August/September 2009 - Low Resolution - PAWPRINT PUBLISHING

August/September 2009 - Low Resolution - PAWPRINT PUBLISHING

August/September 2009 - Low Resolution - PAWPRINT PUBLISHING

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

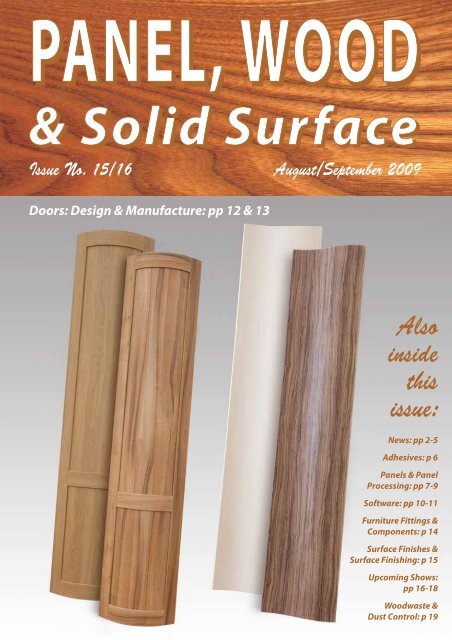

PANEL, WOOD<br />

& Solid Surface<br />

Issue No. 15/16 <strong>August</strong>/<strong>September</strong> <strong>2009</strong><br />

Doors: Design & Manufacture: pp 12 & 13<br />

Also<br />

inside<br />

this<br />

issue:<br />

News: pp 2-5<br />

Adhesives: p 6<br />

Panels & Panel<br />

Processing: pp 7-9<br />

Software: pp 10-11<br />

Furniture Fittings &<br />

Components: p 14<br />

Surface Finishes &<br />

Surface Finishing: p 15<br />

Upcoming Shows:<br />

pp 16-18<br />

Woodwaste &<br />

Dust Control: p 19

NEWS<br />

10,000th Combilift delivered to Weyerhaeuser<br />

COMBILIFT Ltd, believed to be<br />

the world’s leading supplier of<br />

four-way forklifts, celebrated<br />

another milestone in early June<br />

when the 10,000th machine to<br />

roll off its production lines in<br />

Monaghan was delivered to<br />

Weyerhaeuser, a world leading<br />

manufacturer of engineered<br />

lumber products.<br />

Truck number 10,000 will be<br />

working at Weyerhaeuser’s Parallam<br />

Mill in Annacis Island near Vancouver,<br />

and it was officially handed<br />

over to Chuck Antonides, Weyerhaeuser’s<br />

Director of Lean Pro -<br />

cesses, by Combilift USA’s President,<br />

Tommy Cadden. It is also the first 10<br />

tonne capacity Combilift to be operational<br />

at a Weyerhaeuser site.<br />

The majority of Weyerhaeuser’s<br />

products are oversized loads<br />

which can be as long as 20 m, and<br />

having identified the Combilift<br />

four-way concept as the answer to<br />

handling such challenging pro -<br />

ducts, it now operates 130 Combilifts<br />

across its sites in North<br />

America. The trucks play a key role<br />

in the company’s commitment to<br />

the safest material handling procedures<br />

and excellent productivity<br />

and were designed specifically<br />

for Weyerhaeuser’s requirements.<br />

Chuck Antonides, Weyerhaeuser's Director of Lean Processing (left) and Tommy Cadden, President of Combilift USA.<br />

Combilift managing director,<br />

Martin McVicar, says: “Weyerhaeuser’s<br />

case exemplifies how<br />

customer feedback from the wide<br />

variety of industry sectors we supply<br />

has been instrumental in helping<br />

us to continually improve the<br />

Combilift concept, to become the<br />

world’s largest supplier of longload<br />

handling equipment.”<br />

“Product development was<br />

based on close collaboration between<br />

the two companies, with<br />

Combilift acting constantly and<br />

quickly on feedback from Weyerhaeuser<br />

personnel,” says Tommy<br />

Cadden. “Chuck Antonides visited<br />

our manufacturing facility in Ireland<br />

on a number of occasions to<br />

liaise with the management and<br />

engineers. Within a six month time<br />

frame from <strong>August</strong> 2007 to January<br />

2008, Combilift designed, built<br />

and delivered the first of the<br />

Weyerhaeuser six tonne units and<br />

throughout 2008 Weyerhaeuser<br />

ordered and took delivery of a<br />

A selection of the Combilift range<br />

as seen at this year's Ligna.<br />

total of 108 of these models.”<br />

A raft of features designed to<br />

ease the handling of extreme<br />

loads and to make life easier for<br />

drivers are integrated into the<br />

C12,000WSL and the C20,000WSL<br />

models, such as a larger operator<br />

cab, sticker boxes and containers<br />

for chainsaws and tools fixed to<br />

the body of the truck, and an integrated<br />

side shifting mast which<br />

caters for the varying dimensions<br />

of the product. Combilift’s customised<br />

approach has proved to<br />

be such a success that Weyerhaeuser<br />

has embarked on a program<br />

to phase out all other types<br />

of conventional forklifts at its distribution<br />

centres and replace<br />

them with Combilift models.<br />

Combilift Ltd<br />

Tel 07815 314990<br />

Email info@combilift.com<br />

www.combilift.com<br />

Page 2 Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong>

CONTENTS<br />

Panel, Wood &<br />

Solid Surface<br />

is published by<br />

Pawprint Publishing Ltd<br />

Creative Media Centre<br />

Robertson Street<br />

Hastings<br />

East Sussex<br />

TN34 1HL<br />

Tel 01424 205428<br />

Fax 01424 205436<br />

email<br />

info@pawprintuk.co.uk<br />

www.pawprintuk.co.uk<br />

and is printed by<br />

Ghyllprint Ltd<br />

Ghyll Road<br />

Heathfield<br />

East Sussex<br />

TN21 8AW<br />

Tel 01435 866211<br />

Fax 01435 861268<br />

email<br />

sales@ghyllprint.co.uk<br />

www.ghyllprint.co.uk<br />

© Pawprint Publishing Ltd<br />

All rights reserved. No part of<br />

this publication may be<br />

reproduced, stored in a retrieval<br />

system or transmitted in any<br />

form by any means electronic,<br />

mechanical, photocopying,<br />

recording or otherwise without<br />

the prior consent of Pawprint<br />

Publishing Ltd.<br />

This journal includes editorial<br />

photographs provided and paid<br />

for by suppliers.<br />

Panel, Wood & Solid Surface<br />

supports the work of<br />

Hearing Dogs for Deaf<br />

People<br />

Tel 01844 348100<br />

(voice & minicom)<br />

Fax 01844 348101<br />

email<br />

info@hearingdogs.org.uk<br />

www.hearingdogs.org.uk<br />

Editorial<br />

comment<br />

AROUND 25 years ago, the landlord<br />

of the office rented by the<br />

company I worked for at the<br />

time organised a Health &<br />

Safety training session for<br />

everyone in the building.<br />

On one of the videos played to<br />

us, we saw how split water on the<br />

floor was consistently ignored by<br />

those who had an opportunity to<br />

mop it up — until someone slipped<br />

and fell, being injured as a result.<br />

This was, after all, a Health & Safety<br />

training video!<br />

The point made to us was: If you<br />

see something that is a hazard in<br />

the workplace, it is your responsibility<br />

to do something about it.<br />

Don’t leave it to someone else.<br />

I was reminded of this one Sunday<br />

in July by two news stories reported<br />

that day.<br />

The first regarded the rescue by<br />

life guards in Tenby of a group of<br />

young people who had got into difficulty<br />

when the sand bank they<br />

were on proved to be not as substantial<br />

as it had first appeared to be.<br />

When the life guards were interviewed<br />

on television, they were<br />

asked to comment on the fact that<br />

they had been close by when the<br />

problem arose. The reply was that<br />

the area in question was well<br />

known to locals as a dangerous region<br />

— which was why it was outside<br />

the red flags — so when they<br />

had seen people in the hazardous<br />

zone, the life guards had naturally<br />

moved to warn them of the risk. As<br />

a consequence, it is probable that<br />

lives were saved.<br />

The second story concerned the<br />

suspension of Renault from the<br />

European Grand Prix due to safety<br />

violations in Budapest, although<br />

that suspension was subsequntly<br />

lifted on appeal.<br />

According to Formula 1’s official<br />

website, the threat of suspension<br />

arose because: “Budapest stewards<br />

said they believed Renault<br />

had knowingly released [driver<br />

Fernando] Alonso without one of<br />

the retaining devices for the<br />

wheel-nuts being securely in position;<br />

that being aware of this, the<br />

team had failed to take any action<br />

to prevent the car from leaving the<br />

pit lane; and that they had then<br />

failed to inform the driver of this<br />

problem or to advise him to take<br />

appropriate action given the<br />

circumstances.”<br />

As those who watched the race<br />

on TV will recall, Alonso’s wheel<br />

came off his car before he could<br />

complete another lap. PMR<br />

Contents<br />

NEWS<br />

10,000th Combilift delivered to Weyerhaeuser ............................2<br />

Weinig PowerLock celebrates 10th anniversary ...........................4<br />

Price promotion........................................................................................4<br />

