MU March / April 2013

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

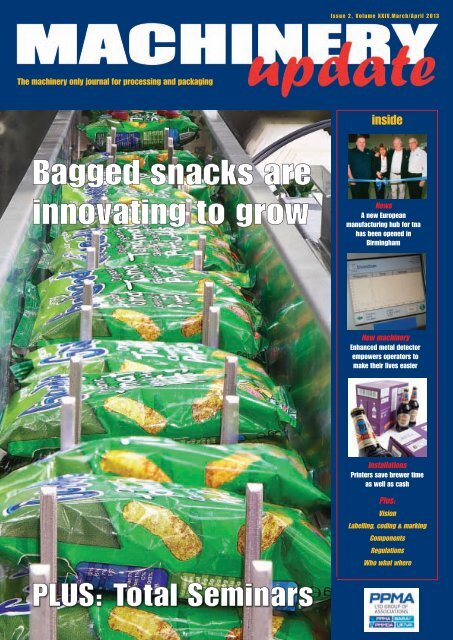

Issue 2, Volume XXIV.<strong>March</strong>/<strong>April</strong> <strong>2013</strong><br />

The machinery only journal for processing and packaging<br />

inside<br />

Bagged snacks are<br />

innovating to grow<br />

News<br />

A new European<br />

manufacturing hub for tna<br />

has been opened in<br />

Birmingham<br />

New machinery<br />

Enhanced metal detector<br />

empowers operators to<br />

make their lives easier<br />

Installations<br />

Printers save brewer time<br />

as well as cash<br />

Plus:<br />

Vision<br />

Labelling, coding & marking<br />

Components<br />

Regulations<br />

Who what where<br />

PLUS: Total Seminars

Join the Evolution<br />

Technology around us is constantly evolving to make our lives easier. The principle remains<br />

the same, but the technology moves on. The new RV-Series multihead is in a class of its<br />

own, pushing the technical boundaries to give your business the edge.<br />

FASTER<br />

The RV multihead has the speed to out-perform<br />

in production as well as during changeovers.<br />

TOUGHER<br />

High performance weighing even in tough conditions.<br />

Waterproof construction, achieving maximum uptime<br />

and minimum downtime.<br />

SMARTER<br />

Latest touch screen technology for enhanced<br />

user-friendliness.<br />

GREENER<br />

Three power modes that can reduce power<br />

consumption by up to 20%.<br />

www.ishidaeurope.com<br />

Ishida Europe Limited, Head Office: 11 Kettles Wood Drive, Woodgate Business Park, Birmingham B32 3DB, UK.<br />

