br />

travel distance increased. As opposed to conventional shaftsinking<br />

winders, this solution allows kibbles to be hoisted<br />

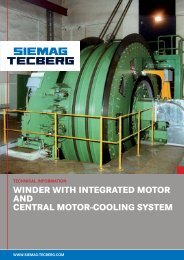

6-Rope Koepe production winder (formerly at Goettelborn shaft, Germany), currently modified as sinking winder

singly and independently of one another. On conclusion of<br />

the sinking operations, the two machines will be cleaned, the<br />

ropes removed, and then converted for Koepe-type hoisting<br />

by bolting metal blocks in a ring around the drum to create<br />

trapezoid grooves, and to fit the usual two-part friction-pulley<br />

liner blocks for six-rope hoisting. This conversion work has<br />

already been rehearsed in our workshop so that the actual<br />

work on-site can be completed as quickly as possible.<br />

SIEMAG TECBERG was able to offer this solution as tried<br />

and tested technology because several conversions of this<br />

type have already been carried out in similar cases and the<br />

concept approved as sound and effective. In addition to<br />

the two winding machines, SIEMAG TECBERG will also be<br />

supplying the rope sheaves for the mining operations. The<br />

great depth makes the stress on the ropes very high, which<br />

means that the machines and the rope sheaves had to be<br />

specially dimensioned.<br />

These two factors – the depth and the high rope weights –<br />

are also the reason why Impala has purchased a large<br />

SIEMAG TECBERG friction winch. This pulley makes it<br />

possible to raise or lower all six ropes, each measuring<br />

2000 metres, at the same time in less than three hours.<br />

The tractive forces occurring can be as high as 180 tonnes.<br />

Like most others, the friction winch is mounted on a chassis<br />

and can therefore be moved to different positions. For this<br />

reason, it is suitable not only for installing and changing the<br />

ropes in the two hoisting systems at Shaft 17, but also for<br />

those two at Shaft 16. (For more details on friction winches,<br />

see our separate technical information).<br />

Clamping and lifting devices are also being installed<br />

at both shafts. These are a fast and reliable means of<br />

relieving the weight in order to carry out frequently<br />

recurring work on the ropes. The two clamping and lifting<br />

devices for shaft 16 were designed for an operating load<br />

of 170 tonnes and are therefore suitable for hoisting a<br />

full conveyance from the very deepest position. A third<br />

clamping and lifting device is intended for handling one<br />

tail rope in each case. Together with the necessary<br />

rope reelers, messenger winches, deflection sheaves<br />

and other aids, SIEMAG TECBERG has developed and<br />

supplied complete solutions for rope-handling and<br />

changing specifically for the customer‘s needs. (For<br />

more details on clamping and lifting devices, see our<br />

separate technical information).<br />

The rope-handling systems selected have made it possible<br />

to avoid processes which are normally time-consuming<br />

and dangerous, as well as the over-dimensioning of the<br />

drive engines for the hoisting machinery which would<br />

otherwise have been necessary to hold the abovementioned<br />

loads.<br />

With its machinery and rope sheaves as well as its<br />

handling devices and other equipment, SIEMAG TECBERG<br />

has again proven its outstanding expertise in the field<br />

of shaft hoisting by again extending the limitations of<br />

previously realised plant and machinery.<br />

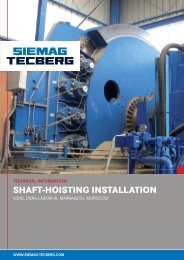

6-Rope Koepe service winder, currently modified as sinking winder

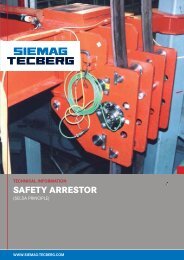

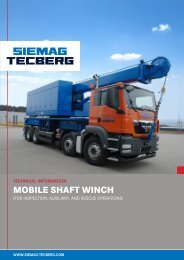

1 to 6-Rope friction winch, max. traction force 1,800 kN<br />

2 x 4-Rope clamping and lifting device, double-sided, max. rope load 1,700 kN

TECHNICAL DATA<br />

KOEPE ROCK <strong>HOISTING</strong> DUTY<br />

Winding data<br />

Type of winding<br />

Type of conveyance<br />

Type of shaft<br />

Monthly winding capacity<br />

Winding capacity<br />

production<br />

skip/skip<br />

vertical<br />

260,000mt/m<br />

700mt/h<br />

Winding distance 1,922m<br />

Payload<br />

Maximum unbalanced load<br />

Maximum suspended load<br />

(T1+T2)<br />

Number of ropes & Diameter<br />

Winding speed<br />

33mt<br />

330kN<br />

3,525kN<br />

6 x 50mm<br />

18m/s<br />

KOEPE MAN <strong>HOISTING</strong> DUTY<br />

Winding data<br />

Type of winding<br />

Type of conveyance<br />

Type of shaft<br />

Winding distance<br />

Payload<br />

Weight of cage, with rope<br />

attachments<br />

Maximum unbalanced load 135 kN<br />

Maximum suspended load 3,560kN<br />

Number of ropes 6<br />

Diameter<br />

50 mm<br />

Winding speed<br />

15 m/s<br />

service<br />

cage/counterweight<br />

vertical<br />

1 872 m<br />

27 t<br />

28.8 t<br />

Friction pulley & drive<br />

Friction pulley & drive<br />

Nominal Diameter<br />

7m<br />

Nominal Diameter<br />

6 m<br />

Pulley / Motor speed<br />

49.1rpm<br />

Pulley / Motor speed<br />

47.8 rpm<br />

Type of motors<br />

overhung AC<br />

Type of motors<br />

overhung AC<br />

Motor power RMS, approx.<br />

1 x 7,500kW<br />

Motor power RMS, approx.<br />

1 x 4,000 kW<br />

SINGLE DRUM SINKING DUTY (BOTH MACHINES)<br />

Winding data<br />

Type of winding<br />

sinking<br />

Type of conveyance<br />

single kibble<br />

Winding distance 1,900m<br />

Payload<br />

16mt<br />

Weight of kibble<br />

7.8mt<br />

Maximum unbalanced load 463kN<br />

Maximum suspended load 463kN<br />

Number of ropes 1<br />

Diameter<br />

51mm<br />

Winding speed<br />

15m/s<br />

Drum & drive<br />

Diameter, centreline of rope,<br />

approx.<br />

Coiling width, approx.<br />

Drum / Motor speed<br />

Type of motors<br />

6.7 / 5.85m<br />

1.85 / 2m<br />

40.9 / 47.8rpm<br />

overhung AC<br />

Rope reelers, drum diameter max. 3.0 m<br />

Installed motor power RMS<br />

7,500 / 4,000kW