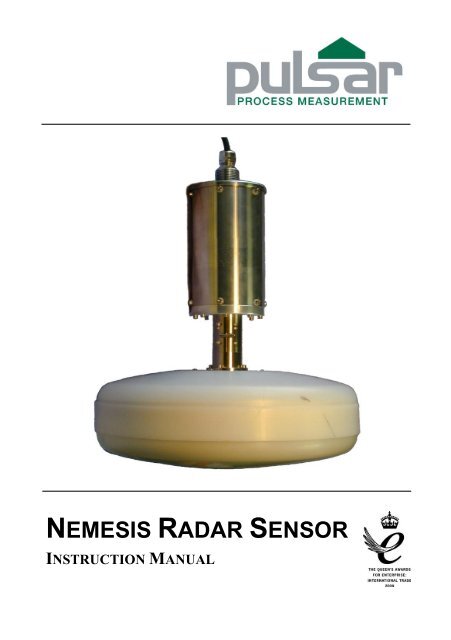

NEMESIS RADAR SENSOR

Nemesis Radar manual - Pulsar Process Measurement

Nemesis Radar manual - Pulsar Process Measurement

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>NEMESIS</strong> <strong>RADAR</strong> <strong>SENSOR</strong><br />

INSTRUCTION MANUAL

<strong>NEMESIS</strong> <strong>RADAR</strong> <strong>SENSOR</strong> (FIRST EDITION REV 2)<br />

February 2013<br />

Part Number M-dBR-0-001-1P<br />

COPYRIGHT<br />

© Pulsar Process Measurement Limited, 2012-13. All rights reserved. No part of this publication may be<br />

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any<br />

form without the written permission of Pulsar Process Measurement Limited.<br />

WARRANTY AND LIABILITY<br />

Pulsar Process Measurement Limited guarantee for a period of 2 years from the date of delivery that it<br />

will either exchange or repair any part of this product returned to Pulsar Process Measurement Limited if<br />

it is found to be defective in material or workmanship, subject to the defect not being due to unfair wear<br />

and tear, misuse, modification or alteration, accident, misapplication or negligence.<br />

DISCLAIMER<br />

Pulsar Process Measurement Limited gives nor implies any process guarantee for this product, and shall<br />

have no liability in respect of any loss, injury or damage whatsoever arising out of the application or use<br />

of any product or circuit described herein.<br />

Every effort has been made to ensure accuracy of this documentation, but Pulsar Process Measurement<br />

Limited cannot be held liable for any errors.<br />

Pulsar Process Measurement Limited operates a policy of constant development and improvement and<br />

reserves the right to amend technical details as necessary.<br />

TECHNICAL ENQUIRIES<br />

Please contact Pulsar Process Measurement Limited for technical support.<br />

COMMENTS AND SUGGESTIONS<br />

If you have any comments or suggestions about this product, then please contact:<br />

Pulsar Process Measurement Limited<br />

Cardinal Building<br />

Enigma Commercial Centre<br />

Sandy’s Road<br />

Malvern<br />

Worcestershire<br />

WR14 1JJ<br />

United Kingdom<br />

Tel: + 44 (0) 870 6039112<br />

Fax: + 44 (0) 870 6039114<br />

Web Site: http://www.pulsar-pm.com<br />

e-mail: info@pulsar-pm.com<br />

(general information)<br />

e-mail: support@ pulsar-pm.com<br />

(product support)<br />

Pulsar Process Measurement Inc.<br />

PO Box 5177<br />

Niceville<br />

FL 32578-5177<br />

USA<br />

Tel: + 1 850 279 4882<br />

Fax: + 1 850 279 4886<br />

Web Site: http://www.pulsar-pm.com<br />

e-mail: info.usa@pulsar-us.com<br />

(general information)<br />

e-mail: support.usa@ pulsar-pm.com<br />

(product support)

Contents<br />

Chapter 1 Start Here… ......................................................................................................................................... 1<br />

About this Manual ........................................................................................................................................... 1<br />

About the Nemesis Radar sensor .................................................................................................................... 2<br />

Functional Description .................................................................................................................................... 3<br />

A simplified diagram of the Nemesis Radar Sensor is shown below. .......................................................... 3<br />

Product Specification....................................................................................................................................... 4<br />

Chapter 2 Installation Guide ................................................................................................................................ 9<br />

Power Supply Requirements ........................................................................................................................... 9<br />

General Installation and Location ................................................................................................................... 9<br />

Aerials / Antennas. ........................................................................................................................................ 10<br />

Internal Fixed Mounting ........................................................................................................................ 11<br />

External Fixed Mounting ...................................................................................................................... 14<br />

Internal Aimed Mounting ...................................................................................................................... 17<br />

Cable. ............................................................................................................................................................. 19<br />

Cable Preparation................................................................................................................................... 19<br />

Removing the Cap ................................................................................................................................. 23<br />

Cable Gland Installation ........................................................................................................................ 24<br />

Terminal Connection Details ................................................................................................................ 26<br />

Ferrite Core and Connector Installation ................................................................................................ 28<br />

Fitting the Cap........................................................................................................................................ 30<br />

Chapter 3 How To Use Your Nemesis Radar Sensor ...................................................................................... 33<br />

PC Handheld Programmer (Standard).......................................................................................................... 33<br />

Communication Port Configuration ..................................................................................................... 34<br />

Handheld Communicator (Optional) ............................................................................................................ 34<br />

Operating the Controls .................................................................................................................................. 35<br />

Display ................................................................................................................................................... 35<br />

Keypad ................................................................................................................................................... 36<br />

Run Mode ...................................................................................................................................................... 38<br />

Program Mode ............................................................................................................................................... 38<br />

How to Access Program Mode ............................................................................................................. 38<br />

Test Mode ...................................................................................................................................................... 40<br />

Using the RS232 Serial Interface .................................................................................................................. 41<br />

Parameter Defaults ........................................................................................................................................ 42<br />

Factory Defaults ..................................................................................................................................... 42<br />

Chapter 4 Programming Guide ........................................................................................................................... 43<br />

Level ............................................................................................................................................................... 43<br />

Example 1 Level Measurement ............................................................................................................ 43<br />

Volume........................................................................................................................................................... 45<br />

Example 2 Volume Application ........................................................................................................... 45<br />

Chapter 5 Parameter Guide ................................................................................................................................ 47<br />

Menu System Diagrams ................................................................................................................................ 47<br />

Top Level Menu .................................................................................................................................... 47<br />

Application Menu .................................................................................................................................. 48<br />

Volume Menu ........................................................................................................................................ 49<br />

Display Menu ........................................................................................................................................ 49<br />

Output Menu .......................................................................................................................................... 50<br />

Compensation ........................................................................................................................................ 50<br />

Stability Menu........................................................................................................................................ 51<br />

Echo Processing Menu .......................................................................................................................... 51<br />

System Menu ......................................................................................................................................... 52

Device Setup ...........................................................................................................................................53<br />

Test Menu ...............................................................................................................................................54<br />

Parameter Listing ...........................................................................................................................................55<br />

Application Parameters ..................................................................................................................................55<br />

Operation ................................................................................................................................................55<br />

Distances .................................................................................................................................................56<br />

Volume Conversions .....................................................................................................................................58<br />

Conversion ..............................................................................................................................................58<br />

Breakpoints .............................................................................................................................................59<br />

Table .......................................................................................................................................................59<br />

Display Parameters ........................................................................................................................................60<br />

Options ....................................................................................................................................................60<br />

