Publications

DEL Custom Built Bodies - Equipment Review Magazine

DEL Custom Built Bodies - Equipment Review Magazine

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fall 2013 <strong>Publications</strong> Mail Agreement Number 41137025<br />

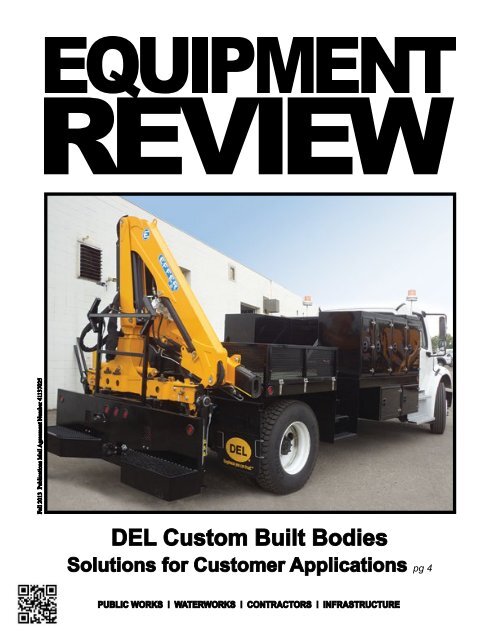

DEL Custom Built Bodies<br />

Solutions for Customer Applications pg 4

Fall Edition 2013<br />

Volume 3 Number 4<br />

Published by:<br />

EQUIPMENT REVIEW INC.<br />

Editorial and Advertising Office<br />

Suite 628,<br />

440-10816 Macleod Trail S.E.<br />

Calgary, Alberta<br />

Canada T2J 5N8<br />

Telephone: (403) 238-8663<br />

email: jerry@equipmentreview.ca<br />

Publisher / Editor<br />

Jerry Skinner<br />

Circulation / Reader<br />

Matters concerning additions, deletions,<br />

address changes etc.<br />

- please use regular mail to contact us at<br />

the address above.<br />

“EQUIPMENT REVIEW”<br />

provides, in good faith, information<br />

that is believed to be accurate about<br />

new products and services. However,<br />

no responsibility is assumed for<br />

inaccuracies or errors, nor should legal<br />

or professional advice be assumed<br />

from our text. Written permission<br />

from the Publisher is required for the<br />

commercial reproduction of any part of<br />

this magazine.<br />

Printed in Canada<br />

<br />

DEL<br />

Custom Built Bodies<br />

DEL Equipment provides a variety of<br />

custom build Computer-Aided Design<br />

(CAD) designed bodies. These are<br />

available in both steel and aluminum.<br />

DEL manufactures Crane Trucks and<br />

other products to a very high quality, at<br />

competitive pricing. It can also refurbish<br />

and reinstall Equipment and Service<br />

Bodies on current year chassis.<br />

IMI<br />

New KM Distributor<br />

Industrial Machine Inc. recently<br />

announced its appointment as distributor<br />

for KM International. KM manufactures<br />

superior quality asphalt maintenance<br />

equipment for contractors and government<br />

agencies. IMI is the sole distributor for<br />

KM in Alberta, Saskatchewan and British<br />

Columbia.<br />

Greatwest Kenworth<br />

New T880 - Vocational<br />

Custom-engineered from bumper to<br />

taillight, the T880 is the most versatile<br />

vehicle to ever roll off a Kenworth<br />

assembly line. Distinctively Kenworth,<br />

this bold new truck is as comfortable<br />

hauling 140,000 pounds over the Rockies<br />

as it is navigating city streets with a tanker<br />

full of fuel.<br />

INSIDE THIS ISSUE<br />

4<br />

8<br />

14<br />

Return Undeliverable Canadian<br />

Addresses to:<br />

Equipment Review<br />

Suite 628<br />

440-10816 Macleod Trail, SE<br />

Calgary, Alberta<br />

T2J 5N8<br />

Publication Mail Agreement Number:<br />

41137025<br />

EMCO Waterworks<br />

ZCL Tanks<br />

With sustainable power consumption on<br />

the rise, ATCO and Siemens have teamed<br />

up to meet this ever growing demand. The<br />

Newell ATCO site near Brooks, Alberta<br />

has been a beehive of activity this year<br />

creating a convertor station that changes<br />

AC power to DC power, making the<br />

logistics of electrical transmission a reality<br />

for Albertans.<br />

20<br />

2 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013<br />

EQUIPMENT REVIEW 3

Custom Manufacturing and<br />

Dedicated Service<br />

DEL EQUIPMENT<br />

DEL Equipment Ltd. is a Canadian<br />

national truck equipment company<br />

with eight branches from coast to coast.<br />

Specializing in custom manufactured<br />

equipment, DEL Equipment’s dedicated<br />

teams and advanced facilities produce<br />

custom manufactured products designed<br />

to exceed customer expectations, and<br />

delivered on time. The company’s claim<br />

to, “Stand behind all the products we<br />

provide and service what we sell.” is one<br />

that DEL takes very seriously.<br />

In Alberta, DEL Equipment Ltd. was<br />

formerly known as CAYTEC Equipment.<br />

CAYTEC began business in 1985 in a<br />

10,000 square foot facility. CAYTEC<br />

was purchased by Diesel Equipment Ltd<br />

(DEL) out of Toronto in 2004. Today, DEL<br />

Equipment Ltd. occupies a 50,000 square<br />

foot manufacturing facility in Calgary, and<br />

a 22,000 square foot facility in Edmonton.<br />

The expansion of facilities was necessary to<br />

support the increasing amount of business,<br />

and to meet the demands of product supply<br />

and service. DEL Equipment Ltd. now<br />

employs more than sixty highly-trained<br />

staff in its Alberta locations.<br />

All of DEL Equipment’s facilities<br />

are certified under a designated<br />

National Safety Mark number (NSM)<br />

as an Intermediate and Final Stage<br />

Manufacturer. This requires that every<br />

truck up-fit performed at its facilities is<br />

done so in accordance with Transport<br />

Canada’s Standards for lighting, weight<br />

distribution and best practices.<br />

DEL’s experienced sales staff is always on<br />

hand to share its experience, knowledge<br />

and enthusiasm with customers. The<br />

company’s aim is to offer “One Stop<br />

Shopping”, with no need for customers<br />

to transport trucks to numerous locations<br />

for up-fitting. It also has a significant pool<br />

of OEM inventories of popular Ford, GM<br />

and Dodge models that are available to<br />

customers through dealers.<br />

DEL’s highly qualified technicians are<br />

committed to providing exceptional<br />

service in a timely manner. From crane<br />

re-certifications to hydraulic cylinder<br />

repairs, they are dedicated to maintaining<br />

top tier customer service. DEL has a long<br />

history of providing custom solutions<br />

for customer applications including:<br />

Construction, Oil & Gas, Landscaping,<br />

Industrial, Military, Snow & Ice Removal,<br />

Retail Delivery, Refuse Bin Movement,<br />

Rental Equipment Movement, Railroad<br />

Services, Utilities, Towing and Wrecker<br />