Selecting Lamont.....................................................................................5<br />

ADHESIVES<br />

Attention to detail ...................................................................................6<br />

PANELS & PANEL PROCESSING<br />

Cutting Corian...........................................................................................7<br />

Bespoke solutions....................................................................................7<br />

Wide range of panel processing machines from SCM................8<br />

Koolkut boosts timber trade in Rochdale .......................................9<br />

Rising to the challenge ..........................................................................9<br />

SOFTWARE<br />

Beating the downturn at R Foden Ltd............................................10<br />

20-20 Integration Pack.........................................................................11<br />

StairCon at Just Stairs...........................................................................11<br />

DOORS: DESIGN & MANUFACTURE<br />

Full height curves in vinyl from Bellissimo ...................................12<br />

Award for fire door manufacturer CB Solutions .........................12<br />

Leaderflush Shapland installs Stefani post former....................13<br />

FURNITURE FITTINGS & COMPONENTS<br />

Banbury Plastic Fittings launches new website .........................14<br />

New from Martin....................................................................................14<br />

SURFACE FINISHES & SURFACE FINISHING<br />

Furniture lacquer ...................................................................................15<br />

Sanding with Mirka...............................................................................15<br />

Hi-Tec Spray at Ridon............................................................................15<br />

UPCOMING SHOWS<br />

Plenty to see at Open Week ...............................................................16<br />

Wood-Mizer at Saltex ...........................................................................16<br />

Interbuild <strong>2009</strong>.......................................................................................16<br />

Lightweight board event....................................................................16<br />

SCM Autumn In-House: October 13-15.........................................17<br />

SCM Rimini in-house for window manufacturers......................17<br />

RWM: a one stop shop for recycling solutions............................18<br />

GreCon Ltd at RWM ..............................................................................18<br />

Dantherm at RWM.................................................................................18<br />

WOODWASTE & DUST CONTROL<br />

DCS wraps up dust at Silverwood ...................................................19<br />

Waste to energy .....................................................................................19<br />