Tel: +44 (0)121 607 7700, Fax: +44 (0)121 607 7888. Email: info@ishidaeurope.com

ISSUE 2, VOLUME XXIV. MARCH/APRIL <strong>2013</strong><br />

T H E J O U R N A L O F T H E P P M A<br />

Editor: Gail Hunt<br />

Sales Manager: David Chadd<br />

Production Manager: Bill Lake<br />

A PPMA Publication<br />

PPMA Ltd,<br />

New Progress House,<br />

34 Stafford Road, Wallington,<br />

Surrey SM6 9AA<br />

Tel: +44 (0) 20 8773 8111<br />

Fax: +44 (0) 20 8773 0022<br />

E-mail addresses:<br />

publishing@ppma.co.uk<br />

show@ppma.co.uk<br />

technical@ppma.co.uk<br />

Website: www.ppma.co.uk<br />

Applications for free copies<br />

of Machinery Update are<br />

considered from specifiers,<br />

managers and purchasers of<br />

processing and packaging<br />

machinery in the UK.<br />

Annual subscription:<br />

£35 (UK), £50 (Continental<br />

Europe), £65 (rest of world).<br />

ISSN 0969-4145<br />

contents<br />

7 news<br />

There are many positive stories<br />

this issue with news of<br />

investments in new products;<br />

new manufacturing premises;<br />

new in-house services; new<br />

partnerships and even a new company in the plastics sector.<br />

There’s also news about future exhibitions and conferences<br />

12 new machinery<br />

Five pages of kit that includes a<br />

case erector; a vacuum chamber<br />

belt machine; a thermoformer;<br />

a metal detector; a shrink wrapper;<br />

a robotic case packer; a box<br />

sizer; a pallet dispenser; a shrink wrapper; an x-ray inspection<br />

system and a sandwich wedge erector<br />

18 installations<br />

If installations are a barometer of how<br />

the market is performing right now, it is<br />

good news that we have 14 stories<br />

covering a wide variety of industries<br />

included in our 7 pages<br />

28 total exhibition<br />

The full seminar programme at the Total<br />

Processing and Packaging exhibition taking<br />

place at the NEC, Birmingham – June 4-6<br />

is revealed<br />

30 special feature – snacks<br />

Printed by:<br />

Manor Creative, 7-8 Edison<br />

Road, Highfield Industrial<br />

Estate, Hampden Park,<br />

Eastbourne BN23 6PT.<br />

Tel: +44 (0) 1323 514400<br />

The Processing and Packaging<br />

Machinery Association assumes<br />

no responsibility for the<br />

statements or opinions, whether<br />

attributed or otherwise, in<br />

Machinery Update.<br />

This publication is copyright<br />

under the Berne convention and<br />

the International copyright<br />

convention. Apart from any fair<br />

dealing for the purposes of<br />

research or private study, as<br />

permitted under the Copyright,<br />

Designs and Patents Act 1988,<br />

no part of this publication may<br />

be reproduced, stored in a<br />

retrieval system or transmitted in<br />

any form or by any means in any<br />

form without prior written<br />

permission of the publishers.<br />

Publishers: PPMA LTD<br />

www.machineryupdate.co.uk<br />

This 14 page feature looks at the latest developments in<br />

this market that loves its NPD and new packaging formats<br />

as well as big volume production efficiencies<br />

regular features<br />

44 vision<br />

Systems to suit hot cross buns and foil seals in plastic lids<br />

46 labelling, coding & marking<br />

The latest sensors; barcode readers as well as installations<br />

48 components<br />

Capacitors offer energy savings for machine builders<br />

50 regulations<br />

The need for machine validation<br />

52 who what where<br />

People, events and diary dates<br />

53 classified<br />

Machinery and services<br />

54 buyers’ guides<br />

MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong><br />

3

CEIA<br />

The latest technology<br />

in Metal Detection<br />

Systems<br />

Enhanced Metal Detectors<br />

for Quality Control<br />

Multi-Spectrum<br />

Technology<br />

Conveyor Inspection<br />

Systems<br />

Full compliance<br />

with HACCP and<br />

GMP criteria<br />

Integrated Systems<br />

with Metal Detector<br />

and ejection valve<br />

M.D.S.Ltd.<br />

METAL DETECTION SERVICES<br />

CEIA Authorised Dealer - Phone: 0161 286 8750<br />

w ww.mds. org .uk

ppma matters<br />

It really matters how<br />

you present yourself<br />

I was recently a fortunate invitee<br />

to the Government’s latest<br />

workshop on developing a UK<br />

Industrial Strategy. The day before<br />

the workshop I was a speaker at a<br />

conference on the importance of<br />

automation and robotics in<br />

securing the future of UK<br />

manufacturing. One theme that<br />

dominated at both events was the<br />

fact that whilst we have very large<br />

numbers of unemployed<br />

youngsters seeking work, the<br />

single major obstacle to business<br />

growth was a shortage of people to fill the posts necessary to<br />

deliver what are often very healthy business pipelines.<br />

Nick Clegg himself, the keynote speaker at the Strategy<br />

workshop, bemoaned this apparently mysterious conundrum.<br />

The truth is, to anyone trying to recruit at the moment, there is<br />

no mystery as to the reason for this ‘mismatch’. It is simply too<br />

unpalatable to politicians (and bad for votes), to have to admit it.<br />

The ability of most new recruits (I exclude those fortunate<br />

enough to have educated parents and a good schooling), to<br />

communicate at even the most basic of levels either in writing or<br />

with the spoken word is nothing less than alarming! Years of<br />

politicians meddling in our education system has lowered<br />

standards to the point where rather than everyone being able to<br />

secure a good education, the academic standards have been<br />

reduced to a level where few can claim to have the required skills<br />

despite what is written on the certificate that they receive at the<br />

end of the process! I am of-course, generalising. There are some<br />

very good candidates but sadly they are in a minority and are<br />

quickly ‘snapped-up’ by large blue-chip organisations paying<br />

starting salaries that most SME’s (who generate the lion’s share<br />

of UK GDP), are unable to match.<br />

How many employers can tell stories of so called ‘graduate<br />

applicants’ who could hardly write a coherent job application and<br />

clearly didn’t even have the initiative to use the spell-check on<br />

their PC’s? How many have encountered applicants who have<br />

turned up looking like they have an allergy to soap and water and<br />

have never used a comb in their lives?<br />

The fact is; it does matter how we dress; how we speak; how<br />

punctual we are; whether or not we can spell and whether or not<br />

we are prepared to work hard for that much sought after salary!<br />

The politicians must ‘grasp-the-nettle’ and raise basic educational<br />

standards and equally – it is the responsibility of parents to instill<br />

decent life-values in their off-spring if they want them to play a<br />

part in the future of the UK economy.<br />

CEO PPMA Group of Associations<br />

(Incorporating PPMA, BARA, UKIVA & PMMDA)<br />

If you need to recruit,<br />

look no further<br />

Exclusive Recruitment<br />

Partner to the<br />

Call Mike Horsley on 01604 758857<br />

or email him at mph@wallacehind.com<br />

<br />

Specialists in recruitment to the<br />

packaging and process machinery industry since1996<br />

www.machineryupdate.co.uk<br />

MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong><br />

5

news<br />

Robot sales last year<br />

were best on record<br />

SHOW NEWS<br />

Annual sales of industrial<br />

robots for 2012 have beaten<br />

any other year to date but<br />

disappointingly, 22% fewer<br />

units were sold into the food<br />

and drink industry even<br />

though there has been a big<br />

push to encourage sales in<br />

this sector.<br />

The figures are reported by<br />

the British Automation and<br />

Robot Association (BARA) and<br />

the consensus is that there is<br />

much interest in automation<br />

from the food and drink<br />

sectors but the fickleness of<br />

supermarket demands is still<br />

the main barrier to any<br />

investment. For instance,<br />

supermarkets continue to<br />

apply short contracts and<br />

retain the ability to change<br />

packaging designs with little<br />

notice to suppliers.<br />

“These issues have become<br />

an increasingly reported barrier<br />

to investing in automation in<br />

this sector even though the<br />

programmability of robotic<br />

systems today means they are<br />

more than capable of adapting<br />

to new packaging designs,”<br />

says head of marketing for<br />

BARA Grant Collier.<br />

Sales for 2012 have<br />

doubled over the 2011 figure<br />

with 2,476 units sold and once<br />

again, the automotive and<br />

automotive components<br />

sectors have been the main<br />

source of this growth. “Whilst<br />

this is good news and the<br />

automotive sector has<br />

unsurprisingly generated most<br />

of these sales, we are<br />

witnessing only a modest<br />

upward trend over the last few<br />

years in the uptake of robotics<br />

across other sectors,” says<br />

BARA chairman Mike Wilson.<br />

The pharmaceutical industry<br />

has the strongest growth while<br />

electronics was also a strong<br />

performer.<br />

Collier is also responsible<br />

for the Automating<br />

Manufacturing Programme, a<br />

government initiative that<br />

made £250,000 available to<br />

help persuade UK companies<br />