Failsafe ....................................................................................................................................................60<br />

mA Output Parameters ..................................................................................................................................61<br />

Range ......................................................................................................................................................61<br />

Operation ................................................................................................................................................61<br />

Setpoint ...................................................................................................................................................62<br />

Limits ......................................................................................................................................................62<br />

Trim ........................................................................................................................................................63<br />

Failsafe ....................................................................................................................................................63<br />

Compensation Parameters .............................................................................................................................64<br />

Offset ......................................................................................................................................................64<br />

Stability Parameters .......................................................................................................................................64<br />

Damping .................................................................................................................................................64<br />

Filters ......................................................................................................................................................64<br />

Echo Processing Parameters ..........................................................................................................................65<br />

Sensor Status ..........................................................................................................................................65<br />

System Parameters .........................................................................................................................................66<br />

Passcode..................................................................................................................................................66<br />

System Information ................................................................................................................................66<br />

Date & Time ...........................................................................................................................................67<br />

Device Setup ..................................................................................................................................................68<br />

Modbus Set Up .......................................................................................................................................68<br />

Profibus Set Up ......................................................................................................................................69<br />

HART Set Up .........................................................................................................................................69<br />

Test Parameters ..............................................................................................................................................70<br />

Simulation ...............................................................................................................................................70<br />

Hardware ................................................................................................................................................70<br />

Chapter 6 Troubleshooting .................................................................................................................................71<br />

Parameter Record .................................................................................................................................................73

Chapter 1<br />

Start Here…<br />

Congratulations on your purchase of a Pulsar Nemesis Radar sensor. This<br />

quality system has been developed over many years and represents the latest<br />

in high technology level and process monitoring.<br />

It has been designed to give you years of trouble free performance, and a<br />

few minutes spent reading this operating manual will ensure that your<br />

installation is as simple as possible.<br />

About this Manual<br />

It is important that this manual is referred to for correct installation<br />

and operation.<br />

There are various parts of the manual that offer additional help or<br />

information as shown.<br />

Tips<br />

TIP<br />

At various parts of this<br />

manual you may find tips to<br />

help you.<br />

Additional Information<br />

Additional Information<br />

At various parts of the manual, you will find sections<br />

like this that explain specific things in more detail.<br />

References<br />

See Also<br />

References to other parts of the manual<br />

Page 1

About the Nemesis Radar sensor<br />

The sensor uses radio waves to detect the interface between two materials using<br />

the principle of FMCW radar. This detection method has advantages over<br />

ultrasonic waves in some applications. The Nemesis Radar Sensor has several<br />

options to ensure optimal operation for various installations and process<br />

requirements.<br />

The Nemesis Radar Sensor is available with three aerial/antenna options and<br />

three signalling interface options. Please contact Pulsar for advice on the optimal<br />

model and installation accessories for your application.<br />

PC software is available to allow setup and monitoring via either a local RS232<br />

port or a remote connection using Modbus, Profibus or Hart modem.<br />

The Pulsar Radar Levelstar is a matching controller which provides a complete<br />

user interface for the Nemesis Radar Sensor and is recommended for most<br />

installations.<br />

Page 2

Functional Description<br />

A simplified diagram of the Nemesis Radar Sensor is shown below.<br />

The Frequency Modulated Continuous Wave, Radio Detection And Ranging<br />

principle has been developed over many years to accurately measure targets at<br />

relatively short distances. The transmitter section generates a radio signal that is<br />

linearly swept over the 8.9 to 10.1 GHz frequency range. This signal is beamed<br />

by the aerial/antenna towards the target or material where it is reflected back<br />

towards the sensor’s receiver. The receiver mixes a sample of the transmitted<br />

signal with the received signal. The receiver output is a low frequency, linearly<br />

dependent on the target distance. This ‘beat’ frequency is generated by the<br />

Doppler effect and is stable and predictable.<br />

The Doppler beat frequency is amplified, filtered and then digitised by an<br />

Analogue-to-Digital converter (A2D). The following Digital Signal Processor<br />

(DSP) performs a frequency analysis of the received signal to determine the target<br />

distance and strength. The output of this Fast-Fourier Transform (FFT) process is<br />

then passed to the post-processing algorithms to identify the correct target, which<br />

is the contents of the container or process level.<br />

The target-finding algorithms have been developed and optimised by Pulsar over<br />

many years experience to reliably identify and track process levels for liquids,<br />

sludges, powders and solids.<br />

The Nemesis Radar Sensor signal interface communicates the measurement<br />

information to other process equipment or the Pulsar radar LevelStar controller.<br />

