Machinery Update Sep Oct 2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MACHINERY UPDATE - ISSUE 5, VOLUME XXX, SEPTEMBER/OCTOBER <strong>2019</strong> PPMA TOTAL SHOW PREVIEW • SUSTAINABILITY<br />

Issue 5, Volume XXX, <strong>Sep</strong>tember/<strong>Oct</strong>ober <strong>2019</strong><br />

The machinery only journal for processing & packaging | www.machineryupdate.co.uk<br />

PREVIEW<br />

FREE<br />

REGISTER<br />

WWW.PPMATOTALSHOW.CO.UK<br />

INSIDE<br />

NEWS<br />

As Lorem membership ipsum dolor of the sit PPMA<br />

Group amet, approaches consectetuer 600 adipiscing<br />

first elit, time, sed diam more nonum-<br />

confidence<br />

for<br />

the<br />

in my the nibh trade euismod association tincidunt will be<br />

demonstrated ut laoreet dolore by the magna 400 firms<br />

seen at its PPMA Total Show<br />

SUSTAINABILITY<br />

Our major sustainability feature<br />

covers how industry is using<br />

scarce resources responsibly,<br />

with several new products and<br />

sector initiatives highlighted<br />

by the machinery sector<br />

Find out more on page 134<br />

INSTALLATIONS<br />

Using one supplier<br />

for all wrapping,<br />

weighing and<br />

bagging kit<br />

has worked<br />

for 2 Sisters<br />

Group<br />

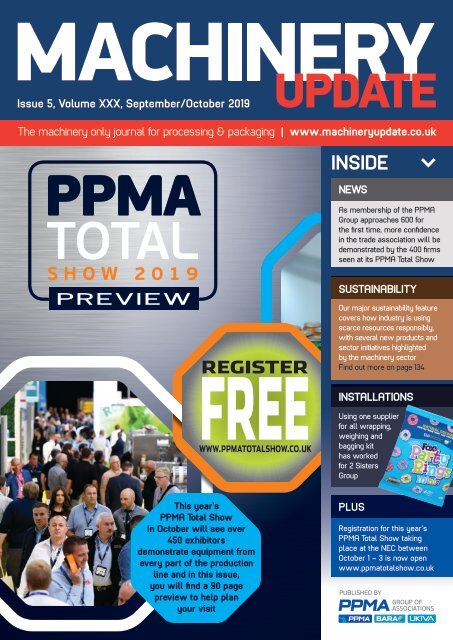

This year’s<br />

PPMA Total Show<br />

in <strong>Oct</strong>ober will see over<br />

450 exhibitors<br />

demonstrate equipment from<br />

every part of the production<br />

line and in this issue,<br />

you will find a 90 page<br />

preview to help plan<br />

your visit<br />

PLUS<br />

Registration for this year’s<br />

PPMA Total Show taking<br />

place at the NEC between<br />

<strong>Oct</strong>ober 1 – 3 is now open<br />

www.ppmatotalshow.co.uk

HOTSPOT<br />

NON-CONTACT THERMAL IMAGING TECHNOLOGY<br />

FOR HOT GLUE APPLICATION QUALITY INSPECTION<br />

Check that every one of<br />

your packs is correctly<br />

folded and properly sealed<br />

100% inspection, zero contact<br />

with product<br />

Guarantee presence, location, size and<br />

temperature of every glue spot after<br />

application and folding<br />

Prevent collapsing multipacks<br />

Ensure pallet stability<br />

Eliminate customer complaints<br />

Interested? Give us a call: +44 1564 793174 | bytronic.com

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2019</strong> MACHINERY UPDATE 3<br />