to automate. Funds from the<br />

programme are now all nearly<br />

completely allocated, but he<br />

says that an increasing<br />

number of companies that<br />

applied have asked for a<br />

further detailed review of their<br />

processes. “It’s still early days<br />

in seeing whether these<br />

appraisals turn in to actual<br />

orders for automation and<br />

robotics systems,” he says.<br />

Euro manufacturing hub opens<br />

tna has opened a European<br />

manufacturing hub at its<br />

existing site in Birmingham to<br />

provide a logistical base for<br />

sales, technical service and<br />

project management<br />

capabilities in Europe.<br />

With two manufacturing<br />

sites in Australia and China,<br />

the new Hub creates a<br />

strategic site closer to tna’s<br />

European customers, reducing<br />

lead times and further<br />

enhancing the company’s<br />

service offer.<br />

The 50,000sq ft facility<br />

represents a significant<br />

investment in the European<br />

The Department for Business<br />

Innovation & Skills (BIS) has<br />

published a guide to the<br />

main forms of public support<br />

L-R: Manufacturing manager at tna Andy King; co-founders Nadia<br />

Taylor and Alf Taylor and Tim Moulsdate, tna's general manager, Europe<br />

market and product output is<br />

expected to reach 30% of all<br />

tna’s capital equipment from<br />

around the world. Providing<br />

employment for about 65<br />

SME guidance to finance schemes from BIS<br />

and advice available to<br />

businesses which explains<br />

who can access which<br />

schemes and sets out<br />

people, the site will create a<br />

number of new jobs in the<br />

surrounding area.<br />

0121 628 8900<br />

www.tnasolutions.com<br />

where further information<br />

can be found.<br />

Ref: BIS/13/P176APDF<br />

www.gov.uk<br />

Total Processing and<br />

Packaging <strong>2013</strong> takes place<br />

at the NEC, Birmingham from<br />

4-6 June and comprises three<br />

hubs including Pakex, the<br />

PPMA Show and Interphex,<br />

where hundreds of exhibitors<br />

demonstrating the advantages<br />

of their materials and<br />

equipment will greet visitors.<br />

Free to attend seminars will<br />

also be available across the<br />

three areas, full details of<br />

which can be found on page<br />

29 of this issue. Further details<br />

of other exhibition features can<br />

be found on the same spread.<br />

A full preview of exhibitors<br />

will be included in the next<br />

issue of Machinery Update.<br />

www.totalexhibition.com<br />

VISION is changing to a<br />

biennial cycle with immediate<br />

effect which means that<br />

VISION <strong>2013</strong> will not take<br />

place and the next VISION<br />

will open its doors in Stuttgart<br />

from 4-6 November 2014.<br />

“This decision takes account<br />

of the request by many<br />

exhibitors who want to offer<br />

trade visitors a genuine raft of<br />

innovations,” explains Patrick<br />

Schwarzkopf, head of the<br />

VDMA Machine Vision<br />

Association and supporter of<br />

the event. “The biennial cycle<br />

provides the best conditions in<br />

this respect.”<br />

Organisers believe that the<br />

new biennial cycle of the<br />

event – that just celebrated its<br />

25th anniversary – will extend<br />

its leading position and<br />

consolidate its importance as<br />

a global innovation platform.<br />

www.messe-stuttgart.de<br />

www.machineryupdate.co.uk<br />

MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong><br />

7

news<br />

New consultant<br />

for UK plastics<br />

Plastech Solutions is a new<br />

consultancy designed to<br />

provide a one-stop-shop<br />

service to businesses in the<br />

plastics industry’s medical,<br />

technical and packaging<br />

sectors throughout the UK and<br />

Ireland. The company will help<br />

identify and source the most<br />

cost effective production<br />

solutions, from single items of<br />

equipment to complete<br />

production systems.<br />

Stephen Rundle of Plastech<br />

The new consultancy has<br />

been appointed exclusively to<br />

represent Kebo, Singulus<br />

Technologies, BFA Solutions<br />

and Ilsemann Automation in the<br />

UK and Irish markets. It has<br />

been set up by Stephen Rundle<br />

who has more than 25 years’<br />

experience in the plastics<br />

industry, most recently as vice<br />

president of United Closures &<br />

Plastics. He aims to fill the skills<br />

gap that exists in specifying<br />

equipment to achieve optimum<br />

OEE for clients.<br />

0870 919 8686<br />

Stephen.rundle@plastech<br />

solutions.co.uk<br />

To Russia…<br />

…with love<br />

Jenton Ariana has produced its<br />

first two Convergers equipped<br />

with controllers programmed<br />

with the Russian language. To<br />

date, the company has supplied<br />

Convergers across the world<br />

with HMIs in English, German,<br />

Italian, French and now Russian.<br />

01256 892194<br />

www.jenton.co.uk<br />

Efficiency is delivered<br />

Siemens Industry has launched<br />

the Simatic S7-1500 next<br />

generation controller family for<br />

medium to high-end machine<br />

and plant automation while at<br />

the same time, extending its<br />

Totally Integrated Automation<br />

(TIA) Portal engineering<br />

framework with a number of<br />

new functions, adding power<br />

and efficiency to the existing<br />

framework’s capabilities.<br />

This new generation of<br />

controllers is characterised by<br />

high performance and<br />

efficiency. Siemens says its<br />

features include outstanding<br />

system performance and a<br />

host of functions integrated as<br />

standard, including motion<br />

control, maximum security and<br />

safety applications that are<br />

easy to implement.<br />

“The controllers offer greater<br />

efficiency thanks to the<br />

innovative design for simple<br />

commissioning and safe<br />

operation,” says Simon Keogh<br />

for Siemens Industry.<br />

“Importantly, integration into<br />

the TIA Portal enables<br />

simple engineering and low<br />

project costs.”<br />

The new Simatic S7-1500<br />

controllers range is being<br />

launched in stages. Initially,<br />

the portfolio will comprise<br />

three CPU types 1511, 1513<br />

and 1516 for the medium<br />

performance range. Each is<br />

also available as an F-version<br />

(failsafe) for safety<br />

applications with graded<br />

performance features.<br />

According to the individual<br />

automation task, the CPUs in<br />

the central configuration can be<br />

supplemented with as many as<br />

32 expansion modules, for<br />

instance with the new<br />

communication and technology<br />

modules or IO modules, in the<br />

same format as Simatic ET<br />

200MP from Siemens.<br />

Turning to the engineering<br />

framework, the newly launched<br />

Version 12 enables drives of<br />

the Sinamics G converter<br />

series from Siemens to be<br />

integrated into the TIA Portal.<br />

www.siemens.com<br />

Expanding in-house services<br />

Multivac UK has bought a new<br />

building just across the road<br />

from its existing site in Swindon<br />

to meet demand and expansion<br />

in its after sales services.<br />

The new building provides<br />

22,000sq ft of additional high<br />

quality machine workshops and<br />

spare parts warehousing for its<br />

£3m of UK-held spares plus<br />

additional offices for its<br />

technical services group<br />

including spares, technical<br />

support, workshop engineering<br />

and training.<br />

Two years ago, the company<br />

decided to stop sending sealing<br />

plattens back to Germany or to<br />

outside companies for<br />

refurbishment. Today, its<br />

in-house service strips down,<br />

cleans, sand blasts, re-teflon<br />

coats and bakes the tools on<br />

site before re-assembly with<br />

The Siemens TIA Portal V12 and Simatic S7-1500 controller family<br />

Multivac UK has bought a new building to bring more services in-house<br />

heating elements etc. This<br />

service has grown from<br />

Multivac’s own traysealer and<br />

thermoformer tooling to now<br />

include customers of other<br />

manufacturers including<br />

Mondini, Proseal, Sealpac<br />

taking advantage of the fast<br />

turnaround and high quality.<br />

Surface grinding is another<br />

new service that has been<br />

taken in-house for sharpening<br />

and re-grinding cutting systems<br />

as well as hole plates for its<br />

Risco grinders and mincers. A<br />

further growth area has been<br />

the massive expansion in<br />

workshop overhauls and the<br />

rebuilding of pre-owned<br />

machines.<br />

01793 425800<br />

www.multivac.co.uk<br />

8 MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong><br />

www.machineryupdate.co.uk

news<br />

First UK firm is<br />

systems partner<br />

Kensal Handling has signed an agreement with Kuka Robotics UK<br />

Manufacturers of stainless steel<br />

conveying systems Kensal<br />

Handling Systems is the first UK<br />

company to enter into a<br />

systems partner agreement with<br />

Kuka Robotics UK.<br />

The agreement allows Kensal<br />

sales and design teams to<br />

integrate the latest robotic<br />

technologies into their<br />

conveying systems to deliver<br />

enhanced productivity, process<br />

improvements and additional<br />

cost effectiveness for new and<br />

existing clients.<br />

