Introduction folder 1-4-16 - Repair Care

Introduction folder 1-4-16 - Repair Care

Introduction folder 1-4-16 - Repair Care

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

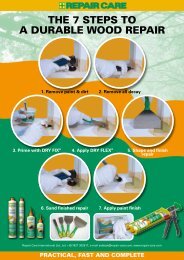

THE NEW GENERATION OF DURABLE<br />

WOOD REPAIR AND ADHESIVE TECHNOLOGY<br />

PROFESSIONAL<br />

STANDARD<br />

2 YEAR<br />

SHELF LIFE!<br />

CURING<br />

TIMES<br />

OF 1, 4 AND<br />

<strong>16</strong> HOURS<br />

AT 20°C POPULAR<br />

WITH TENANTS<br />

INDEPENDENTLY<br />

TESTED<br />

4<br />

SEASONS<br />

PRACTICAL, FAST<br />

AND COMPLETE<br />

USE ALL YEAR<br />

ROUND

The new generation DRY FIX ® /DRY FLEX ® products:<br />

Improved in 14 ways<br />

The new generation of elastic epoxies offers a large<br />

number of improvements to the previous technology:<br />

• DRY FIX ® /DRY FLEX ® 1, 4 and <strong>16</strong> are completely<br />

suitable for all temperature conditions in all seasons.<br />

• At storage temperatures of 5-50°C every product has a<br />

shelf life of two years without loss of quality.<br />

• The consistency of the products remains constant during<br />

use and is not dependent upon the surrounding<br />

temperature or the season.<br />

• DRY FIX ® /DRY FLEX ® 1, 4 and <strong>16</strong> are, as product<br />

systems, completely complementary to one another.<br />

• DRY FLEX ® 1, 4 and <strong>16</strong> resin sets are ready for use; the<br />

tube comes with a screw cap and a pre-cut tip. This gives<br />

a steady flow and eliminates the need to cut open the<br />

container. This means working safer, cleaner and quicker.<br />

• DRY FLEX ® 1, 4 and <strong>16</strong> tubes stay clean; the new top now<br />

