Kenworth’s

Kenworth's - Equipment Review Magazine

Kenworth's - Equipment Review Magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

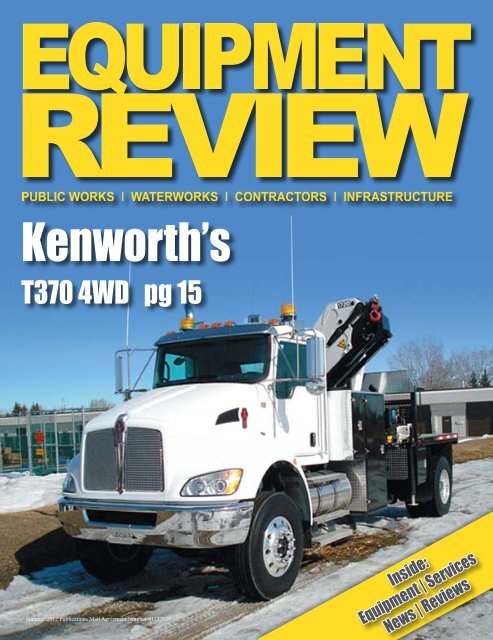

<strong>Kenworth’s</strong><br />

T370 4WD pg 15<br />

Summer 2012 Publications Mail Agreement Number 41137025<br />

Inside:<br />

Equipment | Services<br />

News | Reviews

A Safe Work Zone ... Is A Smart Work Zone!<br />

• Solar Powered Message Boards • Arrowboards • Radar Trailers • Traffic Lights • Camera Trailers •<br />

Full-Size, Solar Powered<br />

PCMS-1500 Full Matrix<br />

Full-Size, Solar Powered<br />

PCMS-1210, Text Matrix<br />

Mid-Size, Solar Powered<br />

PCMS-320 Full Matrix<br />

Available In<br />

RGB<br />

Compact, Solar Powered<br />

PCMS-548 Full Matrix<br />

Available In<br />

RGB<br />

Radar Speed Display Trailer<br />

SP-715<br />

Summer Edition 2012<br />

Volume 2 Number 3<br />

Published by:<br />

EQUIPMENT REVIEW INC.<br />

Editorial and Advertising Office<br />

Suite 628,<br />

440-10816 Macleod Trail S.E.<br />

Calgary, Alberta<br />

Canada T2J 5N8<br />

Telephone: (403) 238-8663<br />

email: jerry@equipmentreview.ca<br />

Cover – Kenworth T370 4WD<br />

This truck is engineered with body<br />

builders in mind. The transfer case is<br />

mounted strategically to not interfere with<br />

the placement of a body. Consequently,<br />

the T370 AWD is perfectly suited for<br />

flatdecks, cranes or plows. Municipalities,<br />

construction, oilfield and many other<br />

industries are potential customers for this<br />

tough and reliable four wheel drive. A<br />

variety of wheel bases and GVW ratings<br />

are available…<br />

15<br />

Sales<br />

&<br />

NTCIP<br />

Compliant<br />

Rentals<br />

*PCMS Units Only<br />

Full-Size Trailer-Mounted Traffic Lights<br />

TLD-3612 Solar-Powered<br />

Semi-Permanent / Permanent Message Signs<br />

Smart Work Zones:<br />

A Portable Solution for Improving Western Canadian Work Zones<br />

((((((((((((((((((((((((<br />

Closed Circut Camera Trailer<br />

CT-2430 Solar-Powered<br />

))))))))))))<br />

(((((((((((((((((((<br />

Solar Powered Arrowboard Trailer<br />

ST-4825 (Mast) & ST-4825 (Cage)<br />

Mid-Size Trailer-Mounted Traffic Lights<br />

TLD-2312 Solar-Powered<br />

))))))))))))<br />

Battery-Powered, Trolley-Mounted Traffic Lights<br />

TLD-1312 & TLD-1312-FLAGGER<br />

Vehicle Mounted Arrowboard<br />

VM-306025<br />

Alberta Traffic Supply provides the equipment, technology<br />

and expertise to help make your work zones smarter ... resulting<br />

in safer roads for motorists, roadworkers and pedestrians.<br />

MANAGE YOUR ENTIRE PCMS FLEET WITH JAMLOGIC<br />

JAMLOGIC SOFTWARE. Boost efficiency and productivity with JamLogic,<br />

the most sophisticated, complete and user-friendly message sign management<br />

tool on the market.<br />

WORK BETTER, FASTER. WORK BETTER, FASTER. Every message sign<br />

equipped with a wireless modem that allows instant internet or server access<br />