“Each systems partner<br />

company is selected according<br />

to stringent criteria including<br />

technical expertise and industry<br />

experience to ensure their<br />

products, technical knowledge<br />

and business philosophies<br />

match Kuka’s standards,”<br />

explains Daniel Lambie, sales<br />

and marketing director for<br />

Kensal. “This agreement<br />

reaffirms our reputation as<br />

experienced integrators of whole<br />

system solutions.”<br />

www.kensal.com<br />

Modified wrapper<br />

The Selo Group first<br />

introduced its Selopack<br />

concept three years ago at<br />

the last Macropak exhibition<br />

and today, it has been taken<br />

on by a Dutch food producer<br />

and embraced by the largest<br />

supermarket in the<br />

Netherlands who has<br />

completely changed their<br />

style to incorporate it for an<br />

assortment of products.<br />

WSP Food has invested in<br />

packaging lines where the<br />

Selopack concept is<br />

produced on a modified<br />

flowrapper. It was this<br />

investment that led to the<br />

supermarkets interest.<br />

Encouraged by the success<br />

of Selopack, ceo of The Selo<br />

Group Jeroen Mulder is now<br />

working on two further<br />

concepts, one is a new<br />

sandwich container while the<br />

The new Selopack is produced<br />

on a modified flowrapper<br />

other is a new snack pack for<br />

not only traditional snacks but<br />

also nuts, raisins, other dried<br />

fruits and cheese cubes.<br />

www.selo.com<br />

• Our 14 page snack feature<br />

starts on page 29.<br />

www.machineryupdate.co.uk<br />

MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong>

news<br />

Tie-in to help<br />

improvements<br />

AutoCoding Systems has<br />

announced a strategic<br />

partnership with Canadian<br />

company Shoplogix, a<br />

leading developer of<br />

manufacturing performance<br />

management solutions with<br />

installations in 40 countries<br />

including the UK and Ireland.<br />

AutoCoding offer<br />

automation solutions across<br />

packaging line operations<br />

and its range of modular<br />

applications go from entry<br />

level coding and packaging<br />

integrity solutions through to<br />

complete set-up and control<br />

of all packaging line devices<br />

such as coders, scanners,<br />

labellers, metal detectors,<br />

checkweighers and vision<br />

solutions. AutoCoding says<br />

the Shoplogix solution,<br />

facilitating the visualisation of<br />

manufacturing KPI data, is a<br />

natural extension of its offer.<br />

The Shoplogix solution<br />

enables companies to<br />

identify and evaluate where<br />

problems, performance<br />

limitations and constraints<br />

exist within their processing<br />

and packaging applications.<br />

Its products concentrate on<br />

capturing real-time<br />

manufacturing data which is<br />

then visualised, via a suite of<br />

reports, to display accurate<br />

machine performance data.<br />

01928 790444<br />

www.autocodingsystems.com<br />

Open House<br />

Yamato Scale Dataweigh<br />

and GEA Food Solutions<br />

held a two week open house<br />

at Yamato’s HQ in Leeds in<br />

<strong>March</strong> with demonstrations<br />

that allowed visitors to gain a<br />

detailed understanding of<br />

weighing and bagging<br />

technology – with a special<br />

focus on fresh produce.<br />

www.yamatoscale.co.uk<br />

www.gea-foodsolutions.com<br />

Sad passing of two<br />

industry stalwarts<br />

Arthur F Organ was described as a charismatic and humorous man<br />

It is with great sadness that we<br />

report the death of Arthur F<br />

Organ at the age of 89.<br />

Organ was the founder of<br />

Arthur F Organ Packaging<br />

Machinery that created the<br />

renowned Organpak brand, a<br />

name synonymous with<br />

fastener and hardware<br />

packaging machinery. He died<br />

in January, as did one of his<br />

first employees Aubrey N<br />

Clarke at the age of 83.<br />

Over three thousand<br />

installations of Organpak<br />

machinery were completed in<br />

more than 70 countries with<br />

many machines still serviced,<br />

being over thirty five years old.<br />

When speaking of him, people<br />

would mention his bow tie, his<br />

The Profibus Group, the UK’s<br />

source of information and<br />

support for Profibus and<br />

Profinet users, 20th<br />

anniversary conference on<br />

June 26 will open with a State<br />

of The (Industrial) Nation<br />

address from Brian Holliday,<br />

one of the ‘founding fathers’ of<br />

the group.<br />

Chairman Karsten<br />

Schneider will then present<br />

the keynote speech to, bring<br />

pipe and his trailer in which he<br />

travelled the globe in search of<br />

new customers. Mr Lofthouse<br />

of Fisherman’s Friends<br />

Lozenges says he can always<br />

remember him turning up with<br />

a machine on the trailer to<br />

demonstrate packing the<br />

famous lozenges. Lofthouse<br />

went on to buy 35 machines<br />

from Arthur over the next<br />

few years.<br />

Following his retirement<br />

from the packaging industry<br />

and the loss of his first wife<br />

Doris to cancer, his<br />

entrepreneurial skills<br />

continued when he moved up<br />

to Loch Fyne in Scotland with<br />

his second wife Jean. At his<br />

funeral, his friend John Knox<br />

news of updates on the<br />

technology including Profinet<br />

for process industry<br />

applications, performance<br />

achievements and the latest<br />

developments on areas such<br />

as Profienergy, the<br />

organisation’s solution for<br />

energy savings during<br />

production idle times.<br />

There will also be a series of<br />

case studies and other<br />

practical presentations as well<br />

said he felt sure that on<br />

reaching the Pearly Gates,<br />

Arthur would be discussing<br />

how to make the gates open<br />

automatically and<br />

St Peter saying: “It’s a deal.”<br />

Aubrey N Clarke has died aged 83<br />

Aubrey N Clarke died in<br />

Redditch in January. He was<br />

one of Arthurs first employees<br />

and his role in this and the<br />

subsequent companies was in<br />

production, service and<br />

technical backup to overseas<br />

agents. His continued service<br />

to the packaging industry<br />

lasted until his retirement at<br />

the age of 70.<br />

Conference addresses key industry issues<br />

as a number of Master Classes<br />

and Workshops. There will be<br />

a presentation on the new<br />

Certified Profibus system<br />

designer course delivered by<br />

the group’s technical officer<br />

Andy Verwer which will outline<br />

the course content, while Peter<br />

Thomas of Control Specialists<br />

will discuss how the use of<br />

Profinet can take users into the<br />

realms of the IT world.<br />

www.profibusgroup.com<br />

10 MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong><br />

www.machineryupdate.co.uk

CAMA HIGH TECHNOLOGY AND SAFETY,<br />

A GUARANTEED RETURN ON YOUR INVESTMENT.<br />

Cama Group is a leading supplier of advanced technology secondary<br />

packaging systems, continuously investing in innovative solutions.<br />

Cama engineers design and develop packaging lines following a well<br />

developed and adopted motto: “Technology with Added Value”.<br />

www.camagroup.com<br />

CAMA UK Ltd - cama3@camagroup.com - Tel. 0 1793 831111<br />

Birmingham - UK<br />

04 -06 June <strong>2013</strong><br />

Stand B20

new machinery<br />

Future proof<br />

case erector<br />

German company B&B –<br />

Maf has launched its newly<br />

designed CombiMatic<br />

corrugated case erector<br />

which is available in the UK<br />

and Ireland from agent<br />

ShrinkPack.<br />

After several years of<br />

development and testing, the<br />

company is confident it has<br />

devised the ultimate in<br />

modular multi-functional<br />

design, allowing multiple<br />

format packaging options.<br />

“The machine allows clients to<br />

future proof against changes<br />

in packaging formats ensuring<br />

their investment is safeguarded,”<br />

says Alan Lewis of<br />

ShrinkPack.<br />

Trays, high-sided trays,<br />

trays with U-boards, trays<br />

with enclosed lids and<br />

several wraparound options<br />

are all available from one<br />

base machine. The modular<br />

design allows the base<br />

machine to be expanded at a<br />

later date to incorporate even<br />

more packaging formats.<br />

The expandability of the<br />

design allows users to specify<br />

their minimal initial requirement<br />

as it can be upgraded for a<br />

relatively low cost.<br />

The same modular concept<br />

is available on the film<br />

solutions from the German<br />

company.<br />

01226 320762<br />

www.shrinkpack.co.uk<br />

Unit is energy efficient<br />

Multivac will be showing its<br />

energy-efficient, entry level<br />

thermoformer – the R 095<br />

e-concept – at IFFA <strong>2013</strong>, the<br />

international exhibition for the<br />

meat industry in Frankfurt<br />

from 4-9 May.<br />

The machine has been<br />

developed for the handproduced<br />

meat industry which<br />

is an energy-intensive trade<br />

across Europe and one that is<br />

affected by rising energy<br />

prices. The R 095 consumes<br />

at least 20% less energy than<br />

comparable models and is<br />

particularly suited to small and<br />

medium-sized food producing<br />

companies.<br />

The lifting units and cutting<br />

