TITECH finder

TITECH finder

TITECH finder

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

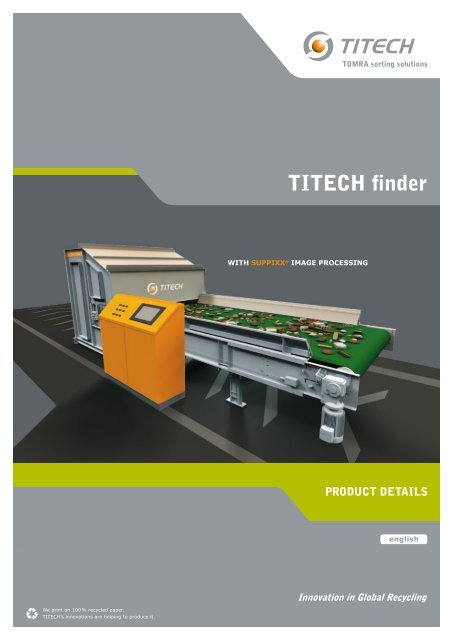

<strong>TITECH</strong> <strong>finder</strong><br />

WITH SUPPIXX ® IMAGE PROCESSING<br />

PRODUCT DETAILS<br />

english<br />

We print on 100 % recycled paper.<br />

<strong>TITECH</strong>’s innovations are helping to produce it.

1<br />

3<br />

4<br />

2<br />

1<br />

2<br />

3<br />

4<br />

Feeding of unsorted material<br />

Electromagnetic sensor<br />

Optional NIR scanner<br />

Separation chamber<br />

New 12.5 mm sensors with SUPPIXX ® technology increases<br />

purity and recovery rate<br />

<strong>TITECH</strong> <strong>finder</strong><br />

<br />

<br />

<br />

TECHNOLOGY<br />

The new Finder generation uses the highly sophisticated SUPPIXX ® image processing<br />

technology and provides a completely new quality of sensitivity and accuracy. The<br />

®<br />

image processing enhances the resolution of the digitalised sensor signals. Thus<br />

<br />

subsequently separate them with a high degree of purity.<br />

Resolution //<br />

<br />

<br />

<br />

BENEFITS<br />

Even lower operating costs due to SUPPIXX ®<br />

Extremely fast payoff<br />

High degree of purity of the metal fraction<br />

Extremely high throughput without loss of purity<br />

High metal output – more valuable material<br />

New sortable tasks due integration of NIR sensor (like wire recovery)<br />

Emergency service hotline

EXAMPLE // AUTOMOBILE RECYCLING<br />

Automobile shredder systems can recycle a high percentage of ferrous and nonferrous<br />

metals from the crushed car bodies. The residues however still contain up<br />

<br />

highly sensitive sensors can detect even the smallest metal particles and separate<br />

<br />

fraction, the eddy-current waste and the lightweight fraction. Mixed metals are thus<br />

<br />

free of metals.<br />

<br />

conditions. You are welcome to check your individual material in our test<br />

facility. E-mail: info@titech.com<br />

SENSOR CONFIGURATIONS<br />

A // Our highly sensitive electromagnetic sensor (EM) with SUPPIXX ® image processing<br />

recognizes materials based on their conductivity for highest product purities on<br />

high throughput requirements – EM3<br />

B // The combination of an EM sensor and a near infrared (NIR) spectrometry sensor<br />

delivers information to recognize materials based on their conductivity and<br />