to all your signs and data. As a result, you can:<br />

Manage all your signs from any location<br />

Keep track of all your equipment with GPS mapping<br />

Communicate with several signs at once<br />

Monitor power and communication levels remotely<br />

Receive email alerts for low battery and theft<br />

Interface with any project from a single screen<br />

Publisher / Editor<br />

Jerry Skinner<br />

Circulation / Reader<br />

Matters concerning additions, deletions,<br />

address changes etc.<br />

- please use regular mail to contact us at<br />

the address above.<br />

“EQUIPMENT REVIEW”<br />

provides, in good faith, information<br />

that is believed to be accurate about<br />

new products and services. However,<br />

no responsibility is assumed for<br />

inaccuracies or errors, nor should legal<br />

or professional advice be assumed<br />

from our text. Written permission<br />

from the Publisher is required for the<br />

commercial reproduction of any part of<br />

this magazine.<br />

Printed in Canada<br />

<br />

Return Undeliverable Canadian<br />

Addresses to:<br />

Equipment Review<br />

Suite 628<br />

440-10816 Macleod Trail, SE<br />

Calgary, Alberta<br />

T2J 5N8<br />

Publication Mail Agreement Number:<br />

41137025<br />

The Smarter Work Zone<br />

Signal timings, permanent message<br />

systems, traffic video feeds and a variety<br />

of sensors have all contributed to better<br />

management of traffic in our day to day<br />

travels. However, when construction<br />

work zones are considered we all feel<br />

like we are thrown back to the Stone<br />

Age, and are compelled to tough it out<br />

with the aggravation that comes from any<br />

disruption to our normal commute. So,<br />

why can’t work zones be smarter as well?<br />

Peter Magnien, Alberta Traffic Supply,<br />

explains why they can…<br />

Peterbilt Ranks Highest in Customer<br />

Satisfaction Study<br />

Peterbilt has achieved the highest ranking<br />

in customer satisfaction in the J.D. Power<br />

and Associates 2011 ‘Heavy-Duty Truck<br />

Customer Satisfaction Study’ in the<br />

vocational truck segment. The Study is<br />

based on interviews with more than 1,651<br />

owner/operators and fleet managers of<br />

1-year-old trucks. It analyzes customer<br />

satisfaction in six key areas: engine;<br />

transmission; ride/handling/braking; cab/<br />

body; cost of operation; and warranty…<br />

The SNO-WAY 29 VHD Plow<br />

The 29VHD is the top of the line in Vee<br />

Plow technology. The unique single<br />

adjusting arm blade leveling system<br />

allows the operator to adjust the center<br />

hinge for perfect plowing alignment and<br />

no snow trail. With the Down Pressure<br />

Hydraulic System as standard equipment<br />

this plow will, according to Sno-Way,<br />

clean better and can cut 30% of your<br />

plowing time…<br />

5<br />

11<br />

20<br />

2 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW<br />

3

Alberta Traffic Supply<br />

The Smarter Work Zone<br />

By Peter Magnien, Alberta Traffic Supply<br />

We’ve all been there; stuck in traffic,<br />

looking at an endless stream of taillights<br />

stretched out in front of us. We inch<br />

forward with no idea of what may be<br />

contributing to our aggravation and are left<br />

wondering how long we will have to wait<br />

or if we should have taken another route.<br />

Fortunately, the days of languishing in<br />

this type of uncertainty are nearing an end<br />

with the expanding world of intelligent<br />

transportations systems.<br />

Whether we are aware of it or not, in<br />

many of our municipalities Intelligent<br />

Transportation Systems (ITS) have had an<br />

active role in our lives for quite a while<br />

now. Signal timings, permanent message<br />

systems, traffic video feeds and a variety<br />

of sensors have all contributed to better<br />

management of traffic in our day to day<br />

travels. However, when construction<br />

work zones are considered, we all feel<br />

like we are thrown back to the Stone Age<br />

and are compelled to tough it out with<br />

the aggravation that comes from any<br />

disruption to our normal commute. So,<br />

why can’t work zones be smarter as well?<br />

4 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 5

The truth is this capability does exist.<br />

A Smart Work Zone, or SWZ, uses a<br />

similar approach to ‘ITS’ in that a more<br />

sophisticated approach is employed to<br />

communicate real time information to<br />

motorists so that they can make informed<br />

choices. Let’s imagine that you’re looking<br />

at that same stream of taillights mentioned<br />

earlier but the difference now is that there<br />

is a message trailer that informs you that<br />

your travel time will be delayed by 10<br />

minutes. Compared to not knowing what’s<br />

going on at all, a delay of a few minutes<br />

doesn’t seem so bad now does it? In itself<br />

– this is one of the greatest benefits of an<br />

’SWZ’ system; communicating real time<br />

information to minimize driver frustration<br />

and reduce traffic incidents.<br />

An SWZ uses a variety of sensors that<br />

are deployed along a roadway to collect<br />

and send data to a computer that then<br />

determines what message needs to be<br />

uploaded to a portable message trailer<br />

and displayed to the motorist. Changing<br />

road conditions act as different triggers<br />

for the type of message that needs to be<br />

displayed. Imagine that – a truly dynamic<br />

messaging system!<br />

Three basic types of SWZ<br />

systems<br />

Traffic-responsive systems: Continuously<br />

monitor real-time traffic conditions and<br />

automatically respond with appropriate<br />

and dynamic messaging, such as driving<br />

instructions and traffic condition<br />

information. These systems are designed<br />

to manage work zone traffic control and<br />

to meet temporary traveler information<br />

needs. They include; travel time<br />

information, delay time information, route<br />

management information, stopped traffic<br />

warnings, dynamic speed displays and<br />

dynamic lane merges.<br />

Vehicle-responsive systems:<br />

Continuously evaluate individual vehicle<br />

characteristics and automatically produce<br />

warnings directed to those specific vehicles.<br />

These types of systems include; dynamic<br />

speed displays, (radar trailers,) work space<br />

intrusion warnings, and over dimension<br />

warnings, (height clearance warnings).<br />

Condition-responsive systems: Identify<br />

and provide motorists with guidance about<br />

real-time, a-typical roadway conditions,<br />

especially hazardous or unique roadway<br />

and weather conditions. Condition<br />

responsive systems would include;<br />

changeable speed limits, hazardous<br />

roadway warnings (icy road conditions)<br />

and truck entry, exit or crossing warnings.<br />

When one considers the scope of these<br />

basic systems, it becomes clear that<br />

the benefits of SMZ’s are not limited<br />

to simply reducing driver frustration.<br />

Enhanced safety, reduced queue lengths,<br />

increased roadway capacity, better<br />

information quality and delivery, superior<br />

work zone management and flexibility,<br />

all improve with the collection of<br />

relevant data and the delivery of real time<br />

information to the motorist.<br />

So, the next time that you are stuck trying to<br />

plan another tricky traffic set-up, or worse,<br />

are stuck in one – consider how an SMZ<br />

might be the solution that you are looking for.<br />

Solar Message Board<br />

(PCMS-1210)<br />

Radar Speed Display<br />

Trailer (SP-715)<br />

Closed Circuit Camera<br />

Trailer (CT-2430)<br />

To find out how you can implement smart<br />

work zones through intelligent message<br />

boards, arrow boards and user-friendly<br />

traffic management software, please<br />

contact Alberta Traffic Supply at<br />

1-800-661-7346 or visit:<br />

www.AtsTrafficGroup.com<br />

A safe work zone…is a smart work zone!<br />

6 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 7

CUBEX Announces<br />

New Sales and Service<br />

