You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INTRODUCTION<br />

The starting system is designed to provide the vehicle<br />

operator with a convenient, efficient and reliable means of<br />

cranking and starting the internal combustion engine used to<br />

power the vehicle and all of its accessory systems from within<br />

the safe and secure confines of the passenger compartment.<br />

The starting system consists of the following components:<br />

0 Battery<br />

Starter relay<br />

0 Starter motor (including an integral starter solenoid)<br />

0 Ignition switch<br />

0 Parkheutral position switch<br />

0 Wire harnesses and connections (including the battery<br />

cables).<br />

Operation<br />

The starting system components form two separate circuits.<br />

A high-amperage feed circuit that feeds the starter motor<br />

between 150 and 350 amperes, and a low-amperage control<br />

circuit that operates on less than 20 amperes. The highamperage<br />

feed circuit components include the battery,<br />

battery cables, the contact disc portion of the starter<br />

solenoid, and the starter motor. The low-amperage control<br />

circuit components include the ignition switch, the<br />

parkheutral position switch, the starter relay, the<br />

electromagnetic windings of the starter solenoid, and the<br />

connecting wire harness components.<br />

Battery voltage is supplied through the low-amperage<br />

control circuit to the coil battery terminal of the starter relay<br />

when the ignition switch is turned to the momentary Start<br />

position. The parkheutral position switch is installed in<br />

series between the starter relay coil ground terminal and<br />

ground. This normally open switch prevents the starter<br />

relay from being energized and the starter motor from<br />

operating unless the automatic transmission gear selector is<br />

in the Neutral or Park positions.<br />

When the starter relay coil is energized, the normally open<br />

relay contacts close. The relay contacts connect the relay<br />

Common feed terminal to the relay normally open<br />

terminal. The closed relay contacts energize the starter<br />

solenoid coil windings.<br />

The energized solenoid pull-in coil pulls in the solenoid<br />

Plunger. The solenoid plunger pulls the shift lever in the<br />

starter motor. This engages the starter overrunning clutch<br />

and pinion gear with the starter ring gear on the automatic<br />

transmission torque converter drive plate.<br />

4.OL POWER TECH IN-LINE 6 (STARTING SYSTEM) 247<br />

<strong>Starting</strong> <strong>System</strong><br />

As the solenoid plunger reaches the end of its travel, the<br />

solenoid contact disc completes the high-amperage starter<br />

feed circuit and energizes the solenoid plunger hold-in coil.<br />

Current now flows between the solenoid battery terminal<br />

and the starter motor, energizing the starter.<br />

Once the engine starts, the overrunning clutch protects the<br />

starter motor from damage by allowing the starter pinion<br />

gear to spin faster than the pinion shaft. When the driver<br />

releases the ignition switch to the On position, the starter<br />

relay coil is de-energized. This causes the relay contacts to<br />

open. When the relay contacts open, the starter solenoid<br />

plunger hold-in coil is de-energized.<br />

When the solenoid plunger hold-in coil is de-energized, the<br />

solenoid plunger return spring returns the plunger to its<br />

relaxed position. This causes the contact disc to open the<br />

starter feed circuit, and the shift lever to disengage the<br />

overrunning clutch and pinion gear from the starter ring gear.<br />

Following are general descriptions of the major<br />

components in the starting system.<br />

STARTER MOTOR<br />

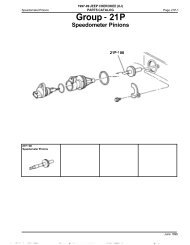

(Refer to Figure 4-52.)<br />

The starter motor incorporates several features to create a<br />

reliable, efficient, compact, lightweight and powerful unit.<br />

The electric motor of the starter features four<br />

electromagnetic field coils wound around four pole shoes,<br />

and four brushes contact the motor commutator. The starter<br />

motor is rated at 1.4 kilowatts (about 1.9 horsepower)<br />

output at 12 volts.<br />

The starter motor is serviced only as a unit with its starter<br />

solenoid and cannot be repaired. If either component is<br />

faulty or damaged, the entire starter motor and starter<br />

solenoid unit must be replaced.<br />

Operation<br />

The starter motor is equipped with a planetary gear<br />

reduction (intermediate transmission) system. The<br />

planetary gear reduction system consists of a gear that is<br />

integral to the output end of the electric motor armature<br />

shaft that is in continual engagement with a larger gear that<br />

is splined to the input end of the starter pinion gear shaft.<br />

This feature makes it possible to reduce the dimensions of<br />

the starter. At the same time, it allows higher armature<br />

rotational speed and delivers increased torque through the<br />

starter pinion gear to the starter ring gear.