New BWF president elected<br />

THIS YEAR’S AGM of the British Woodworking Federation (BWF)<br />

saw the election of a new president, the launch of the Annual<br />

Review and the preview of a new website, launched in July.<br />

Ian Purkis, Technical Director of JELD-WEN UK Ltd, was elected<br />

President of the BWF. Ian takes over from Pauline Kelly, who will be<br />

stepping down after two years as BWF President. Ian has been an<br />

Officer of the BWF since 2003 and told the AGM audience that he<br />

was “truly honoured” to be elected as BWF President following 25<br />

years’ membership of the BWF. “My objective as President is to focus<br />

on ensuring that the BWF continues to support its members, helping<br />

to increase their sales and profitability,” he added.<br />

British Woodworking Federation<br />

www.bwf.org.uk<br />

Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong> Page 3

NEWS<br />

Weinig PowerLock celebrates 10th anniversary<br />

FAR-RANGING technical innovations<br />

are rare. PowerLock is one<br />

of them and the Weinig tool system<br />

generated a revolution in<br />

solid wood processing.<br />

Ten years after being launched,<br />

the enthusiasm remains as pal -<br />

pable as at the very beginning.<br />

The superior quality of the final<br />

product has always been the chief<br />

goal when processing solid wood.<br />

Good tools are the most important<br />

factor.<br />

For quite a while, people had to<br />

make do with a series of compromises:<br />

The tools fastened to the<br />

spindle with a nut did not have the<br />

necessary rigidity or concentricity<br />

to ensure the best quality at high<br />

feed speeds. Satis factory results<br />

were only achieved after the introduction<br />

of hydraulic tools. Nevertheless,<br />

even this technology<br />

could not yield a satisfactory response<br />

to the new demands for<br />

flexibility in production.<br />

Price promotion<br />

WOOD-MIZER is promoting its<br />

small LT10 and LT15 band<br />

sawmills after ‘time and effort’<br />

analyses of production at its European<br />

manufacturing facility.<br />

New approaches to its engineering<br />

design, purchasing,<br />

manufacture, assembly and transportation<br />

have saved costs.<br />

According to Wood-Mizer, the<br />

six months review resulted in significant<br />

cost reductions without<br />

compromising quality.<br />

It also says that the savings enable<br />

it to promote this particular<br />

product range and open new markets<br />

for its products.<br />

The mills’ prices have been dramatically<br />

reduced.<br />

The decisive step came in 1999:<br />

The PowerLock tool system was<br />

born. To the surprise of many, this<br />

quantum leap did not originate<br />

from a specialist but from Weinig,<br />

a world leader in the market for<br />

machines and systems for processing<br />

solid wood. In comparison<br />

to conventional tools, the Power-<br />

Lock system was much lighter,<br />

more compact and extremely easy<br />

to handle. It clamps and releases<br />

at the push of a button. The lightning-fast<br />

exchange of tools allows<br />

you to reduce setup time to a minimum.<br />

This is a major factor in attracting<br />

customers who were<br />

confronted with increasingly<br />

smaller batch sizes and shorter delivery<br />

times.<br />

Nevertheless, PowerLock would<br />

not have succeeded if it were not<br />

able to artfully link greater productivity<br />

with outstanding surface<br />

quality. This is provided by the extremely<br />

precise HSK grip of the tool<br />

Weinig PowerLock: perfect surfaces up to 12,000 rpm.<br />

The LT15 series of mills are<br />

simple, manually handled and use<br />

the same blade and blade guide<br />

systems as the company’s more<br />

productive mills. They are most<br />

commonly bought by farmers, estate<br />

owners and individuals who<br />

convert their own timber for local<br />

use.<br />

The LT10 is a compact, ‘hobbyist’<br />

mill with an easy hand push<br />

feed system.<br />

It is generally regarded as an<br />

‘entry level’ mill for weekend<br />

sawyers.<br />

Wood-Mizer UK<br />

Tel 01622 813201<br />

Email info@woodmizer.co.uk<br />

www.woodmizer.co.uk<br />

Weinig PowerLock: a clever idea revolutionises solid wood processing.<br />

by a special tool holder. A respectable<br />

three tons of pull force<br />

makes the two components a perfect<br />

unit without any tolerance for<br />

fit. This enables speeds up to 12,000<br />

rpm: an unheard of speed before<br />

PowerLock came on the scene.<br />

An increasing number of companies<br />

will be replacing their old<br />

machines with the new Weinig<br />

Powermat series with the Power-<br />

Lock system. Today, 10 years after<br />

its launch, more than 5,000 moulders<br />

with the PowerLock tool system<br />

are being used around the<br />

globe. Nearly every well-known<br />

tool manufacturer includes it in<br />

their standing line.<br />

Of course, just like with every<br />

outstanding development, Power-<br />

Lock has its imitators. Nevertheless,<br />

on its 10th anniversary, the patented<br />

original Weinig PowerLock tool<br />

system is still clearly a leader.<br />

Peter Martin, manager of devel-<br />

opment for moulders, says: “Only<br />

the Weinig PowerLock runs up to<br />

12,000 rpm, is joinable up to<br />

10,000 rpm and achieves feed<br />

speeds up to 200 m/min, if necessary.”<br />

Another feature, believed to<br />

be unique, is its 300 mm working<br />

width without an outboard bearing.<br />

In addition,Weinig is able to<br />

deliver machines, tools and accessories<br />

from a single source.<br />

Perfectly harmonised grinding<br />

and measuring systems, adjusting<br />

tools and software that transfer online<br />

data to the machine control:<br />

these all ensure that the system can<br />

operate at maximum efficiency.<br />

“Weinig PowerLock will remain<br />

highly attractive to woodworkers<br />

around the world well into the future,”<br />

says Peter Martin.<br />

Michael Weinig (UK) Ltd<br />

Tel 01235 557600<br />

Email sales@weinig.co.uk<br />

www.weinig.co.uk<br />

Page 4 Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong>

NEWS<br />

Selecting Lamont<br />

IN AUGUST 2008, we reported<br />

on the recent purchase by Chris<br />

Bullock Joinery, of Hereford, of<br />

a gluesetter from Lamont. Chris<br />

was so pleased with the product<br />

that, in the Spring of <strong>2009</strong>, he<br />

added to it by purchasing a<br />

clamp from the same company.<br />

Chris Bullock Joinery has been<br />

manufacturing “anything in timber”<br />

since 1982. With a team of<br />

seven, the company manufactures<br />

windows, doors, doorframes, staircases<br />

and small built-in furniture<br />

for customers large and small.<br />

Quality of service is important:<br />

“We try to look after everybody,”<br />

Chris Bullock told PW&SS.<br />

In common with many in the industry,<br />

Chris has found the last<br />

year to be hard work, but has remained<br />

profitable and has had the<br />

confidence to invest for the future.<br />

“We have had to fight for our share<br />

of the market, but have come out<br />

well,” he says.<br />

The decision to purchase the<br />

clamp arose from new, larger jobs<br />

coming into the workshop.<br />

“When you have got a large job<br />

going through and you’ve got a<br />

deadline, anything you can do to<br />

save time is valuable. The larger<br />

jobs increased our capacity no<br />

end,” Chris told PW&SS.<br />

“We use the clamp mostly for<br />

window casement assembly: it is<br />

incredibly quick.<br />

“Quality control is improved:<br />

because of the way the clamp<br />

works, every frame that comes out<br />

is perfectly square. There is no<br />

need for any checking, because it<br />

is all done for you.<br />

“It is very operator friendly: and<br />

because it is a vertical clamp, the<br />

operator is not bending over a<br />

bench, so it is much more comfortable<br />

to use. It is also very helpful<br />

that the clamp is on wheels:<br />

you can move it around the workshop<br />

to wherever you want it, and<br />

it can be kept safely out of the way<br />

when not in use. We have also got<br />

the plastic backing board on it.<br />

Not only does it help keep it clean,<br />

but you can use the RF gluesetter<br />

on there as well. That has been<br />

quite beneficial.”<br />

Chris chose to return to Alan Lamont<br />

to purchase the clamp because<br />

“Alan comes across as being<br />

very knowledgeable and helpful,<br />

and is very fair with his prices.” He<br />

would definitely recommend him<br />

to others.<br />

Lamont<br />

Tel 01461 40017<br />

Email aalamont@hotmail.com<br />

www.lamontclamping.co.uk<br />

Chris Bullock Joinery has added a clamp from Lamont (abve) to<br />

the gluesetter purchased from the same company last year.<br />

… news in brief … news in brief … news in brief …<br />

The British Woodworking Federation<br />

(BWF) has unveiled a new<br />

service, which allows members<br />

to carry out credit checks on<br />

new and existing customers.<br />

The service is available through<br />

the BWF’s website. Members are<br />

also provided with advice on how<br />

to interpret financial reports.<br />

The new credit-checking service<br />

takes its place alongside the BWF’s<br />

other membership benefits, including<br />

free expert advice on technical<br />

issues, employment and contractual<br />

law, health and safety, tax issues<br />

and environmental matters.<br />

British Woodworking Federation<br />

www.bwf.org.uk<br />

Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong> Page 5

ADHESIVES<br />

Attention to detail<br />

AT 3M, the company’s product<br />

range, experience and track<br />

record in innovation mean that<br />

whatever the application, 3M is<br />

likely to have a solution.<br />

Panel, Wood & Solid Surface<br />

toured 3M’s UK headquarters in<br />

Bracknell, and saw what this<br />

meant in terms of adhesives and<br />

abrasives for joinery, shopfitting,<br />

kitchen fitting, furniture manufacturing<br />

and allied industries.<br />

In 1902, 3M — or Minnesota<br />

Mining & Manufacturing Company<br />

— began by manufacturing<br />

sandpaper. Since then, it has become<br />

a worldwide organisation<br />

with a vast product range, from<br />

the screens that allowed the development<br />

of laptop computers to<br />

be a practicality, to the Post-It<br />

notes found in most offices.<br />

3M’s adhesives and tapes cover<br />

every possible application, from<br />

light use through medium<br />

strength to structural quality.<br />

3M’s water-based contact adhesives<br />

produce a strong bond as<br />

soon as pressure is applied to the<br />

dry surfaces. They can be sprayed,<br />

rolled or brushed on. Some versions<br />

come in blue, so the operator<br />

can see where they have been<br />

applied.<br />

These adhesives bond with a<br />

wide variety of materials, with<br />

some products allowing instant<br />

bonding, unlike traditional contact<br />

adhesives, which must be dry<br />

before bonding. Advanced Tech -<br />

nologist Chris Hall demonstrating<br />

this by spraying an area of marble<br />

worktop 30 cm x 30 cm and a similar<br />

sized piece of plywood with<br />

Scotch-Weld 2000, and then immediately<br />