Recovery, and Service Industries such as<br />

HVAC, Mobile Repairs, Plumbing, etc.<br />

DEL provides a variety of custom built<br />

Computer-Aided Design (CAD) bodies.<br />

These are available in both steel and<br />

aluminum. DEL has the expertise to<br />

manufacture Crane Trucks and other<br />

products to a very high quality, at<br />

competitive pricing. It can also refurbish<br />

and reinstall Equipment and Service<br />

Bodies on current year chassis.<br />

The “EFFER” Advantage<br />

DEL Equipment Ltd. is an exclusive<br />

EFFER Dealer across Canada. EFFER<br />

is a world leader in crane manufacturing<br />

since 1965, with a highest power-toweight<br />

ratio amongst the best in the world.<br />

This enables a larger lifting capacity with<br />

less combined weight for more chassis<br />

payload, often having the ability to mount<br />

a crane with more “lift” without sacrificing<br />

safety. Lifting capacities of the EFFER<br />

cranes range from 2 txm to 300 txm, and<br />

DEL Equipment maintains a very large<br />

selection of cranes in its inventory.<br />

The company’s close relationship with<br />

EFFER has resulted in a successful<br />

combination of skills, team spirit and the<br />

delivery of many units that have more than<br />

proven their performance in the field.<br />

4 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 5

CUBEX<br />

Henke’s FVX-12 Folding Vee Plow<br />

For Mid and Heavy Duty Trucks<br />

Henke has combined two of its most<br />

innovative truck line products; the FVX<br />

multi- directional folding vee plow, and<br />

the industrial-style parallel lift plow to<br />

produce their latest in snow fighting<br />

equipment - the Henke Parallel-lift FVX-<br />

12 plow for mid and heavy duty trucks.<br />

The FVX-12 is designed to be used<br />

anywhere operators need to carry snow,<br />

with applications that include bridges,<br />

overpasses, bus stops, intersections,<br />

driveways, and more.<br />

The FVX-12 includes a center hinge<br />

that allows independent control of the<br />

left and right moldboards. This allows<br />

configurations such as the “Drift Buster”,<br />

where both moldboards have the cylinders<br />

retracted into a ‘Vee’ position, and the<br />

“Stacker”, where both cylinders are<br />

extended to Full Stroke configuring the plow<br />

in a scoop position. This allows the operator<br />

to stack the snow load, or where complete<br />

removal of snow is required the scoop<br />

position will help prevent side discharge.<br />

Henke undertook exhaustive testing and<br />

development in producing the FVX-12.<br />

A key operational plus is that when the<br />

operator is driving and lowering the unit<br />

the plow front cannot dive into the asphalt,<br />

as the rear must hit the surface initially.<br />

This was an extremely difficult function<br />

to design, and required all of Henke’s<br />

experience and expertise to perfect.<br />

Another key feature is the Industrial-style<br />

parallel lift. Very similar to that of an<br />

industrial grade, the parallel lift keeps the<br />

unit parallel to the road surface while still<br />

allowing for changes in the road contour.<br />

This is accomplished though adjustable<br />

oscillation tension screws. The flat plat<br />

hitch design is easy on trucks as it positions<br />

the plow closer to the truck, thus relieving<br />

some stress from the frame. The FVX-12<br />

requires less off season maintenance by<br />

eliminating the lift arm.<br />

Other features include an anti-swivel<br />

mechanism. When the unit is lifted<br />

a mechanical device is activated that<br />

prevents the unit from swiveling. This<br />

keeps the plow in place while lifting and<br />

allows it to follow the road contour while<br />

plowing. The lift cylinder and the reversing<br />

cylinders are identical parts, helping to<br />

reduce inventory in cases where operators<br />

want to carry stock replacement parts.<br />

The FVX-12’s rugged design is 41” tall with<br />

a 147” long moldboard and compression<br />

trip edge safety trip device. Vee mode width<br />

is 125.5”, angled is 121” wide, and scoop<br />

mode is 116” wide. An additional 28 bar of<br />

down pressure can be applied to the unit,<br />

this allows for removal of packed ice and<br />

also for removal of the hitch.<br />

An impressive display of Epokes pictured<br />

recently at the CUBEX Calgary facility.<br />

These units were awaiting delivery to the<br />

City of Calgary, along with an order of 15<br />

Henke Folding Vee Plows.<br />

6 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 7

• Remove bird baths, lower high spots,<br />

repair catch basins<br />

• Eliminate potholes, remove oil spots<br />

• Correct asphalt imperfections &<br />

alligator cracking<br />

• Thermoplastic installation<br />

• Printing Asphalt<br />

• Asphalt repairs can be made year-round<br />

• All units available Propane or Diesel<br />

When new asphalt is unavailable, stockpiled<br />

or used material can be loaded<br />

for reclaiming, resulting in hot mix<br />

availability year-round.<br />

will produce a quality batch (2,600 lbs.<br />

every 20 minutes) of asphalt from recycled<br />

pulverized asphalt, millings, or saw-cut<br />

materials to produce a patching material<br />

that will (according to KM) exceed<br />

Department of Transportation asphalt<br />

specifications and standards.<br />

IMI Appointed Distributor for<br />

KM International Industrial Machine<br />

Once softened and scarified, hot mix is<br />

added to bring the recycled area back<br />

to proper grade. Compacting produces<br />

a permanent hot patch level with the<br />

existing asphalt, and water seepage is<br />

eliminated because the repair is seamless.<br />

The procedure described can be used<br />

to repair large areas by sequentially<br />

moving the KM 4-40 or KM 4-48 over the<br />

damaged area.<br />

Features and benefits<br />