unique spectral properties – EM3-NIR1 (“poly”)<br />

MODELS<br />

STANDARD APPLICATION PACKAGES<br />

A<br />

B<br />

ALL METAL recovery<br />

STAINLESS STEEL<br />

WIRE recovery<br />

PLASTICS recovery<br />

Recovering all metals<br />

Producing a clean stainless steel fraction<br />

Producing a clean insulated copper wire fraction<br />

Recovering all visible plastics<br />

<br />

<br />

<br />

<br />

<br />

<br />

POLYMER sorting<br />

SPECIAL APPLICATIONS<br />

Separating different polymers, e.g. PP/PS/PE, ABS/<br />

ABS-PC<br />

on request

<strong>TITECH</strong> autosort<br />

C<br />

E<br />

B<br />

A<br />

Installation example<br />

<strong>TITECH</strong> <strong>finder</strong><br />

D<br />

<strong>finder</strong><br />

600<br />

<strong>finder</strong><br />

1200<br />

<strong>finder</strong><br />

1800<br />

<strong>finder</strong>*<br />

2400<br />

<strong>finder</strong>*<br />

3000<br />

A // 600 mm 1,200 mm 1,800 mm 2,400 mm 3,000 mm<br />

B // 1,400 mm 2,000 mm 2,600 mm 3,200 mm 3,800 mm<br />

C // 4,000 mm 4,000 mm 4,000 mm 5,000 mm 6,000 mm<br />

D // 6,218 mm 6,218 mm 6,218 mm 7,659 mm 8,659 mm<br />

E // 2,084 mm 2,084 mm 2,084 mm 2,115 mm 2,115 mm<br />

Valve block model, nozzle distance<br />

<strong>finder</strong><br />

600<br />

<strong>finder</strong><br />

1200<br />

<strong>finder</strong><br />

1800<br />

<strong>finder</strong>*<br />

2400<br />

<strong>finder</strong>*<br />

3000<br />

Economic, 12.5 mm 24 valves 48 valves 72 valves 96 valves 120 valves<br />

Power, 6.25 mm 48 valves 96 valves 144 valves 192 valves 240 valves<br />

Speed, 6.25 mm 96 valves 192 valves 288 valves 384 valves 480 valves<br />

Weight 2580 kg 3550 kg 4360 kg 5760 kg 6520 kg<br />

Power Consumption 4.3 kW 4.3 kW 6.1 kW 6.6 kW 8.1 kW<br />

OPTIONS<br />

Sensor height adjustment<br />

For improved adaptability to special<br />

application needs<br />

Wear and tear package<br />

Heavy duty version for higher<br />

robustness and a longer life<br />

Remote Access<br />

Safe network connection for easy and<br />

fast service reaction<br />

Rotating splitter<br />

Automatic cleaning of the splitter for<br />

higher purity<br />

Double track<br />

Sorting two grain sizes with one<br />

detection unit<br />

Satellite solution<br />

Use one operation panel for the<br />

control of two detection units<br />

PRODUCT RANGE<br />

<strong>TITECH</strong> autosort<br />

Mixed packaging waste, RDF, Sorting<br />

paper, PET/PE recycling<br />

<strong>TITECH</strong> <strong>finder</strong><br />

Metal recovery and metal contaminant<br />

removal<br />

<strong>TITECH</strong> combisense<br />

E-scrap recycling, nonferrous metal<br />

processing, cable recycling<br />

<strong>TITECH</strong> x-tract<br />

Automobile recycling, CRT glass,<br />

industrial/domestic waste, RDF<br />

production<br />

*not available in configuration B // EM3 – NIR1<br />

Keep up to date with<br />

sensor-based sorting at:<br />

WWW.<strong>TITECH</strong>.COM<br />

Headquarter & Nordic<br />

<strong>TITECH</strong> AS<br />

Drengsrudhagen 2<br />

PO box 278<br />

1372 Asker<br />

Norway<br />

Phone: +47 66 75 24 40<br />

Fax: +47 66 79 91 11<br />

info@titech.com<br />

UK & Ireland<br />

<strong>TITECH</strong> UK<br />

The Springboard Centre<br />

Mantle Lane, Coalville<br />

Leicestershire, LE67 3DW<br />

United Kingdom<br />

Phone: +44 1530 839 531<br />

Fax: +44 1530 810 231<br />

info-uk@titech.com<br />

Australia<br />

DKSH Australia Pty. Ltd.<br />

1 4 - 1 7 D a n s u C o u r t<br />

Hallam Vic 3803<br />

Australia<br />

Phone: +61 3 9554 6666<br />

Fax: +61 3 9554 6688<br />

eric.paulsen@dksh.com<br />

www.dksh.com.au/ets<br />

India<br />

Leevams Incorporated<br />

465, G.I.D.C., Makarpura<br />

Vadodara – 390 010<br />

Gujarat (India)<br />

Phone: +91 265 2637545<br />

Fax: +91 265 3932464<br />

sales@leevams.in<br />

www.leevams.in<br />

2011/08 GB M010302-07 www.neuekoordinaten.de