Page 3

Product Specification<br />

Physical & Environmental<br />

Enclosure protection<br />

IP65.<br />

Sensor body dimensions<br />

110mm diameter x 296mm long.<br />

Sensor body weight<br />

1.8 kg.<br />

Sensor body material<br />

Stainless steel & Aluminium.<br />

Nickel-Graphite Flouro-Silicone seals.<br />

Sensor ambient temperature -40ºC to +70ºC / -40 o F to +158 o F.<br />

Option AR;<br />

Parabolic reflector dimensions<br />

360mm diameter x 130mm long.<br />

Parabolic reflector weight<br />

1.6kg.<br />

Parabolic reflector materials<br />

Polypropylene, Aluminium.<br />

Parabolic reflector temperature -40ºC to +100ºC / -40 o F to +212 o F.<br />

Parabolic reflector characteristics<br />

Gain 27dB, beamwidth +/-3.3deg.<br />

Option AH;<br />

Horn dimensions<br />

150mm diameter x 240mm long.<br />

Horn weight<br />

0.8kg.<br />

Horn materials<br />

Stainless steel, PTFE (Teflon).<br />

Horn temperature -40ºC to +200ºC / -40 o F to +392 o F.<br />

Horn characteristics<br />

Gain 22dB, beamwidth +/-6deg.<br />

Option AP;<br />

Polyrod dimensions<br />

55mm diameter x 380mm long.<br />

Polyrod weight<br />

0.4kg.<br />

Polyrod materials<br />

Aluminium, PTFE (Teflon).<br />

Polyrod temperature -40ºC to +200ºC / -40 o F to +392 o F.<br />

Polyrod characteristics<br />

Gain 19dB, beamwidth +/-10deg.<br />

Cable entry detail<br />

Cable gland.<br />

Sensor cable conductors<br />

Four core 16/0.2, 0.5mm 2 standard.<br />

Sensor cable outer sheath<br />

Polyurethane (PUR) standard cable.<br />

Maximum cable length<br />

85m for standard Pulsar 4 core cable.<br />

Custom cables 130m / 425’ 24/0.2mm, 0.75mm 2 ,<br />

170m / 560’ 32/0.2mm, 1mm 2 .<br />

Installation requirements<br />

Flammable atmosphere approval<br />

Power supply<br />

Power consumption<br />

Container<br />

Pressure rating<br />

Orientation<br />

Pending.<br />

20 to 28V DC @ 0A75 maximum.<br />

15W maximum, 7W average typical.<br />

Sealed metal or concrete,<br />

screened plastic / fibre-glass possible.<br />

Not standard, contact Pulsar.<br />

Aiming downwards only.<br />

Application material characteristics<br />

States & phases:<br />

Liquids, sludges, powders & solids.<br />

Material velocity:<br />

Static, vibrating & moving.<br />

Dielectric constants (Dk): ≥ 1.5 .<br />

Temperature:<br />

Any, so long as Radar assembly<br />

remains within limits.<br />

Page 4

Performance<br />

Accuracy<br />

0.1% of the measured range or<br />

+/-6mm (whichever is greater)<br />

Resolution 0.03% of the measured range or +/-<br />

2mm (whichever is greater)<br />

Max. range<br />

64m<br />

Min. range min 0.45m<br />

Radio characteristics<br />

Operating frequency<br />

Modulation technique<br />

Output power<br />

8.9 to 10.1GHz (X-band).<br />

FMCW.<br />

1mW (milli-Watt) at aerial port.<br />

Outputs<br />

Analogue output<br />

1 off Isolated (to 150V floating) output<br />

of 4-20 mA into 1k . Source or sink.<br />

(user programmable and adjustable)<br />

+/-50ppm, +/-0.3% WRT 20mA.<br />

ASCII, Half Duplex RS232.<br />

Analogue output stability<br />

RS232<br />

RS485 - Modbus<br />

Modbus ASCII, RTU<br />

RS485 - Profibus Profibus DPV1, EN 50170.<br />

HART 1200 Baud, Hart 7.<br />

Programming<br />

PC programming<br />

Programming security<br />

Programmed data integrity<br />

PC setup and monitoring software<br />

Via RS232 or RS485 Modbus.<br />

Via passcode<br />

Via non-volatile memory.<br />

Pulsar Nemesis PC<br />

Standards and Approvals<br />

Tank Level Probe Radar: EN 302372.<br />

EMC and Radio regulations:<br />

EN 61326-1, EN 61000 series,<br />

FCC CFR47 parts 15 & 18.<br />

IC RSS-210<br />

Enclosure:<br />

IEC 60529, IP65.<br />

Electrical safety:<br />

EN60950.<br />

Pulsar Process Measurement Limited operates a policy of constant development and<br />

improvement and reserve the right to amend technical details as necessary.<br />

Page 5

EU Declaration of Conformity<br />

Pulsar Nemesis Radar Sensor<br />

Relevant Directives 2004/108/EC EMC directive<br />

2006/95/EC<br />

Low voltage directive<br />

Manufacturer’s name<br />

Manufacturer’s address<br />

Apparatus<br />

Type of equipment<br />

Equipment class<br />

Primary standards applied<br />

Test laboratory<br />

Signed;<br />

Pulsar Process Measurement Ltd.<br />

Cardinal Building<br />

Enigma Commercial Centre<br />

Sandys Road<br />

Malvern<br />

Worcestershire<br />

WR14 1JJ<br />

U.K.<br />

Pulsar Nemesis Radar Sensor.<br />

Measurement and process control.<br />

Industrial.<br />

EN302372<br />

EN301489<br />

EN61326<br />

R.N. Electronics Ltd.<br />

Arnolds Court<br />

Arnolds Farm Lane<br />

Mountnessing<br />

Essex<br />

CM13 1UT<br />

U.K.<br />

Date;<br />

24 th August 2012<br />

Name; Tim Brown Revision; 1.0<br />

Position; Pulsar engineer<br />

Page 6

Page 7

This device shall be installed and operated in a completely enclosed container to<br />

prevent RF emission which otherwise can interfere with aeronautical navigation.<br />

Installation shall be done by trained installers, in strict compliance with the<br />

manufacturer’s instructions.<br />

The use of this device is on a “no-interference, no-protection” basis. That is, the<br />

user shall accept operations of high-powered radar in the same frequency band<br />

which may interfere with or damage this device. On the other hand, devices found<br />

to interfere with primary licensing operations will be required to be removed at<br />

the user’s expense.<br />

Changes or modifications not expressly approved by the manufacturer could void<br />

the user’s authority to operate the equipment<br />

RF exposure: The output power of the sensor is 1 milli-Watt. This is well below<br />

established risk levels (Specific Absorption Rate) for RF exposure. Additionally<br />

the equipment is intended for installation within sealed containers.<br />

Page 8

Chapter 2<br />

Installation Guide<br />

Power Supply Requirements<br />

The Nemesis Radar sensor operates from a DC supply of 20 to 28V DC. The peak<br />

power is 15W and the average power is 7W. Typical peak current draw is;<br />

750mA @ 20V 630mA @ 24V 540mA @ 28V<br />

When calculating the cable requirements the peak current figure should be used<br />

and the voltage drop in the cable should be considered.<br />

General Installation and Location<br />

The Nemesis Radar Sensor is intended for operation within enclosed tanks or<br />

silos. The enclosure should typically be metal or concrete. Thin plastic or fibreglass<br />

would not normally be acceptable because the Radar emissions must not<br />

escape or leak through the enclosure.<br />

Outdoor operation is not permissible.<br />

The sensor should be mounted in a manner described by the following diagrams.<br />

The sensor shouldn’t be situated dead centre of a vessel because this makes<br />

internal reflections worse.<br />

The flanges should be sealed to Radio Frequency (RF) energy, typically by<br />

adding a braided cable seal under the mounting flange(s). For a 5mm diameter<br />

braid seal, typically common co-axial cable is OK after removing the outer<br />

sheath, for example:<br />

Belden RG6, Propower CBBR0123, CF0003, CF0094<br />

Conductive graphite grease may also be employed to seal tight gaps and large<br />

bolt threads. Many types of ‘graphite grease’ are not conductive; the following<br />

type has been tested and proven effective by the manufacturer:<br />

Fuchs Lubritech ZX-13<br />

Ensure that the sensor body is not exposed to temperatures above +70 degrees<br />

Centigrade / +158 degrees Farenheit. Where higher temperatures are expected<br />

contact the manufacturer for advice and refer to the external mounting methods<br />

described by the following diagrams.<br />

Page 9

Aerials / Antennas.<br />

The three aerial / antenna options allow optimisation for various process<br />

materials:<br />

Aerial: Gain: Total beamwidth:<br />

Applications:<br />

Reflector 27dB 6.5 deg. Difficult; low Dk materials,<br />

dense dust, long distances,<br />

steep angles of repose.<br />

Horn 22dB 12.5 deg. Typical; general purpose<br />

and high temperatures.<br />

Polyrod 19dB 20 deg. Flat surfaces; liquids, slurries and<br />

high temperatures.<br />

Page 10

Internal Fixed Mounting<br />

Page 11

Page 12

Page 13

External Fixed Mounting<br />

Page 14

Page 15

Page 16

Internal Aimed Mounting<br />

Page 17

Page 18

Cable.<br />

Pulsar can supply a four-core screened cable suitable for most installations up to<br />

85m from the power supply or controller. When calculating the voltage drop<br />

along the cable, remember the ambient temperature and that current draw<br />

increases at lower voltages.<br />

Typical specification at 50 o C / 122 o F ambient, based on 4V loss in the cable;<br />

Maximum cable run: Each conductor: Conductor area:<br />

85m / 280’ 16/0.2mm 0.5mm 2 , standard<br />

128m / 420’ 24/0.2mm 0.75mm 2<br />

170m / 560’ 32/0.2mm 1mm 2<br />

Cable Preparation<br />

For installation of the cable please refer to the mounting options shown in the<br />

previous diagrams, as the cable may need routing via the mounting flange(s),<br />

aimer and conduit before finalising cable installation in the sensor as described<br />

below.<br />

The cable described is standard Pulsar four core screened cable. Identification<br />

below:<br />

Page 19

Step 1<br />

Step 2<br />

Page 20

Step 3<br />

Step 4<br />

Page 21

Step 5<br />

Step 6<br />

Page 22

Removing the Cap<br />

Step 1<br />

Step 2<br />

Loosen the cable gland nut and unscrew the six screws using a suitable<br />

allen key.<br />

Page 23

Cable Gland Installation<br />

Step 1<br />

Step 2<br />

Page 24

Step 3<br />

Step 4<br />

Page 25

Terminal Connection Details<br />

There are three connectors on the sensor interface board; power, RS485 and mA<br />

loop. The primary connections are listed below, including those of the optional<br />