Facility in Edmonton<br />

Low Volume Roads – Load<br />

Management Practices<br />

CUBEX has announced the opening of a new sales and service<br />

facility in Edmonton. According to CUBEX, the decision to<br />

expand its operations to Edmonton is in line with its policy<br />

of providing superior sales and service support to its new and<br />

existing customer base throughout the province. The new<br />

Edmonton location will provide the required facilities to better<br />

serve its customers in the Edmonton and northern Alberta region.<br />

The new facility will be located at:<br />

11720-181 Street<br />

Edmonton, AB T5S 1M6<br />

Telephone: 1 877-GO-CUBEX<br />

See the next edition of EQUIPMENT REVIEW for more...<br />

A pooled fund project by TAC (Transportation Association of<br />

Canada)<br />

Almost all Canadian provinces restrict truck axle weights to<br />

varying extents during the spring thaw period. This results in<br />

an extra hauling cost for the trucking industry. The extra energy<br />

consumption also results in environmental pollution. On the<br />

other hand, several provinces allow trucks to carry extra weight<br />

during the winter months. The weight limit, methods used to<br />

trigger the start, end and duration of the spring load restriction and<br />

winter premium periods vary among Canadian jurisdictions. The<br />

varying load limits and durations may hinder the route and load<br />

management for interprovincial truck traffic.<br />

The TAC Pavements and Soils and Materials Standing Committees<br />

have identified issues including a lack of pavement design<br />

procedures that specifically address very low truck volume roads,<br />

continued industry pressure for variations to weights and tire<br />

configurations, the lack of a robust mechanistic-based analysis<br />

procedure for identifying the need for weight restrictions, the<br />

impacts of varying weights on such roads, and others. A brief survey<br />

of low volume road pavement design and load management practices<br />

in Canada was conducted at the end of 2011 to determine the current<br />

state of practices. The survey indicated that there is a need for a<br />

load management best practice guide. Accordingly, this project is<br />

intended to synthesize the state of practice in transportation agencies<br />

and provide guidance for possible enhancements. Future work<br />

could examine the potential for harmonization of load management<br />

practices among Canadian jurisdictions.<br />

The project will involve review and assessment of the current<br />

practices and research to:<br />

• Manage seasonal weights including the selection of roads,<br />

weight limits, methods used to determine dates of the spring<br />

restrictions and winter weight premiums.<br />

• Provide recommendations to identify a pavement structure as<br />

requiring spring load restrictions.<br />

• Summarize the mechanistic responses of weak pavements<br />

including the seasonal variation and the impact on pavement<br />

service life.<br />

• Recommend how pavement designs can be adjusted to optimize<br />

the economic aspect of weight restrictions and premiums.<br />

• Synthesize relevant technology that is available to manage the<br />

seasonal loadings. Project deliverables will include a final<br />

report (in English and French) and a workshop to present the<br />

findings and recommendations.<br />

8 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 9

Kobelco SK210<br />

Mark 9 Excavator<br />

More power and faster<br />

engine response<br />

News from Stahl<br />

Peterbilt<br />

Kobelco has introduced the SK210 fullsize,<br />

high-performance excavator to the<br />

Kobelco Mark 9 excavator series. These<br />

new Tier 4 models include the SK260,<br />

SK295, SK350 and SK485 excavators.<br />

The versatile SK210 Mark 9 delivers<br />

a 10-percent improvement in both fuel<br />

efficiency and productivity, with more<br />

power and faster engine response.<br />

Featuring an upgrade to Kobelco’s<br />

intelligent hydraulics and a new<br />

Economy Power Mode, the SK210 Mark<br />

9 is equipped with a selective catalytic<br />

reduction (SCR) emission solution for<br />

excavators. A new ROPS/FOPS certified<br />

cab provides a larger, more comfortable<br />

work environment, and a low engine cover<br />

and standard rear-view camera improve<br />

operator visibility and productivity.<br />

For improved system efficiency and<br />

reduced component wear, the Kobelco<br />

SK210 Mark 9 also features a fully<br />

automatic engine and hydraulic warm-up<br />

system. This warms the hydraulic circuit<br />

to an optimum 126° F (52° C).<br />

“As with all the Mark 9 models, the<br />

SK210 continues Kobelco’s tradition as a<br />

technology leader,” said Reece Norwood,<br />

Kobelco platform manager. “This new<br />

machine delivers the precise control and<br />

feel expert operators prefer. The SK210<br />

Mark 9 can dig the trench, crane the pipe<br />

and finish with even better precision. Plus,<br />

our new SCR solution will deliver more<br />

useable engine power and fuel efficiency.”<br />

The Kobelco SK210 Mark 9 features an<br />

operating weight of 47,840 lbs (21,700<br />

kg) and a dig depth of 21 ft 3 in (6.47 m).<br />

The new model delivers 160 horsepower<br />

(119.3 kW).<br />

Improved controllability and<br />

productivity<br />

The upgraded Intelligent Total Control<br />

System (ITCS) incorporates the<br />

culmination of three generations of<br />

continuous improvement in hydraulic<br />

controls, based on extensive customer<br />

input and product testing.<br />

“The SK210 Mark 9 excavator maximizes<br />

the unique capabilities of its Tier 4 Interim<br />

certified FPT engine and optimized<br />

hydraulics with the upgraded ITCS,”<br />

Norwood said. “ITCS recognizes the<br />

operator’s moves and assists by providing<br />

power where and when it is needed. It<br />

also provides hydraulic sensitivity for fine<br />

grading and leveling.”<br />

Integrated swing priority provides<br />

seamless and smooth transition<br />

of additional pump power to the<br />

swing function. Automatic hydraulic<br />

regeneration feeds the cylinder demanding<br />

oil first, with oil that is being pushed<br />

out of another cylinder. This requires<br />

much less energy than having to re-pump<br />

the oil again, and also allows the next<br />

action to happen with faster response.<br />

The independent travel feature, activated<br />

with a switch, dedicates a pump to<br />

travel motors for better movement while<br />

performing other functions, such as when<br />

handling pipe while moving to the trench.<br />

“The Kobelco Mark 9 excavators<br />

set the industry standard in terms of<br />

controllability, especially in multifunction<br />

applications,” Norwood said. “Operators<br />

will appreciate the impressive control and<br />

smoothness of the SK210 Mark 9, and the<br />

added confidence will make them even<br />

more productive. The ease of operation<br />

makes a good operator a great operator,<br />

and allows a novice excavator operator to<br />

be a good, productive operator.”<br />

Kobelco Mark 9 upgrades to the main<br />

valve and intelligent hydraulics, as well as<br />

new joysticks with proportional controls<br />

for the auxiliary hydraulics, contribute to<br />

the controllability upgrades of this new<br />

excavator.<br />

The Power Boost feature on the SK210<br />

Mark 9 delivers 10-percent more bucket<br />

breakout force on command, without<br />

time limit, while the Heavy Lift delivers<br />

10-percent more lifting and swing<br />

capability on command, without time limit.<br />

For more information contact your local<br />

Kobelco dealer.<br />

Peterbilt Ranks Highest in<br />

Customer Satisfaction among<br />

Heavy-Duty Vocational Trucks in<br />

J.D. POWER and Associates Study.<br />

Peterbilt has achieved the highest ranking<br />

in customer satisfaction in the J.D. Power<br />

and Associates 2011 ‘Heavy-Duty Truck<br />

Customer Satisfaction Study’ in the<br />

vocational truck segment.<br />

“Peterbilt’s vocational vehicles consistently<br />

exceed customer expectations in a wide<br />