bonding them together,<br />

without having to wait for<br />

the contact adhesive to dry. The<br />

finished composite could be lifted<br />

and was available for further pro-<br />

cessing and finishing immediately.<br />

The applicator used was one<br />

also on display in 3M’s Innovation<br />

Centre. Visiting an automotive<br />

workshop, a 3M engineer noticed<br />

it took a while to clean paint applicators<br />

between spraying different<br />

colours. Believing there must<br />

be a better way of handling this,<br />

he went back to 3M’s laboratories<br />

and developed a solution — the<br />

3M PPS Paint Preparation System<br />

(illustrated). The fluid is placed in a<br />

disposable liner, a lid with filter is<br />

attached and placed in a PPS Mixing<br />

Cup, which attaches directly to<br />

the spray gun. This speeds up the<br />

changing process, while cutting<br />

the time spent cleaning the applicator,<br />

which can handle a wide<br />

range of fluids.<br />

This attention to detail is also<br />

reflected in 3M’s Scotchweld PUR<br />

moisture-curing adhesive applicator<br />

gun. The original design used<br />

a metallic nozzle, with a non-return<br />

valve to dispense the hot adhesive.<br />

However, a small amount<br />

of atmospheric moisture was getting<br />

in through the threaded components,<br />

which could cause the<br />

adhesive to harden prematurely<br />

within the nozzle. To counter this,<br />

3M developed a plastic disposable<br />

nozzle.<br />

The Scotchweld PUR adhesive<br />

system is ideal for wood, plastics,<br />

glass and metals. The adhesive<br />

cures using the microscopic<br />

amount of moisture found on the<br />

surface of many materials. The adhesive<br />

is heated in the applicator<br />

and applied as a viscous liquid.<br />

Within a few minutes it sets to a<br />

waxy state, producing an adhesive<br />

bond. At this point, any excess adhesive<br />

can be removed with a<br />

scraper or a blade. As the moisture<br />

enables the adhesive to cure over<br />

time, its strength increases to pro-<br />

duce a bond of structural performance<br />

and excellent durability.<br />

Two of 3M’s tape products I<br />

would particularly like to highlight<br />

are the Dual-Lock system (illustrated)<br />

and VHB high-strength<br />

tape.<br />

Dual-Lock is of great advantage<br />

to those creating any type of display<br />

needing to be changed regularly.<br />

The system comes in two<br />

parts: one tape is applied to each<br />

item to be joined. These are then<br />

joined together, by applying<br />

medium pressure: how easily they<br />

can be separated depends on the<br />

grade of Dual-Lock selected.<br />

Standing for Very High Bond,<br />

VHB is so strong it has been approved<br />

for use in structural situations.<br />

Certainly it is impossible to<br />

pull apart using hand pressure! Examples<br />

of applications are fixing<br />

windows into the front of a luxury<br />

glass-fronted hotel in Dubai, and attaching<br />

tailfins to major civil aircraft.<br />

In fact, VHB can replace mechanical<br />

fixings in many applications.<br />

3M also has a highly-equipped<br />

troubleshooting analytical lab<br />

which can investigate surface<br />

chemistry to incredible detail. The<br />

Bracknell facility has what is believed<br />

to be one of only two X-Ray<br />

Photoelectron Spectrometers in<br />

Europe, which analyse surface<br />

depths of 5-10 nanometres: that’s<br />

the top 5-10 millionths of a millimetre!<br />

3M also has equipment to<br />

analyse substances by molecule<br />

and by element, as well as any<br />

vapours given off.<br />

Abrasives remain an important<br />

part of 3M’s range, with products<br />

for every type of material, including<br />

those where a high gloss finish is required.<br />

The range covers hand<br />

tools, such as orbital sanders, as well<br />

as abrasive materials themselves.<br />

The Finesse-It System Box is an<br />

abrasives kit providing everything<br />

needed for a variety of abrasives<br />

tasks. Containing five types of<br />

sanding disc, plus sanding accessories,<br />

three types of polish and<br />

polishing accessories, it is considered<br />

ideal for shop and trade fair<br />

manufacturers, and furniture,<br />

kitchens, bathrooms, worktops<br />

and musical instruments.<br />

For the past century, 3M has<br />

been at the forefront of innovation<br />

in many fields, impacting on many<br />

people’s daily lives. This same innovation<br />

has led to the development<br />

of a range of adhesives and<br />

abrasives products, to meet the<br />

ever-changing needs of Britain’s<br />

workshops and craftsmen.<br />

3M<br />

Tel 08705 360036<br />

Email khorsfall@mmm.com<br />

www.3m.co.uk/adhesives<br />

www.3m.co.uk/abrasives<br />

Page 6 Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong>

PANELS & PANEL PROCESSING<br />

Cutting Corian Bespoke solutions<br />

A STRIEBIG Compact vertical<br />

panel saw has proved the ideal<br />

solution to Corian sheet cutting<br />

problems at a Midlands-based<br />

building and refurbishment<br />

company.<br />

BRIK Contracting, of Daventry,<br />

part of the BRIK Group, is a bespoke<br />

manufacturer and fitter of<br />

timber, joinery, Corian and acrylic<br />

items for retail and commercial interiors.<br />

Its growing customer base<br />

includes major players in the financial<br />

and leisure industries.<br />

The Striebig Compact has replaced<br />

a German-made vertical<br />

panel saw in the Corian fabrication<br />

shop that was not delivering accurate<br />

results.<br />

The Striebig was bought largely<br />

on the recommendation of Corian<br />

fabricator, Ivan Barker. “I had used<br />

Striebig saws for about 20 years in<br />

other jobs and was familiar with<br />

their build quality and accuracy.”<br />

The Swiss-made Compact is an<br />

entry level machine that enables<br />

small and medium sized businesses<br />

to move into the world of precision<br />

quality vertical panel saws. It combines<br />

ergonomics and visual appearance<br />

with quality functionality.<br />

The Compact 5207 model chosen<br />

by BRIK has a maximum cut<br />

size of 4,600 mm x 2,070 mm and<br />

a maximum cutting depth of 60<br />

mm. Fitted with a 250 mm dia -<br />

meter saw blade, it is used chiefly<br />

to cut up 12.7 mm thick Corian<br />

sheets measuring 3,680 mm x 760<br />

mm into sections for use in desking,<br />

as kitchen and bar tops and in<br />

vanity units.<br />

It was supplied together with<br />

an optional strip cutting gauge<br />

which has proved useful when<br />

cutting down stands used in<br />

kitchen worktops.<br />

“The Striebig is a far more robust<br />

and better quality machine<br />

that gives us a clean cut every<br />

time and is never inaccurate,” said<br />

Mr Barker. “It is also very easy to set<br />

up and use.”<br />

When not cutting Corian sheet,<br />

the Compact sizes 25 mm thick<br />

MDF and plywood panels, which<br />

are used in the Corian components’<br />

substrate. This has led to<br />

greater productivity as two 25 mm<br />

sheets can now be put on the saw<br />

at a time.<br />

Among other features of the<br />

saw that Mr Barker likes are the<br />

two-part longitudinal stops, which<br />

are handy when cutting large and<br />

small pieces, and the simple<br />

mechanism that allows for ultrafast<br />

blade changing. “The saw’s<br />

built-in extraction is also very effective<br />

and there’s now far less<br />

dust around the operator than we<br />

had with the old saw,” he says.<br />

The Compact, together with an<br />

Al-Ko dust extraction unit, was<br />

supplied by Striebig’s exclusive UK<br />

agent, TM Machinery Sales, of<br />

Leicester.<br />

TM Machinery Sales<br />

Tel 0116 271 7155<br />

Email sales@tmservices.co.uk<br />

www.tmpartnership.co.uk<br />

FOR LARGE-format and panel<br />

processing applications, AXYZ<br />

International can provide a wide<br />

choice of standard CNC routers.<br />

These are recognised as being<br />

among the most technically advanced<br />

and competitively priced<br />

machines available.<br />

However, there are many industries<br />

where there is the need to<br />

machine larger and/or multiple<br />

sheets of material. This is a task<br />

that has invariably proved beyond<br />

the capabilities of smaller routers<br />

and has resulted in the use of manual<br />

routing with all of its attendant<br />

variables in terms of increased production<br />

time, material wastage<br />

and exposure to human error.<br />

To resolve this situation, AXYZ<br />

Automation has taken the lead in<br />

the development and installation<br />

of an increasing number of be-<br />

C.R. ONSRUD<br />

CNC Routers ■ Inverted Routers ® ■ Cutting Tools<br />

The company that knows routing best!<br />

This impressive range of high quality CNC routers is now available in Europe<br />

ATA Engineering Processes<br />

Tel: 01442 264411 — Fax: 01442 231383<br />

www.ataeng.com — www.cronsrud.com<br />

spoke routing solutions. These<br />

have now assumed benchmark<br />

status within those industries<br />

where a large- or super largeformat<br />

production requirement<br />

exists.<br />

These robust and totally reliable<br />

customised routing solutions incorporate<br />

all of the design features<br />

and components inherent in the<br />

standard machines, whilst providing<br />

a greater capacity for individual<br />

machine configuration to<br />

meet specific processing requirements.<br />

Key features include AXYZ<br />

Automation’s powerful and versatile<br />

Automatic Tool Changer (ATC)<br />

to provide a host of production<br />

options.<br />

AXYZ International<br />

Tel 01902 375600<br />

Email sales@axyz.co.uk<br />

www.axyz.co.uk<br />

Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong> Page 7

PANELS & PANEL PROCESSING<br />

Wide range of panel processing<br />

machines from SCM<br />

THE SCM Group can offer and supply a complete range of panel processing<br />

machines, from sliding table and beam saws to<br />

edge banders and CNC machining centres for<br />

routing, drilling and grooving.<br />

At the recent Ligna <strong>2009</strong> exhibition, a<br />

number of new models to complement<br />

the already extensive range were introduced,<br />

the Sigma Impact 87 Beam Saw<br />

(illustrated right) being one of them. It is<br />

a winning combination with the comfort<br />

of a technological panel beam saw and a<br />

competitively priced investment.<br />

Sigma Impact 87 has a new design and a robust<br />

structure, with a shape and framework carefully<br />

designed to ensure any vibration is absorbed by the ground.<br />

It offers rapid and precise axes movements of up to 135 m/min on the sawblade<br />

carriage and up to 75 m/min on the rear pusher. Automatic detection of panel<br />

length, width and thickness by photocells ensures that the cyclical speed is maintained. The saw also features<br />

an immediate sawblade changeover system: a pneumatic selector enables the sawblades to be changed<br />

quickly and without using keys or spanners, or having to unscrew tools. The sawblade is fitted with a self-teaching upstroke, consisting of a bar which<br />

automatically reads the height of the panel pack and calibrates the optimum height of the saw accordingly.<br />