has a special anti-leak edge.<br />

• The new series DRY FIX ® 1, 4 and <strong>16</strong> have a low<br />

viscosity and, therefore, improved penetration: above all,<br />

they are in a handy squeeze bottle.<br />

• The quality of the new generation, when fully cured, is<br />

guaranteed: the product properties are guaranteed even<br />

in extreme temperatures.<br />

• The trained specialist contractor can deliver tailor-made<br />

craftsmanship with the complete series of products for<br />

every specific project situation.<br />

• Improved modelling qualities, even for the quick curing<br />

DRY FLEX ® 1 and DRY FLEX ® 4 are excellent and<br />

comparable to the characteristics of DRY FLEX ® <strong>16</strong><br />

(better than DRY FLEX ® RP and WQ).<br />

• The adhesive qualities of DRY FLEX ® 1, 4 and <strong>16</strong> are<br />

improved compared with the old Dry Flex products.<br />

• Stays in shape even before curing – high slump<br />

resistance.<br />

• The repair and adhesive properties have been thoroughly<br />

tested by independent institutes and certified users in<br />

various countries.<br />

• Each batch that is produced is subjected to a precise and<br />

completely documented thermo graphic quality control.<br />

Curing Time at 20°C 1 hour 4 hours <strong>16</strong> hours<br />

Recommended<br />

Application temperature<br />

Ready to sand<br />

and paint<br />

Recommended<br />

Application volume<br />

0-25° C 0-35° C 10-35° C<br />

After 1 hour After 4 hours After <strong>16</strong> hours<br />

5-10 mm thickness 5-20 mm thickness* 5-50 mm thickness**<br />

Shelf life<br />

2 years with storage<br />

temp. 5 - 50°C<br />

2 years with storage<br />

temp. 5 - 50°C<br />

2 years with storage<br />

temp. 5 - 50°C<br />

Typical<br />

Application<br />

Small repairs/splits<br />

Splicing<br />

Emergency repairs<br />

Spot repairs<br />

<strong>Repair</strong>s to be primed/<br />

painted on the same day<br />

Small resin only and timber/<br />

resin repairs<br />

<strong>Repair</strong>s to be primed/<br />

painted on the same day<br />

<strong>Repair</strong>s in low temperature<br />

environments<br />

Large resin only and<br />

timber/resin repairs<br />

Large projects<br />

Projects without time<br />

constraints<br />

Contents<br />

Dry Fix squeeze<br />

bottle<br />

200 ml Component A<br />

(red colour)<br />

100 ml Component B<br />

(transparant)<br />

200 ml Component A<br />

(orange colour)<br />

100 ml Component B<br />

(transparent)<br />

200 ml Component A<br />

(green colour)<br />

100 ml Component B<br />

(transparent)<br />

Contents<br />

Dry Flex tubes<br />

200 ml Component A<br />

(red colour)<br />

100 ml Component B<br />

(transparent)<br />

300 ml Component A<br />

(orange colour)<br />

100 ml Component B<br />

(transparent)<br />

300 ml Component A<br />

(green colour)<br />

100 ml Component B<br />

(transparent)<br />

Mixing control<br />

system<br />

DRY FLEX ® : Yes DRY FLEX ® : Yes DRY FLEX ® : Yes<br />

*at an application temperature of between 0°C and 10°C: to 50 mm thickness. **for deeper repairs, the use of timber and resin is recommended.<br />

PRACTICAL, FAST AND COMPLETE

Specific purposes<br />

QUICK SMALL REPAIRS QUICK SMALL/MEDIUM REPAIRS LARGE REPAIRS<br />

Easy and clean to use<br />

PRACTICAL, FAST AND COMPLETE

Improved tools and accessories<br />

MIX & FIX ®<br />

Mix efficiently without making a mess.<br />

Thanks to the specially developed<br />

leak-proof and stable mixing cups with<br />

a handy wooden spatula.<br />

The new mixing board<br />

A small, simple improvement; a<br />

smoother surface which makes mixing<br />

and cleaning even easier.<br />

The REPAIR CARE SELECTOR ®<br />

A useful repair indicator for projects.<br />

Always make the right DRY FIX ® /<br />

DRY FLEX ® system choice thanks to the<br />

handy product overview. Full of clear<br />

instructions, practical tips and answers<br />

to the most common<br />

questions.<br />

The new, universal, light-weight dosing gun for<br />

DRY FLEX ®<br />

Light-weight<br />

A completely new, recently developed light-weight<br />

dosing gun made from high quality nylon, reinforced with<br />

fibreglass.<br />

Unique anti-drip system<br />

When the handle is released, the pressure automatically<br />

drops, so that the products do not drip.<br />

Anti-leak caps<br />

The anti-leak caps have a special<br />

notch (anti-leak edge) which<br />

means they are easier and<br />

cleaner to put onto<br />

the tube.<br />

PRACTICAL, FAST AND COMPLETE<br />

Universal for 1 - 4 - <strong>16</strong><br />

The dosing gun can be used for all<br />

DRY FLEX ® containers; DRY FLEX ® 1<br />

with a set of 200 ml and 100 ml as well<br />

as with the DRY FLEX ® 4 and <strong>16</strong> with<br />

containers of 300 ml and 100 ml<br />

combined. Using the red slider on the<br />

gun, it is easy to change the setting to<br />

suit both combinations.<br />

Anti-leak caps<br />

Unique anti-drip system

Innovation from a practical perspective<br />

Market developments<br />

Since its introduction in 1989, the Window <strong>Care</strong> System<br />

approach has set the standard for durable wood repairs<br />

and conservation. <strong>Repair</strong> <strong>Care</strong> trained contractors offer<br />