Radar LevelStar, if applicable:<br />

Sensor<br />

Terminals: Wire: Function:<br />

LevelStar<br />

Terminals:<br />

1 Red Power Vs+ 37<br />

2 Black<br />

Power Vs-<br />

(0V / GND) 40<br />

5 White Modbus A- 38<br />

4 Orange Modbus B+ 39<br />

Cable gland Shield Shield 40<br />

Physical installation of the cable connections is shown below:<br />

Page 26

The mA loop output may be configured for either sourcing or sinking circuits.<br />

The sensor’s mA loop output terminals are isolated and floating.<br />

The RJ11 RS232 connector is normally only used for setup and maintenance.<br />

Refer to chapter 3 for information on how to use this port.<br />

Page 27

Ferrite Core and Connector Installation<br />

Step 1<br />

Step 2<br />

Page 28

Step 3<br />

Step 4<br />

Page 29

Fitting the Cap<br />

Step 1<br />

Step 2<br />

Page 30

Step 3<br />

Tighten the cable gland nut to a firm torque once the Radar sensor is<br />

mounted on the flange.<br />

Page 31

Page 32<br />

This page left blank intentionally

Chapter 3<br />

How To Use Your Nemesis Radar Sensor<br />

In order to view or change parameter values one of the following methods<br />

must be used:<br />

PC Handheld Programmer (Standard)<br />

Your Nemesis Radar Sensor comes complete with the Blackbox PC<br />

Handheld Programmer software, contained on CD. Insert the CD into the<br />

CD drive of the PC intended to be used to carry out the programming of the<br />

Nemesis Radar Sensor and install the software, following the on screen<br />

instructions. Once the software is installed connect the computer via its<br />

serial port to the Nemesis Radar Sensor RS232 serial interface RJ11<br />

connector, located on the terminal board underneath Nemesis Radar<br />

Sensor’s top cap, to access remove the cap as per Chapter 2 Installation<br />

Guide – Cable Preparation.<br />

Double click the ‘Handheld Programmer’ icon, installed on your desktop<br />

and the PC will automatically connect to the Nemesis Radar Sensor. Once<br />

connected you will briefly see the message illustrated on the display below<br />

which, after connecting successfully, will then change to display the current<br />

measurement, dependent on mode and measurement unit's chosen. When<br />

using the PC Handheld Programmer software, keypad input can be achieved<br />

by using a ‘mouse’ or similar device to place the cursor over the relevant<br />

key followed by a ‘left’ click, alternatively numeric detail can be entered<br />

directly from the PC keyboard as can ‘ENTER’ and ‘CANCEL’ (Esc. Key).<br />

Page 33

Communication Port Configuration<br />

If the PC Handheld Programmer fails to connect to the Nemesis Radar<br />

Sensor you may need to change the communications port that is being<br />

used, to do this ‘right click’ on the PC Handheld Programmer keypad and<br />

a ‘pop up’ menu will appear allowing you to select the appropriate<br />

communications port.<br />

Handheld Communicator (Optional)<br />

The optional Handheld communicator can be used to program any number<br />

of Nemesis Radar Sensors and works in a similar way to the PC Software.<br />

Connect the Handheld Communicator, with the cable supplied, to the RS232<br />

interface via the RJ11 connector, located on the terminal board underneath<br />

Nemesis Radar Sensor’s top cap, to access remove the cap as per Chapter 2<br />

Installation Guide – Cable Preparation.<br />

Once connected you will briefly see a message, similar to that as seen when<br />

using the PC Software which, after connecting successfully, will then<br />

change to display the current measurement, dependent on mode and<br />

measurement unit's chosen.<br />

Page 34

Radar Level Star (Optional)<br />

When installed and connected to the optional Radar Level Star, the Nemesis<br />

Radar Sensor can be programmed directly via the Level Star’s integral<br />

keypad. See Radar Level Star manual for full details<br />

Operating the Controls<br />

Display<br />

The display of both the PC Handheld Communicator and the Hand Held<br />

Calibrator (optional) is identical.<br />

While in the Run Mode it will display the current level reading and its units<br />

of measure, along with status messages with regards to the Transducer, Echo<br />

reception and Fail Safe Mode. When in the Program mode the display is<br />

used to read information on the Menu System, Parameter Number and<br />

parameter details and values, which can be entered. During Test Mode the<br />

display is used to monitor the simulated level.<br />

1<br />

1234.56<br />

mm<br />

2<br />

1) Main Display, 6 digit numeric display:<br />

Run Mode, current measurement displayed, dependent on mode and<br />

measurement unit's chosen, and value of Hot Key function selected.<br />

Program Mode, displays parameter number and values entered for<br />

parameters.<br />

Test Mode, displays simulated level.<br />

2) Auxiliary Display, scrolling twelve digit alpha numeric display<br />

Run Mode, displays measurement units (P104), status messages on<br />

signal and transducer, detail of Hot Key function selected.<br />

Program Mode, displays Menu and Sub Menu headings, parameter<br />

details and options.<br />

Page 35

Keypad<br />

Hot Keys<br />

There are five hot keys on the keypad, which can be used to quickly access<br />

common parameters for viewing only, while in Run Mode. Pressing the hot<br />

key once will display the first parameter, repeated pressing will display<br />

subsequent parameters, as available.<br />

In program mode, they have different functions, the functions are shown<br />

below.<br />

Hot<br />

Key<br />

Run Mode<br />

Not used with Nemesis.<br />

Program Mode<br />

Not used with Nemesis.<br />

Displays echo confidence, echo<br />

strength, H.A.L.L., average<br />

noise, peak noise or temperature.<br />

Not used with Nemesis.<br />

Not used with Nemesis.<br />

Reset parameter to default<br />

setting.<br />

Instantaneous mA output.<br />

Not used with Nemesis.<br />

Dependant on application<br />

displays Distance, Level, Space<br />

or Volume (optional) in units of<br />

measurement.<br />

Not used with Nemesis.<br />

Gives details of unit type,<br />

software revision and serial<br />

number.<br />

Not used with Nemesis.<br />

Takes you to the last<br />

parameter edited, when you<br />

first enter program mode.<br />

Enter Decimal Point.<br />

Page 36

Menu Keys<br />

The menu keys are used to navigate around the built in menu system and<br />

have the following functions:<br />

Menu Key<br />

Function<br />

1) Arrow keys for moving left and right around the menu<br />

system.<br />

2) Used in test mode to simulate the level moving up and<br />

down.<br />

1) Used to confirm each action (for example select a<br />

menu option) or when entering a parameter number or<br />

value.<br />

2) Used to confirm questions asked by your Nemesis<br />

Radar Sensor such as before restoring factory defaults.<br />

Used to navigate up a level in the menu system, and back<br />

to run mode.<br />

Used to cancel a value entered in error.<br />

Numeric Keys<br />

These keys are used for entering numerical information during<br />

programming.<br />

Page 37

There are two main operating modes for your Nemesis Radar Sensor, Run<br />

Mode and Program Mode. There is also a Test Mode, used for checking<br />

the set-up. All modes are now described.<br />

Run Mode<br />

This mode is used once the Nemesis Radar Sensor has been set up in<br />

program mode. It is also the default mode that the unit reverts to when it<br />

resumes operation after a power failure.<br />

When the Nemesis Radar Sensor is switched on for the first time, it will<br />

provide an output proportional to the distance from the transducer to the<br />

target, in metres. All relays by default are switched off.<br />

If either the PC Handheld Programmer software (standard), or the Hand<br />

Held Calibrator (optional), are connected to the Nemesis Radar Sensor, via<br />

the RS232 interface, while the Nemesis Radar Sensor is in the RUN mode<br />

then the current measurement will be displayed, dependent on mode and<br />

measurement units chosen.<br />

Program Mode<br />

This mode is used to set up the Nemesis Radar Sensor or change<br />

information already set. You must use either the PC Handheld software<br />

supplied (standard), or alternatively the unit can be set up with a Hand Held<br />