Four independent heating zones produce<br />

a very high yield of infrared energy per<br />

amount of propane expended. Utilize KM<br />

repair equipment for permanent yearround<br />

repairs. Save time and money by<br />

only visiting the jobsite once.<br />

Asphalt Hot Box Reclaimers<br />

KM 4000 / KM 8000<br />

The KM 4000 2-ton Hotbox is designed<br />

to slide into pick-up trucks. The KM 8000<br />

4-ton Hotbox is designed to fit on the back<br />

of a flat bed truck or trailer.<br />

Teamed with the KM Infrared and Asphalt<br />

Recyclers, KM Hotbox Reclaimers offer<br />

permanent asphalt repairs year-round.<br />

• Extend the working seasons with KM<br />

repair equipment.<br />

• The KM 4000 and KM 8000 allow<br />

work when plants are closed and are the<br />

perfect match to the Asphalt Recycler.<br />

• Operators no longer need to discard old<br />

asphalt.<br />

• Teamed with a KM Asphalt Recycler,<br />

operators can stockpile and recycle with<br />

a KM Asphalt Hotbox Reclaimer.<br />

Asphalt Recycling<br />

KM T2 Asphalt Recycler<br />

The KM International Asphalt Recycler<br />

The KM T2 Asphalt Recycler will<br />

produce:<br />

• Approx. (2.5) tons per hour using either<br />

broken, chunk, or milled asphalt<br />

• Using reclaimed asphalt and used<br />

asphalt shingles is not just “Green” but<br />

also “’Smart”<br />

• The cost savings are immediate<br />

• Operators can perfectly customize their<br />

asphalt blend by adding more or less<br />

asphalt shingles to every load<br />

For further information contact Industrial<br />

Machine at 780-944-6986, or visit:<br />

www.industrialmachine.ca<br />

Industrial Machine Inc.<br />

recently announced<br />

its appointment as<br />

distributor for KM<br />

International. KM<br />

manufactures superior<br />

quality asphalt<br />

maintenance equipment<br />

for contractors and<br />

government agencies.<br />

IMI is the sole distributor<br />

for KM in Alberta,<br />

Saskatchewan and<br />

British Columbia.<br />

Infrared Asphalt Heaters<br />

Why infrared?<br />

Why waste perfectly good asphalt when<br />

you can “Recycle and Repair”? Infrared<br />

provides a permanent repair with seamless<br />

welded edges and no saw cut joints that<br />

allow water seepage to quickly deteriorate<br />

repairs. It also avoids freeze/thaw issues<br />

that occur from traditional methods.<br />

Infrared is cost efficient and time saving<br />

as much less new asphalt required. With<br />

no unnecessary equipment, less manpower<br />

per repair, infrared is a green process that<br />

makes sense - and money. Operators can<br />

eliminate saw cutting, jack hammering,<br />

loading, trucking and disposal. According<br />

to KM, the Infrared Process takes one-half<br />

the time of traditional methods of Asphalt<br />

Repair. There is only one trip to the<br />

jobsite, with less noise and less mess.<br />

Typical Uses<br />

Trip hazards, paving “cold” seams,<br />

isolated failures, catch basins, manhole<br />

repairs, bird baths, potholes, utility cuts,<br />

decorative imprints and thermoplastic<br />

markings.<br />

These versatile infrared asphalt recyclers<br />

are designed for common occurring<br />

asphalt problems - repair improper seams,<br />

sunken utility cuts, lower elevated or<br />

buckled surfaces, refinish manholes,<br />

potholes or other broken areas.<br />

The penetrating infrared rays of the<br />

recyclers quickly soften the existing<br />

asphalt without burning. Typically the top<br />

1 1/2” to 2” of asphalt is ready for raking<br />

within 7 - 10 minutes.<br />

Thermostatically controlled heat allows<br />

minimum propane consumption while<br />

keeping asphalt at working temperature<br />

for up to 3 days.<br />

• Reclaim asphalt within 8 to 10 hours,<br />

material is ready for use<br />

8 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 9

Alberta Traffic Supply<br />

SnowEx’s New Rotary Broom<br />

Provides Versatile Solution for<br />

Sidewalk Applications<br />

By Jeff Adolf, Alberta Traffic Supply<br />

SnowEx has recently introduced a<br />

versatile new walk-behind rotary broom<br />

with a plow attachment for snow removal<br />

and other cleanup applications. Powered<br />

by a 160cc Honda GXV Series engine, the<br />

SS-4000 is designed to provide maximum<br />

productivity for sidewalk applications.<br />

The SS-4000 features a floating pivotal<br />

broom head with five angle settings<br />

to adjust the trajectory of snow and<br />

other materials. The 16-inch-diameter<br />

broom is centrally driven, allowing the<br />

unit to work against curbs, walls and<br />

other obstacles from either the left - or<br />

right-hand side. Brush rotation speed is<br />

infinitely adjustable, and down pressure<br />

can be increased or decreased by raising or<br />

lowering the pneumatic support wheel.<br />

For heavier snow conditions, the operator<br />

can install a front-mounted blade<br />

attachment, which comes standard with the<br />

SS-4000. The 40-inch blade uses a unique<br />

pin system for easy installation and removal.<br />

Operation is simple, thanks to userfriendly<br />

controls and seven-position height<br />

adjustment of the handlebars. The unit<br />

offers three forward gears and one reverse<br />

gear, and a locking differential helps<br />

the machine drive in a straight path. A<br />

freewheel feature is also included to allow<br />

easy 360-degree turning.<br />

The frame of the SS-4000 folds for<br />

easy storage, and the wheels are easily<br />

removable. Other standard features include<br />

winter-tread tires and a corrosion-resistant<br />

paint finish. Optional equipment includes<br />

a debris collector box for catching material<br />

during cleanup applications.<br />

The SS-4000 is backed by an industryleading<br />

two-year warranty.<br />

10 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 11

SnowEx SP-8500/8550:<br />

Snow & Ice<br />