<strong>Sep</strong>tember/<strong>Oct</strong>ober<br />

Sollas MU J-F <strong>2019</strong><br />

ARTWORK<br />

Contents<br />

7 NEWS<br />

12 NEW MACHINERY<br />

26 INSTALLATIONS<br />

45 SPECIAL FEATURE<br />

TOTAL SHOW PREVIEW<br />

This year’s PPMA Total Show<br />

will fill the whole of Hall 5 at the<br />

NEC, Birmingham and so our<br />

preview of new products is our<br />

biggest ever at 90 pages strong<br />

134 SPECIAL FEATURE<br />

SUSTAINABILITY<br />

We examine the state of play<br />

for plastics bottles and trays<br />

as well as hearing views from<br />

INCPEN and finding out how<br />

CCEP works with its suppliers<br />

138<br />

REGULAR FEATURES<br />

148 COMPONENTS<br />

To keep up with the change of<br />

pace in manufacturing, many<br />

companies are now starting out<br />

on their own Industry 4.0<br />

journeys, and while there is no<br />

single magic formula to this<br />

transformation, this article<br />

points out just some of the<br />

common stumbling blocks<br />

that should be avoided<br />

10<br />

152 REGULATIONS<br />

In this current state of political<br />

uncertainty, here’s an overview<br />

of the mandatory EHSRs and<br />

how they relate to machinery<br />

154 WHO WHAT WHERE<br />

People, events and diary dates<br />

155 MACHINERY FINDER<br />

<strong>Machinery</strong> and services<br />

EDITOR:<br />

Gail Hunt<br />

PUBLISHING MANAGER:<br />

Bill Lake<br />

ADVERTISING SALES<br />

EXECUTIVE:<br />

Robert Beswick<br />

ARTWORK CONTRIBUTOR:<br />

Barry Heath<br />

HEAD OF PUBLISHING:<br />

David Chadd<br />

A PPMA PUBLICATION<br />

PPMA Ltd<br />

New Progress House,<br />

34 Stafford Road,<br />

Wallington,<br />

SM6 9AA<br />

TEL: +44 (0) 20 8773 8111<br />

E-MAIL ADDRESSES:<br />

publishing@ppma.co.uk<br />

show@ppma.co.uk<br />

technical@ppma.co.uk<br />

WEBSITE:<br />

www.machineryupdate.co.uk<br />

APPLICATIONS FOR FREE COPIES<br />

of <strong>Machinery</strong> <strong>Update</strong> are<br />

considered from specifiers,<br />

managers and purchasers of<br />

processing and packaging<br />

machinery in the UK.<br />

ANNUAL SUBSCRIPTION:<br />

£35 (UK), £50 (Continental<br />

Europe), £65 (rest of world).<br />

ISSN 0969-4145<br />

PRINTED BY:<br />

Latimer Trend & Company Ltd<br />

Estover Road<br />

Plymouth<br />

PL6 7PY<br />

Tel: 01752 <strong>2019</strong>30<br />

The Processing and Packaging <strong>Machinery</strong><br />

Association assumes no responsibility for the<br />

statements or opinions, whether attributed<br />

or otherwise, in <strong>Machinery</strong> <strong>Update</strong>.<br />

This publication is copyright under the Berne<br />

convention and the International copyright<br />

convention. Apart from any fair dealing for<br />

the purposes of research or private study, as<br />

permitted under the Copyright, Designs and<br />

Patents Act 1988, no part of this publication<br />

may be reproduced, stored in a retrieval<br />

system or transmitted in any form or by any<br />

means in any form without prior written<br />

permission of the publishers.

Easy palletising -<br />

a collaborative robot solution<br />

The standardised palletising cell from FlexLink is compact, quick to install and easy to configure.<br />

Operators can work safely side-by-side with the collaborative robot, without the need for a fence<br />

or cage. A tablet application allows you to create a palletising pattern in just a few minutes, using<br />

the intuitive drag-and-drop interface.<br />

Call us on 01908 327200 or email us at info.uk@flexlink.com for further information.<br />

flexlink.com<br />

FlexLink is part of Coesia, a group of innovation-based industrial and packaging<br />