Olimpic K1000 (illustrated right) is the new leading<br />

model amongst SCM edge-banding machines,<br />

designed to meet the requirements<br />

of small and medium-sized woodworking<br />

and panel processing workshops. Derived<br />

from SCM’s vast experience with<br />

larger, industrial machines, Olimpic<br />

K1000 was created to cater for all flexible<br />

machining operations and edge banding<br />

requirements, and it is available in 10 configurations.<br />

It has more kit and it is even more<br />

user-friendly. The trimmer introduces to the K series the possibility<br />

of adjusting material removal on the edge of the panel, to deal with<br />

cases of incorrect application of edging materials and to achieve the desired dimensions. The optional<br />

tracer adds to this device, giving precise operations even on long panels. The gluing unit has been<br />

revamped and now perfectly glues solid wood edging strips measuring up to 12 mm width. The quick-release feature enables fast changeover from<br />

the hot-melt or even polyurethane glue simply and easily.<br />

The new StarTouch electronic control systems is the show-piece of the all the options available on the K1000. This innovative control utilises a large<br />

12in touch-screen for graphical representations of all machine functions. The graphics are specially designed so that the operator will understand them<br />

immediately and easily. This means that it is very easy to interpret information about the type of edging, thickness, machining operations and the insertion<br />

side for the panel on which the edging will be applied. Machining programs can be retrieved using practical, customisable keys.<br />

The new TECH Z1 (illustrated below), is derived from its “big sister”, the model Z2, from which it has inherited the same features of flexibility, versatility<br />

and performance, but now in a more compact version. Unveiled at Technodomus in <strong>2009</strong>, the TECH Z1 was of great interest to visitors because<br />

of its compact dimensions, the use of ‘bumpers’ in place of safety mats and the very competitive level<br />

of investment. The ‘bumpers’, integrated into the machine’s head guard, guarantee minimum<br />

overall dimensions, despite the fact that they provide complete safety. They<br />

also allow freedom of movement and great comfort<br />

during pendulum machining operations for<br />

the operator and the possibility of machining<br />

larger dimensioned panels than with the solution<br />

requiring safety mats.<br />

In particular, in this machining mode with<br />

alternate loading, two workpieces can be<br />

processed, each up to 1,125 mm long. Obviously,<br />

these dimension may vary according to individual<br />

requirements, provided that the total is always 2,250<br />

mm, guaranteeing great flexibility compared<br />

with the previous solution using mats.<br />

SCM Group (UK) Ltd<br />

Tel 0115 977 0044<br />

Email scmgroupuk@scmgroup.com ● www.scmgb.co.uk<br />

Page 8 Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong>

PANELS & PANEL PROCESSING<br />

Koolkut boosts timber trade in Rochdale<br />

FOR MANY YEARS, in common with numerous other timber dealers, Howard Brothers Mica Hardware used a table saw to cut sheet materials<br />

to size. Replacing their table saw with a Koolkut KK 12 vertical panel saw from Sagetech Industries was a watershed moment.<br />

Established in Rochdale, Lancashire, over 60 years ago, Howard Brothers Mica Hardware is a family-owned retail business providing a wide range<br />

of hardware and DIY products, including sheet materials such as chipboard, melamine and MDF. As the business grew, shop floor manager, Daniel<br />

Gooding, and his colleagues were finding the company’s ageing table saw increasingly inadequate. Daniel began looking for a suitable replacement<br />

machine and discovered the Sagetech website, www.sagetech.co.uk. There he found out<br />

about the Koolkut range of space-saving, economically priced vertical panel saws.<br />

“I was impressed with Sage tech,” commented Daniel. “It was immediately obvious that<br />

they knew what they were talking about, and they were extremely helpful, too.”<br />

Daniel ordered a Koolkut KK12, noting the machine’s small operating footprint, dust extraction<br />

facilities, single operator capability, accuracy and competitive price.<br />

The company is working its Koolkut hard, cutting five to ten sheets to length, width or<br />

specific square footage every day. Some customers ring their orders in ahead of visits, while<br />

others take advantage of the company’s ‘while-you-wait’ cutting service. This service brings<br />

additional business in for the store, and allows for more flexible stocking. Despite the workload,<br />

the machine has proved highly reliable. “It’s great,” said Daniel. “Nothing has needed replacing<br />

apart from the blade — we cut a lot of melamine. It hasn’t let us down once.”<br />

The model’s compact operating footprint has paid dividends, too. The new saw has released<br />

sufficient floor space to allow Howard Brothers Mica Hardware to install a radial arm<br />

saw, further enhancing the service that the company can offer to customers.<br />

Daniel summed up, “It’s a great machine at a great price and it’s proved its worth many<br />

times over: recommended!”<br />

The Koolkut range of vertical panel saws uses an innovative design to offer exceptional rigidity<br />

and accuracy of cut within a compact footprint. Koolkut saws offer a range of advanced features<br />

such as simple and compound angle cutting to the full length and width of the sheet, scoring<br />

and plunge cutting capability. They cut timber products, plastics, card, non-ferrous metals and<br />

composite panels. Koolkut Series 1 saws are ideal for light to medium use; the Series 2 is built for<br />

medium to heavy use. Koolkut Series 3 are heavy-duty machines, designed for continuous use.<br />