Control<br />

Solutions for<br />

Municipal<br />

Supervisors<br />

Designed for use with pickups (8-foot<br />

beds or larger), flat-bed trucks and<br />

dump-bed trucks, the V-Maxx 8500 from<br />

SnowEx features a patented multi-angle<br />

hopper combined with an inverted “V”<br />

salt/sand baffle and attached vibrator<br />

that allows for continuous material flow,<br />

no matter what is being spread. From<br />

100-percent salt to 100-percent sand, the<br />

V-Maxx can spread a combination of<br />

material effectively and efficiently.<br />

The V-Maxx 8500 comes with a 2.2<br />

cubic yard capacity polyethylene hopper<br />

to eliminate corrosion concerns and<br />

constant maintenance. It is powered by a<br />

½-horsepower, high-torque commercial<br />

continuous-duty 12-volt electric drive<br />

system, and it produces an impressive<br />

1,800 inch-pounds of torque at the auger<br />

transmission output shaft. This fully<br />

electric design means there are no engines,<br />

pulleys, sprockets, belts or chains, which<br />

provides for low-maintenance, worry-free<br />

operation. The only difference between the<br />

SP-8500 and SP-8550 is the 8550 spreads<br />

295 to 680 pounds of material per minute,<br />

double the rate of the V-Maxx 8500.<br />

The independent spinner/auger controller<br />

makes the SnowEx V-box-style spreader<br />

user-friendly. The cab-mounted controller<br />

allows for both independent spinner speed<br />

and an infinitely adjustable ratio between<br />

the spinner and auger, maximizing material<br />

use. Spread width is variable between 5 to<br />

40 feet. A digital system LED display with<br />

status monitoring and system protection<br />

is standard as well as an auto-reverse<br />

function in the event of auger jams.<br />

Furthermore, as with all SnowEx V-boxstyle<br />

spreaders, the V-Maxx 8500 is built<br />

with a Quick-Pin hitch for fast and easy<br />

spinner assembly removal. Compared<br />

with some competitive models that require<br />

the spreader assembly to be unbolted<br />

or for the entire spreader to be removed<br />

from the truck’s bed before being able<br />

to tow, the Quick-Pin hitch allows the<br />

conversion to take place in a matter of<br />

seconds. The feature effectively makes the<br />

service vehicle more useful, not having to<br />

be dedicated to one function, while also<br />

simplifying off-season spreader storage.<br />

Product Highlights:<br />

• Patented polyethylene hopper to<br />

eliminate corrosion<br />

• Longitudinal auger for superior material<br />

flow<br />

• Independent spinner and auger controls<br />

• Quick-connect drop chute spinner assembly<br />

SnowEx, an authority in ice control, has a<br />

full line of salt spreaders, sand spreaders,<br />

de-icing sprayers, and snow brooms with<br />

capacities to meet any size and need.<br />

Salt-Traxx Digital Job Tracker<br />

SnowEx’s new Salt-Traxx is an innovative<br />

tracking device that works with select<br />

models of V-Maxx spreaders, including<br />

the SP-8500. It plugs into the spreader’s<br />

existing controller and records useful<br />

jobsite data, such as time spent and amount<br />

of salt used. This information is saved to<br />

a standard removable USB memory stick,<br />

and at the end of the day, all information<br />

can be uploaded to a personal computer<br />

in a format compatible with Microsoft<br />

Excel. With the Salt-Traxx, snow and ice<br />

professionals can closely evaluate their<br />

operations and create better documentation<br />

for billing and liability purposes.<br />

SnowEx is a product division of TrynEx<br />

International. Other TrynEx brands<br />

include TurfEx turf care equipment and<br />

SweepEx broom attachments.<br />

For more information, contact Alberta<br />

Traffic Supply, an authorized SnowEx<br />

dealer, or visit www.AtsTrafficGroup.com<br />

12 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 13

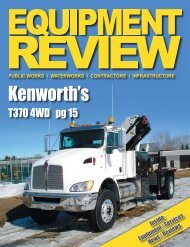

Greatwest Kenworth<br />

The New<br />

Kenworth<br />

T880<br />

Vocational<br />

A balance of form, function<br />

and flexibility<br />

Custom-engineered from bumper to taillight,<br />

the T880 is the most versatile vehicle to<br />

ever roll off a Kenworth assembly line.<br />

Distinctively Kenworth, this bold new<br />

truck is as comfortable hauling 140,000<br />

pounds over the Rockies as it is navigating<br />

city streets with a tanker full of fuel. It’s<br />

a sound choice as a dump truck, lowboy,<br />

logger, concrete mixer, refuse transporter,<br />

construction or oil field service vehicle. The<br />

T880 can shoulder maximum payload with<br />

minimum tare weight, and move loads over<br />

terrain and through job sites operators could<br />

not negotiate with other vehicles.<br />

With a low sloped hood and wide open<br />

visibility, the T880 sports a do-anything,<br />

go-anywhere attitude that takes it easy<br />

on the driver. Available in 122.5-inch and<br />

116.5-inch BBC models, operators can select<br />

from a variety of specialized options to get<br />

exactly what they need for specific payload<br />

and operating requirements. There’s even a<br />

sleeper option to enhance flexibility, comfort<br />

and lifestyle.<br />

Keeping the driver informed,<br />

in control and on schedule<br />

If knowledge is power, according to<br />

Kenworth, this is one of the most powerful<br />

work truck users have ever seen, featuring<br />

groundbreaking technology that clarifies<br />

and enriches the driving experience like<br />

never before. Kenworth’s exclusive leatherwrapped<br />

SmartWheel multifunction<br />

steering wheel puts the most frequently<br />

used controls right under the driver’s<br />

fingertips. High-definition instrumentation<br />

includes crisply detailed virtual gauges that<br />

deliver real-time information at a glance<br />

in all lighting conditions. And Kenworth<br />

NavPlus — a revolutionary driver interface<br />

