EDITION

Cutting Tools Manufacturing 8 - Europa Tool Co. Ltd

Cutting Tools Manufacturing 8 - Europa Tool Co. Ltd

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SOLID CARBIDE TIALN THREAD MILLS Europa Tool Co.,Ltd 359<br />

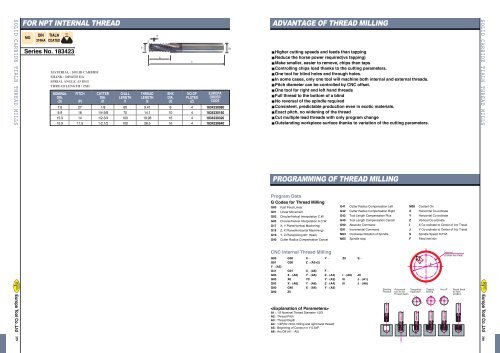

FOR NPT INTERNAL THREAD<br />

MG<br />

DIN<br />

374HA<br />

TIALN<br />

COATED<br />

Series No. 183423<br />

MATERIAL : SOLID CARBIDE<br />

SHANK : DIN6535 HA<br />

SPRIAL ANGLE :15 DEG<br />

THREAD LENGTH : 2XD<br />

NOMINAL<br />

DIA.<br />

(D)<br />

7.6<br />

9.9<br />

15.9<br />

15.9<br />

PITCH<br />

(P)<br />

27<br />

18<br />

14<br />

11.5<br />

CUTTER<br />

DIA.<br />

d1<br />

1/8<br />

1/4-3/8<br />

1/2-3/4<br />

1-2.1/2<br />

O/ALL<br />

LENGTH<br />

I1<br />

60<br />

70<br />

100<br />

100<br />

THREAD<br />

LENGTH<br />

I2<br />

9.41<br />

14.1<br />

19.96<br />

26.5<br />

SHK<br />

DIA.<br />

d2<br />

8<br />

10<br />

16<br />

16<br />

NO.OF<br />

FLUTES<br />

(Z)<br />

4<br />

4<br />

4<br />

4<br />

EUROPA<br />

ORDER<br />

CODE<br />

1834230080<br />

1834230160<br />

1834230320<br />

1834230640<br />

ADVANTAGE OF THREAD MILLING<br />

Higher cutting speeds and feeds than tapping<br />

Reduce the horse power required(vs tapping)<br />

Make smaller, easier to remove, chips than taps<br />

Controlling chips load thanks to the cutting parameters.<br />

One tool for blind holes and through holes.<br />

In some cases, only one tool will machine both internal and external threads.<br />

Pitch diameter can be controlled by CNC offset.<br />

One tool for right and left hand threads<br />

Full thread to the bottom of a blind<br />

No reversal of the spindle required<br />

Consistent, predictable production even in exotic materials.<br />

Exact pitch, no widening of the thread<br />

Cut multiple lead threads with only program change<br />

Outstanding workpiece surface thanks to variation of the cutting parameters.<br />

PROGRAMMING OF THREAD MILLING<br />

Program Data<br />

G Codes for Thread Milling<br />

G00 Fast Feed Linear<br />

G01 Linear Movement<br />

G02 Circular/Helical Interpolation C.W.<br />

G03 Circular/Helical Interpolation A.C.W.<br />

G17 X, Y Plane(Vertical Machining)<br />

G18 Z, X Plane(Horizontal Machining)<br />

G19 Y, Z Plane(Using 90 Head)<br />

G40 Cutter Radius Compensation Cancel<br />

CNC Internal Thread Milling<br />

G41<br />

G42<br />

G43<br />

G49<br />

G90<br />

G91<br />

M03<br />

M05<br />

Cutter Radius Compensation Left<br />

Cutter Radius Compensation Right<br />

Tool Length Compensation Plus<br />

Tool Length Compensation Cancel<br />

Absolute Command<br />

Incremental Command<br />

Clockwise Rotation of Spindle<br />

Spindle stop<br />

G90 G00 X Y Z5 S<br />

G91 G00 Z (A3+2)<br />

Y (A5)<br />

G41 G01 X (A6) F<br />

G03 X (A6) Y (A6) Z (A4) I (A6) J0<br />

G03 X0 Y0 Y (A2) I0 J (A1)<br />

G03 X (A6) Y (A6) Z (A4) I0 J (A6)<br />

G00 G40 X (A6) Y (A5)<br />

G90 Z5<br />

<br />

A1 : 1/2 Nominal Thread Diameter 1/2D<br />

A2 : Thread Pitch<br />

A3 : Thread Depth<br />

A4 : 1/4P(for climb milling and right-hand thread)<br />

A5 : Beginning of Contour in Y 0.5xP<br />

A6 : Arc Off (A1 - A5)<br />

M08<br />

X<br />

Y<br />

Z<br />

I<br />

J<br />

S<br />

F<br />

Coolant On<br />

Horizontal Co-ordinate<br />

Horizontal Co-ordinate<br />

Vertical Co-ordinate<br />

X Co-ordinate to Center of Arc Travel<br />

Y Co-ordinate to Center of Arc Travel<br />

Spindle Speed R.P.M.<br />

Feed mm/min<br />

SOLID CARBIDE TIALN THREAD MILLS Europa Tool Co.,Ltd 360