Sagetech Ltd<br />

Tel 0118 970 1950 ● Email info@sagetech.co.uk ● www.sagetech.co.uk<br />

Rising to the challenge<br />

A WORLDWIDE industrial forestry<br />

company, the Finnish megacompany<br />

UPM KYMMENE, has<br />

just recently gone into production<br />

with its new Schelling cut to<br />

size plant type ASH with full automated<br />

stacking.<br />

The new Schelling angle plant<br />

was installed in the veneer factory<br />

at Kalso in Vuohijärvi, Finland. The<br />

yearly production of this factory is<br />

80,000 m 3 of pine peel vener,<br />

which is used in the production of<br />

parquet flooring.<br />

The big challenge for Schelling<br />

was the material the customer<br />

used. The Schelling plant has to<br />

cut 2 mm thick veneer in book<br />

form and then stack this afterwards<br />

automatically. Due to the<br />

production process of these veneers,<br />

they are very wavy and a<br />

book of 80 veneers with a thickness<br />

of 2 mm can be up to 320<br />

mm thick, which is double the<br />

thickness it would measure if it<br />

were flat. Therefore, the material<br />

needs to be compressed, starting<br />

at the first material take-over position<br />

before the rip-cut saw and<br />

consequently at the rip-cut and<br />

cross-cut saw cycles.<br />

The Schelling Angle plant was<br />

specially designed for this pro cess<br />

and the production on this machine<br />

has proved to be a great success.<br />

Schelling UK Ltd<br />

Tel 01937 586340<br />

Email info@schelling.co.uk<br />

www.schelling.co.uk<br />

IT’S FULLY PORTABLE<br />

LOW BUDGET PRICE<br />

Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong> Page 9

SOFTWARE<br />

Beating the downturn at R Foden Ltd<br />

SINCE investing in joinery software<br />

and internet advertising,<br />

Mike Foden of R Foden Ltd believes<br />

that if it hadn’t been for<br />

the economy taking a downturn<br />

last year, Foden’s would have<br />

been a lot further forward.<br />

In reality, because the company<br />

now has the infrastructure in place<br />

to produce high quality joinery, it<br />

is in a strong position to weather<br />

the downturn and capitalise when<br />

the market does recover.<br />

R Foden Ltd has a long established<br />

reputation in Chester. It is<br />

run by Mike Foden, the fourth<br />

generation of his family involved<br />

in building and joinery. Just five<br />

years ago, Mike decided to concentrate<br />

more on the joinery side<br />

of the business. Keen to grow the<br />

business further, he is realistic in<br />

the current climate and with nine<br />

staff now and a turnover of half a<br />

million pounds, his main goal currently<br />

is simply to keep his current<br />

staff and get through this difficult<br />

time. Even though he is reasonably<br />

busy at the moment, Mike is<br />

not complacent about the future.<br />

His reasons for purchasing software<br />

are clear. “I was finding it so<br />

time consuming to sit down and<br />

work out prices for a number of<br />

windows, often all different sizes,<br />

and providing prices for hard and<br />

softwoods. With each different<br />

timber having a different wastage<br />

factor, I thought I was going to<br />

spend the rest of my life in the office<br />

working out figures,” says<br />

Mike. The end result was that not<br />

all quotes were priced, because it<br />

took too long: in reality, only the<br />

quotes that they thought they<br />

could win were quoted.<br />

Like many other small joinery<br />

companies, every penny spent has<br />

to be justified. The initial purchase of<br />

Joinerysoft’s Joinery Management<br />

Software (JMS) was helped by a 50%<br />

grant from the Welsh Development<br />

Agency: however, two years on,<br />

Mike describes JMS as “one of the<br />

best things I’ve ever bought.”<br />

JMS now saves 50% of Mike’s<br />

time in the office, and with JMS installed<br />

on his laptop he is able to<br />

quote more jobs, both at home<br />

and on site, if needed. “This is<br />

great when customers are struggling<br />

to visualise the design. I can<br />

draw windows or doors in front of<br />

them so they can see the finished<br />

effect,” he says. Mike describes the<br />

visual element of JMS as really important.<br />

True scale diagrams show<br />

the customers exactly what they<br />

are getting.<br />

During the initial sales demonstration<br />

at his premises, Mike could<br />

see the potential instantly. “I liked<br />

Joinerysoft works with joiners and fitters at R Foden Ltd to set<br />

high customer standards.<br />

the fact that you can change the<br />

wood at the click of a button.” He<br />

continues, “Often customers don’t<br />

know what they want and I can<br />

suggest softwood windows with<br />

hardwood cills, if budget is tight.”<br />

Mike adds, “JMS is easy to use. It<br />

provides us with accurate costs<br />

and enables us to alter our rates to<br />

remain competitive, yet profitable.<br />

We try and keep our costs down<br />

where possible.”<br />

Foden’s has never advertised in<br />

the past, relying upon word of<br />

mouth. As a member of the Guild<br />

of Master Craftsmen and member<br />

of the Federation of Master<br />

Builders, this has been sufficient to<br />

ensure continued growth.<br />

Never one to rest on his laurels,<br />

though, Mike has more recently<br />

invested in internet advertising.<br />

Mike believes, “Because of the current<br />

climate you have to spread<br />

your wings a bit. You can’t be reliant<br />

on just the catchment area<br />

you used to have.”<br />

When they first launched their<br />

internet campaign, Foden’s went<br />

nationwide and received enquiries<br />

from all over the country for supply<br />

and fitting. As a result of this<br />

they have now limited fitting to<br />

within a 60 mile radius, offering<br />

supply only further afield.<br />

Mike has been pleased with the<br />

service received from Joinerysoft,<br />

right from the initial two days’<br />

training. The installer/trainer was a<br />

joiner himself and though the<br />

training was intense, Mike was able<br />

to find his way around the software<br />

straight away. “At the end of<br />

the day, Joinerysoft offers a great<br />

backup service. They are only a<br />

telephone call away. Generally, if<br />

they can’t fix the problem over the<br />

phone, they can remotely access<br />

over the internet,” says Mike.<br />

JMS is not simply a quoting<br />

package, saving time in the workshop<br />

providing cutting lists and<br />

machining information. Keen to<br />

grow further, Mike believes JMS<br />

has kept the company in the market<br />

place, helping them to set their<br />

standard and present a professional<br />

image to their customers.<br />

With the building trade suffering,<br />

Mike is able to be more responsive<br />

to enquiries that come in.<br />

The results are also starting to<br />

come through from Foden’s website<br />

based advertising campaign.<br />

Mike says, “We have already<br />

picked up some jobs that have<br />

been purely internet based. JMS<br />

enables me to respond quickly<br />

and win work. What ever happens,<br />

we are in it for the long haul.”<br />

R Foden Ltd<br />

Tel 01244 682899<br />

Email mike@rfoden.co.uk<br />

www.rfoden.co.uk<br />

Joinerysoft Ltd<br />

Tel 01608 643302<br />

Email enquiries@joinerysoft.com<br />

www.joinerysoft.com<br />

Page 10 Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong>

SOFTWARE<br />

20-20 Integration pack<br />

20-20 TECHNOLOGIES — Modular<br />

Manufacturing Solutions have<br />

been designed specifically for the<br />

cabinet industry and cover a wide<br />

range of products and services.<br />

They are designed to provide<br />

an end-to-end solution based on<br />

reliable and lean manufacturing<br />

practices with software implemented<br />

based on users’ business<br />

processes, product configuration<br />

and needs, versus an out-of-thebox<br />

solution that requires businesses<br />

to conform their processes<br />

to how the software works.<br />

New to the 20-20 Technologies<br />

range of software is an “Integration<br />

Pack” that works in conjunction<br />

with 20-20 Product Planner, a parametric<br />

cut listing program, which<br />

facilitates the seamless importing<br />

of products, both modular and custom<br />

sized, included within kitchen<br />

and bedroom design layouts created<br />

in the 20-20 Design program.<br />

The Integration Pack facilitates<br />

the mapping of product information<br />

held in 20-20 Designs catalogue<br />

to those within 20-20 Product<br />

GANG-Nail Systems is helping to<br />

increase the productivity of<br />

stair manufacturer Just Stairs,<br />

based in Essex, by supplying its<br />

StairCon design and production<br />

software, providing a fast and<br />

easy approach to the creation of<br />

timber staircases.<br />

StairCon software is used extensively<br />

for the detailing of timber<br />

staircases producing material<br />

schedules, 3D visualisation and<br />

manufacturing drawings for manual<br />

production, along with direct links<br />

to industry used CNC machinery.<br />

Steve Bull, manager of Just<br />

Stairs, is sure that the introduction<br />

of the software will help to increase<br />

the overall productivity of<br />

the company, commenting: “We<br />

decided to use Gang-Nail’s Stair-<br />

Con software as it offers all the<br />

functionalities we were looking<br />

Planner, which not only enables details<br />

on the width, height, depth and<br />

hinging of the products to be automatically<br />

passed across, but also<br />

other user defined features such as<br />

back-inset, quantity of shelves, extended<br />

side left, right, both etc.<br />

When products are imported<br />

into 20-20 Product Planner using<br />

the Integration Pack, they are<br />

placed in a Job Tree, under a job<br />

name with sub folders for Base,<br />

Wall and Tall products, etc. This enables<br />

designers to specify different<br />

door styles, carcase types, colours<br />

etc to groups of products, which is<br />

extremely useful where door styles<br />

and colours on wall cabinets are<br />

different from those on base and<br />

or tall cabinets. This also applies to<br />

carcase construction and colours.<br />

With information imported<br />

from 20-20 Design into 20-20<br />

Product Planner, the smaller manufacturer<br />

will no doubt be mainly<br />

interested in cut parts lists and<br />

door requirements, be they manufactured<br />

in house or purchased<br />

from a third party, and possibly<br />

StairCon at Just Stairs<br />

for. In addition, we were able to<br />

avoid any problems during the installation<br />