and productivity tool — seamlessly<br />

integrates vehicle navigation, entertainment,<br />

diagnostics and cutting-edge communication<br />

into a single intuitive full-color touchscreen.<br />

A quiet, spacious, state-ofthe-art<br />

control center<br />

Inside the handsome exterior of the T880 is a<br />

quiet, spacious, state-of-the-art control center<br />

that fits professionals of every shape and<br />

size. The superior quality, craftsmanship, fit<br />

and finish of the wide and wide-open interior<br />

is easy to see, but it’s the driving experience<br />

that truly distinguishes the T880.<br />

The Paccar MX-13 Engine<br />

At the heart of the T880 is a fully optimized<br />

and integrated drivetrain featuring the<br />

quality and proven reliability of the<br />

PACCAR MX-13 engine. These highly<br />

efficient, clean running engines deliver up to<br />

500 hp and 1,850 lb-ft of torque. In addition<br />

to exceptional fuel economy, the PACCAR<br />

MX-13 employs innovative high-strength<br />

yet lightweight components and premium<br />

materials to achieve superior durability and<br />

power-to-weight performance.<br />

The technologically advanced design<br />

reduces in-cab noise levels significantly for<br />

a more comfortable driving environment.<br />

Selective Catalytic Reduction (SCR) in<br />

combination with exhaust gas recirculation<br />

(EGR) enables the PACCAR MX-13 to<br />

boast near-zero emissions. The bottom line<br />

is Kenworth claims longer service intervals,<br />

increased uptime, lower operating costs and<br />

higher resale value.<br />

For further information contact your local<br />

Greatwest Kenworth branch, or visit:<br />

www.greatwestkenworth.com<br />

14 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 15

Prairie Hydraulic Equipment<br />

Viking-Cives Winter Maintenance<br />

Equipment and Accu-Cast Sand<br />

and Liquid Systems<br />

Viking-Cives Group has<br />

been manufacturing<br />

Snow and Ice Equipment<br />

for forty years. With<br />

manufacturing facilities<br />

in Canada and the<br />

United States, Viking-<br />

Cives continues to bring<br />

innovative solutions<br />

to an ever changing<br />

industry. Prairie<br />

Hydraulic Equipment,<br />

having the same focus<br />

and values, has been<br />

representing these<br />

products and systems<br />

for almost fifteen years.<br />

Prairie Hydraulic Equipment Ltd. (PHE)<br />

has been manufacturing and distributing<br />

Sanding and Liquid controls for road<br />

maintenance applications for over twenty<br />

five years. PHE started developing its own<br />

control systems in the early 1990’s and<br />

continues to introduce products under the<br />

Accu-Cast brand name.<br />

Together Viking-Cives and PHE combined<br />

their innovative products and systems to<br />

provide road maintenance solutions to<br />

municipal and rural customers, as well as<br />

large highway contractors - from light duty<br />

applications to large highway requirements.<br />

From concept to delivery commitment to<br />

its customers is total, as well as aftermarket<br />

product and technical support. Shop and<br />

field technicians are fully trained and<br />

experienced on all its products and systems.<br />

Plows and Plow Harnesses<br />

Viking manufactures and distributes a full<br />

line of plows from light-medium duty to<br />

heavy duty:<br />

One-way plows, Power Reversing<br />

Two-way plows, Underbody Scrapers,<br />

Underbody Salt Saver Finger plows, Flex<br />

plows, Extendable Front plows, and Sidemounted<br />

Wing plows and Airport plows.<br />

Front plows are available with various<br />

cutting edge lengths from 10ft to 24ft.<br />

These are available in full trip and trip<br />

edge configurations. Side mounted wings<br />

from 8ft to 12ft cutting edges.<br />

Viking manufactures numerous Plow<br />

Harness systems that are designed to meet<br />

regional and application standards with<br />

mounting hardware designed specifically<br />

for each type of truck chassis.<br />

Kuper Plow Blades<br />

PHE distributes Kuper Plow Blades<br />

offering a variety of Carbide and Rubber<br />

options coupled with advanced Kueper<br />

blade technology. These blades come in<br />

standard lengths and bolt patterns to fit all<br />

North American manufactured plows.<br />

Tow Plows<br />

Viking has over 450 Tow Plows in service<br />

going into the 2013-2014 winter season.<br />

There will be 8 units working in British<br />

Columbia amongst three of the province’s<br />

highway contractors. In Alberta there<br />

are 7 units working on the ring roads<br />

around Edmonton and Calgary along with<br />

additional units on major highways.<br />

The Viking Tow Plow is available in left or<br />

16 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 17

ight hand configurations and with options<br />

including an 8yd Sander or Anti-Ice System.<br />

The Tow Plow greatly increases plowing<br />

capability while reducing operational<br />

costs, allowing for clearing path widths of<br />

26ft and higher - depending on main tow<br />

vehicle plow configuration.<br />

“V” Hopper Sanders<br />

Viking manufactures a full line of Front or<br />

Rear Discharge sanders. Slide-in sanders<br />

or Fame-mount sanders from 6 cubic yard<br />

to 20 cubic yard capacity in Stainless Steel<br />

or Corten Steel.<br />

Various options tailored to customers’<br />

needs are available such as different<br />

lighting options specific to regional<br />

requirements, tarp systems, vibrators,<br />

cab shields, discharge chute and spinner<br />

configurations<br />

Combination Sanders (“U”<br />

Body)<br />

Viking’s Proline Series bodies offers<br />

features such as Full Radius Design,<br />

Auto Chain Adjustment, Front or Rear<br />

discharge, with capacities from 6 cubic<br />

yards to 20 cubic yards and available in<br />

Corten Steel, Aluminum, Hardox and<br />

