TotalArc 3000 / 4000 / 5000

TotalArc² 3000/4000/5000 - Eutectic

TotalArc² 3000/4000/5000 - Eutectic

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

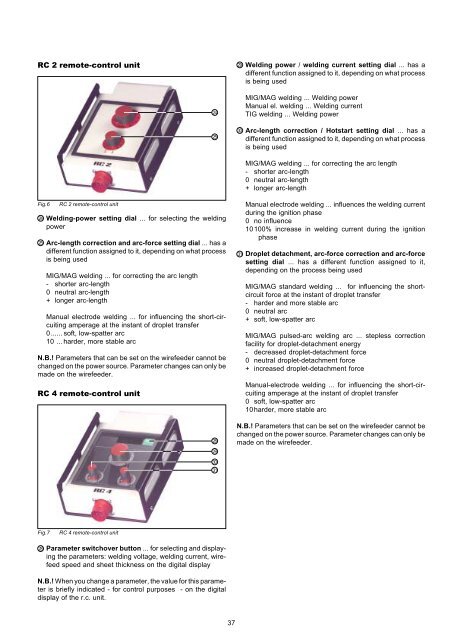

RC 2 remote-control unit<br />

Welding power / welding current setting dial ... has a<br />

different function assigned to it, depending on what process<br />

is being used<br />

MIG/MAG welding ... Welding power<br />

Manual el. welding ... Welding current<br />

TIG welding ... Welding power<br />

Arc-length correction / Hotstart setting dial ... has a<br />

different function assigned to it, depending on what process<br />

is being used<br />

MIG/MAG welding ... for correcting the arc length<br />

- shorter arc-length<br />

0 neutral arc-length<br />

+ longer arc-length<br />

Fig.6<br />

RC 2 remote-control unit<br />

Welding-power setting dial ... for selecting the welding<br />

power<br />

Arc-length correction and arc-force setting dial ... has a<br />

different function assigned to it, depending on what process<br />

is being used<br />

MIG/MAG welding ... for correcting the arc length<br />

- shorter arc-length<br />

0 neutral arc-length<br />

+ longer arc-length<br />

Manual electrode welding ... for influencing the short-circuiting<br />

amperage at the instant of droplet transfer<br />

0...... soft, low-spatter arc<br />

10 ... harder, more stable arc<br />

N.B.! Parameters that can be set on the wirefeeder cannot be<br />

changed on the power source. Parameter changes can only be<br />

made on the wirefeeder.<br />

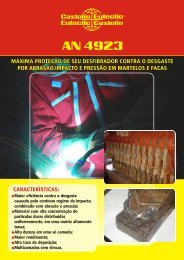

RC 4 remote-control unit<br />

Manual electrode welding ... influences the welding current<br />

during the ignition phase<br />

0 no influence<br />

10100% increase in welding current during the ignition<br />

phase<br />

Droplet detachment, arc-force correction and arc-force<br />

setting dial ... has a different function assigned to it,<br />

depending on the process being used<br />

MIG/MAG standard welding ... for influencing the shortcircuit<br />

force at the instant of droplet transfer<br />

- harder and more stable arc<br />

0 neutral arc<br />

+ soft, low-spatter arc<br />

MIG/MAG pulsed-arc welding arc ... stepless correction<br />

facility for droplet-detachment energy<br />

- decreased droplet-detachment force<br />

0 neutral droplet-detachment force<br />

+ increased droplet-detachment force<br />

Manual-electrode welding ... for influencing the short-circuiting<br />

amperage at the instant of droplet transfer<br />

0 soft, low-spatter arc<br />

10harder, more stable arc<br />

N.B.! Parameters that can be set on the wirefeeder cannot be<br />

changed on the power source. Parameter changes can only be<br />

made on the wirefeeder.<br />

Fig.7<br />

RC 4 remote-control unit<br />

Parameter switchover button ... for selecting and displaying<br />

the parameters: welding voltage, welding current, wirefeed<br />

speed and sheet thickness on the digital display<br />

N.B.! When you change a parameter, the value for this parameter<br />

is briefly indicated - for control purposes - on the digital<br />

display of the r.c. unit.<br />

37