Calibrator (optional), both of which must be connected to the Nemesis<br />

Radar Sensor via the RS 232 Serial Interface.<br />

Entering a value for each of the parameters that are relevant to your<br />

application provides all the programming information.<br />

How to Access Program Mode<br />

To enter program mode, you simply enter the passcode, via the keypad on<br />

the PC Handheld Programmer software (standard), or Hand Held Calibrator<br />

(optional), followed by the ENTER key. The default passcode is 1997, so<br />

you would press the following:<br />

Page 38

Note<br />

There is a time-out period of 15 minutes when in program mode, after<br />

which time run mode will be resumed if you do not press any keys.<br />

There are two means of editing parameters, directly or using the menu<br />

system. Each is now described.<br />

Using The Menu System<br />

The menu system has been designed to make the changing of parameters<br />

very simple. There are two levels of menu: Main Menu and Sub Menu.<br />

On the display there is a line of text that shows the menu system. Pressing<br />

the arrow keys scrolls the display between the top-level menu items, (as<br />

shown below, starting at Application).<br />

Application<br />

Volume<br />

Display<br />

Output<br />

Compensation<br />

Stability<br />

Echo Process<br />

System<br />

Device Setup<br />

Test<br />

Service<br />

As you press the cursor keys to scroll left and right between these, you can<br />

press ENTER at any time to select it and take you to the sub-menu.<br />

Each of these options, along with their sub-menus are described in Chapter<br />

5, Parameter Guide. When you move down into the sub-menu, you can<br />

scroll round using the arrow keys, press ENTER to go to the required section<br />

of parameters.<br />

Once you have reached the relevant section, scroll through the parameters,<br />

and enter the necessary information. To enter the information, use the<br />

numeric keys and press ENTER and you will see the message “Saved!”, if<br />

you press CANCEL, then no change will be made, and the message<br />

“Unchanged!!” will be displayed.<br />

Page 39

When you have finished, press CANCEL to go back to the previous level.<br />

When you have reached the top level, then the Nemesis Radar Sensor will<br />

ask for confirmation before allowing you to go back into run mode. This is<br />

done by pressing ENTER at the display prompt.<br />

Directly Editing Parameters<br />

If you already know the number of the parameter, that you wish to look at or<br />

edit, simply type the number in at any time while you are in the menu<br />

system. Thus, if you are in either the menu or sub-menu level by pressing a<br />

numeric key, you can enter the parameter number directly and jump straight<br />

there. You cannot type a parameter number while at parameter level, only at<br />

one of the two menu levels.<br />

When you are at a parameter, the text line rotates automatically displaying<br />

the parameter name, number, the applicable units and the maximum and<br />

minimum figure you can enter. The top line shows the value you are setting.<br />

Once you have accessed a parameter, you can just look at it, or change it.<br />

Once a parameter has been changed, press ENTER and you will see the<br />

message “Saved!” If you press CANCEL, then no change will be made, and<br />

the message “Unchanged!!” will be displayed.<br />

TIP<br />

You can jump straight to the<br />

last parameter you edited, by<br />

pressing ‘+/-’ when you first<br />

enter program mode.<br />

Test Mode<br />

Test mode is used to simulate the application and confirm that all parameters<br />

and relay setpoints have been entered as expected. During simulation, there<br />

is a choice of whether the relays will physically change state (hard<br />

simulation) or not (soft simulation), the LED’s will always change state to<br />

indicate that the relay setpoints have been activated, and the output will<br />

change in accordance to the chosen mode of operation. If you wish to test<br />

the logic of the system that the relays are connected to then select hard<br />

simulation, but if you don’t want to change the relay state, then select a<br />

soft simulation.<br />

Page 40

There are two simulation modes, automatic and manual. Automatic<br />

simulation will move the level up and down between empty level and<br />

maximum span, whereas manual simulation will allow you to move the<br />

level up and down using the arrow keys.<br />

To enter simulation, first go to program mode. Then, using the menu<br />

system, select menu item ‘Test’ then sub-menu item ‘Simulation’. Simply<br />

change the value of the parameter P980 to one of the following:<br />

1= Manual<br />

2= Automatic<br />

To return to program mode, press CANCEL and test mode will end.<br />

When in manual simulation, by default test mode will move the level by<br />

0.25m steps. Altering the increment (P981) will change this value.<br />

In automatic mode, the rate at which the level moves up and down is set by<br />

the increment (P981) in metres. To make the simulated level move slower,<br />

decrease the value in increment (P981). To make the simulated level move<br />

faster, increase the value in increment (P981).<br />

Using the RS232 Serial Interface<br />

The RS232 serial interface is used to program the Nemesis Radar Sensor,<br />

and communicate between the Nemesis Radar Sensor and a PC using the<br />

optional Nemesis PC and other associated Pulsar software packages, to<br />

obtain information such as data logging and view echo traces upload,<br />

download and save parameter files. In addition it can also be used to control<br />

or obtain information using a standard PC or other computer based<br />

equipment. To do so, the settings for control are as follows: baud rate<br />

19,200, 8 data bits, no parity, 1 stop bits.<br />

The device should be connected to the RS232 Interface via the RJ11<br />

connector as shown in Chapter 2 Installation.<br />

Page 41

Parameter Defaults<br />

Factory Defaults<br />

Factory Defaults<br />

When first installing the Nemesis Radar Sensor, or subsequently<br />

moving or using the unit on a new application, before proceeding to<br />

program the unit for its intended application it is recommended that<br />

you ensure that all parameters are at their default values by<br />

completing a Factory Defaults P930, as described in Chapter 5<br />

Parameter Guide.<br />

When you first switch the Nemesis Radar Sensor on it will provide an<br />

output proportional to the distance from the sensor the surface of the<br />

material.<br />

The date (P931) and time (P932) in the Nemesis Radar Sensor were set at<br />

the factory, but may need checking, and amending if, for example the<br />

application is in a time zone other than GMT, see Chapter 5 Parameter<br />

Guide for full details.<br />

TIP<br />

In some applications it is simplest to empty the<br />

vessel, take a reading from the Nemesis Radar<br />

Sensor for distance and then setup the empty<br />

level to this figure.<br />

Once you are satisfied with the installation, and the Nemesis Radar Sensor is<br />

reading what you would expect in terms of distance from the face of the<br />

transducer to the material level, then you can proceed with programming,<br />

for the intended application. It is sensible to program all of the required<br />

parameters at the same time. The system will be then set-up.<br />

Note that the span is automatically calculated from the empty level, so the<br />

empty level should be entered first.<br />

Page 42

Chapter 4 Programming Guide<br />

Level<br />

Example 1 Level Measurement<br />

empty distance (P105), 10m<br />

100%, span (P106), 9.5m<br />

(output = 20mA)<br />

0% , empty level (output = 4mA)<br />

In this example, the Nemesis Radar Sensor with a Polyrod Antenna is being<br />

used to monitor a moving liquid level within a vessel and is required to<br />

provide a 4 to 20mA output proportional to the level, over a range of 9.5m.<br />