Stainless Steel.<br />

Also, various options tailored to<br />

customers’ needs are available such as<br />

different lighting options specific to<br />

regional requirements, Tarp systems,<br />

Material Screens, Vibrators, Cab<br />

Shields, Discharge Chute and Spinner<br />

configurations, Cross Conveyors, Side<br />

mounted Discharge Conveyors, Belt and<br />

Conveyor Chain options, etc.<br />

Roll-Off Systems<br />

Viking manufactures multi-use roll-off<br />

systems with options including Sanders,<br />

Liquid Tanks, Flat Decks and Refuse Bins.<br />

Accu-Cast Products<br />

Under the Accu-Cast Label, PHE offers<br />

a variety of in-cab controllers from on/<br />

off manual through to full proportional<br />

closed loop systems with one of the most<br />

comprehensive list of standard features in<br />

the market. Other products such as Accu<br />

-Cast Power Float, Hydraulic Valve and<br />

Tank Packages, Prewet Packages, Anti-<br />

Ice Packages, Road Temperature Sensors,<br />

Guidance Lasers, AVLS (GPS) Solutions<br />

and many more are available.<br />

For further information contact Prairie<br />

Hydraulic Equipment.<br />

18 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 19

PROJECT PROFILE: EMCO Waterworks<br />

ZCL Tanks Provide the Solution<br />

for ATCO/Siemens Project<br />

“…making the<br />

logistics of electrical<br />

transmission a reality<br />

for Albertans.”<br />

By Chad Placsko, Water Management<br />

Specialist, EMCO Waterworks, Calgary<br />

With sustainable power consumption on<br />

the rise, ATCO and Siemens have teamed<br />

up to meet this ever growing demand. The<br />

Newell ATCO site near Brooks, Alberta<br />

has been a beehive of activity this year<br />

creating a convertor station that changes<br />

AC power to DC power, making the<br />

logistics of electrical transmission a reality<br />

for Albertans.<br />

The project itself was an exciting challenge<br />

for the owners, the engineers working on<br />

the system, and the contractor that was<br />

hired to make this plan a reality. As the<br />

location of the site was remote, each aspect<br />

of the project needed to be calculated<br />

carefully. EMCO Waterworks in Calgary<br />

was charged with the responsibility to<br />

“Project Manage” the purchasing and<br />

supply of most of the project items<br />

required, including twelve large ZCL<br />

Fiberglass tanks. ZCL tanks were<br />

chosen for a variety of reasons. They are<br />

watertight, lightweight, easy to install, and<br />

corrosion resistant. ZCL’s unique outside-in<br />

fabrication process and fully integrated rib<br />

structure result in tanks that can withstand<br />

the pressures of being submerged in water<br />

to grade while empty with simultaneous<br />

H-20 traffic loads. Being underground these<br />

tanks don’t take up valuable land space<br />

and eliminate concerns relating to frost and<br />

freezing. Unlike above-ground tanks that<br />

can create a negative visual impact, the<br />

ZCL tanks also make the property more<br />

aesthetically pleasing.<br />

Seven of the ZCL tanks were used as part<br />

of the project’s fire suppression system - a<br />

holding tank system allowing for nearly<br />

a million liters of emergency and fire<br />

suppression water to be pumped through<br />

almost a kilometer of IPEX pipe. The<br />

system creates a fire loop that feeds eight<br />

separate hydrants. The largest of the tanks<br />

measures over 70 feet long and 10 feet in<br />

diameter. Using a trombone trailer, Spruce<br />

Valley Carriers transported the tanks<br />

which were delivered to the site and then<br />

craned into place. The tanks are connected<br />

through a header system that feeds a 16”<br />

pump that pressurizes the system, on<br />

standby and ready for usage as required.<br />

Two of the remaining five tanks were<br />

designed for both a potable water holding<br />

system and a centralized septic holding<br />

tank, and three of the tanks were designed<br />

to handle the septic drainage associated<br />

with individual buildings around the site.<br />

The ZCL tanks are anchored to the ground<br />

with an engineered system of precast<br />

concrete anchors and specially fabricated<br />

fiberglass straps allowing them to stay in<br />

place after backfill, even when empty. The<br />

fourteen straps holding down the largest<br />

of the tanks are attached to the concrete<br />

anchors with turnbuckles. The tanks<br />

themselves are a single-walled design,<br />

fabricated with vents and “manways” to<br />

allow access and entry if needed. The grid<br />

of seven tanks is tied together with a header<br />

to equalize the levels as well as to drain<br />

them evenly if needed in an emergency.<br />

Water is a growing concern for many<br />

projects such as this. The ability to be<br />

self-sufficient in this regard was of vital<br />

interest to ATCO and Siemens. The ZCL<br />

tanks allow each water-related step of this<br />

project to be maintained and sustained for<br />

years to come.<br />

PROJECT PARTNERS<br />

Owner: ATCO Electrical<br />

Prime Contractor: Siemens Canada<br />

Electrical / Civil General: Black &<br />

McDonald, ON<br />

Civil Contractor: Four Season Site<br />

Development, ON<br />

Tank Supplier: EMCO Calgary<br />

For more information on this project or the<br />

tanks shown, contact your local EMCO<br />

Waterworks location.<br />

20 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 21

Commercial Truck Equipment<br />

MONROE WINTER ROAD<br />

MAINTENANCE EQUIPMENT<br />

The Monroe Truck Equipment Snow & Ice Division has been manufacturing quality equipment since<br />

1983. It markets and services products throughout the world and has an international network of<br />

distributors in the USA and Canada. Monroe manufactures a complete line of winter road maintenance<br />

equipment and is represented in western Canada by Commercial Truck Equipment.<br />