process thanks to Gang-<br />

Nail’s excellent telephone and<br />

online support centres.”<br />

He added, “StairCon offers userfriendly<br />

features, allowing for quick<br />

navigation across the entire software<br />

package, helping to save time<br />

during the initial planning stages.<br />

“From a practical point of view,<br />

we can use the StairCon software<br />

on a laptop, out of normal office<br />

hours, and then transfer the data<br />

across the following day, linking<br />

directly to our CNC machinery.”<br />

StairCon and StairCon CNC is<br />

specifically developed for the design,<br />

manufacture, price estimation<br />

and real view 3D visualisation of timber<br />

staircases. It is fully compatible<br />

with Microsoft® Windows XP or Vista.<br />

Paul Baron, managing director<br />

the optimisation of parts from<br />

sheets; whereas the larger manufacturer<br />

will no doubt want to<br />

batch jobs together, produce cut<br />

parts lists by material type and<br />

colour, list hardware by product,<br />

batch optimise jobs, automatically<br />

produce custom sized product<br />

drilling patterns for parts, whilst<br />

producing product and part bar<br />

code labels; all of which can be<br />

achieved by implementing 20-20<br />

Cut Planner optimiser and 20-20<br />

Drill Mate programs, both of<br />

which have the ability to link respectively<br />

to NC saws and CNC<br />

equipment from most major manufacturers<br />

of this type of equipment<br />

on the market today.<br />

Alternatively, Nested Based<br />

Manufacturing may well be preferred:<br />

this is also available when<br />

using 20-20 Drill Mate.<br />

So, what does this mean for the<br />

furniture manufacturer? The<br />

beauty of these programmes lies<br />

in their ability to reach out to manufacturing<br />

operations of all sizes,<br />

from the smallest to the largest<br />

of Gang-Nail Systems, said: “Our<br />

StairCon software is creating an increasing<br />

number of enquiries from<br />

businesses, such as Just Stairs,<br />

who like many others, still have<br />

many projects underway, despite<br />

the economic downturn. As such,<br />

we regularly update StairCon to<br />

factory, and to streamline their design<br />

and manufacture processes.<br />

The Integration Pack essentially<br />

saves time by allowing users to<br />

stream information from one programme<br />

to the other without having<br />

to key in the same information<br />

twice. This reduces the errors<br />

made during the re-entering of information,<br />

which of course reduces<br />

costs and increases profits.<br />

The whole process becomes<br />

even more streamlined where<br />

sales teams, retail outlets and<br />

manufacturers all use the same<br />

programmes, as designs can simply<br />

be emailed to the manufacturer<br />

and imported into 20-20<br />

Product Planner with cutlists created<br />

and scheduled within minutes.<br />

It’s all about using specialist<br />

computer programmes like 20-20<br />

Product Planner to make the business<br />

of manufacturing furniture<br />

increasingly efficient and simple.<br />

20-20 Technologies<br />

Tel 01276 684343<br />

Email ukmanufacturing@2020.net<br />

www.2020technologies.com<br />

help meet these needs and provide<br />

support where needed, helping<br />

to improve our customer’s<br />

production efficiencies.”<br />

Gang-Nail Systems<br />

Tel 01252 334691<br />

Email gang-nail@eleco.com<br />

www.gangnail.co.uk<br />

Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong> Page 11

DOORS: DESIGN & MANUFACTURE<br />

Full height curves in vinyl from Bellissimo<br />

AT A STROKE, kitchen, bedroom<br />

and bathroom designers can<br />

offer all customers floor to ceiling<br />

curved and ‘S’ shaped doors,<br />

now that Bellissimo has brought<br />

out the UK’s first range of full<br />

height vinyls in these options.<br />

Bellissimo’s new range means<br />

full height curves and ‘S’ shapes<br />

are no longer restricted to solid<br />

timber (which Bellissimo also<br />

offers).<br />

The new doors are offered in<br />

eight height options from the<br />

standard 715 mm and 895 mm<br />

right up to 2,250 mm.<br />

All are offered in Bellissimo’s<br />

Saturn range of 50 finishes, ranging<br />

from high gloss and matt solid<br />

colours to many varieties of woodgrain:<br />

what is believed to be by far<br />

the widest choice in the industry.<br />

Also believed to be unmatched<br />

in the KBB sector is the fact that<br />

Bellissimo offers wood finishes in<br />

horizontal grain on curved and ‘S’<br />

shaped doors.<br />

Bellissimo managing director,<br />

Warnock Watson, said: “I know the<br />

word unique is over-used, but<br />

there is no other way to describe<br />

these full-height curves for the UK<br />

industry.<br />

“The ability to finish a fullheight<br />

cabinet run with a pleasing<br />

curve, and to insert ‘S’ shapes as a<br />

feature in a line of doors, is significant<br />

for the designer in terms of<br />

impressing the customer and<br />

adding value.<br />

“Until now these options have<br />

been restricted to top-end solid<br />

timber products.<br />

“Horizontal woodgrain is another<br />

distinguishing feature,<br />

which can totally change the feel<br />

of a room.<br />

“For example, the visual impact<br />

of horizontal woodgrain on a<br />

2,250 mm wardrobe with curves at<br />

either end is quite stunning — totally<br />

different from a vertical grain<br />

— and a real competitive advantage<br />

for the retailer.”<br />

The curved doors are offered in<br />

300 mm and 400 mm widths,<br />

while the ‘S’ shaped doors come in<br />

900 mm and 1,200 mm widths.<br />

Bellissimo<br />

Tel 01772 696959<br />

Email<br />

warnock.ktw@btconnect.com<br />

Award for fire door manufacturer CB Solutions<br />

A MANUFACTURER and installer of fire door and door sets for the construction industry<br />

is celebrating success after being recognised at the Fire Excellence Awards<br />

<strong>2009</strong>.<br />

Yorkshire based CB Solutions was awarded second prize in the Passive Fire Protection<br />

Equipment Installer category. The awards, which took place in May, celebrate and<br />

acknowledge excellence in fire safety engineering, product design and innovation.<br />

CB Solutions manufactures fire doors and door sets, which are cost effective, stylish<br />

and safe. The company’s CERTIFIRE and FIRAS approved doors and installations are cur-<br />

Datum Tools Ltd<br />

Tel 01892 667800 www.flipstop.com<br />

rently keeping people safe in all sorts of work places, from<br />

hospitals to offices, army bases and even an Olympic Village.<br />

Business Development Manager, Jonathan Clark, said:<br />

“We have worked hard over the past 12 months to create<br />

products that combine safety, good looks and affordability<br />

and are delighted that our endeavours have been recognised<br />

and rewarded at the Fire Excellence Awards.”<br />

Over the past 12 months, CB Solutions has seen a large<br />

increase in enquiries from businesses in a wide range of sectors<br />

including healthcare, leisure and housing associations.<br />

CB Solutions was recently awarded the contract to manufacture<br />

and install fire doorsets at Bradford Royal Infirmary<br />

(illustrated) and in just three weeks manufactured and installed<br />

148 doorsets across two floors that concluded with<br />

the rigorous FIRAS onsite audit.<br />

CB Solutions Ltd ● Tel 01262 488919<br />

Email info@cbsol.co.uk ● www.cbsol.co.uk<br />

Page 12 Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong>

DOORS: DESIGN & MANUFACTURE<br />

Leaderflush Shapland installs Stefani post former<br />

LEADERFLUSH Shapland, one of the UK’s<br />

leading doorset manufacturers and a significant<br />

member of SIG Plc, has seen<br />

large growth in its Plasform® post formed<br />

product range over the past two years.<br />

Leaderflush Shapland’s Barn staple site<br />

now has its own business centre within the<br />

factory dedicated to producing post<br />

formed products, whereas before it was just<br />

an additional area for manufacturing a<br />

small range of pro ducts. As the demand for<br />

Leader flush Shapland’s Plasform® range<br />

and high security products have grown rapidly,<br />

it became apparent that additional investment<br />

was necessary. Todd Altman,<br />

Leaderflush Shapland’s managing director,<br />

approached the SIG Board and an investment<br />

proposal and program was approved.<br />

Leaderflush Shapland’s development<br />

manager, engineering manager and production<br />

engineering manager were given<br />

the task of investigating investment opportunities<br />

to provide their customers with superior<br />

products. To do this, it becomes<br />

evident that Leaderflush Shapland’s existing<br />

post forming machinery had to be replaced<br />

with a higher technologically<br />

advanced machine.<br />

According to a spokesperson from<br />

Leaderflush Shapland, “Our existing machine was susceptible to the climate<br />

and temperature, resulting in an inconsistent product exiting the<br />

machine. It was also difficult to set up from one profile to the next, especially<br />

as we have such a diverse range of products and materials. With an<br />

open mind, we approached potential machinery suppliers with our requirements,<br />

but we also wanted to see what was available that could assist<br />

us with future developments to meet the needs of our customers.”<br />

With a great deal of knowledge gained on the company’s existing<br />

American post former, Leaderflush Shapland wanted to have a partnership<br />

with a machinery supplier to evaluate their proposals and configure<br />

the specification of the machine in order to arrive at a final proposal that<br />

would deal with Leaderflush Shapland’s current and future requirements.<br />

A Leaderflush Shapland spokes person comments: “The majority of machinery<br />

suppliers have a standard range of machines that they will not deviate<br />

from, but we required a bespoke machine that would easily and<br />

simply deal with a ‘batch size of one’, with very fast changeovers between<br />

successive jobs. Mirko Maino, an engineer from Stefani, listened to our requirements<br />

and it soon became clear that they could design a machine to<br />

suit our needs, even though we required “Herriaus” lamps to be fitted, as we<br />

had good results from these on our existing machine and our engineers<br />

had built up a great deal of knowledge on how to use and maintain them.”<br />

Stefani Evolution PSF2 trimming units at Leaderflush Shapland.<br />

Stefani Evolution PSF2 double-sided post forming machine at Leaderflush Shapland.<br />