Page 43

To program the Nemesis Radar for this Example, proceed as follows.<br />

Access the Program Mode<br />

Key in the passcode 1997 and press ENTER<br />

Using the menu system access the parameters, as detailed below, and select<br />

the relevant options and ENTER.<br />

Top Level<br />

Parameter Detail Selected<br />

Sub Menu<br />

Menu<br />

Value<br />

Application Operation P100 Mode 2 = Level<br />

P101 Antenna 3 = Polyrod<br />

P102 Material Type 1 = Liquid<br />

Distances P104 Measnt Units 1 = metres<br />

P105 Empty Level 10 metres<br />

P106 Span 9.5 metres<br />

Programming is now complete and the unit can be returned to the run mode,<br />

press CANCEL until Run Mode? Is displayed on the display press<br />

ENTER, and the Nemesis Radar will return to the Run Mode.<br />

Note<br />

The 4 to 20mA output will be automatically set to the value of P106<br />

Span, with 4mA being representative of 0% of Span (zero level) and<br />

20mA 100% of Span (Full level).<br />

Page 44

Volume<br />

Example 2 Volume Application<br />

A cylindrical tank with a diameter of 2m and a flat base that is typically<br />

used to temporarily hold liquid, and you wish to know the volume of liquid.<br />

You also require a high and low alarm.<br />

empty distance (P105), 4.5m<br />

100%, span (P106), 4.0m<br />

(output = 20mA)<br />

0% , empty level (output = 4mA)<br />

The display will show the volume of fluid in the tank and the mA output<br />

will be representative of Volume where 4mA = empty (0%) and 20mA =<br />

Max Volume (100%).<br />

Page 45

To program the Nemesis Radar for this Example, proceed as follows.<br />

Access the Program Mode<br />

Key in the passcode 1997 and press ENTER<br />

Using the menu system access the parameters, as detailed below, and select<br />

the relevant options and ENTER.<br />

Top Sub Parameter Detail Selected Value<br />

Level<br />

Application Menu<br />

Menu<br />

Operation P100 Mode 4 = Volume<br />

P101 Antenna 3 = Polyrod<br />

P102 Material Type 1 = Liquid<br />

Distances P104 Measnt Units 1 = metres<br />

P105 Empty Level 4.5<br />

P106 Span 4.0<br />

Volume Conversio P600 Vessel Shape 0 = Cyl.Flat Base<br />

nnnn<br />

P601 – P603<br />

Vessel Dimensions<br />

Enter dimensions as<br />

required<br />

P604 Calc.Volume Shows the volume<br />

as calculated by the<br />

Nemesis Radar<br />

P605 Volume Units Select as required<br />

P606<br />

Enter value of any<br />

Correction Factor correction factor<br />

e.g. specific gravity<br />

of material<br />

P607 Max. Volume Displays the Max.<br />

Vol. as calculated<br />

by the Nemesis<br />

Programming is now complete and the unit can be returned to the run mode,<br />

press CANCEL until Run Mode? Is displayed on the display press<br />

ENTER, and the Nemesis Radar will return to the Run Mode.<br />

Page 46

Chapter 5<br />

Parameter Guide<br />

This section outlines all parameters available in the Nemesis Radar Sensor,<br />

as they appear in the menu system.<br />

Menu System Diagrams<br />

Shown below is a set of charts to show you how all the various parts can be<br />

found using the menu system.<br />

For further details and a full description of all parameters refer to Chapter 6<br />