variety of configurations and applications.<br />

We are extremely proud that our superior<br />

level of customer satisfaction is reflected in<br />

the J.D. Power and Associates 2011 study<br />

as customers rated Peterbilt’s vocational<br />

vehicles as the greatest in the industry,”<br />

says Robert Woodall, Peterbilt Director of<br />

Sales and Marketing.<br />

“This recognition represents the dedication<br />

of the entire Peterbilt organization from<br />

our superior dealer network, which<br />

provides exceptional customer service, to<br />

our employees across North America who<br />

are committed to designing, manufacturing<br />

and supporting the highest quality product<br />

available in the marketplace today.”<br />

In the study, J.D. Power and Associates<br />

reported, “Peterbilt ranks highest and<br />

performs particularly well in the engine<br />

and cost of operation factors.” The J.D.<br />

Power and Associates study is based on<br />

interviews with more than 1,651 owner/<br />

operators and fleet managers of 1-yearold<br />

trucks. The study analyzes customer<br />

satisfaction in six key areas: engine;<br />

transmission; ride/handling/braking; cab/<br />

body; cost of operation; and warranty.<br />

Peterbilt’s Class 8 vocational lineup<br />

includes the rugged Models 367, 365<br />

and 348, designed to withstand the<br />

rigors of daily severe service markets in<br />

construction, dump, mixer, logging and<br />

other vocational applications, where the<br />

workload and environment demand trucks<br />

to perform day in and day out.<br />

“Peterbilt’s Models 367 and 365<br />

provide unmatched quality, durability,<br />

reliability and overall performance,”<br />

says Woodall. “Each vehicle is designed<br />

and manufactured to endure the most<br />

challenging work environments, provide<br />

lasting value and ensure our customers’<br />

business needs are always addressed to<br />

help increase their profitability.”<br />

Also introducing Speaker’s Full<br />

Line of LED Headlights<br />

J.W. Speaker has announced the release<br />

of a revolutionary family of new LED<br />

headlights, which, according to J.W.<br />

Speaker are designed to change the world<br />

of vehicular lighting as we know it. More<br />

energy efficient, more durable, longerlasting<br />

and considerably less costly to<br />

maintain, J.W. Speaker claims this new<br />

breed of LED headlight is unlike anything<br />

else currently available on the market.<br />

Perfect for OEM or retrofit applications,<br />

these non-glare headlights offer brighter,<br />

whiter colour and a superior light pattern<br />

– ultimately providing drivers with<br />

improved visibility.<br />

To find out more, contact Stahl Peterbilt<br />

at 800-252-7981, or visit Facebook/<br />

StahlPeterbilt.<br />

10 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 11

RPM Tech Snow<br />

Blowers<br />

Industrial Machine Inc., known to many as<br />

IMI, is an Alberta-based equipment company<br />

with over forty five years of experience<br />

specializing in the sale and service of<br />

municipal equipment. The manufacturers<br />

IMI represents in Alberta include:<br />

• ZAMBONI COMPANY - Zamboni Ice<br />

Resurfacers<br />

• RPM TECH INC. - Loader Mounted<br />

and Self Propelled Snow blowers<br />

• RPM. TECH INC. - Cameleon<br />

Municipal Utility Vehicles<br />

• HI-WAY EQUIPMENT COMPANY -<br />

Sanders and Snow Plows<br />

• CRAFCO INC - Magnum Spray Patchers<br />

• BOSS - Snow Plows<br />

• RoadHog - Cold Planers, Road Saws<br />

RPM Tech’s line of loader-mounted<br />

industrial snow blowers<br />

R.P.M. Tech is a North American leader<br />

in the design, manufacture, maintenance<br />

and distribution of industrial loader<br />

mounted snow blowers, self propelled<br />

snow blowers, multifunctional vehicles,<br />

Rail and metro maintenance vehicles,<br />

Airport maintenance vehicles construction<br />

equipment as well as heavy equipment and<br />

specialized on and off highway vehicles<br />

for worldwide markets.<br />

R.P.M. manufactures a line of mounted<br />

industrial snow blowers for loaders and<br />

tractors offering a snow removal capacity<br />

ranging from 1600 to 5000 tons of snow<br />

per hour. Practical and economical, these<br />

detachable snow blowers can adapt<br />

your equipment to the toughest snow<br />

conditions and provide solutions to snow<br />

removal needs.<br />

RPM217 Detachable Snow Blower<br />

The RPM217 is dual stage loader mounted<br />

snow blower, featuring two 17 inch<br />

augers, a CAT C6.6 turbo diesel engine<br />

and telescopic loading chute. The RPM<br />

217 can clear up to 2000 tons of snow per<br />

hour and cast snow up to 150ft either left<br />

or right through the drum or load trucks<br />

RPM217 Detachable Snow Blower<br />

12 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 13

either on the left or right through the<br />

telescopic loading chute.<br />

RPM220 Detachable Snow Blower<br />

The RPM220 is dual stage loader mounted<br />

snow blower, featuring two 20 inch<br />

augers, a CAT C7turbo diesel engine and<br />

telescopic loading chute. The RPM 220<br />

can clear up to 2,750 tons of snow per<br />

hour and cast snow up to 150ft either left<br />

or right through the drum or load trucks<br />

either on the left or right through the<br />

telescopic loading chute.<br />

RPM227 and 227M Detachable Snow<br />

Blower<br />

The most powerful two stage dual auger<br />

detachable industrial snow blower of the<br />

RPM220 Detachable Snow Blower<br />

line, the RPM 227 and RPM 227M both<br />

feature two 27 inch augers, a CAT C9<br />

turbo diesel engine and telescopic loading<br />

chute. The RPM 227 can clear up to 3,000<br />

tons of snow per hour and cast snow up to<br />

150ft either left or right through the drum<br />

or load trucks either on the left or right<br />

through the telescopic loading chute.<br />

RPM Tech continues to be a leader in<br />

the industry in quality, technology and<br />

innovation. One area where RPM Tech<br />

stands out is its investment in technology<br />

and controls for ease of operation,<br />

maintenance and fleet management. All<br />

RPM Tech loader mounted snow blowers<br />

feature the heavy duty control and display<br />

system PLUS +1 from Sauer Danfoss<br />

which has many advantages, some of<br />

which are noted below:<br />

• A controller using a muliplex CAN<br />

communication<br />

• Display on a 256 color LCD screen of<br />

31/8 inch by 53/4 in.<br />

• Joystick with integrated functions such<br />

as control of hydraulic functions, engine<br />

speed and chute.<br />

• One key ignition switch<br />

• Simultaneous display on one page of<br />

the engine information such as RPM,<br />

oil pressure, coolant temperature, fuel<br />

level, engine load, battery voltage and<br />

engine hours.<br />

• Alarms and warning lights are also<br />

displayed such as engine alarm lights,<br />

engine clutch light, headlight state, low<br />

engine oil pressure light, high engine<br />

temperature lights (air and coolant) and<br />

low level engine load.<br />

• Error code display<br />

• Periodic maintenance display<br />

• Service menu allowing for:<br />

• Configuration of clutch<br />

• Configuration of joystick<br />

• Engine codes<br />

• Password protected.<br />

Industrial Machine Inc, has over twenty-plus<br />

years of experience selling and servicing<br />

RPM Tech snow blowers in Alberta, with a<br />

large stock of OEM parts, a knowledgeable<br />

and dedicated parts department and factory<br />

trained service technicians.<br />

For more information on the featured<br />

RPM Tech loader mounted snow blowers<br />

or any other product manufactured by<br />

RPM Tech, please contact Industrial<br />

Machine Inc. at: (780) 944 6986 or visit:<br />

www.industrialmachine.ca<br />

<strong>Kenworth’s</strong> T370 4WD<br />

Power, Versatility<br />

and Traction<br />

The recently introduced Kenworth<br />

T370 Four Wheel Drive is <strong>Kenworth’s</strong><br />

entry into the medium duty four wheel<br />

drive market. The T370 is available in<br />

a single rear axle configuration with the<br />