After several months of investigating the market, with technical meetings,<br />

discussions and demonstrations, Leaderflush Shapland decided to<br />

place an order for a Stefani Double-Sided Post Forming machine Model<br />

Evolution PSF2, Stefani being a manufacturing division of the SCM Group.<br />

The Stefani machine had to be capable of handling heavy, high-performance<br />

doors up to 200 kg in weight and therefore the Stefani heavyduty<br />

track was specified. Also, accepting components from 3,000 mm<br />

long by 1,600 mm wide, with changes in component width being dialled<br />

in to set the moving beam of the Stefani, with the thickness and height<br />

of the two top pressure beams being set with a remote calliper up to 85<br />

mm in height. Depending upon the profile being machined, the post<br />

forming rollers are capable of being changed rapidly using a jig system<br />

believed to be unique. There are 12 “Herriaus” lamps per side of the Stefani<br />

post former, with each one being independently controlled.<br />

“After purchasing a large DMC sanding line from the SCM Group, we have<br />

now built up a good partnership with SCM and their area sales manager,<br />

Mike Lee. Of course the price of a machine is important within our budgeting<br />

constraints, but equally the design, delivery, installation, commissioning<br />

and after sales capabilities with factory trained service engineers from a supplier<br />

are extremely important to us and we have found SCM Group UK and<br />

their manufacturing divisions great partners to work with.”<br />

Leaderflush Shapland<br />

Tel 01271 321007 ● www.leaderflushshapland.co.uk<br />

SCM Group UK ● Tel 0115 977 0044<br />

Email scmgroupuk@scmgroup.com ● www.scmgb.co.uk<br />

Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong> Page 13

FURNITURE FITTINGS & COMPONENTS<br />

Banbury Plastic Fittings launches new website<br />

BANBURY PLASTIC Fittings Ltd,<br />

a supplier of furniture components<br />

and accessories, has recently<br />

launched a brand new<br />

website, www.bpfittings.co.uk<br />

It’s a fully functional eCommerce<br />

site enabling visitors to<br />

download technical drawings,<br />

place orders and pay online via a<br />

secure credit card server.<br />

All the company’s core product<br />

ranges, such as desk grommets,<br />

cable management systems, pop<br />

up power units and tube fittings,<br />

have all been expanded, together<br />

with a number of new lines including<br />

table leg adjusters, corner<br />

New<br />

protectors and kitchen legs, to<br />

name just a few!<br />

Sales director, Jason Stead,<br />

stated: “We’re conscious of the fact<br />

that many of our customers appreciate<br />

a hard copy catalogue, which<br />

will remain a key selling platform for<br />

us — but we can update this new<br />

website daily with New Products<br />

and Stock Promotions, without having<br />

to wait between catalogue<br />

prints — that’s a huge advantage to<br />

us, and our customers!”<br />

The new site has no minimum<br />

order charge as such and each<br />

product has its own series of discounted<br />

pack options available for<br />

1 Meadow Street, Marsh, Huddersfield HD1 4QB<br />

Tel: 0870 760 9194 Fax: 01484 422605 Mobile: 07709 13149<br />

email: gareth@n-m-o.com www.n-m-o.com<br />

Maggi Junior 640 CE Radial Arm Cross Cut Saw<br />

Maggi 2034 Power Feed Unit<br />

Used<br />

Wadkin GC220 5 Head Planer Moulder<br />

Saomad UT4S Single End Tenoner<br />

Wadkin LS Pin Router with compound table<br />

Wadkin PAR 300 x 100 mm Four Side Planer<br />

Stromab RS650 Radial Arm C/c Saw 2003 CE<br />

SCM T110 Spindle Moulder with tenon table 2004 CE<br />

Stenner VHM 36” Resaw with 4” blade & DC brake<br />

Robinson EF/T 36” Resaw with 3” blade & DC brake<br />

Wadkin DP 10 Head Double End Tenoner<br />

Pickles ST Stair Trencher<br />

Wadin BRA350 Cross Cut Saw DC brake<br />

Wadkin FM 24” x 9” Planer thicknesser<br />

Wadkin WLCS 900 mm Combi Belt Sander<br />

Wadkin SP130 Panel Scoring Saw<br />

Ortza S320F 3.2m Panel Scoring Saw<br />

Weinig U22E 6 Head Planing Moulder<br />

Wadkin JY Bobbin Sander<br />

ACME C90 3.5 x 2.5 m Frame Cramp<br />

Wadkin GA220 6 Head Planer Moulder with booth<br />

Wadkin BZB 30” Bandsaw<br />

1/2/3 & 4 Bag Extractors<br />

Over 70 new and used machines in stock<br />

For our full list, please check out our web site<br />

www.n-m-o.com<br />

volume enquiries. All prices on the<br />

site include VAT and there is also a<br />

linke to BLPF’s sister company,<br />

Tepco Engineering, who operate<br />

from the same office and warehouse<br />

in Banbury. Tepco brings in<br />

regular containers from its own<br />

ISO Approved factory in Northern<br />

India, with recent shipments including<br />

office screen brackets, stability<br />

feet, castors and folding<br />

table clips.<br />

Banbury Plastic Fittings Ltd<br />

Tel 01295 264800<br />

Email sales@bpfittings.co.uk<br />

www.bpfittings.co.uk<br />

New from Martin<br />

MARTIN showcases an American Style Retro Refrigerator Roller Latch<br />

in Polished Nickel on solid brass.<br />

As well as kitchen cabinets, it would add a fabulous and tactile quality<br />

to numerous other applications. A complementary 3/8” offset hinge is<br />

also available and the latch can be supplied to suit flush doors.<br />

These are some of the many new and innovative items available from<br />

Martin’s Birmingham factory.<br />

Martin Furniture and Interior Fittings (a division of Armac Mfg Ltd)<br />

Tel 0121 359 2111<br />

Email sales@martin.co.uk ● www.martin.co.uk<br />

Page 14 Panel, Wood & Solid Surface <strong>August</strong>/<strong>September</strong> <strong>2009</strong>

SURFACE FINISHES & SURFACE FINISHING<br />

BECKER Acroma has launched a<br />

revolutionary water-based lacquer,<br />

Lacroma Clear, which offers<br />

exceptional clarity and<br />

THE 30-year established family<br />

business of Ridon Joinery has<br />

carved a reputation for supplying<br />

fine joinery to the building<br />

industry and private clients alike.<br />

durability, plus fast drying times<br />

from just 15 minutes!<br />

This innovation is already being<br />

held up by manufacturers as a<br />

Sanding with Mirka<br />

IN LINE with its aim to provide<br />

all customers with access to a<br />

total sanding solution, Mirka<br />

has developed a new Compact<br />

Electric Random Orbital Sander.<br />

Its new design (patent pending)<br />

means it offers superior versatility<br />

and performance in a compact,<br />

lightweight package. It is considered<br />

ideal for a multitude of dustfree<br />

sanding and polishing tasks,<br />

from timber to filler and gel-coats<br />

to auto motive finishes.<br />

Electrical power sources are generally<br />

more available and convenient<br />

than the compressed air<br />

alternative — this combined with<br />

the remarkably small electric motor<br />

unit, which is believed to be unique,<br />