units are electrically driven<br />

and, combined with its special<br />

forming and sealing processes,<br />

the e-concept does not require<br />

any compressed air or cooling<br />

water. This also adds to its<br />

choice of location as all it<br />

requires is a power supply.<br />

The R 095 is equipped with<br />

an interface for installing a<br />

slicer and, at the exhibition it<br />

will be shown with the A 406<br />

FB-<strong>MU</strong> slicer from Bizerba.<br />

The fully automatic slicer<br />

offers a wide variety of<br />

possible formats and<br />

placement positions for the<br />

sliced product, as well as an<br />

extensive range of options for<br />

pre-selecting the number and<br />

thickness of slices.<br />

01793 425800<br />

www.multivac.co.uk<br />

Vacuum chamber machine is giant<br />

Vacuum and modified<br />

atmosphere company VC999<br />

Packaging Systems UK has<br />

launched the K9 vacuum<br />

chamber belt machine which<br />

is its largest chamber machine<br />

designed to date.<br />

Known as ‘The Giant,’ the<br />

machine is ideal for packing<br />

large products on an<br />

industrial scale and offers<br />

“unparalleled vacuum<br />

technology and Bi-Active<br />

sealing ability”.<br />

The machine features a<br />

variable height adjusting lid<br />

design for cycle speeds up to<br />

3.3 cycles a minute and is<br />

The<br />

thermoformer<br />

is equipped<br />

with an<br />

interface for<br />

installing a<br />

slicer<br />

The K9 vacuum chamber belt machine is known as ‘The Giant’<br />

designed to meet the highest<br />

hygiene standards.<br />

“This robust, reliable<br />

machine has a special sealing<br />

system and offers a low life<br />

cycle cost, says Rona Nixon,<br />

general manager of VC999<br />

Packaging Systems UK.<br />

01604 644086<br />

www.vc999.co.uk<br />

THERMAL TRANSFER PRINTERS - INKJET CODERS - HOT FOIL PRINTERS<br />

Thermocode iQ<br />

‘state-of-the-art ‘<br />

thermal transfer printing<br />

World Class Coding & Marking Systems<br />

+44 (0)20 8655 4999 sales@opendate.co.uk www.opendate.co.uk<br />

getting you<br />

up to speed

new machinery<br />

Enhanced detection<br />

A number of upgrades have<br />

been made by Loma<br />

Systems to its IQ3+ metal<br />

detector to ensure it still<br />

meets all the latest<br />

inspection codes of practice<br />

while at the same time<br />

empowering operators to<br />

make their lives easier.<br />

“This series of<br />

incremental enhancements<br />

have been made to the<br />

machine to deliver greater<br />

functionality and reduce the<br />

risk of human error, so<br />

improving safety, efficiency<br />

and overall performance,”<br />

explains David Phillips,<br />

research and development<br />

manager at Loma.<br />

Enhancements include a<br />

20% increase in field<br />

strength for improved<br />

contaminant detection as<br />

well as the first integration of<br />

its EnviroScan software and<br />

patented AutoBalance<br />

technology in a variable<br />

frequency system. Together<br />

with additional technical<br />

updates to key operational<br />

features, the changes are<br />

designed to ensure the<br />

robust IQ3+ keeps pace with<br />

both regulatory demands<br />

and business developments.<br />

The IQ3+ achieves a 20%<br />

increase in field strength<br />

through improved<br />

componentry and enhanced<br />

thermal management in its<br />

MaxDrive feature. This is of<br />

particular benefit for the<br />

inspection of dry goods,<br />

such as biscuits, breads and<br />

cereals which lack moisture<br />

An automatic shrink wrapper<br />

has been introduced by<br />

Audion Elektro and is now<br />

available in two versions from<br />

UK and Ireland agent<br />

Friedheim International.<br />

The CS100 and CS200<br />

work with a continuous<br />

www.machineryupdate.co.uk<br />

Operators can switch between frequencies without relying on<br />

hand held metering systems<br />

and so do not interact with<br />

the magnetic field.<br />

Outside environmental<br />

noise resulting from<br />

vibrations or electrical<br />

interference can impair<br />

detection performance.<br />

Hand held metering systems<br />

are normally brought in to<br />

monitor such noise levels,<br />

identify ‘hotspots’ and<br />

facilitate line adjustments but<br />

are often not available for line<br />

operators to use on a just-intime<br />

basis. The IQ3+ now<br />

streamlines this process with<br />

its built-in EnviroScan<br />

software which intuitively<br />

In-built EnviroScan software<br />

intuitively scans across<br />

frequencies from 30-900kHz<br />

side sealer and a<br />

longitudinal intermittent<br />

sealing system that offers<br />

unlimited length of product<br />

that can be packed; an<br />

increase in production<br />

capacity and less waste film,<br />

which results in lower costs.<br />

scans across frequencies<br />

from 30-900kHz to check if<br />

interference is detected,<br />

then these issues can be<br />

easily eliminated by<br />

switching to one of the<br />

alternative 70 frequencies<br />

available on the IQ3+ and<br />

quickly repeated by the<br />

operator on an ad hoc basis<br />

as the factory environment<br />

changes.<br />

In addition, technical<br />

enhancements to the noise<br />

filtering system further<br />

improve stability of the coil<br />

head by increasing its<br />

resistance to harsh<br />

electronic noise close to the<br />

contaminant signal.<br />

Another step forward is<br />

the integration of Loma’s<br />

patented AutoBalance<br />

technology. This feature<br />

can be used to re-balance<br />

the coil heads in the IQ3+<br />

which may expand or<br />

contract due to changes in<br />

temperature over time.<br />

01252 893300<br />

www.loma.com<br />

Two versions of automatic shrink wrapper<br />

Friedheim says the<br />

Audion CS Matic shrink<br />

wrapper is operator<br />

friendly as it is easy to<br />

work with, to clean and to<br />

maintain.<br />

01442 206100<br />

www.friedheim.co.uk<br />

Capping heads<br />

Applied Torque<br />

Sensing & Monitoring<br />

Torque sensing and monitoring<br />

is supplied by a torque transducer in<br />

both digital and analogue data for<br />

validation purposes and further<br />

analysis.<br />

Cap Coder capping heads come in<br />

single and multi-head formats for<br />

multiple product applications<br />

ranging from Food to Chemicals,<br />

Cosmetics to Drinks.<br />

Cap Coder Ltd<br />

Monument Business Park<br />

Chalgrove, Oxford OX44 7RW<br />

Tel: 01865 891466<br />

Fax: 01865 891292<br />

e-mail: sales@capcoder.co.uk<br />

www.capcoder.co.uk

new machinery<br />

Quick change<br />

for bagging<br />

Rovema now offers a new<br />

mobile lifting device along with a<br />

new bag forming set carriage to<br />

match all the forming sets for<br />

baggers it produces. The mobile<br />

lifting device ensures that the<br />

bag forming sets and rolls of foil<br />

may be changed quickly,<br />

smoothly and reliably, says the<br />

company.<br />

Apart from assisting with the<br />

changing process, the lifting<br />

device ensures safe<br />

transportation from the storage<br />

area to the bagger, while the<br />

mobile bag forming carriage can<br />

accommodate four bag forming<br />

sets with the respective<br />

accessories.<br />

Installation height of the lifting<br />

device is easily adjusted and it<br />

eliminates heavy lifting work to<br />

help operators to change bag<br />

forming sets rapidly, gently and<br />

also reliably.<br />

Both products have plenty of<br />

room to store tools, small parts<br />

and accessories.<br />

01296 310490<br />

www.rovema.co.uk<br />

Shrink sleever<br />

sees eco-gains<br />

Karlville exhibited its SP600<br />

automatic high speed shrink<br />

sleeve application machine that<br />

is capable of applying up to 600<br />

sleeves a minute during Pack<br />

Expo 2012. It ran two different<br />

materials: a standard PET-G<br />

material and a new 30 micron<br />

PET shrink film during the event.<br />

UK and Ireland agent<br />

ShrinkPack believes Karlville’s<br />

30 micron solution achieved<br />

during the show demonstrates<br />

the company’s drive to offer<br />

advanced technology and<br />

sustainable options to<br />

customers. This material applied<br />

sleeves at 600 bottles a minute<br />

onto a 200ml bottle.<br />

01226 320762<br />

www.shrinkpack.co.uk<br />

Robotic case packer is<br />

flexible off-line option<br />

Tekpak has launched a pick<br />

and place case packer that it<br />

describes as a flexible high<br />

speed system for vertical case<br />

packing quad bags, pouches<br />

and doy packs. The new robot<br />

uses an Elau/Schneider<br />

control system, is particularly<br />

suited for manufacturers of<br />

snack packs and bags,<br />

confectionery and coffee.<br />

Key features include a<br />

special product transfer<br />

system that collates the<br />

products beneath the gripper<br />

so that the pick and place can<br />

handle a complete case<br />

formation – ie groups of ten<br />

products at a time – which<br />

increases throughput on the<br />

line. The gripper head and<br />

case opening system has<br />

been specially designed for<br />

vertical case packing in to<br />

display cases and other shelf<br />

ready formats.<br />

The robot can pack bags<br />

direct from the bagger to<br />