Allison automatic transmission. Fabco is<br />

the supplier for the front drive axle with<br />

weights available up to 16,000 lbs. Rear<br />

axle ratings are up to 23,000lbs complete<br />

with 26,000lb springs. The T370 is<br />

powered by Paccar’s fully compliant and<br />

industry leading PX6 or PX8 engine with<br />

horsepower up to 325 providing<br />

excellent performance over a smooth rpm<br />

range. The Fabco transfer case is a two<br />

speed design with high and low ranges.<br />

This truck is engineered with body<br />

builders in mind. The transfer case is<br />

mounted strategically to not interfere with<br />

the placement of a body. Consequently,<br />

the T370 AWD is perfectly suited for<br />

flatdecks, cranes or plows. Municipalities,<br />

construction, oilfield and many other<br />

industries are potential customers for this<br />

tough and reliable four wheel drive. A<br />

variety of wheel bases and GVW ratings<br />

are available.<br />

The T370 cab is renowned in the trucking<br />

industry for quality and strength. The cab<br />

is a huck-bolted aluminum cab complete<br />

with piano hinges. Mirrors are mounted to<br />

the cab rather than the door to eliminate<br />

vibration and continual adjustment. The<br />

sloped hood of the T370 allows for<br />

excellent visibility and increased safety.<br />

RPM227 and 227M Detachable Snow Blower<br />

The T370 also features large windows, a ‘real<br />

truck’ instrument panel and air-ride driver’s<br />

seat. Almost nothing in it looks ‘automotive’<br />

except the steering wheel, but its smoothly<br />

contoured spokes provide a place for drivers<br />

to comfortably rest their hands, and in a<br />

frontal wreck the wheel won’t pierce a<br />

driver’s chest in the way an old-fashioned<br />

straight-spoke and small-hub wheel might.<br />

The steering column tilts and telescopes so<br />

drivers can get the wheel just right.<br />

Features & Options<br />

• Front axles from 10K - 16K<br />

• Rear Axles from 16K - 23K<br />

• Paccar PX8 Engine<br />

• Allison Automatic<br />

• PTO capability with Allison<br />

• Air Brakes<br />

• Fabco Transfer Case<br />

For further information contact your local<br />

Greatwest Kenworth branch, or visit:<br />

www.greatwestkenworth.com<br />

14 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 15

MONROE WINTER<br />

ROAD MAINTENANCE<br />

EQUIPMENT<br />

FROM COMMERCIAL<br />

TRUCK EQUIPMENT<br />

The Monroe Truck Equipment Snow<br />

& Ice Division has been manufacturing<br />

quality equipment since 1983. It markets<br />

and services products throughout the<br />

world and has an international network<br />

of distributors in the USA and Canada.<br />

Monroe manufactures a complete line<br />

of winter road maintenance equipment<br />

and is represented in western Canada by<br />

Commercial Truck Equipment.<br />

PLOWS<br />

Full Trip Straight Reversible Plows<br />

Monroe straight reversible plows feature<br />

a full list of advanced specifications.<br />

Slotted Trip, Compression Trip Edge,<br />

and Torsion Trip Edge plows are<br />

available in 10’, 11’, and 12’ lengths,<br />

with available heights of 36”, 41”,<br />

and 48”. Durability is provided with<br />

horizontal bracing and a heavy duty<br />

3/4” x 4” x 4” bottom angle.<br />

The cutting edge is 5/8” x 8”,<br />

AASHTO top punched. Durable<br />

compression springs, heavy duty<br />

4-point hinged pushframe, various<br />

light packages, two double-acting<br />

3” x 10” reversing cylinders with<br />

adjustable Chevron packing, crossover<br />

relief valve, ship and car channel<br />

A-frame, and abrasion-resistant hoses<br />

with steel clamps complete the long<br />

list of standard features.<br />

Monroe’s Full Trip One Way Plows<br />

One way plows incorporate the same<br />

rugged design characteristics as straight<br />

reversible plows.<br />

Specifications include all those listed<br />

for the straight reversible plows with the<br />

main difference of a ‘No Trip’ feature,<br />

heights of 30” and 39”, and discharges<br />

of 47”, 52”, and 66”. One Way plows are<br />

also available in fixed angle or reversible<br />

with an adjustable moldboard pitch. They<br />

are manufactured in 100% continuouslywelded<br />

moldboard and with heavy duty,<br />

4-point hinged push-frames.<br />

SPREADERS<br />

Pickup V-Box<br />

The Monroe Pickup V-Box Spreader is<br />

available for light duty vehicles including:<br />

3/4-ton pickups, 1-ton and HD-Super<br />

Duty with flatbed or dump body, and<br />

Pull-behind trailer mount. Spreaders are<br />

available in mild steel, and 304 stainless<br />

steel. A choice of engine-driven or<br />

hydraulic-driven units are available.<br />

Features:<br />

• 8’, 1.8 cubic yard capacity<br />

• 100% continuously-welded<br />

• Self-cleaning pintle chain<br />

• Short spinner for pickup truck<br />

mounting, adjustable baffles, 13”<br />

spinner disc<br />

• 9 HP engine<br />

• 1-1/4” drive and idler shafts<br />

• 4-bolt relubeable bearing<br />

Options:<br />

• Inverted V<br />

• Hold down kit<br />

• Vertical hopper extensions<br />

• 7’ and 10’ lengths<br />

• Electric throttle control<br />

• Battery<br />

• Center high-mount stop light<br />

• Hydraulic drive auger in lieu of chain<br />

16 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 17

SNOWBLAST<br />

MSV and MV V-Box Spreaders<br />

The Monroe V-Box Spreader is designed<br />

and built for long lasting, heavy duty,<br />

reliable service. Both models, MSV and<br />

MV, are available in mild steel, and 304<br />

stainless steel with 100% continuouslywelded<br />

construction. A choice of slidein<br />

or chassis-mount is offered, in sizes<br />

ranging from 8’ to 17’.<br />

Snowblowers<br />

Features (MSV):<br />

• Tip-up spinner assembly<br />

• 4-bolt flange bearings<br />

• 2” idler shaft<br />

• Spring-loaded chain take-up bearing<br />

• Front and rear wipers<br />

• Rear diverter chute<br />

• Replaceable chain shields, 10 gauge<br />

• 3/8” x 1-1/2” bar flights<br />

• 50:1 or 25:1 gearbox with 2” drive shaft<br />

• Top screens<br />

Features (MV):<br />

• Bolt-on spinner assembly<br />

• 4-Bolt flange bearings<br />

• 1-1/2” idler shaft<br />

• Spring-loaded chain take-up bearing<br />

• Front and rear wipers<br />

• Rear diverter chute<br />

• Formed chain shields, 10 gauge<br />

• 1/4” x 1-1/2” bar flights<br />

• 50:1 or 25:1 gearbox with 1-1/2” drive<br />

shaft<br />

• Top screens<br />

Pre-wetting Systems<br />

Pre-wetting is increasing in popularity<br />

with up to 40% savings in granular<br />

materials being reported when pre-wetting<br />

with liquids deicing chemicals.<br />

Features:<br />

• Hydraulic and electric systems available<br />

• 15 to 400 gallon tank capacities<br />

• Simple on/off systems to closed-loop<br />

system<br />

• Mounting hardware available in powdercoated<br />

mild steel or stainless steel<br />

For more information contact your local<br />

branch of Commercial Truck Equipment,<br />

or visit: www.comtruck.ca<br />

Commercial’s new Sales, Service and Parts facility in Calgary<br />

Along with recent corporate expansion and consolidation, Commercial has moved to a new<br />

purpose built, state-of-the-art facility in Calgary. Situated on a five acre parcel, the facility<br />

has more than ample capacity to accommodate future expansion.<br />

The building has fourteen service bays and has been designed so that additional service bays,<br />

up to fourteen more, can be added without disrupting day to day business. Commercial’s<br />

facility also includes a full service driveline shop for repair, installation and custom<br />

builds - also a dedicated PTO bench for custom build and repairs of PTO’s and hydraulic<br />

components. A large warehouse and extra large yard provide generous space for parts<br />

inventory and equipment and vehicle storage.<br />

Commercial Equipment Corporation, Commercial’s utility and utility rental division, has<br />

now been brought under the umbrella of CTEC and is now working in this facility. Ideally<br />

located in the foothills Industrial area of Calgary, the facility offers extremely easy access,<br />