Parameter Listings and Descriptions<br />

Top Level Menu<br />

Application<br />

Volume<br />

Display<br />

Output<br />

Compensation<br />

Stability<br />

Echo Process<br />

System<br />

Device Setup<br />

Test<br />

Service<br />

Page 47

Application Menu<br />

Operation<br />

Distances<br />

P100<br />

Mode<br />

P101<br />

Antenna<br />

P102<br />

Material Type<br />

P103<br />

Waveguide Ext.<br />

P104<br />

Measurement<br />

Units<br />

P105<br />

Empty Level<br />

P106<br />

Span<br />

P107<br />

Near Blanking<br />

P108<br />

Far Blanking<br />

Page 48

Volume Menu<br />

Conversion<br />

Breakpoints<br />

Tables<br />

P600<br />

Vessel Shape<br />

P601<br />

As Required<br />

Vol. Dimension 1<br />

P602<br />

As Required<br />

Vol. Dimension 2<br />

P603<br />

As Required<br />

Vol. Dimension 3<br />

P604<br />

Calculated<br />

Volume<br />

P605<br />

Volume Units<br />

P606<br />

Correct. Factor<br />

P607<br />

Max. Volume<br />

P610<br />

Level Bkpt. 1<br />

P611<br />

Vol. Bkpt. 1<br />

P612, 614, 616, 618,<br />

620, 622, 624, 626,<br />

628, 630, 632, 634,<br />

636, 638, 640, 642,<br />

644, 646, 648, 650,<br />

652, 654, 656, 658,<br />

660, 662, 664, 666,<br />

668, 670<br />

Level Bkpts. 2 to 31<br />

P613, 615, 617, 619,<br />

621, 623, 625, 627,<br />

629, 631, 633, 635,<br />

637, 639, 641, 643,<br />

645, 647, 649, 651,<br />

653, 655, 657, 659,<br />

661, 663, 665, 667,<br />

669, 671<br />

Vol. Bkpts. 2 to 31<br />

P672<br />

Level Bkpt. 32<br />

P673<br />

Vol. Bkpt. 32<br />

P696<br />

Reset<br />

Bkpts.<br />

P697<br />

Number<br />

Bkpts. Set<br />

Display Menu<br />

Page 49

Options<br />

Fail Safe<br />

P801<br />

Decimal<br />

Places<br />

P808<br />

Fail Mode<br />

P809<br />

Fail Time<br />

Output Menu<br />

Range Operation Setpoint Limits Trim Fail Safe<br />

P830<br />

Out<br />

Range<br />

P831<br />

Out Mode<br />

P834<br />

Low<br />

Value<br />

P836<br />

Low<br />

Limit<br />

P838<br />

Low<br />

Trim<br />

P840<br />

Fail<br />

Mode<br />

P835<br />

High<br />

Value<br />

P837<br />

High<br />

Limit<br />

P839<br />

High<br />

Trim<br />

Compensation<br />

Offset<br />

P851<br />

Measurement<br />

Offset<br />

Page 50

Stability Menu<br />

Damping<br />

Filters<br />

P870<br />

Fill Damping<br />

P881<br />

Fixed Distance<br />

P871<br />

Empty Damping<br />

P882<br />

Process Filter<br />

Echo Processing Menu<br />

Sensor<br />

Status<br />

P900<br />

Xdr. 1 Status<br />

P901<br />

Echo<br />

Confidence<br />

P902<br />

Echo Strength<br />

P903<br />

Average Noise<br />

P904<br />

Peak Noise<br />

P905<br />

Sensitivity<br />

P906<br />

Side Clearance<br />

Page 51

System Menu<br />

Passcode<br />

System<br />

Info<br />

Date<br />

&<br />

Time<br />

P921<br />

Enable<br />

Code<br />

P922<br />

Passcode<br />

P926<br />

Software<br />

Revision<br />

P927<br />

Hardware<br />

Revision<br />

P928<br />

Serial<br />

Number<br />

P931<br />

Date<br />

P932<br />

Time<br />

P933<br />

Date<br />

Format<br />

P929<br />

Site<br />

Ident.<br />

P930<br />

Factory<br />

Default<br />

Page 52

Device Setup<br />

RS232<br />

Set Up<br />

RS485 Set Up<br />

(Optional)<br />

HART<br />

(Optional)<br />

P061<br />

Comms Baud<br />

If Comms. Type<br />

MODBUS<br />

If Comms. Type<br />

PROFIBUS<br />

P130<br />

Device Mode<br />

P131<br />

Protocol<br />

P132<br />

Device Address<br />

P133<br />

Device Baud<br />

P132<br />

Device Address<br />

P132<br />

Device<br />

Address<br />

P134<br />

Parity<br />

P135<br />

Stop Bit<br />

P136<br />

Data Format<br />

P137<br />

Delay<br />

(milliseconds)<br />

P143<br />

Address Lock<br />

Page 53

Test Menu<br />

Simulation<br />

Hardware<br />

P980<br />

Simulate<br />

P992<br />

mA Out Test<br />

P981<br />

Increment<br />

Page 54

Parameter Listing<br />

This section describes all of the parameters available.<br />

Application Parameters<br />

Operation<br />

P100 Mode of Operation<br />

This parameter sets the mode of operation in run mode, and can be set to one<br />

of the following:<br />

Option<br />

Description<br />

1 = Distance (Default) Display shows the distance from the<br />

transducer face to the surface.<br />

2 = Level Display shows how full the vessel is.<br />

3 = Space Display shows how empty a vessel is.<br />

4 = Volume Display shows volume<br />

P101 Antenna Type<br />

This parameter sets the type of antenna, when in run mode, and can be set to<br />

one of the following:<br />

Option<br />

Description<br />

1 = Reflector (Default) Display shows the reflector antenna<br />

2 = Horn Display shows the horn antenna<br />

3 = PolyRod Display shows the polyrod antenna<br />

P102 Material Type<br />

This parameter sets the type of material used in the application, when in run<br />

mode, and can be set to one of the following:<br />

Option<br />

Description<br />

1 = Liquid (Default) Display shows material type of liquid<br />

2 = Solid Display shows material type of solid<br />

3 = Foam Display shows material type of foam<br />

P103 Waveguide Extension<br />

This parameter sets the extension length of the waveguide. Default is 0.<br />

The effective distance change is automatically calculated by the software.<br />

Page 55

Distances<br />

P104 Measurement Units<br />

This parameter sets the units you want to use for programming and display<br />

Option<br />

Description<br />

1 = metres (Default) All units of measure are METRES<br />

2 = cm All units of measure are CENTIMETRES<br />

3 = mm All units of measure are MILLIMETRES<br />

4 = feet All units of measure are FEET<br />

5 = inches All units of measure are INCHES<br />

P105 Empty Level<br />

This parameter is to be set to the maximum distance from the flange of the<br />

sensor to the empty point, in P104 Measurement Units.<br />

Note this value affects span as well, (see important information below), so<br />

should be set before span.<br />

P106 Span<br />

This parameter should be set to the maximum distance from the Empty<br />

Level (P105) to the maximum material level. It is automatically set to be<br />

equal to the Empty Level (P105) less the Near Blanking distance (P107),<br />

when you set the empty level.<br />

P107 Near Blanking Distance<br />

This parameter is the distance from the flange of the sensor, and is pre-set to<br />

the minimum value. It should not be set to less than this figure, but can be<br />

increased, typically to ignore close in obstructions. The default is defined by<br />

the aerial/antenna type.<br />

P108 Far Blanking Distance<br />

This is the distance (as a percentage of empty level P105) beyond the<br />

empty point that the unit will be able to measure, and by default is pre-set to<br />

20% of the empty level.<br />

If the surface being monitored can extend beyond the Empty Level (P105)<br />

then the far blanking distance can be increased to a maximum of 100% of<br />

empty level provided it does not exceed the maximum range of the sensor.<br />

This parameter is always entered as a % of empty level.<br />

Page 56

The following diagram illustrates the above parameter definitions and their<br />

reference point.<br />

Page 57

Volume Conversions<br />

Conversion<br />

P600 Vessel Shape<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

Option<br />

Description<br />

1 = Measured (Default) Display is in selected units dependant in<br />

Mode (P100)<br />

2 = Percentage Display is in percentage of span<br />

dependant in Mode (P100).<br />

P601 Diameter<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

P604 Calculated Volume<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

P605 Volume Unit<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

P606 Correction Factor<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

P607 Maximum Volume<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

Page 58

Breakpoints<br />

P610 Level Breakpoint 1<br />

This parameter determines whether the reading displayed is<br />

Measurement Units (P104), or as a percentage of span.<br />

in<br />

P611 Volume Breakpoint 1<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

P672 Level Breakpoint 32<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

P673 Volume Breakpoint 32<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

Table<br />

P696 Reset Breakpoints<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

P697 Number of Breakpoints<br />

This parameter determines whether the reading displayed is in<br />

Measurement Units (P104), or as a percentage of span.<br />

Page 59

Display Parameters<br />

Options<br />

P801 Decimal Places<br />

This parameter determines the number of decimal places on the reading<br />

during run mode.<br />

Minimum = 0 (No decimal places), Maximum 3 = (3 decimal Places)<br />

Default = 2 (2 decimal Places)<br />

Failsafe<br />

P808 Fail-safe Mode<br />

By default, if a fail-safe condition occurs, then the display, relays and the<br />

mA output are held at their last known values until a valid reading is<br />

obtained.<br />

If required, then you can change this so that the unit goes to high (100% of<br />

span), or low (empty) as follows:<br />

Option<br />

Description<br />

1 = Known (Default) Remain at the last known value<br />

2 = High Will fail to the high value (100% of Span).<br />

3 = Low Will fail to the low value (empty)<br />

See Also P840 mA Output Fail-safe<br />

Important Information<br />

In the event of a fail-safe condition occurring, the mA Output can be<br />

configured to fail to a condition which is independent of each other. To set<br />

independent mA Output Failsafe see P840.<br />

P809 Fail-safe Time<br />

In the event of a fail-safe condition the fail safe timer determines the time<br />

before fail-safe mode is activated. Default = 2mins<br />

If the timer activates, the unit goes into fail-safe, as determined by P808<br />

and P840 (mA Output). When a valid measurement is obtained the mA<br />

output is restored and the timer reset.<br />

Page 60

mA Output Parameters<br />

Range<br />

P830 mA Range<br />

This parameter determines the range of the mA output, from the following.<br />

Option<br />

Description<br />

0= Off mA output disabled.<br />

1= 4 to 20 mA mA output directly proportional to the mA mode<br />

(Default) (P831), so if the reading is 0% the output is 4 mA. If<br />

the reading is 100% the output is 20 mA.<br />

2= 20 to 4 mA mA output inversely proportional to the mA mode<br />

(P831), so if the reading is 0% the output is 20 mA. If<br />

the reading is 100% the output is 4 mA.<br />

Operation<br />

P831 mA Mode<br />

This parameter determines how the mA Output relates to what is measured.<br />

By default it operates exactly the same as the display (P100), but it can be<br />

