Slurry Management Systems

Supavac Overview

Supavac Overview

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Slurry</strong> <strong>Management</strong> <strong>Systems</strong>

SUPAVAC - a brief background:<br />

• Supavac Pty Ltd are Australian based company that commenced operations in its<br />

current format in 1993. Over the past 17 years Supavac has developed a diverse<br />

range of <strong>Slurry</strong> <strong>Management</strong> <strong>Systems</strong> which includes our comprehensive range of<br />

compressed air driven vacuum loading solids pumps.<br />

• Supavac have long been at the forefront of venturi technology and design<br />

manufacturing both bespoke systems along with our standard lines. Currently<br />

exporting to some 13 countries and have operations in Santiago, Chile and Jinan,<br />

China and the United States.<br />

• Supavac solids pumps have been employed in a range of applications around the<br />

globe. These include both coal and hard rock mining, on and offshore drilling,<br />

municipal waste, intensive feedlot and aquaculture operations and hazardous waste<br />

capture and transfer.<br />

• Supavac's base range of pumps can recover and convey a vast array of products not<br />

normally considered "pumpable“. These include coal, drill cuttings, bentonite, oil<br />

sludge, concrete waste, sewage, bauxite, mud, fly ash, copper concentrate, sand,<br />

grains and fibres, in fact most flowable materials.

SUPAVAC – the advantages:<br />

• Supavac’s pumps are not a competitor for conventional pumps, they come into their own<br />

when traditional pumps fail due to the high solids nature of the material being conveyed. In<br />

order to move a large amount of solids, centrifugal and submersible pumps must operate<br />

with high flows, usually having to oversize for the job.<br />

• Supavac pumps are fully automatic, with capacities from 13 to 80 yd 3 /h of heavy solids and<br />

are available in carbon steel or optional 316 stainless steel construction. Units are compact<br />

and fully enclosed for zero discharge for environmental compliance.<br />

Supavac’s vacuum slurry pumps are entirely compressed air operated, leading to wide use<br />

in many hazardous areas. Features of the pumps are:<br />

• No electricity<br />

• Self priming<br />

• No rotating parts<br />

• No moving parts in contact with the material being pumped<br />

• Can be run dry indefinitely<br />

• Lean or dense phase conveying<br />

• Creates high vacuum and airflow independently of the material being conveyed<br />

• Robust construction<br />

• Simple and fast setup

SUPAVAC – In Action<br />

•FAST<br />

• SG 2.2 – 2.5<br />

• FIXED<br />

• MOBILE

SUPAVAC

SUPAVAC - Offshore<br />

•OBM O and WBM Capture and transfer<br />

• Rates up to 30 tonnes per hour<br />

• 100% air powered and operated<br />

• Pendingan Indonesia<br />

• UK North Sea

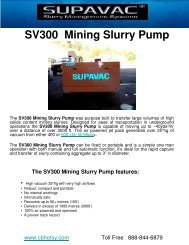

SUPAVAC - Mining<br />

Typical Submersible<br />

issues ..with a typical<br />

Supavac Solution….<br />

TYPICAL APPLICATIONS

SUPAVAC - Tank Cleaning

SUPAVAC – Discharge/Delivery<br />

• Supavac’s can discharge material from 5 to<br />

1000 metres depending on both the pipe run and<br />

the material being conveyed.<br />

Dead Head<br />

SV250-250<br />

SV250-V400

SUPAVAC - Applications<br />

• COAL AND HARDROCK MINING<br />

• PITS AND QUARRIES<br />

• TUNNELING AND CIVIL WORKS<br />

• MUNICIPAL FILTRATION, WWTP AND PUBLIC WORKS<br />

• ON AND OFFSHORE DRILLING, CUTTINGS AND MUD<br />

TRANSFER<br />

• BARGE, TANKER AND HOLD CLEANING<br />

• PNEUMATIC EXCAVATION AND TRANSFER<br />

• PETROCHEMICAL INDUSTRY<br />

• AGRICULTURE AND AQUACULTURE<br />

• HAZARDOUS WASTE TRANSFER AND SPILLAGE RECOVERY<br />

• CONTRACTORS<br />

• EMERGENCY SPILL RESPONSE

SUPAVAC – Maintenance<br />

• All units utilize the<br />

same components<br />

• Few moving parts<br />

while in operation<br />

• Basic operation<br />

• Built strong<br />

• Simple<br />

• Low wear<br />

• Easy to<br />

maintain

SUPAVAC – <strong>Slurry</strong> Dewatering<br />

DESIGN CONCEPT:<br />

The SUPAVAC SMS unit was<br />

developed to address two significant<br />

issues. The first, what to do with the<br />

increasing amount of slurry generated<br />

by today’s Longwall operations. The<br />

second, deliver a cost effective system<br />

of self cleaning “fish tanks” to keep<br />

the solids out of a mines pump<br />

system.<br />

DESIGN CRITERIA:<br />

The SMS unit’s had to be<br />

• Safe, workable and user friendly<br />

• Versatile<br />

• Simple and efficient<br />

• Robust in construction<br />

• Built for variable mine applications<br />

• High volume return for a low energy<br />

input<br />

The SMS unit manufactured in 304 s/steel on a<br />

heavy duty skid base.<br />

All rights reserved ©

SMS ‐ Versatility<br />

This SMS‐366 unit installed below operates a single 366 Bisalloy 400 shaftless<br />

screw, capable of dewatering 30,000 litres of slurry per hour

SMS

SUPAVAC SMS‐<br />

*366‐280 and 197<br />

SMS‐366 unit supplied to Allied Contracting,<br />

* TECHNICAL SPEC’S:<br />

dewatering casting sludge.<br />

BHP Billiton Port Kembla steel works.<br />

• Weight‐ 2931 Lb (1332 kg)<br />

• Height‐ 9’8” (2.9m)<br />

• Length‐ 19’5” (5.8m)<br />

• Throughput 8,600 GPH (30,000L)<br />

000L)<br />

• Particle size

SUPAVAC SMS Unit General Arrangement drawing.<br />

All rights reserved ©

SUPAVAC SMS<br />

Note: Water<br />

from overflow .<br />

Casting sludge dewatered, note overflow pump sample.<br />

All rights reserved ©

SUPAVAC – <strong>Slurry</strong> <strong>Management</strong><br />

Recovery….Solids handling… SMS……….….dewatering.<br />

Note:<br />

Residual<br />

moisture<br />

content.<br />

All rights reserved ©

SUPAVAC – SMS197<br />

Material Inlet<br />

•FAST<br />

•RELIABLE<br />

•EFFICIENT<br />

Clean<br />

Water<br />

Overflow<br />

• Compact<br />

• Low Power .11kwatt<br />

• 20cfm Air Drive<br />

• Full 304 s/steel<br />

• Bisalloy 400 Auger<br />

• 5,700 GPH Capacity<br />

• Hot dipped gal frame<br />

• 9’8” Length<br />

• 5’ 8” Height ih<br />

• 4’ Width

GLOBAL PRESENCE

SUPAVAC –<br />

www.supavac.com<br />

• SALES<br />

• CONTRACTING<br />

• RENTAL