being located at the junction of 114 Avenue and 48 Street SE.<br />

The address is: 11199-48th Street S.E. Calgary, Alberta, T2C 5H4.<br />

An efficient and effective solution<br />

SNOWBLAST are single stage<br />

snowblowers designed for the roughest<br />

winters and built to work in extreme<br />

conditions. Charles Mehlhaf, original<br />

founder of Wildcat Manufacturing Co.<br />

Inc., designed the “Wildcat” snowblower<br />

product line in the mid 1970’s. “Wildcat”<br />

blowers was a very popular brand in<br />

Alberta, and many units remain in<br />

operation today. “Wildcat” is now known<br />

as “SNOWBLAST”, with the same<br />

principles of quality and design being<br />

applied in the manufacture of the blowers.<br />

There are no second stage augers to plug,<br />

and the heavy-duty construction of the<br />

frame, fans, and CAT II-III Quick Hitch<br />

provide excellent durability.<br />

The SNOWBLAST tractor-mounted series<br />

snowblowers is a solution to blowing in<br />

all types of snow conditions from wet<br />

slushy snow to hard compacted frozen<br />

snow. SNOWBLAST snowblowers will<br />

efficiently blow snow on roads, in fields,<br />

farm yards, even inside livestock pens.<br />

This provides operators with effective<br />

and efficient performance combined with<br />

quality workmanship.<br />

SNOWBLAST tractor-mounted blowers<br />

use a unique spiral feeding system. Two<br />

bars stretching in front of the fans cut and<br />

slice the snow, throwing it back into the<br />

impellars. The angle of the spiral cutting<br />

bar lines up to the paddles and snow<br />

comes from the bar directly into the blade<br />

for a fast, even discharge. The fans are<br />

constructed of 3/8” backs, 3/8” paddles,<br />

and 3/8” gussets. All fans are balanced<br />

with a balance weight to prevent vibration.<br />

Two Spout options available allow<br />

operators to choose what fits their needs.<br />

Use the single chute to blow in a specific<br />

area or into trucks, or use the double-chute<br />

for free casting. This allows tailoring<br />

of the blower to specific needs. Eight<br />

bearing mounted rollers on the base of the<br />

spout allow for easy rotation plus raises<br />

the spout up creating an air gap which<br />

eliminates spout freeze downs.<br />

The outer cutting edge surrounds the<br />

entire blower for easy cutting through the<br />

toughest of packed snow. A shear Bolt<br />

on the front of each fan will shear off if<br />

the blower hits any major obstructions<br />

preventing blower damage. The shear<br />

bolts are located on the front of each fan<br />

for easy access to replace them, plus with<br />

individual fan shear bolts it eliminates any<br />

sudden stresses or jars to pass through the<br />

rest of the drive system. When shear bolts<br />

shear, brass bushings prevent the fan from<br />

seizing onto the shaft.<br />

On all “A” Series blowers, all chains<br />

and sprockets are completely enclosed<br />

in an oil reservoir creating quality<br />

lubrication which translates into longer<br />

chain and sprocket life and less friction.<br />

This translates into more efficiency for<br />

increased productivity. Fan shaft bearing<br />

are 4-bolt piloted flange which fit into the<br />

chain drive housing which takes the stress<br />

off of the 4 bolts. Cylindrical pressure<br />

is absorbed from the bearing, through<br />

the pilot, and into the housing itself. The<br />

blower is<br />

mounted to<br />

the tractor<br />

using a<br />

heavy duty<br />

hitch system<br />

that will<br />

accommodate<br />

a standard<br />

3-point<br />

or Quick-<br />

Coupler hitch<br />

on the tractor.<br />

SNOWBLAST offers a 2-Year Limited<br />

Warranty (1-year parts and labor, 2-years<br />

parts).<br />

For further information contact CUBEX<br />

in Calgary, or the new CUBEX facility in<br />

Edmonton, or visit: www.cubexltd.com<br />

18 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 19

plow hydraulics allows operators to<br />

scrape or back-drag more snow in less<br />

time resulting in 30% more efficiency.”<br />

• Pre-Drilled Top Blade Rail - allows for<br />

E-Z Installation of E-Z Fit Deflector<br />

• Custom designed to accept the E-Z<br />

Switch Wings<br />

• Patented Shock Killer Trip Return<br />

System - reduces return shock to truck<br />

and driver<br />

• Fast-Force Hydraulic System<br />

• EIS – Energy Interruption System<br />

- down-time reduction, corrosion<br />

elimination and plug and play design<br />

• Down Pressure Hydraulics System<br />

- scrapes clean forward and back<br />

dragging and increases snow-moving<br />

efficiency by up to 30%<br />

• Superior Paint for Corrosion Resistance<br />

- zinc phosphate rinse, E-Coat primer<br />

and powder coat finish<br />

For more information contact your local<br />

DEL branch, or visit: www.caytec.com<br />

The SNO-WAY 29<br />

VHD Plow<br />

Fits HD 3/4 Ton to Class 5 Trucks<br />

The 29VHD is the top of the line in Vee Plow technology. The<br />

unique single adjusting arm blade leveling system allows the<br />

operator to adjust the center hinge for perfect plowing alignment<br />

and no snow trail. With the Down Pressure Hydraulic System as<br />

standard equipment, this plow, according to SNO-WAY, will clean<br />

better and can cut 30% of plowing time. With the addition of<br />

the optional E-Z Switch Wings operators have a plow that offers<br />

exceptional versatility and durability.<br />

‘Down Pressure’ hydraulics for<br />

scraping and back-dragging<br />

According to Sno-Way, its patented Down Pressure snow plow<br />

hydraulics is a superior plow upgrade, and only Sno-Way has it.<br />

Sno-Way also claims that no other plow manufacturer offers this<br />

option. Sno-Way states, “Some may claim that their heavy weight<br />

plows produce results like Down Pressure snow plow hydraulics,<br />

but take it from us no plow will clean as efficiently or as quickly<br />

as a Sno-Way plow. Sno-Way’s exclusive Down Pressure snow<br />

20 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

The hydraulic system design virtually<br />

eliminates “skipping” during backdragging,<br />

a problem found in other plow<br />

type designs.<br />

Wireless and<br />

Programmable<br />

Sno-Way’s patented wireless Pro Control<br />

plow control offers the ultimate in-cab<br />

flexibility. The Sno-Way wireless control<br />

can be mounted virtually anywhere in<br />

the cab and is simple to operate with<br />

either hand. In addition, the wireless Pro<br />

Control eliminates cumbersome dash<br />

wires that can easily become tangled<br />

or restrict placement of the control -<br />

especially for left hand use. The wireless<br />

Pro Control keeps truck cabs in original<br />

condition and installs in minutes with<br />

no drilling or wire harness “snaking”<br />

through the vehicle firewall. A wired<br />

version is also available.<br />

Features<br />

• Patented Ground Hugger Blade Design<br />

- keeps plow on the ground<br />

• Patented MaxADJUST Leveling<br />

System<br />

• Double Acting Wing Cylinders –<br />

maximum force forward and back<br />

• Tube Steel/Tab-Slot and Lock<br />

Construction - engineered for load<br />

force absorption and durability<br />

Summer 2012 EQUIPMENT REVIEW 21

Healthy landscape,<br />

conserving resources,<br />

saving money<br />

WMS will assist your irrigation crews and<br />

turf managers in doing what they do best,<br />

and that is manage turf, lower maintenance<br />

costs, and an increase in community<br />

acceptance as the green spaces will look<br />

better - and the irrigation will only be<br />

running in times of need. The vandalism<br />

issue in every community is always a<br />

concern and a WMS will give you all<br />

the best tools to combat this. Whether<br />

it’s an entire system shutoff during grad<br />

weekend, water window management to<br />

stay out of the peak vandal hours, or zone<br />

shutdown and alarm, once a sprinkler is<br />

kicked off it minimizes water waste and<br />

site damage liability. Keeping your water<br />

window to a minimum is of paramount<br />

importance in the summer months. User<br />

groups playing soccer or baseball etc on<br />

overly wet fields in the morning causes<br />

turf damage, site liability, as well as bad<br />

rapport with the user groups. Then the<br />

favorite, in the back of the minds of all<br />

municipal agencies, are the calls from<br />

locals on a rainy day giving you grief<br />

that the city irrigation is running during<br />

rainfall. A good quality WMS solves all of<br />

these issues, and more.<br />

Alberta User Groups Lead the Way<br />

The Toro ‘Sentinel’ Series WMS is<br />

an advanced, state-of-the-art Water<br />

Management System. Recently, with<br />

consulting from Ion Irrigation, based<br />

in Calgary, the Government of Alberta<br />

installed a Sentinel system at the<br />

Legislative Grounds in Edmonton. As<br />

this project nears completion, they are<br />

already reaping the rewards of an efficient,<br />

reliable, state of the art WMS.<br />

In Canada, Toro supplies sites such as;<br />

The Cities of Nanaimo, Kelowna, Prince<br />

George, Burnaby, North Van, West Van,<br />

Delta, U of A, U of C, U of S, along<br />

with a number of large commercial<br />

users. In September of 2009, the City of<br />

Saskatoon began what is believed to be<br />

the largest one-time purchase of central<br />

control products seen to date. The Beijing<br />

Olympic village was 162 controllers. The<br />

combined controller count of AC and DC<br />

sites in Saskatoon is in excess of 200 as of<br />

August 2010. Network communications to<br />

five hubs and four weather stations control<br />

the ET based run times. Their choice for<br />

the project was the Toro Sentinel System,<br />

with the cities of Trail, Coquitlam, and the<br />

Town of Ajax choosing Sentinel as well,<br />

soon after. Other customers include the<br />

Beijing Olympic city, Disney World Wide<br />

World of Sports, Notre Dame University,<br />

and Princeton University.<br />

Who is your Sentinel?<br />

The Sentinel WMS will automatically<br />

adjust irrigation runtimes based on<br />

current weather data provided by your<br />

choice of a number of weather sources.<br />

The system will monitor all irrigation<br />

cycles and respond to any anomalies due<br />

to vandalism, broken mainlines, ‘real<br />

time’ rainfall, or other hydraulic issues as<br />

well as managing the flow of the system<br />

maximizing efficiency of the sprinklers<br />

and minimizing the water/vandalism<br />

window. Maintenance of irrigation sites is<br />

made efficient and user-friendly with the<br />

handheld remote radio for accurate and<br />

instant zone activations. A well designed<br />

and operated WMS can show an end-user<br />

a savings in Irrigation water use in the<br />

range of 35% and beyond.<br />

Using a Water Management Control System Can Achieve All Three<br />

By EMCO Waterworks Group<br />