Specifications include all those listed<br />

for the straight reversible plows with the<br />

main difference of a ‘No Trip’ feature,<br />

heights of 30” and 39”, and discharges<br />

of 47”, 52”, and 66”. One Way plows are<br />

also available in fixed angle or reversible<br />

with an adjustable moldboard pitch. They<br />

are manufactured in 100% continuouslywelded<br />

moldboard and with heavy duty,<br />

4-point hinged push-frames.<br />

SPREADERS<br />

PLOWS<br />

Full Trip Straight Reversible Plows<br />

Monroe straight reversible plows feature a<br />

full list of advanced specifications. Slotted<br />

Trip, Compression Trip Edge, and Torsion<br />

Trip Edge plows are available in 10’, 11’,<br />

and 12’ lengths, with available heights of<br />

36”, 41”, and 48”. Durability is provided<br />

with horizontal bracing and a heavy duty<br />

3/4” x 4” x 4” bottom angle.<br />

The cutting edge is 5/8” x 8”, AASHTO<br />

top punched. Durable compression<br />

springs, heavy duty 4-point hinged<br />

pushframe, various light packages, two<br />

double-acting 3” x 10” reversing cylinders<br />

with adjustable Chevron packing,<br />

crossover relief valve, ship and car<br />

channel A-frame, and abrasion-resistant<br />

hoses with steel clamps complete the long<br />

list of standard features.<br />

Monroe’s Full Trip One Way Plows<br />

One way plows incorporate the same<br />

rugged design characteristics as straight<br />

reversible plows.<br />

Pickup V-Box<br />

The Monroe Pickup V-Box Spreader is<br />

available for light duty vehicles including:<br />

3/4-ton pickups, 1-ton and HD-Super<br />

Duty with flatbed or dump body, and<br />

Pull-behind trailer mount. Spreaders are<br />

available in mild steel, and 304 stainless<br />

steel. A choice of engine-driven or<br />

hydraulic-driven units are available.<br />

22 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 23

Pickup V-Box Features:<br />

• 4-bolt relubeable bearing<br />

Options:<br />

• Inverted V<br />

• Hold down kit<br />

• Vertical hopper extensions<br />

• 7’ and 10’ lengths<br />

• Electric throttle control<br />

• Battery<br />

• Center high-mount stop light<br />

• Hydraulic drive auger in lieu of chain<br />

MSV and MV V-Box Spreaders<br />

The Monroe V-Box Spreader is designed<br />

and built for long lasting, heavy duty,<br />

reliable service. Both models, MSV and<br />

MV, are available in mild steel, and 304<br />

stainless steel with 100% continuouslywelded<br />

construction. A choice of slidein<br />

or chassis-mount is offered, in sizes<br />

ranging from 8’ to 17’.<br />

MSV Features :<br />

• Tip-up spinner assembly<br />

• 4-bolt flange bearings<br />

• 2” idler shaft<br />

• Spring-loaded chain take-up bearing<br />

• Front and rear wipers<br />

• Rear diverter chute<br />

• Replaceable chain shields, 10 gauge<br />

• 3/8” x 1-1/2” bar flights<br />

• 50:1 or 25:1 gearbox with 2” drive shaft<br />

• Top screens<br />

MV Features :<br />

• Bolt-on spinner assembly<br />

• 4-Bolt flange bearings<br />

• 1-1/2” idler shaft<br />

• Spring-loaded chain take-up bearing<br />

• Front and rear wipers<br />

• Rear diverter chute<br />

• Formed chain shields, 10 gauge<br />

• 1/4” x 1-1/2” bar flights<br />

• 50:1 or 25:1 gearbox with 1-1/2” drive<br />

shaft<br />

• Top screens<br />

Pre-wetting Systems<br />

Pre-wetting is increasing in popularity<br />

with up to 40% savings in granular<br />

materials being reported when pre-wetting<br />

with liquids deicing chemicals.<br />

Pre-wetting Systems Features:<br />

• Hydraulic and electric systems available<br />

• 15 to 400 gallon tank capacities<br />

• Simple on/off systems to closed-loop<br />

system<br />

• Mounting hardware available in powdercoated<br />

mild steel or stainless steel<br />

For more information contact your local<br />

branch of Commercial Truck Equipment,<br />

or visit: www.comtruck.ca<br />

24 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 25

Komatsu’s “Intelligent<br />

Machine Control”<br />

Dozer<br />

The D61EXi/PXi-23 is Komatsu’s first<br />

intelligent Machine Control model to the<br />

North American market. Due to its first<br />

fully automatic blade control, the D61i-23<br />

dozer can perform not only finish grading,<br />

which has been possible with conventional<br />

Machine Control, but also rough dozing.<br />

As a result, it achieves outstanding<br />

improvement in productivity. According<br />

to Komatsu, this is the first machine using<br />

this new innovative technology, and it is<br />

scalable to other products manufactured<br />

by Komatsu.<br />

Longer track-on ground standard (EX)<br />

and low ground pressure (PX) models are<br />

available to offer customers flotation and<br />

weight distribution options that best match<br />

their applications. Operating weights range<br />

from 39,441 lbs. to 41,381 lbs. depending<br />

on the configuration with a net 168HP<br />

at 2200 rpm. The D61i-23 also features<br />

the integration of Komatsu’s proprietary<br />

KOMTRAX (Komatsu Machine Tracking<br />

System) and TOPCON’s construction<br />

management system. In the near future,<br />

this integrated system will enable highefficiency,<br />

unified management of<br />

construction work through access to realtime<br />

machine data, via its web service, to<br />

track work progress including the amount<br />

of soil dozed at jobsites.<br />

Fully Automatic Blade Control for<br />

Rough and Fine Dozing<br />

While crawler dozers have been able to<br />

perform high-precision finish grading<br />

after installing an add-on machine<br />

control system, the D61i-23 can perform<br />

rough dozing as well as finish grading<br />

in automatic mode, thanks to its fully<br />

automatic blade control. When rough<br />

dozing, the automatic blade control<br />

monitors blade load and adjusts blade<br />

elevation to minimize track slip and<br />

perform high-efficiency dozing. As work<br />

progresses closer to the target finish<br />

grade, the automatic blade control adjusts<br />

accordingly to provide finish grade<br />

performance with high-level precision.<br />

Komatsu claims that improvement in<br />

combination rough dozing efficiency is<br />

up to 13% higher compared to add-on<br />

machine control systems.<br />

Standard Factory-installed Integrated<br />

Machine Control System<br />

With the D61EXi/PXi-23, typical addon<br />

machine control system components<br />

mounted on the blade have been replaced<br />

with factory-installed cab top GNSS<br />

(Global Navigation Satellite System)<br />

antenna, enhanced inertial measuring unit<br />

(IMU+), and stroke sensing hydraulic<br />

cylinders. These components along<br />

with the machine control monitor and<br />

controllers mounted inside of the cab are<br />

installed at the Komatsu manufacturing<br />

facility during machine assembly, ensuring<br />

a quality installation with reliability.<br />

Intelligence: Enhancements for<br />

Optimized Performance<br />