solutions companies operating globally, headquartered in Bologna, Italy.<br />

www.coesia.com<br />

210x297_RC10_UK FLEXLINK.indd 1 2018-05-30 15:36:29

www.machineryupdate.co.uk MACHINERY UPDATE 5<br />

PPMA matters<br />

Adelphi Masterfil MU S-O <strong>2019</strong><br />

ARTWORK<br />

Adelphi Manufacturing<br />

Total Show<br />

leads charge<br />

to success<br />

Richard Little<br />

PPMA TOTAL SHOW DIRECTOR<br />

The autumn. For some, it’s the time of year when things<br />

slow down – but not at the Processing and Packaging<br />

<strong>Machinery</strong> Association (PPMA), where plans for the<br />

PPMA Total Show are currently in full swing.<br />

The (surely) final PPMA show before Brexit is bursting with<br />

opportunity for the future. It’s our largest show ever, sold out,<br />

with 450 exhibitors and 2500 brands on display, many live<br />

demonstrations and plenty of innovation for these changing<br />

times. Most importantly, you are all very welcome to join<br />

us at the NEC, Birmingham from 1-3 <strong>Oct</strong>ober!<br />

For years we were told that the internet would signal the<br />

end of exhibitions, but our biggest show ever makes us believe<br />

otherwise – and a visit to our event will hopefully convince you<br />

too. At PPMA Total <strong>2019</strong>, visitors can see innovative working<br />

equipment from nearly all the major industry suppliers and be<br />

presented with a variety of solutions, many of which are new.<br />

Engineers and marketers are encouraged to present their<br />

challenges – and samples – to the experts on their stands<br />

who have many years of experience in their fields.<br />

Response<br />

Response<br />

Monobloc Filler<br />

An automatic filling and capping<br />

machine which provides many<br />

advantages for customers compared<br />

with traditional inline packaging systems.<br />

Our largest ever exhibition<br />

and this, our biggest ever magazine,<br />

demonstrate the PPMA’s relevance<br />

Our event is also the biggest networking event in the<br />

production line calendar. The ‘Enterprise Zone’ is host to a great<br />

variety of talks and discussion opportunities and the PPMA<br />

BEST charity will be covering what we offer apprentices and our<br />

sponsorship for higher level education – including supporting<br />

existing employees. This year we welcome Joanna Yarrow, the<br />

head of Sustainability from IKEA and Peter Conradi from The<br />

Sunday Times as keynote speakers accompanied by a packed<br />

seminar programme with expert speakers from our industry.<br />

We’re also delighted to have a full-scale version of Bloodhound<br />

LSR (supersonic car) and Bloodhound Education on site.<br />

Sustainability is, of course, at the heart of all packaging<br />

discussions right now and our biggest ever edition of <strong>Machinery</strong><br />

<strong>Update</strong> (are your arms aching yet?) includes an in-depth 14-page<br />

feature covering a range of sustainable solutions (starts page 130).<br />

Meanwhile, an incredible 86-page PPMA Total Show Preview<br />

starts on page 44. Technology is jumping at the chance to help<br />

reduce waste and support the circular economy by developing<br />

equipment and new materials that reduces the use of plastics,<br />

delivers longer shelf life and reduces handling/transit costs. n<br />

Capable of filling 3ml to<br />

250ml containers<br />

Fill-accuracy +/- 0.25%<br />

Find out more about our full range of<br />

liquid filling machinery:<br />

+44 (0)1444 472300<br />

www.adelphi.uk.com<br />

info@adelphi.uk.com

SMC MU S-O <strong>2019</strong> ARTWORK

News<br />

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2019</strong> MACHINERY UPDATE 7<br />