maintain a continuous<br />

packing process.<br />

“Automating the offline/work<br />

in progress<br />

operation is a major benefit to<br />

our customers because it<br />

A product transfer system collates the products beneath the gripper<br />

reduces product lead time and<br />

can have a big impact on line<br />

efficiency,” explains Tekpak’s<br />

business development director<br />

Imelda Kehoe.<br />

The system can include an<br />

integrated case erector and<br />

closer for shelf ready display<br />

cases which allows for a more<br />

compact footprint of just<br />

8sq metres.<br />

In operation, bags or<br />

pouches arrive into the collator<br />

pocket on edge direct from a<br />

VFFS machine or bagger.<br />

They are rotated to an upright<br />

position then collated in the<br />

pick position in the required<br />

matrix to fill the case –<br />

typically two rows of 4, 5 or 6.<br />

Product speeds of up to 150<br />

a minute and a case speed of<br />

10-15 a minute can be<br />

achieved by one operative.<br />

0800 633 5553<br />

www.tekpak.co.uk<br />

Box sizer cuts shipping costs<br />

With carriage costs now<br />

frequently dependent on the<br />

volume as well as the weight<br />

of packages, Linkx Systems<br />

says its new intelligent<br />

random box sizer makes it<br />

easy to achieve substantial<br />

savings.<br />

When presented with<br />

packed boxes, the new<br />

machine automatically<br />

measures the height of the<br />

contents of each box, then<br />

cuts and creases the box to<br />

suit, thereby ensuring that the<br />

shipping volume – and<br />

carriage costs – are<br />

minimised. A further benefit is<br />

that as the box is accurately<br />

sized to suit the content, the<br />

need for packing material is<br />

also reduced.<br />

The machine, which is<br />

ideally suited for use in mail<br />

order warehouses and the<br />

order fulfilment operations of<br />

on-line retailers, is capable of<br />

working with boxes presented<br />

in random sizes and is<br />

compatible with almost any<br />

type and size of box content.<br />

Dependable operation and<br />

high accuracy are ensured by<br />

the use of a high performance<br />

sensor system for measuring<br />

box content, while the<br />

machine’s servo-controlled<br />

motion systems allow it to<br />

achieve consistently high<br />

throughput.<br />

The system can be<br />

customised to suit specific<br />

customer requirements and<br />

can be readily integrated into<br />

existing or new packaging<br />

lines.<br />

01502 713777<br />

www.linkx.co.uk<br />

14 MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong> www.machineryupdate.co.uk

new machinery<br />

This new all-electric model is now available from Brillopak<br />

New all-electric<br />

pallet dispenser<br />

Brillopak is further extending<br />

its range of in-line over<br />

conveyor pallet dispensers for<br />

the food industry with the<br />

introduction of a new allelectric<br />

model. The 2010E<br />

requires no air supply and is<br />

capable of stacking and<br />

destacking pallets at up to<br />

120 pallets an hour.<br />

Key to its speed is its<br />

automatic adjustment feature<br />

which enables the machine to<br />

adapt to different sizes of<br />

pallet without the need for any<br />

manual adjustment.<br />

The robust design<br />

incorporates SEW Eurodrive<br />

Flexicon has launched a<br />

sanitary tilt-down flexible<br />

screw conveyor on a castermounted<br />

frame that can be<br />

manoeuvred through narrow<br />

aisles and around corners.<br />

With the hopper, support<br />

boom and conveyor assembly<br />

tilted down, the unit fits<br />

through standard doorways<br />

and orients the conveyor tube<br />

horizontally, allowing the<br />

flexible screw to be removed<br />

easily for thorough cleaning<br />

www.machineryupdate.co.uk<br />

and Norgren components,<br />

ensuring the machine is<br />

capable of 24/7 operation. It<br />

also features compact<br />

dimensions to allow it to fit into<br />

virtually any factory space<br />

combined with the flexibility to<br />

cope with short and long runs<br />

and the ability to integrate<br />

seamlessly with all equipment<br />

on the line.<br />

It can handle most pallet<br />

types from 1200 x 1200 to<br />

800 x 800mm and can also<br />

deal with 2-way and 4-way<br />

pallets.<br />

01622 872907<br />

www.brillopak.co.uk<br />

Manoeuvrable conveyor<br />

and inspection.<br />

The conveyor transports<br />

bulk ingredients ranging from<br />

sub-micron powders to large<br />

pellets, while the gentle rolling<br />

action of material being<br />

conveyed prevents the<br />

separation of blends. Its<br />

mobile frame is constructed in<br />

stainless steel or in carbon<br />

steel with durable industrial<br />

coatings.<br />

01227 374710<br />

www.flexicon.co.uk

new machinery<br />

Entry levels<br />

are flexible<br />

PFM Packaging Machinery<br />

demonstrated its two latest<br />

entry-level machines for the<br />

food industry at the Pro2Pac<br />

exhibition at ExCel in <strong>March</strong>:<br />

the Pearl servo driven flow<br />

wrapper and the ZC1<br />

combined weigher-bagger.<br />

Pro2Pac is co-located with<br />

IFE13, the UK’s largest food<br />

and drink trade event.<br />

“Both machines have been<br />

developed to meet the need<br />

for inexpensive systems that<br />

offer a high degree of<br />

flexibility and accuracy and<br />

are simple to use,” explains<br />

PFM’s sales and operations<br />

director Chris Bolton.<br />

The Pearl provides smaller<br />

or start-up operations with the<br />

advantages of multi-axis servo<br />

drive, reducing maintenance<br />

requirements and providing<br />

easy programming and<br />

changeover for different pack<br />

formats, which can be held in<br />

the memory for press-button<br />

recall. Speed is up to 120 a<br />

minute.<br />

In particular, the machine is<br />

built to food industry hygiene<br />

requirements with a<br />

cantilever construction and<br />

gently radiussed guard<br />

panels that avoid dirt traps.<br />

The ZC1 is an integrated<br />

multihead weigher and<br />

bagging machine for<br />

mid-speed duties of up to<br />

80 bags a minute, handling<br />

dry goods such as snacks,<br />

confectionery, pet food,<br />

granular products, biscuits<br />

and short pasta.<br />

It brings together the PFM<br />

Zenith bagger and the PFM<br />

C1 multihead weigher, which<br />

is mounted on the bagger<br />

itself, avoiding the cost of the<br />

usual supporting gantry. In<br />

addition, drop height is kept<br />

short to provide gentle<br />

handling for delicate goods.<br />

0113 239 3401<br />

www.pfmuk.com<br />

Unit inspects for glass<br />

in glass at high speed<br />

Mettler-Toledo Safeline has<br />

launched InspireX R50G x-ray<br />

inspection system to enhance<br />

glass foreign body detection in<br />

glass packaging at high<br />

throughput speeds.<br />

Designed to inspect small to<br />

large diameter glass jars<br />

containing a broad range of<br />

food and pharmaceutical<br />

products, the new machine<br />

offers manufacturers high<br />

detection levels across the<br />

entire container to meet<br />

increasingly stringent food<br />

safety standards.<br />

Traditionally, the base of<br />

glass jars has presented a<br />

challenge for x-ray inspection<br />

systems as the thicker glass in<br />

the base absorbs more x-rays<br />

than the thinner side wall,<br />

masking foreign bodies. The<br />

InspireX R50G, however,<br />

features an angled single x-ray<br />

beam to inspect blind spots at<br />

the base, as well as in the<br />

body, maximising the likelihood<br />

of detection.<br />

The body, neck and cap are<br />

all fully imaged on the x-ray<br />

detector; ensuring<br />

comprehensive inspection of<br />

Proseal has expanded its<br />

range of sandwich packing<br />

equipment with the<br />

introduction of a fully<br />

automatic high speed wedge<br />

erector and heat sealing<br />

system capable of speeds up<br />

to 90 packs a minute. This<br />

range also includes the first<br />

modified atmosphere system<br />

for sandwiches.<br />

The GT3S features a three<br />

axis pick and place system<br />

that is able to transfer filled<br />

packs quickly to the sealing<br />

area. It can handle carton<br />

the container and enabling<br />

inspection of jar fill level as well,<br />

says Mettler.<br />

The InspireX R50G can<br />

accurately inspect up to 1,000<br />

containers per minute,<br />

optimising production line<br />

efficiency for food and<br />

pharmaceutical manufacturers.<br />

The high speed automated<br />

reject device ensures only<br />

contaminated products are<br />

removed without the need to<br />

slow production, while the<br />

machine’s data logging and<br />

x-ray image library include<br />

automatic time stamps for<br />

rejected products, enabling<br />

manufacturers to demonstrate<br />

widths of up to 110mm and<br />

the single point size<br />

adjustment means<br />

changeovers between pack<br />

sizes can be carried out in<br />

less than five minutes.<br />

This system also<br />

incorporates automatic carton<br />

de-nesting and erecting and<br />

can be integrated with label<br />

applicators, printers,<br />

checkweighers and metal<br />

detectors for a complete<br />

sandwich packing operation.<br />

The V style outfeed conveyor<br />