For some, the cost of water is not something<br />

they look at by means of “dollars and<br />

cents”. In the end, the cost to filter, deliver,<br />

and maintain our potable water supply<br />

is substantial. Reducing water usage<br />

ultimately minimizes the demand on the<br />

entire infrastructure throughout the country.<br />

Each city may have different considerations<br />

for considering a water management<br />

system, and these may change from one<br />

year to the next. Considering a system with<br />

quality, and versatility in mind will aid in<br />

maximizing your return on investment.<br />

We are all aware of low flush toilets, low<br />

water use shower heads, and rain sensing<br />

devices to reduce our water consumption.<br />

In the heat of the summer we can typically<br />

expect water consumption to double.<br />

Irrigation of parks, sports fields, and green<br />

spaces will comprise the highest use of<br />

water within your region. In turn, this also<br />

creates the greatest potential area for water<br />

savings. Today’s technological capability<br />

is readily available. An integrated<br />

irrigation water management system can,<br />

and should, save 30-50% of the summer’s<br />

water expenditure. This savings alone<br />

would allow for a solid investment on<br />

your conservation efforts.<br />

If we take this one step further, and<br />

consider the municipal infrastructure:<br />

Pumping stations, pressure regulating<br />

valves, piping, etc., they have all been<br />

designed to withstand maximum flow<br />

capacity. This capacity would be seen<br />

during the hottest week of the summer,<br />

and irrigation is the catalyst for achieving<br />

this peak. If you are able to reduce that<br />

peak, this will reduce the demand, and<br />

strain on the infrastructure. In turn, this<br />

will increase the life span, and defer<br />

costly upgrades to the system. Liability<br />

is always an issue, and managing your<br />

parks irrigation systems to minimize<br />

the liability of a hillside slumping - or a<br />

park or buildings flooding is a concern as<br />

well. This is answered by a quality Water<br />

Management System (WMS). Benefits<br />

beyond those already mentioned are: A<br />

22 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 23

Features of the Central Control<br />

System<br />

Sentinel has been designed to operate as<br />

an ‘Irrigation Central Control’ system<br />

without a middle manager or the continual<br />

reliance on the office-based computer<br />

or any additional hardware in the field.<br />

Operating outside of the bounds of these<br />

hardware limitations and maintenance<br />

issues is a great benefit to the end user;<br />

as Sentinel relies on nothing more<br />

than the power to be on to operate as<br />

a fully functional water management<br />

system. Sentinel features true two-way<br />

Industry Canada compliant UHF radio<br />

communication, as well as the option<br />

of Landline phone, Cellular, Ethernet,<br />

SCADA, Fiber Optic, or Spread Spectrum,<br />

or a combination of some or all of these<br />

options.<br />

The numerous communication options<br />

allows users to talk to an unlimited<br />

number of satellites over any distance<br />

overcoming typical communication<br />

obstacles rendering many of Toro’s<br />

competitors inoperable. Reporting<br />

capabilities include: Water schedule; Water<br />

usage, ET, Rain fall data, flow graphs,<br />

zone runtimes, alarms status, electrical<br />

status, rain fall and or rain off status,<br />

and daily ET rates, just to mention a few<br />

reports, in print or graph format.<br />

Field Satellite Features<br />

Some features of the Sentinel Field<br />

Satellite include:<br />

• Real time flow monitoring at the<br />

Satellite without requiring additional<br />

components when using flow sensors<br />

with-in the system<br />

• Field satellite retains full functionality<br />

of the entire system thus not being<br />

susceptible to any office computer or<br />

communication malfunctions elsewhere<br />

in the system<br />

• Modular station counts from 12 to 96 in<br />

12-station increments or in a two wire<br />

decoder configuration for up to 200<br />

stations or a hybrid of both<br />

• Two sensor inputs per satellite; up to 4<br />

flow sensor inputs per satellite<br />

• Up to 16 programs and 8 start times per<br />

program, station run times from one<br />

minute to four hours and 59 minutes, or<br />

options of repeats or continuous run<br />

• Global adjustment from 0–250%;<br />

percent adjust by program from 0–250%<br />

• Ability to read and respond to numerous<br />

high end weather stations<br />

• Electrical current draw monitoring will<br />

shut down a station with excessively<br />

high electrical draw and notify the user<br />

and continue program operation<br />

• Ability to operate from one to six<br />

programs simultaneously<br />

• Its true two-way communication allows<br />

for changes in the field to be uploaded<br />

to the central computer and allows twoway<br />

communication with a hand-held<br />

radio in stand –alone mode<br />

• The Sentinel controller in the field<br />

can also act as a re-hub (leapfrog) of<br />

communication in the case of a remote<br />

Sentinel controller residing beyond<br />

the limitations of the standard UHF<br />

communications. Again allowing for<br />

a solid system and minimizing the<br />

customer’s capital expenditures along<br />

the way<br />

Reducing the Carbon Footprint<br />

In addition, all of this can be run without<br />

a connection to the local power grid.<br />

Solar panels and DC power are quickly<br />

taking over the Sentinel picture as more<br />

than just a far-fetched option for power.<br />

Now virtually every one of your Sentinel<br />

irrigation controllers can be solar powered<br />

and retain 100% of the functionality<br />

of the AC powered units. Saves on the<br />

connection cost to the grid and of course<br />

the power to run the site. Saving power<br />

goes hand in hand with saving water and<br />

Sentinel does both very well.<br />

Hand-held and Other Remote<br />

Features<br />

• The hand-held capability in stand-alone<br />

or Central mode allows data commands<br />

to manually turn on individual or<br />

multiple stations, initiate programs,<br />

advance through the system during<br />

winterizing, or complete rain shutdown<br />

to note a few<br />

• Voice and data capable<br />

• System on and off command activation<br />

• Great remote access to zones positioned<br />

in medians, boulevards, distant or hard<br />

to reach sites<br />

• Considered an advancement in Safety<br />

management<br />

• Onsite staffs’ best friend<br />

For more information contact your local<br />

EMCO Waterworks Group location, or<br />

visit: www.toro.com<br />

24 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 25

New Case 621F<br />

Wheel Loader<br />

Case Construction Equipment<br />

has introduced the new 621F<br />

wheel loader. The new machine<br />

provides up to a 10-percent<br />

increase in fuel economy over the<br />

previous model, while delivering<br />

faster acceleration, quicker cycle<br />

times and higher travel speeds.<br />

The new Case 621F wheel loader, like other<br />

models in the product line, evolved from the<br />

company’s E Series machines. To meet Tier<br />

4 Interim emissions standards, the Case F<br />

Series wheel loaders use selective catalytic<br />

reduction (SCR) technology, which results<br />

in lower temperatures in the exhaust system<br />

while optimizing combustion. The Case<br />

621F wheel loader features a 6.7-liter Tier 4<br />

Interim-certified engine that delivers up to<br />

162 hp (121 kW). Classified as a 2.75 yd3<br />

(2.1 m3) wheel loader, the Case 621F has an<br />

operating weight of 26,641 lb (12 084 kg).<br />

Significant fuel savings<br />

Like other F Series models, the 621F<br />

offers four programmable power modes<br />

to save fuel and increase available power.<br />

These easy-to-program power modes –<br />

Economy, Standard, Max and Auto – give<br />

operators flexibility in matching engine<br />

power to their jobs. A new dual-mode<br />

shutdown feature maximizes fuel economy<br />

and monitors vital engine components.<br />

Using the fuel-saver mode, the operator<br />

can limit the time the machine will idle.<br />

The desired shutdown time can be set in<br />

five-minute increments. The automatic<br />

engine shutdown feature can provide up to<br />

another 30 percent in fuel savings.<br />

Breakthrough productivity<br />

The new Case wheel loaders include<br />

standard limited-slip front and rear<br />

axles that provide outstanding traction<br />

in all conditions, especially in noncompacted<br />

surfaces, such as gravel.<br />

Optional heavy-duty axles with locking<br />

front and conventional rear differentials<br />

help reduce tire wear when working on<br />

hard surfaces. The standard four-speed<br />

transmission with manual kick-down<br />

capability provides maximum traction and<br />

increased bucket penetration.<br />

The Case 621F wheel loader can perform<br />

in a wide range of applications, from<br />

construction sites to aggregate operations.<br />

Case also offers a Commodity King<br />

option package that takes advantage<br />

of its unique mid-mounted cooling<br />

module. The Commodity King package<br />

provides special cooling and air filtration<br />

components for working in cement plants,<br />

agriculture and other applications where<br />

the machine operates in extremely dusty<br />

or particulate-laden environments.<br />

The award-winning Case joystick<br />

steering enables operators to seamlessly<br />

move between the joystick and steering<br />

wheel for high-production operations.<br />

An optional two-lever hydraulic control<br />

system is available. The Case PowerInch<br />

feature lets the operator quickly and<br />

precisely approach targets in tight areas,<br />

regardless of engine speed. PowerInch<br />

maintains high RPMs to maximize<br />

hydraulic power and control.<br />

Comfort in the Cab<br />

The Case 621F is the latest F Series<br />

wheel loader model to provide enhanced<br />

comfort and safety features that help boost<br />

operator productivity. The cab offers an<br />

unobstructed view to both edges of the<br />

bucket or attachment, while a wide window<br />

and sloping hood provide clear vision<br />

to the rear. A new rearview, wide-angle<br />

camera with an adjustable color monitor is<br />

available in the Case F Series. The camera<br />

option nearly eliminates blind spots and is<br />

ideal for jobs that require operating around<br />

other machines or workers.<br />

For further information contact your local<br />

Case dealer.<br />

26 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012-06 2012StahlPeterbilt EquipReviewAd - 7-5x10 - outlined.indd 1 EQUIPMENT 6/19/2012 REVIEW 11:14:41 AM27