Find new technology at<br />

the PPMA Total Show<br />

at the NEC this autumn<br />

Putting theory into practice at PA<br />

Encouraging girls<br />

to become successful<br />

engineers in sector<br />

Packaging Automation (PA)<br />

is keen to champion girls<br />

in engineering, as Tanya<br />

Westenraad demonstrates.<br />

She joined the company<br />

as an apprentice mechanical<br />

design engineer at the age of<br />

18 and completed a four year<br />

advanced modern engineering<br />

apprenticeship as well as being<br />

supported by the company<br />

during a four year, part-time<br />

B.Eng (Hons) degree in<br />

mechanical engineering.<br />

“In this day and age, I think<br />

it’s fantastic that women can be<br />

part of engineering,” she says.<br />

“Working while learning really<br />

helped to apply the theory in<br />

reality, gaining experience at<br />

the same time.”<br />

PPMA Total Show <strong>2019</strong><br />

will open its doors at the<br />

NEC, Birmingham from<br />

1 – 3 <strong>Oct</strong>ober for what will<br />

be the most comprehensive<br />

production line event in the UK.<br />

During the three days,<br />

visitors will have access to 450<br />

exhibitors and approximately<br />

2,500 brands, showcasing the<br />

latest innovations in smart<br />

manufacturing, processing<br />

equipment and packaging<br />

solutions for the full range of<br />

manufacturing sectors.<br />

Renowned by the industry as<br />

a platform for launching new<br />

products, the <strong>2019</strong> show will<br />

be no exception, with multiple<br />

exhibitors announcing plans<br />

ahead of the event, many of<br />

which are highlighted in our<br />

90-page preview which starts<br />

on page 45 of this issue.<br />

“We’re entering a phase<br />

where political changes are<br />

set to impact our business<br />

dealings internationally<br />

but I am very confident that<br />

GREENWASHING WON’T DO FOR TODAY’S CONSUMER<br />

Sustaining practical options<br />

So-called ‘greenwashing’ is no longer appropriate in <strong>2019</strong> as any<br />