their clients both high quality and economic timber repairs,<br />

maintaining, as far as possible, the original joinery.<br />

This is especially important for those clients managing long<br />

term maintenance budgets, listed buildings and properties<br />

in sensitive conservation areas.<br />

Working closely with both contractors and specifiers, we<br />

have always sought ways to improve the DRY FLEX ® resin<br />

and repair systems.<br />

In particular, the level of control with regard to speed of<br />

curing, ease of use under differing seasonal temperatures<br />

whilst still maintaining the modelling qualities of the<br />

original system.<br />

The perfect product for the perfect repair<br />

With the new generation elastic epoxy systems DRY FIX ® /<br />

DRY FLEX ® 1, 4 and <strong>16</strong> we are able to fulfil completely the<br />

demands of the trained contractor and the most demanding<br />

specifier. No matter what the circumstances, with<br />

DRY FIX ® /DRY FLEX ® 1, 4 and <strong>16</strong> the contractor has the<br />

right product available for every season.<br />

The user simply selects the appropriate system based upon<br />

the following criteria:<br />

• How quickly the project has to be finished (the same day<br />

or later)<br />

• What the temperature conditions are in which the project<br />

is being completed (high or low temperature)<br />

• The size of the repair (volume, density)<br />

• The type of wood repair (resin repair or resin and timber<br />

splice repair)<br />

Commitment to excellence<br />

In order to fulfil the practical demands and exacting<br />

standards of the professional contractor and specifier, we<br />

are committed to a continuing and exhaustive research<br />

and development programme.<br />

4<br />

SEASONS<br />

With a team of international specialists, we have been<br />

working intensively for many years on the development<br />

of the new epoxy systems. The whole range of<br />

DRY FIX ® /DRY FLEX ® 1, 4 and <strong>16</strong> is therefore based on<br />

the most recent technology and has been thoroughly<br />

tested by leading, independent institutes across Europe.<br />

We tested, among others, the repair and adhesive<br />

qualities of the new epoxy technology under extreme<br />

temperature conditions. Such exceptional situations are<br />

becoming increasingly frequent and can have an<br />

enormous effect on the durability and the nature of the<br />

wood repair, including the way it has been painted. The<br />

test results are convincing: the durability of the repair as<br />

well as the adhesive properties of DRY FIX ® /DRY FLEX ®<br />

1, 4 and <strong>16</strong> is better than ever, even under extreme<br />

temperature conditions!<br />

International practical tests with certified application<br />

specialists also confirm the improvements: “The new<br />

DRY FLEX ® has a fantastic adhesive quality and the<br />

modelling is also improved. Mixing was already fast and<br />

controlled. Now it is even better”.<br />

“With a 4-season range that we can use for all practical<br />

situations, together with the two year shelf life, we now<br />

have everything”.<br />

It has been proved in practice!<br />

PRACTICAL, FAST AND COMPLETE

Practical training with added value<br />

Quality products alone are not enough. The durability of<br />

wood repairs depends on the skill of the contractor.<br />

A <strong>Repair</strong> <strong>Care</strong> practical course helps the contractor:<br />

• Understand the causes of timber decay.<br />

• Inspect and assess the most practical Window <strong>Care</strong> repair<br />

methods required.<br />

• Learn the practical uses of various methods of wood<br />

repair and restoration using the Window <strong>Care</strong> System.<br />

On completion of the course, the contractor receives a<br />

certificate.<br />

After the training, we can provide help with inspection for<br />

specific projects.<br />

Refresher courses to improve practical experience and to<br />

discuss new developments can also be arranged.<br />

We also provide training for specifiers to ensure that the<br />

Window <strong>Care</strong> System is used as effectively as possible.<br />

Training is provided throughout the year and can be<br />

organised for individual companies.<br />

Durable wood repair is the work of a specialist!<br />

THE<br />

WOOD REPAIR SYSTEM<br />

PRACTICAL, FAST AND COMPLETE<br />

You can find more information at www.repair-care.com<br />

9602011-01/08<br />

<strong>Repair</strong> <strong>Care</strong> International Ltd., Unit E, Sawtry Business Park, Glatton Road, Sawtry, Huntingdon, Cambridgeshire, PE28 5GQ<br />

Phone +44 (0)1487 830 311, Fax +44 (0)1487 832 876, www.repair-care.com, e-mail salesuk@repair-care.com