248 MOPAR PERFORMANCE PARTS<br />

1<br />

Starter Motor and Solenoid<br />

Manufacturer<br />

Mitsubishi<br />

Engine Application 2.5L, 4.0L<br />

2.5L 1.2 Kilowatt (1.6 Horsepower)<br />

Power Rating<br />

4.0L - 1.4 Kilowatt (1.9 Horsepower)<br />

Voltaae I 12 Volts I<br />

"<br />

Number of Fields 4<br />

Number of Poles 4<br />

Number of Brushes 4<br />

nrive -...- Tvne<br />

Planetarv Gear Reduction<br />

.,r-<br />

I<br />

" -<br />

Free Running Test Maximum Amperage Draw<br />

90 Amperes<br />

Free Running Test Minimum Speed<br />

2.5L 2600 rpm<br />

4.0L - 2500 rpm<br />

Solenoid Closina - Maximum Voltage - Required<br />

7.8 volts<br />

Free Runnina Test Voltaae I 11.2 Volts I<br />

2.5L - 130 Amperes<br />

4.0L - 160 Amperes<br />

*Cranking Amperage Draw Test<br />

I<br />

*Test at operating temperature. Cold engine, tight (new) engine, or heavy oil will increase starter amperage draw.<br />

Figure 4 - 52<br />

The starter motor is activated by an integral heavy duty<br />

starter solenoid switch mounted to the overrunning clutch<br />

housing. This electromechanical switch connects and<br />

disconnects the feed of battery voltage to the starter motor<br />

and actuates a shift fork that engages and disengages the<br />

starter pinion gear with the starter ring gear.<br />

The starter motor uses an overrunning clutch and starter<br />

pinion gear unit to engage and drive a starter ring gear that<br />

is integral to the torque converter drive plate mounted on<br />

the rear crankshaft flange.<br />

STARTER RELAY<br />

The starter relay is an electromechanical device that<br />

switches battery current to the pull-in coil of the starter<br />

solenoid when the ignition switch is turned to the Start<br />

position. The starter relay is located in the Power<br />

Distribution Center (PDC) in the engine compartment. See<br />

the fuse and relay layout label affixed to the inside surface<br />

of the PDC cover for starter relay identification and<br />

location. The starter relay cannot be repaired or adjusted<br />

and, if faulty or damaged, it must be replaced.<br />

BAlTERY<br />

It is very important that the battery be fully charged in<br />

racing applications with an electronic ignition. A volt meter<br />

should be used to check the battery voltage before the<br />

vehicle is raced. The voltage should not be allowed to drop<br />

below 12.0 volts. Lower voltage will cause poor ignition<br />

performance such as misfires and will result in slowing the<br />

vehicle down. It may also cut down on the electric fuel<br />

pump's efficiency.<br />

Brass Battery Terminals<br />

Here's a variety of brass terminals in different styles that<br />

offer maximum conductivity. Feature positive threaded<br />

attachments. Designed for large gauge wire used in battery<br />

relocation kits with features best liked and required by<br />

racers.<br />

P4349575<br />

P4349576<br />

P4349577<br />

P4349578<br />

P4349579<br />

P4349580<br />

Battery terminal with left or right cable<br />

connection - 1 gauge wire.<br />

Ring terminal, 3/8" eye - 1 gauge .wire.<br />

Battery terminal with left or right cable<br />

connection - 4 gauge wire.<br />

Ring terminal, 318" eye - 4 gauge wire.<br />

Quick disconnect "positive" battery<br />

terminal with 318" stud.<br />

Quick disconnect "negative" battery<br />

terminal with 318" stud.

4.0L POWER TECH IN-LINE 6 (STARTING SYSTEM) 249<br />

Battery Relocation<br />

Most race vehicles begin life with the battery in the<br />

engine compartment.<br />

Mounting the battery in the trunk of a RWD race vehicle<br />

helps by shifting weight over the drive wheels (improving<br />

traction) and by making the engine compartment less<br />

cluttered. But there's more to a trunk mounted battery kit<br />

than just putting the battery in the trunk. Physically moving<br />

the battery is easy. The problem is that the battery must still<br />

operate the engine's ignition and fuel delivery systems, and<br />

with the battery eight feet away from the ignition system<br />

(usually a high output electronic race unit), minimizing<br />

voltage drop is critical.<br />

To minimize voltage drop, the Mopar Performance Parts<br />

trunk mounted battery kit (P4349500) uses #1 gauge wire,<br />

while the competition uses #4 gauge. The smaller the gauge<br />

number the bigger the wire size. The bigger the wire size<br />

the less voltage drop occurs. To provide the best electrical<br />

conductor available, Mopar Performance Parts supplies<br />

copper wire-the competition uses aluminum. Copper is a<br />

better electrical conductor than aluminum. The better the<br />

conductor, the less voltage drop occurs in the same<br />

distance; that is, trunk to engine compartment. Handcrimped<br />

terminals can lead to problems such as voltage<br />

losses, loose connections, and so on. That's why the Mopar<br />

Performance Parts cable has factory-installed threaded<br />

brass terminals.<br />

Some people feel that a full length ground cable is required.<br />

This is acceptable, but it adds a lot of weight and isn't<br />

necessary. The engine is already grounded from the block<br />

to the firewall of the body/frame (unibody). Check to be<br />

sure. The Mopar Performance Parts package includes a<br />

ground strap to ground the battery to the frame in the trunk<br />

area. The Mopar Performance Parts package also includes<br />

many convenience items such as starter to relay and<br />

solenoid wires, terminals, firewall grommets, and battery<br />

cover. Other kits don't include these items. However, it<br />

does not include a battery.<br />

Trunk Mounted Battery Kit<br />

This improved kit is designed for moving the battery to<br />

the trunk. Improves weight distribution which is so<br />

important for drag racers. It means less clutter in the<br />

engine compartment, and helps provide better traction. It<br />

will even contribute to improved braking and less<br />

understeer in hard turns for oval trackers and rallyers. Kit<br />

will fit nearly any vehicle. Does not include battery.<br />

P4349500<br />

Trunk mounted battery kit.<br />

i<br />

I I IP I 1 I I I II I' ' 1'<br />

I1 1 I 1 I