ethical/eco claims made by marketers need to be proven to consumers,<br />

as this ice lolly maker LICKALIX did when it switched all its products<br />

into compostable films. Our major feature on sustainability discusses<br />

this further and can be found from page 134 onwards of this issue.<br />

See products from the 450 exhibitors<br />

this year’s PPMA Total Show<br />

will again provide visitors<br />

and exhibitors alike with<br />

new ideas, solutions and<br />

networking opportunities to<br />

help drive their businesses<br />

forward,” says Richard Little,<br />

show director for the PPMA<br />

Group of Associations.<br />

• Free registration is now open<br />

at this website.<br />

W www.ppmatotalshow.co.uk<br />

Date is set for MVC<br />

next year, following<br />

this year’s success<br />

The date for the next UKIVA<br />

Machine Vision Conference<br />

(MVC) has been set for<br />

Thursday 14 May 2020, at<br />

the MK Arena, Milton Keynes<br />

where visitors can learn from<br />

speakers on vision topics<br />

ranging from entry-level up<br />

to expert as well as visiting<br />

a co-located exhibition.<br />

“Visitor numbers at MVC<br />

have grown steadily over the<br />

last three years,” explains<br />

UKIVA chairman Allan<br />

Anderson. “This has now<br />

become an established event<br />

in the vision and robotics<br />

calendar, and we look forward<br />

to making it an even bigger<br />

attraction in 2020.”<br />

Kyle Constable, apprentice at OAL<br />

Apprentices<br />

will compete<br />

for top spot<br />

The PPMA Group Industry<br />

Awards have received the most<br />

entries in its history this year,<br />

especially in the Apprentice of<br />

the Year category, the winner of<br />

which will be taking over from<br />

last year’s successful apprentice,<br />

Kyle Constable of OAL.<br />

Apprentices competing for<br />

this year’s Apprentice of the Year<br />

award are:<br />

• Laura Baulch from Farleygreene<br />

• Tobias Cowan from HepcoMotion<br />

• Cory Hoggard from LAC<br />

Conveyors & Automation<br />

• Jack Woolmer from<br />

Mettler Toledo Safeline<br />

• Joe Bacon from Projex Solutions<br />

• Joseph Morrey from Radwell<br />

International, and<br />

• Tom Steele from Wittenstein.<br />

These seven young people have<br />

made the shortlist of apprentices<br />

and the winner will be announced<br />

on Tuesday 1 <strong>Oct</strong>ober (the first<br />

night of the PPMA Total Show)<br />

at a gala dinner to be held at the<br />

National Conference Centre in<br />

Birmingham. This gala evening<br />

will be hosted by one of the UK’s<br />

top entertainers Jon Culshaw.<br />

All other finalists are listed on<br />

page 10 of this issue.<br />

W www.ppmatotalshow.co.uk<br />

Jon Culshaw will be hosting awards

8 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

News<br />

Bosch plans to sell machinery<br />

business to new private entity<br />

Bosch plans to sell its<br />

Waiblingen-based<br />

packaging machinery<br />

business to a newly<br />

incorporated entity managed<br />

by CVC Capital Partners (CVC).<br />

The company, and its Pharma<br />

and Food units, will remain<br />

intact in this process.<br />

Based in Luxembourg, CVC is<br />

a private equity and investment<br />

advisory firm with 24 offices in<br />

Europe, Asia, and the United<br />

States that currently manages<br />

more than US$75 billion of<br />

assets. The parties signed an<br />

agreement on July 11, <strong>2019</strong><br />

effecting the transfer of the<br />

entire packaging technology<br />

business and its 6,100<br />

associates in 15 countries.<br />

PRICE NOT DISCLOSED<br />

It has been agreed that the<br />

purchase price and other<br />

details of the purchase<br />

agreement will not be<br />

disclosed. Completion of the<br />

sale is subject to the approval<br />

of various bodies, including<br />

antitrust authorities, and is<br />

expected to close at the turn<br />

of this year.<br />

“Bosch Packaging<br />

Technology is a strong<br />

company in an attractive<br />

market with long-term growth<br />

prospects,” says Dr Alexander<br />

Dibelius, managing partner<br />

of CVC. “Together with the<br />

management team, we will<br />

work to take the business<br />

forward in the years ahead,<br />

and to make it even more<br />

competitive.”<br />

Bosch announced a year ago<br />

that it was looking for a buyer<br />

for its packaging technology<br />

business. It firmly believes<br />

that the Packaging Technology<br />

division’s competitiveness,<br />

and thus also its future<br />

viability, can be further<br />

enhanced through this<br />

new partnership, and that<br />

significant stimuli for growth<br />

can be created.

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2019</strong> MACHINERY UPDATE 9<br />