Inside the cab, customer selectable dozing<br />

modes allow system response to be tailored<br />

to the current machine operation for<br />

optimized performance. Similarly, blade<br />

load settings are adjustable between pre-sets<br />

to match actual material conditions. Pass to<br />

pass, the intelligent Machine Control system<br />

can be left with the automatic blade control<br />

engaged because of its ability to precisely<br />

automate the lowering of the blade at the<br />

start of a pass and raise it at the end of a pass.<br />

When the machine travels around the job<br />

site, the cab top GNSS antenna collects<br />

accurate surface data by measuring actual<br />

elevations. The stroke sensing angle<br />

cylinder measures the actual angle of the<br />

blade for high precision grading accuracy<br />

on cross-slope, blade angled or not.<br />

KOMTRAX<br />

The D61i-23 crawler dozer is equipped<br />

with the latest KOMTRAX technology,<br />

which is fully integrated with Komatsu’s<br />

Tier 4 technology and sends machine<br />

operating information to a secure website<br />

utilizing wireless technology. Hour<br />

meter, location, cautions, load ratio, fuel<br />

consumption and maintenance alerts – to<br />

name a few of its features – are relayed to<br />

the web application for analysis.<br />

For further information contact your local<br />

SMS Equipment branch.<br />

26 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 27

Polar Mobility Research<br />

Polar on<br />

the<br />

Expansive new facility meets growing<br />

demand for products and services<br />

Since 1981 Polar Mobility Research has<br />

been dedicated to the design, manufacture<br />

and distribution of Air Conditioning,<br />

Heating and Ventilating systems for<br />

heavy-duty mobile equipment including<br />

highway trucks, off-highway vehicles,<br />

oilfield equipment, boom trucks,<br />

logging machinery, military and mining<br />

equipment. Polar specializes in custom<br />

design and manufacture of unique and<br />

special purpose HVAC solutions.<br />

Due to the continued growth experienced<br />

by Polar a dramatic expansion in service<br />

and manufacturing capability was<br />

required. As of November, Polar will be<br />

moving to a new, custom designed facility<br />

in Calgary. Providing more than double<br />

its existing capacity, the new building will<br />

provide Polar with a significant increase<br />

in office and warehousing space, along<br />

with a similar expansion in shop floor<br />

area. The facility also features a 2-acre<br />

secured fenced yard for customer vehicle<br />

storage. The expanded manufacturing<br />

and warehousing area will allow Polar<br />

to warehouse more product and parts<br />

inventory, and better service customer<br />

requirements. It will also facilitate the<br />

research, development and manufacture of<br />

Polar’s own custom line of HVAC products.<br />

With increased parking, easier access<br />

and the capacity to handle future growth<br />

Polar is excited to announce this major<br />

investment in the company’s future.<br />

The new facility is located at 7860-62<br />

Street, South East in Calgary.<br />

28 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 29

SINGLETON EQUIPMENT<br />

Can you hunt squirrels with<br />

an elephant gun?<br />

By John Singleton, Singleton Equipment, LLC<br />

Whoever coined the phrase, “Out of sight,<br />

out of mind” must have been thinking<br />

about water distribution systems. Most of<br />

us take our water provider for granted -<br />

we turn on the tap, water comes out. No<br />

big deal, right? For water professionals,<br />

it’s a very big deal. Underneath the very<br />

ground we walk on is a vast network of<br />

water pipelines. Even in small cities it’s<br />

not usual to find water pipelines large<br />

enough for a man to crawl through. In<br />

large cities, those pipelines are literally big<br />

enough for a car to drive through. Water<br />

distribution systems must have provisions<br />

to isolate a particular section of pipeline<br />

for maintenance purposes. That’s where<br />

valves come in. After a valve has been in<br />

service for a few years, mineral deposits<br />

and rust (technically called tuberculation)<br />

can bond to the internal parts of the valve,<br />

causing operational problems. The easiest<br />

way to make sure these critical valves will<br />

operate is to exercise them.<br />

Exercise?... Yes! Valves need exercise<br />

just like people. Sadly, we have a limited<br />

desire to exercise our bodies, and even<br />

less desire to exercise water distribution<br />

valves. Why? It’s hard work and takes<br />

precious time.<br />

Generally speaking, valve exercising<br />

equipment has been an expensive<br />

and cumbersome endeavor. Several<br />

companies offer truck or trailer mounted<br />

valve exercising equipment capable of<br />

generating huge amounts of torque. Those<br />

with valves big enough for a car to drive<br />

through may need machines like that,<br />

but what about the vast majority of small<br />

water departments around the globe? Our<br />

research suggests the average small city<br />

water system generally has valves from 4”<br />

to 16”. In addition, they usually don’t have<br />

a huge equipment budget that can handle<br />

a valve exerciser which could easily cost<br />

more than $30,000. If, and when, they<br />

exercise their valves, it’s usually done<br />

by an unlucky guy with a T-handle valve<br />

wrench. There’s another very important<br />

factor to mention as well. Even if your<br />

water crew never exercises a valve, they<br />

will absolutely have to close valves,<br />

sometimes large valves, to do maintenance<br />

downstream. I remember going out to do<br />

a demonstration in a medium sized city<br />

that had a 36” valve and two 30” valves<br />

that had to be shut down one morning for<br />

maintenance. Their crew had manually<br />

closed the 36” valve the day before, but it<br />

took 10 guys an hour, taking turns, to close<br />

the valve. I closed the same valve, working<br />

alone with a Valve Boss Model 70, in 11<br />

minutes. Needless to say, the prospective<br />

customer is now a Valve Boss owner.<br />

The agility of a handheld, totally portable<br />

valve operator/exerciser can make an<br />

overburdened water tech’s job much easier.<br />

Can you hunt squirrels with an elephant<br />

gun? Sure, but why not use a .22? It’s all<br />

about using the right tool for the job. Even<br />

water departments that have large truck<br />

or trailer mounted valve operators might<br />

quickly find out they can save precious<br />

time by using a portable, handheld machine<br />

to exercise and operate their valves before<br />

dragging out the elephant gun.<br />

For further information on Valve Boss<br />

Valve Operation Equipment visit:<br />

www.valveboss.com<br />

30 EQUIPMENT REVIEW<br />

ALL NEW www.equipmentreview.ca<br />

Fall 2013 EQUIPMENT REVIEW 31