Tensar P500<br />

Turf/Earth<br />

Reinforcement<br />

Mats<br />

Lafarge Duraclime<br />

Asphalt<br />

Reduces emissions, fuel consumption,<br />

smoke, and odors<br />

For high-load and severe erosion<br />

applications, the North American<br />

Green P500 Turf/Earth Reinforcement<br />

Mat (TERM) is designed to offer veneer<br />

stabilization and high tensile strength<br />

for increased durability in high-impact<br />

conditions. The combination of highstrength<br />

geogrids, heavy UV-stabilized<br />

nets and a permanent polypropylene<br />

fiber matrix allow for surface vegetation<br />

without soil infilling. Unlike some woven<br />

monofilament TRMs, the stitched matrix<br />

does not impede vegetation growth.<br />

When combined with Tensar’s North<br />

American Green Earth Anchors (EA) the<br />

P500 TERM forms a flexible armoring<br />

system that controls erosion, reinforces<br />

vegetation and stabilizes the earth in the<br />

most extreme situations. The P500 Turf/<br />

Earth Reinforcement Mat (TERM) is<br />

designed to control erosion and reinforce<br />

vegetation in high-load and severe erosion<br />

applications. The P500 TERM features<br />

easy installation with no soil infilling<br />

required, yet offers the high-tensile strength<br />

needed in certain high-impact river, canal,<br />

and levee stabilization projects.<br />

P500 TERM System Features and<br />

Benefits<br />

• Higher tensile strength for increased<br />

durability in high-load conditions and<br />

veneer stabilization<br />

• Combination of high strength geogrid,<br />

heavy UV-stabilized nets, a permanent<br />

polypropylene fiber matrix<br />

• Stitched matrix allows for surface<br />

application without soil infilling and<br />

does not impede vegetation growth like<br />

some woven monofilament TRMs.<br />

• Surface application dramatically reduces<br />

installation time, labor and cost<br />

• Easy to install with no heavy equipment<br />

required<br />

• Offers flexible lining that won’t crack<br />

and deteriorate like concrete, creating a<br />

more economical design<br />

• Provides an aesthetically pleasing,<br />

natural, “green” soft-armor solution<br />

Applications for P500 TERM System<br />

• Roadside channel / swale / slope<br />

applications where conventional TRMs<br />

are subject to damage from vehicular<br />

traffic or maintenance equipment<br />

• Rivers and canals where TRMs are<br />

subject to damage from ice and/or<br />

debris flows<br />

• Levee protection requiring both<br />

permanent erosion control and shallow<br />

soil stability<br />

• Shallow slope (veneer) stabilization and<br />

erosion control<br />

• Construction of reinforced soil lifts for<br />

bioengineering streambank protection<br />

Earth Anchor Technology<br />

Earth Anchors (EA), manufactured<br />

exclusively for Tensar’s North American<br />

Green erosion control product line, can<br />

offer a system that controls erosion and<br />

reinforces vegetation in the most extreme<br />

situations – especially when combined with<br />

turf/earth reinforcement mats (TERMs).<br />

The North American Green Earth Anchors<br />

reach deep into the soil strata to offer<br />

enhanced anchoring in the worst conditions.<br />

How Do Earth Anchors Work?<br />

The corrosion resistant earth anchors<br />

increase the mechanical strength of the<br />

veneer both during installation and use. The<br />

earth anchors are connected to a stainless<br />

steel or galvanized tendon which extends<br />

to the surface and is secured with a plate<br />

that anchors the TRM. The surface plate<br />

exerts a load on the anchor that compresses<br />

the soil above the anchor and provides<br />

resistance to further anchor movement.<br />

Visit: www.nagreen.com for more<br />

information.<br />

As a leading producer of building<br />

materials, Lafarge is developing<br />

innovative products and new solutions<br />

for customers across the construction<br />

industry, including a new range of<br />

cements, high-strength concrete, and<br />

multipurpose drywall, bringing greater<br />

safety, comfort, and quality to everyday<br />

surroundings. Lafarge Asphalt has<br />

developed the ‘Durapave’ product range<br />

to provide asphalt solutions, which deliver<br />

optimum quality, performance, durability<br />

and sustainability. Each of the products<br />

in its Durapave series offers unique<br />

performance characteristics designed to<br />

address a range of needs such as moisture<br />

damage, high axle loading and sound<br />

attenuation.<br />

‘Duraclime’ is one of the products in the<br />

Durapave product range. It uses warm<br />

mix asphalt technology to enable the<br />

production of asphalt mixes at reduced<br />

temperatures while also incorporating<br />

higher levels of reclaimed asphalt<br />

pavement (RAP) and asphalt shingle<br />

modifier (ASM).<br />

Product Overview<br />

Mixed at lower temperatures, Duraclime<br />

reduces emissions, fuel consumption,<br />

smoke, and odors during the<br />

manufacturing process. This improves<br />

the comfort, safety, and environment for<br />

workers during construction operations.<br />

Residents in local communities and the<br />

traveling public notice the improved air<br />

quality near asphalt plants and paving<br />

sites.<br />

The use of Duraclime can reduce the<br />

carbon footprint of a plant by10 to 20<br />

percent. With widespread implementation<br />

at all asphalt plants in North America,<br />

this reduction would be equivalent to<br />

removing the emissions from 200,000 to<br />

500,000 cars a year.<br />

Technical Benefits of Duraclime<br />

• Reduced emissions<br />

• Lower consumption of fossil fuels<br />

• Reduced smoke and odors<br />

• Improved comfort, safety, and working<br />

environment<br />

• Improved workability<br />

• Extended compaction time, with more<br />

uniform compaction across the mat<br />

• Reduced thermal segregation<br />

• Proven performance in warm and cold<br />

climates<br />

• Ability to incorporate high levels of<br />

recycled materials<br />

Product Performance<br />

Duraclime exhibits exceptional<br />

performance characteristics: Longer<br />

pavement life because the light oils<br />

stay in the binder, reducing aging<br />

hardening; reduced thermal segregation;<br />

more uniform compaction; and longer<br />

compaction times.<br />

The superior performance of Duraclime<br />

in North America has been demonstrated<br />

through extensive laboratory testing as<br />

well as on several in-service projects.<br />

The Duraclime production process does<br />

not affect the asphalt binder rheology or<br />

performance grade (PG) classification.<br />

Additionally, the lower mixing<br />

temperatures are a sign of reduced aging<br />

of the asphalt binder.<br />

Asphalt pavement analyzer (APA) wheel<br />

rut testing and tensile strength ratio<br />

(TSR) moisture susceptibility testing<br />

on Duraclime indicate comparable<br />

performance to conventional HMA, with<br />

the TSR results showing that Duraclime<br />

has a high resistance to moisture-induced<br />

damage.<br />

For more information visit:<br />

www.lafargenorthamerica.com<br />

28 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 29

30 EQUIPMENT REVIEW<br />

www.equipmentreview.ca<br />

Summer 2012 EQUIPMENT REVIEW 31