ensures packs are presented<br />

Glass-in-glass inspection<br />

improves regulatory<br />

compliance and brand<br />

protection<br />

due diligence and guarantee<br />

products conform to the highest<br />

food safety standards.<br />

“With tougher food safety<br />

regulations worldwide, it is<br />

more important than ever for<br />

food manufacturers to have x-<br />

ray systems that offer the most<br />

sensitive product inspection,”<br />

explains Niall McRory, product<br />

development and sales<br />

manager, Mettler-Toledo<br />

Safeline. “An x-ray system that<br />

offers flexibility and enhanced<br />

productivity will enable brand<br />

owners to respond to fastchanging<br />

market demands.”<br />

01763 257900<br />

www.mt.com<br />

Modified atmosphere sarnies<br />

perfectly for the coding<br />

operation.<br />

Gas flushing is incorporated<br />

into the sealing operation for<br />

extended shelf life while still<br />

delivering speeds of up to 60<br />

packs a minute.<br />

Both models feature the<br />

‘EcoSeal’ system which is<br />

designed to reduce total<br />

energy consumption by over<br />

65%, while increasing<br />

machine productivity through<br />

a reduced seal time.<br />

01625 856600<br />

www.prosealuk.com<br />

16 MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong> www.machineryupdate.co.uk

Perfect machine DNA<br />

The evolution of packaging machine control<br />

Sysmac Studio<br />

• IEC 61131-3 compliant<br />

• Data-logging & tracking<br />

• 3D Motion simulation<br />

• One machine software<br />

• PLCopen Function Block library<br />

Sysmac Automation Platform<br />

Tel: +44 (0)1908 258258<br />

Email: uk@eu.omron.com<br />

Web: www.industrial.omron.co.uk

installation news<br />

Wrapping up<br />

logistics firm<br />

Potter Logistics has invested<br />

in a 507 Robopac from Aetna<br />

for its York Distribution<br />

Centre (DC) having proved<br />

itself to be a real asset at<br />

other sites with significant<br />

savings in employee time and<br />

packaging film.<br />

This is the seventh<br />

machine purchased across<br />

the group which are already<br />

operating in Ripon, Selby<br />

and Droitwich.<br />

The 507 Robopac from Aetna<br />

“The machine was<br />

purchased with a particular<br />

client in mind and it has been<br />

a godsend,” says operations<br />

manager of Potter Logistics’<br />

York DC John Myers. “We<br />

were previously wrapping up<br />

to 60 pallets by hand each<br />

day which was both awkward<br />

and time consuming.”<br />

The machine has been<br />

introduced to the York DC to<br />

increase product security and<br />

to save money. “We are<br />

planning to analyse the cost<br />

saving in a couple of months<br />

by which time we shall have<br />

been using it for about six<br />

months,” explains Myers.<br />

“Despite not being able to<br />

make a judgement in terms of<br />

financial benefit, staff<br />

members are very happy<br />

with it,” he continued.<br />

01234 825050<br />

www.aetna.co.uk<br />

Round the corner unit<br />

loads pet ingredients<br />

Butcher’s Pet Care chose a<br />

Spiroflow round-the-corner<br />

aero mechanical conveyor for<br />

its new £38 million factory in<br />

Crick, Northamptonshire that<br />

produces over one million<br />

cans of pet food a day. The<br />

new factory is a high roof,<br />

single story building and, as<br />

the mixers are mounted on a<br />

raised platform, a means to<br />

load the rice and dried peas<br />

ingredients from ground floor<br />

level was required.<br />

Spiroflow, who was already<br />

known to senior controls<br />

engineer Andrew Pynn were,<br />

along with others, invited by<br />

Butcher’s Pet Care to offer a<br />

suitable conveying solution.<br />

Spiroflow proposed one of its<br />

Nearly £40m was invested at the<br />

new factory in Northamptonshire<br />

The conveyor loads rice and dried peas ingredients for pet food<br />

aero mechanical conveyors in<br />

which materials are moved<br />

through the partial vacuum<br />

created by a series of discs<br />

travelling at high speed within<br />

an enclosed tube.<br />

Engineers from Butcher’s<br />

Pet Care witnessed trials at<br />

Spiroflow on one of these<br />

conveyors using samples of<br />

its rice and dried peas<br />

ingredients. Similar trials went<br />

ahead with a vacuum<br />

conveyor specialist and, with<br />

nothing to choose between the<br />

two on price, the Spiroflow<br />

aero-mechanical conveyor<br />

was deemed to offer the better<br />

performance in terms of<br />

conveying rate and minimal<br />

product damage.<br />

The Spiroflow aero<br />

mechanical conveyor has<br />

an all stainless steel<br />

construction and comes<br />

complete with an integral sack<br />

tip hopper. From the hopper,<br />

materials are lifted some<br />

4.5 metres then conveyed<br />

horizontally for 3.5 metres<br />

before emptying into an<br />

existing hopper. This hopper<br />

has a reversible auger at its<br />

outlet so that ingredients can<br />

be delivered to either one of<br />

the two mixers. Dependent<br />

upon the particular recipe,<br />

three to four mixes are<br />

produced every hour, 24 hours<br />

a day, 5 days a week.<br />

01200 422525<br />

www.spiroflow.com<br />

Entry level robot for plastics components<br />

A universal robot supplied and<br />

supported by RA Rodriquez<br />

has been used to automate the<br />

de-gating of injection moulded<br />

components for plastics rope<br />

cleats by Hertfordshire-based<br />

Camcleats.<br />

This small, lightweight<br />

industrial robot arm that has<br />

six axes of movement is<br />

quick and easy to install. A<br />

specially developed graphical<br />

user interface means no<br />

expert programming is needed<br />

and within a couple of hours,<br />

it can be ready to run.<br />

RA Rodriguez describes it<br />

as the ideal entry level<br />

automation device that can be<br />

set up by anyone.<br />

“Automation gives us much<br />

greater production flexibility,”<br />

explains Camcleats’ managing<br />

director Julian Emery. And the<br />

company has already gained<br />

production benefits.<br />

“Ultimately we plan to use<br />

the universal robot wherever<br />

we can in the factory,” says<br />

Emery. “It is easy to integrate<br />

and has potential not just in<br />

our rope cleat production but<br />

also for our trade moulding<br />

work too.”<br />

01462 670044<br />

www.rarodriguez.co.uk<br />

18<br />

MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong><br />

www.machineryupdate.co.uk

installation news<br />

Energy saving solution is cool<br />

Process cooling company<br />

IsoCool has supplied an<br />

energy saving cooling solution<br />

to injection moulder Signal<br />

Plastic Components which has<br />

resulted in a dramatic<br />

overnight saving of 90% on<br />

previous costs.<br />

To maximise the efficiency of<br />

the cooling system, IsoCool<br />

proposed to replace the<br />

existing chiller with the<br />

Adcooler, an intelligent<br />

adiabatic dry cooler that<br />

switches automatically between<br />

dry and wet bulb operation<br />

according to the ambient<br />

temperature and humidity.<br />

“Essentially, the Adcooler<br />

functions as an air blast cooler<br />

during low ambient conditions,<br />

providing up to 100% direct air<br />

cooling, and an adiabatic<br />

Pot filling line<br />

brings growth<br />

Packaging Automation has<br />

installed a pot filing and<br />

sealing line at Beacon Foods<br />

to help the company gain<br />

new business.<br />

Beacon installed the<br />

compact FP-6 model<br />

automated pot filler and<br />

sealer which has an operating<br />

speed of 40 cycles a minute.<br />

Due to simple and lightweight<br />

change parts, the machine is<br />

designed for frequent product<br />

changeovers which has<br />

allowed Beacon to handle its<br />

vast range of ready to use<br />

portions of compotes,<br />

chutneys, relishes, dips,<br />

sauces and roasted veg in<br />

pots ranging from 20 to 80g.<br />

“The machine is able to hot<br />

and cold fill and seal reel-fed<br />

film lids which further extends<br />

the packaging formats we are<br />

able to offer our customers,”<br />

explains md of Beacon Foods<br />

Edward Gough.<br />

01565 755000<br />

www.pal.co.uk<br />

cooler when the ambient is<br />

higher than the set point<br />

temperature,” explains Nigel<br />

Hallett, managing director of<br />

IsoCool. “As a result, it is far<br />

more efficient than a<br />

traditional chiller which has a<br />

much higher installed power.”<br />

Managing director of Signal<br />

Alan Franklin was very<br />

surprised by how reasonable<br />

IsoCool’s price was and, he<br />

FUTUREPROOFPACKAGINGEQUIPMENT<br />

says, the energy savings made<br />

it a no-brainer. “We’re saving<br />

over £500 a month on energy<br />

bills at the moment," he says.<br />

01376 328455<br />

www.isocool.ltd.uk<br />

Future proof<br />

sustainable packaging equipment<br />

VE500TRAY ERECTOR<br />

NEW<br />

SHRINKWRAPPER<br />

British made, high performance, fast payback.<br />

Linkx packaging equipment is designed and manufactured in Britain to<br />

ensure high quality and reliability at lower costs.<br />

Our latest range of machines have been designed from the ground up to be<br />

sustainable and future proof. A range of modular options are available that<br />