set to operate as follows:<br />

Option<br />

Description<br />

0 = Default mA output relative to Mode P100<br />

1 = Distance mA output relative to distance.<br />

2 = Level mA output relative to level.<br />

3 = Space mA output is relative to space.<br />

4 = Volume mA output is relative to volume.<br />

Page 61

Setpoint<br />

Limits<br />

By default the mA Output will represent the empty (4mA) and 100% of the<br />

operational span (20mA), but you may wish to have the output represent a<br />

section of the operational span. For example, the application has an<br />

operational span of 6 metres but output is to represent empty (4mA) to a<br />

level of 5 metres (20mA). If so P834 (Low Level) should be set to 0.00<br />

metres and P835 (High Level) should be set to 5 metres.<br />

P834 mA Low Level<br />

This parameter sets the level, distance or space, depending on the selected<br />

mA Out Mode (P831) at which the low mA output will occur (4mA)<br />

Default = 0.000m<br />

P835 mA High Level<br />

This parameter sets the level, distance or space, depending on the selected<br />

mA Out Mode (P831) at which the high mA output will occur (20mA).<br />

Default = 63.500m<br />

P836 mA Low Limit<br />

This parameter sets the lowest level that the mA output will drop to, the<br />

default is 0mA, but you can override this if the device you connect to cannot<br />

for example accept less than 4mA. Default = 0.00mA<br />

P837 mA High Limit<br />

This parameter sets the highest level that the mA output will rise to, the<br />

default is 20 mA, but you can override this if the device you connect to<br />

cannot for example accept more than 18 mA, yet you want to use the 0-20<br />

mA range. Default = 20.00mA<br />

Page 62

Trim<br />

P838 mA Low Trim<br />

If the device you are connected to is not calibrated, and not showing the<br />

correct low value (reading), then you can trim it using this parameter. You<br />

can either type in the offset directly, or use the arrow keys to move the<br />

output up and down until you get the expected result (reading) on the device<br />

that is connected.<br />

P839 mA High Trim<br />

If the device you are connected to is not calibrated, and not showing the<br />

correct high value (reading), then you can trim it using this parameter. You<br />

can either type in the offset directly, or use the arrow keys to move the<br />

output up and down until you get the expected result (reading) on the device<br />

that is connected.<br />

Failsafe<br />

P840 mA Fail-safe Mode<br />

This parameter determines what happens to the mA output in the event of<br />

the unit going into fail-safe mode. The default is to do the same as the<br />

system fail-safe (P808), but this can be overridden to force the mA output<br />

to an independent fail-safe mode as follows:<br />

Option<br />

Description<br />

0 = Default mA output will fail as per P808.<br />

1 = Hold mA output will retain its last known value.<br />

2 = Low mA output will fail to its low (4mA)<br />

condition.<br />

3 = High mA output will fail to its high (20mA)<br />

condition.<br />

4 = Very Low mA output will fail to its low fault<br />

(3.5mA) condition.<br />

5 = Very High mA output will fail to its high fault<br />

(22mA) condition.<br />

Page 63

Compensation Parameters<br />

Offset<br />

P851 Measurement Offset<br />

The value of this parameter is added to the measured distance, in<br />

Measurement Units (P104).<br />

This Offset will be added to the level, as derived from the radar sensor, and<br />

will affect everything including the mA output.<br />

Stability Parameters<br />

Damping<br />

Filters<br />

Damping is used to damp the display, to enable it to keep up with the<br />

process but ignore minor surface fluctuations.<br />

P870 Fill Damping<br />

This parameter determines the maximum rate at which the unit will<br />

respond to an increase in level. It should be set slightly higher than the<br />

maximum vessel fill rate. Default = 10m/min<br />

P871 Empty Damping<br />

This parameter determines the maximum rate at which the unit will<br />

respond to a decrease in level. It should be set slightly higher than the<br />

maximum vessel empty rate. Default = 10m/min<br />

The following three parameters can be used to filter out unwanted changes<br />

of level caused by a ‘rippled’ or agitated surface.<br />

P881 Fixed Distance<br />

This parameter determines the width of gate to be used in tracking an echo<br />

and under normal circumstances will not require changing, but it can be<br />

increased in the cases where the surface is moving extremely fast (in excess<br />

of 10m/min) to ensure smooth processing of the changing level.<br />

Page 64

P882 Process Filter<br />

This parameter determines the number of ‘cycles’ that will be taken before a<br />

change in level is processed and the display updated.<br />

Option<br />

Description<br />

1 = Fast level will be updated every cycle<br />

2 = Medium level will be updated every 8 cycles<br />

3 = Slow (Default) level will be updated every 16 cycles<br />

Echo Processing Parameters<br />

Sensor Status<br />

P900 Sensor Status<br />

This parameter shows the current state of the radar sensor as follows;<br />

Option<br />

Description<br />

0= OK Sensor working correctly.<br />

1= DSP Data Error Sensor fault. Data from DSP is incorrect<br />

2= DSP Timed out Sensor fault. No response from DSP board<br />

P901 Echo Confidence<br />

This parameter displays the most recent echo confidence from the radar<br />

sensor. It is useful to help find the best mounting location for the sensor,<br />

where you should aim to get the highest figure. It is a percentage of<br />

confidence that the echo reporting the level is the correct one.<br />

P902 Echo Strength<br />

This parameter displays the most recent echo strength figure for the sensor,<br />

where a higher figure indicates a better returned echo.<br />

P903 Average Noise<br />

This is the mean noise reading for the sensor. It is measured while the sensor<br />

is transmitting, and gives an indication of the average amount of electrical<br />

noise present in the application environment.<br />

P904 Peak Noise<br />

This is the peak noise reading for the sensor. It is measured while the<br />

transducer is transmitting, and gives an indication of the maximum amount<br />

of electrical noise present in the application environment.<br />

Page 65

P905 Sensitivity<br />

This is the minimum level for datem.<br />

P906 Side Clearance<br />

This is the margin on either side of the echoes to allow for fluctuation in<br />

receiving signals.<br />

System Parameters<br />

Passcode<br />

P921 Enable Code<br />

Enables the passcode (P922), which means the passcode must be entered to<br />

go into program mode. If disabled (set to 0), then no passcode is required,<br />

and ENTER is used to enter program mode. Default =1 (Enabled)<br />

P922 Passcode<br />

This is the passcode that must be used to enter program mode. The default<br />

is 1997, but this can be changed to another value from 0 to 9999.<br />

System Information<br />

The following three parameters do not affect how the unit performs, but details,<br />

contained in them may be required by Pulsar when making technical enquiries.<br />

P926 Software Revision<br />

This parameter will display the current software revision. It is read only.<br />

P927 Hardware Revision<br />

This parameter will display the current hardware revision. It is read only.<br />

P928 Serial Number<br />

This parameter will display the serial number of the unit. It is read only.<br />

P929 Site Identification<br />

This parameter allows you to give each unit an individual reference number,<br />

for identification purposes. You can set any number between 1 and 99999.<br />

Page 66

P930 Factory Defaults<br />

This parameter resets all parameter values to the original Factory Set values<br />

that were installed when the unit was tested, before despatch to you.<br />

To reset parameters, enter 1 (Yes), and press ENTER, then you will see a<br />

message “Entr if sure”, you should press ENTER again. If you press any<br />

other key at this point, the parameters will not be reset, and you will see a<br />

message confirming this.<br />

Once you have done this, program the unit for the desired application.<br />

Date & Time<br />