allow the base model to be re-configured retrospectively and grow with<br />

your production needs.<br />

Make sure your production is sustainable and future proof.<br />

Contact us to find out more: T: +44 (0)1502 713777 E: info@linkx.co.uk<br />

or visit www.linkxpackaging.com/futureproof<br />

NEW<br />

MADE IN BRITAIN<br />

GANTRYPALLETISER<br />

www.linkxpackaging.com<br />

NEW<br />

www.machineryupdate.co.uk

installation news<br />

Filler’s fit for<br />

agrochemicals<br />

AmegA Sciences has<br />

installed its third Masterfil<br />

filling and capping line from<br />

Adelphi after trouble-free<br />

operation of the equipment<br />

since an initial installation<br />

fifteen years ago.<br />

Talking of the first<br />

installation, works manager<br />

at AmegA Mick Skinner says<br />

that the Masterfil equipment<br />

seemed to strike the right<br />

balance between cost and<br />

quality. “The line has by no<br />

means had an easy life, and<br />

the fact that it is still running<br />

reliably today is a testament<br />

to the engineering, and build<br />

quality that we picked up on<br />

all those years ago,” he says.<br />

It was the accuracy and<br />

reliability of the first line that<br />

lead to the second order and,<br />

it also made the return on<br />

investment calculations<br />

relatively simple to calculate<br />

accurately.<br />

An unexpected jump in<br />

orders for the range of<br />

agrochemical products<br />

produced by the company has<br />

led to the latest investment.<br />

“We required quite a<br />

sizeable increase in capacity,<br />

and needed it extremely<br />

quickly,” explains Skinner.<br />

“Adelphi have proved<br />

themselves reliable at<br />

meeting their quoted delivery<br />

dates in the past, and this line<br />

was duly delivered as<br />

promised with the installation<br />

by Adelphi engineers going<br />

smoothly,” he says.<br />

All of the container sizes –<br />

from 1 - 10 litres – were being<br />

filled and capped within<br />

tolerance within about half an<br />

hour of the machine being<br />

signed off. Since then, the<br />

company has found that the<br />

line will run at a higher speed<br />

than they requested.<br />

01444 472300<br />

www.masterfil.com<br />

New robot cleans up an<br />

aggressive environment<br />

The new Kawasaki RS80N<br />

robot installed at aircrete<br />

building block manufacturer<br />

H+H is a ‘swap out’ to replace<br />

the original KS30 mould<br />

cleaning robot installed by<br />

Kawasaki twelve years ago.<br />

The operation requires the<br />

robot to remove all ‘slurry’<br />

residues from the mould,<br />

which is six metres long by<br />

1.2 metres wide by 700mm<br />

deep - before it proceeds<br />

back to the moulding<br />

operation where a new slurry<br />

mix is poured. At this stage,<br />

the slurry is beginning to set<br />

and is particularly abrasive.<br />

This process also requires<br />

the spraying of oil to the sides<br />

of the mould as a release<br />

agent and to help convert any<br />

residue to a mixable<br />

consistency. Powered,<br />

rotating brushes are passed<br />

over the entire surface of the<br />

mould to agitate the residue<br />

and oil mix providing a clean<br />

and even coating over the<br />

surface.<br />

Installed within a fully<br />

enclosed spray booth, the<br />

The RS80N robot is a swap out to replace the original KS30 model<br />

RS80N is mounted on an<br />

8 metre linear axis which<br />

follows the length of the<br />

mould. The robot has a<br />

selection of two different<br />

powered brushes, one for the<br />

base and one for the sides,<br />

which it automatically changes<br />

during the process. A spray<br />

head mounted to the robot<br />

arm allows oil to be sprayed to<br />

the sides and base of the<br />

mould during the process.<br />

“The system has evolved<br />

since originally being<br />

engineered and the robot<br />

operated on site without fault<br />

for 12 years until the swap<br />

out,” explains David Lazenby,<br />

system support engineer at<br />

H+H. “The new robot is more<br />

sophisticated than the<br />

previous robot and in<br />

particular allows more control<br />

options; however our system<br />

is relatively straight forward<br />

and does exactly what we<br />

want without unnecessary<br />

complications being<br />

introduced,” he says.<br />

01925 713000<br />

www.kawasakirobot.co.uk<br />

Raw food ingredients inspected<br />

A high frequency metal<br />

detector from Lock Inspection<br />

Systems has assisted raw<br />

ingredients supplier EHL<br />

Ingredients in meeting BRC<br />

standards, inspecting over<br />

100 tonnes of ingredients<br />

since its installation.<br />

“Along with UK stock we<br />

import vast quantities of<br />

ingredients and anything that<br />

we pack and blend ourselves<br />

goes through a metal detector<br />

to adhere with BRC standards<br />

and satisfy our own quality<br />

control criteria,” explains<br />

Mike Perrin, technical<br />

manager at EHL.<br />

To meet specific customer<br />

A high frequency metal detector from Lock inspects raw ingredients<br />

requirements, the ingredients<br />

are packed into bags from 1 to<br />

25 kilos in weight, all of which<br />

are checked by the end of line<br />

metal detector.<br />

“EHL has our MET30+<br />

Universal detector which has<br />

been designed to<br />

accommodate a wide range of<br />

pack sizes and has a one touch<br />

product recall for each recipe<br />

set-up to assist production staff<br />

with quick changeovers,”<br />

explains Rob Gray of Lock.<br />

0161 624 0333<br />

www.lockinspection.com<br />

20<br />

MACHINERY UPDATE: MARCH/APRIL <strong>2013</strong><br />

www.machineryupdate.co.uk

A D V E R T O R I A L<br />

CORPORATE OFFICE AND<br />

MANUFACTURING FACILITY:<br />

3580 HOLLY LANE NORTH<br />

PLYMOUTH, MN 55447-1269 USA<br />

TEL: +1 (763) 557-1313<br />

EMAIL: SALES@SCCRAPLY.COM<br />

WWW.ACCRAPLY.COM<br />

SALES OFFICES AND<br />

MANUFACTURING FACILITIES:<br />

HALL WORKS, CHURCH ROAD<br />

BRIGHTLINGSEA, ESSEX<br />

CO7 0RZ, UNITED KINGDOM<br />

TEL: +44 (0)1206 304 982<br />

KENNEDY WAY<br />

CLACTON-ON-SEA, ESSEX<br />

CO15 4AB, UNITED KINGDOM<br />

TEL: +44 (0) 1255 423402<br />

3070 MAINWAY<br />

UNITS 16-19<br />

BURLINGTON, ON<br />

L7M 3X1, CANADA<br />

TEL: +1 (905) 336-8880<br />

SALES OFFICES:<br />

760 SOUTH ROCHESTER AVE.<br />

SUITE A<br />

ONTARIO, CA 91761-8181 USA<br />

TEL: +1 (909) 605-8200<br />

1139 SOUTH BROADWAY<br />

SALEM, IL 62881 USA<br />

TEL: +1 (618) 548-2600<br />

GRAHAM, SLEEVIT<br />

NOW PART OF<br />

ACCRAPLY EUROPE, LTD.<br />

Welcome to the new face of<br />

shrink sleeving technology.<br />

Or rather, the same face<br />

with a new name.<br />

Graham Labelling & Sleeving<br />

has joined forces with Sleevit<br />

Systems under the banner of<br />

Accraply Europe, Ltd.<br />

This partnership strengthens the<br />

company’s ongoing commitment<br />

to the Shrink Sleeve Labelling<br />

industry by uniting brands you<br />

know and trust. The addition of<br />

Graham and Sleevit within the<br />

Accraply family of brands<br />

enhances their standing as global<br />

providers of a complete range of<br />

Labelling and Shrink Sleeve<br />

Application and Converting<br />

equipment and services.<br />

Accraply’s multiple Manufacturing,<br />

Engineering and Service Centers –<br />

which support an extensive sales<br />

and service network worldwide –<br />

serve as an added advantage to<br />

provide superior accessibility to<br />

the market.<br />

The shrink sleeve label format is<br />

growing rapidly in popularity due<br />

to its versatility labelling complex<br />

container shapes and 360° topto-bottom<br />

coverage.<br />

Accraply’s bespoke shrink sleeve<br />

labelling equipment is designed<br />

to fit the specific needs of each<br />

unique application. They also<br />

offer a full range of Shrink Tunnels<br />

to complete any labelling system.<br />

www.accraply.com

installation news<br />

Detector speeds paper making<br />

Equipment from Fortress<br />

Technology has solved a<br />

metal detecting issue that was<br />

slowing down the production<br />

process at French company,<br />

Papeteries de Clairefontaine.<br />

Much of the paper used by<br />

Papeteries de Clairefontaine<br />