Capri-Sun investments<br />

celebrated during visit<br />

In-house event will<br />

highlight packaging<br />

and processing units<br />

Multivac UK will be hosting its<br />

Packaging and Processing Forum<br />

on <strong>Oct</strong>ober 9 and 10 at its facility<br />

in Swindon. Held across one and<br />

a half days, visitors can discover<br />

a range of solutions including<br />

four new product launches and<br />

hear from an industry keynote<br />

speaker before joining in with an<br />

Oktoberfest in the evening.<br />

Following launches and<br />

topical discussions on the<br />

first morning, visitors will see<br />

a range of live demonstrations<br />

from the processing product<br />

portfolio as well as exploring<br />

three educational forums.<br />

A fully integrated line will be<br />

demonstrated on the second day.<br />

W www.multivac.co.uk<br />

Schubert has supplied two<br />

TLM-F2 pouch cartoners<br />

to the East Kilbride site of<br />

Coca-Cola European Partners<br />

(CCEP) as part of the drinks<br />

giant’s £23 million investment<br />

at the site this year.<br />

The investment marks a<br />

landmark year in the sites<br />

55 year operational history and<br />

First Minister of Scotland Nicola<br />

Sturgeon joined CCEP’s vicepresident<br />

and general manager<br />

Leendert den Hollander to<br />

celebrate their opening.<br />

The money has been spent<br />

on two new production lines<br />

dedicated to making Capri-Sun,<br />

one of the largest kids’ juice<br />

drinks brands in GB.<br />

The new lines incorporate<br />

the latest Schubert technology<br />

to enable the fullest line<br />

flexibility coupled with the<br />

highest line efficiency.<br />

These lines also use the latest<br />

energy-saving technology<br />

to reduce energy use and<br />

First Minister of Scotland Nicola Sturgeon celebrates the new investments<br />

water consumption. It includes<br />

automatic control of conveyors,<br />

energy sub-metering to aid<br />

monitoring and water efficient<br />

pouch-cooling technology.<br />

In addition, the lines are<br />

equipped to pack Capri-Sun<br />

multi-packs using a newly<br />

developed lightweight<br />

corrugated cardboard that<br />

enables the use of thinner<br />

material with equal strength<br />

to the previous card used.<br />

T 01676 525825<br />

W www.schubert-uk.co.uk<br />

• CCEPs VP supply chain GB<br />

Steve Adams outlines the<br />

company’s sustainable pack<br />

strategy on page 140.<br />

The new workshop at St Neots<br />

Investment in repair<br />

capability delivers<br />

faster throughput<br />

Bosch Rexroth has invested in its<br />

UK service and repair centre based<br />

at its UK HQ in Cambridgeshire,<br />

resulting in a facility with higher<br />

capacity, faster throughput and<br />

new technology for the repair of<br />

hydraulic products. A seven-figure<br />

hydraulic test station has also been<br />

installed at the site to give clients<br />

peace of mind that all equipment<br />

has been tested thoroughly.<br />

Director has been shortlisted for<br />

the Young Manufacturer Award<br />

Adelphi Masterfil director<br />

Francisco Neto has been<br />

shortlisted for the title of<br />

Young Manufacturer of the<br />

Year in the MX Awards run by<br />

The Manufacturer. The group<br />

has also made the shortlist<br />

for the operational excellence<br />

category, too.<br />

Adelphi says that in just<br />

five years, Neto has been<br />

hugely influential in his role at<br />

Adelphi Masterfil, being part<br />

of the team that introduced the<br />

new System F range of filling<br />

machines. His charismatic<br />

nature and way with people<br />

make him instantly likeable<br />

with a range of customers who<br />

respect his engineering advice<br />

and opinions.<br />

Francisco Neto of Adelphi Masterfil<br />

As a finalist, Adelphi goes<br />

through to the second round<br />

of the competition in which<br />

judging teams visit all the sites.<br />

In brief<br />

STUDENTS LEARN AT RNA<br />

Postgraduate students from<br />

the University of Warwick,<br />

visited RNA Automation for a<br />

presentation from managing<br />

director Stuart Brettell and sales<br />

director David Hanslow before<br />

being taken around the factory<br />

to learn more about the company’s<br />

processes.<br />

SMART FINANCING DEALS<br />

Siemens Financial Services<br />

has released a research paper<br />

examining how UK manufacturers<br />

can implement energy optimisation<br />

solutions to reduce energy usage<br />

more easily with the help of special<br />

financing methods.<br />

W www.siemens.co.uk/<br />

energyasaservice

10 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

PPMA Group Industry Awards<br />

The first round of judging<br />

has taken place in the<br />

PPMA Group Industry<br />

Awards and the following<br />

companies have made<br />

it onto the shortlist. Winners will<br />

be named at a gala evening to be<br />

held at the National Conference<br />

Centre, Birmingham on Tuesday 1<br />

<strong>Oct</strong>ober. The Apprentice of the Year<br />

and the Outstanding Achievement<br />

awards will also be named during<br />

the industry night of the year.<br />

Environmental Initiative<br />

of the Year<br />

DataLase<br />

Garçon Wines<br />

Holmach<br />

Leeways Packaging Services<br />

Samson Nano<br />

SEALPAC UK<br />

Exceptional Sales Performance<br />

Clearmark Solutions<br />

Colin Mear Engineering<br />

Epson UK<br />

Industrial Washing Machines<br />

Minebea Intec<br />

Yorkshire Packaging Systems<br />

Exporter of the Year<br />

BCH<br />

Farleygreene<br />

HERMA UK<br />

Industrial Washing Machines<br />

Radwell International<br />

Russell Finex<br />

Innovative Ancillary Equipment<br />

Busch (UK)<br />

Clearmark Solutions<br />

Elesa (UK)<br />

Logopak International<br />

Innovative Processing System<br />

Active8 Robots<br />

DC Norris<br />

Farleygreene<br />

Jenton Group<br />

Kenray Forming<br />

LOMA Systems<br />

PPG<br />

Russell Finex<br />

SF Engineering<br />

Watson-Marlow Fluid<br />

Technology Group<br />

Awards are<br />

fought over<br />

Last year’s award<br />

winners celebrate<br />

their successes...<br />

• Tickets for this<br />

year’s event, which<br />

takes place on the<br />

first night of the<br />

PPMA Total Show,<br />

cost £90 each or<br />

£810 for a table<br />

of ten (including<br />

one free space)<br />

Innovative Packaging<br />

<strong>Machinery</strong><br />

Active8 Robots<br />

Brillopak<br />

G Mondini (UK)<br />

Gordian Strapping<br />

Kenray Forming<br />

Keymac Packaging Systems<br />

Martek Industries<br />

Rotech Machines<br />

Shemesh Automation<br />

TrakRap<br />

ULMA Packaging<br />

Innovative Robotics Solution<br />

Active8 Robots<br />

Automata Technologies<br />

Brillopak<br />

CNC Robotics<br />

FT SYSTEM<br />

Schubert UK<br />

Universal Robots<br />

Ward Automation<br />

Innovative Vision Solution<br />

AutoCoding Systems<br />

Bytronic Automation<br />

Cognex UK<br />

CKF Systems<br />

Conveyor Systems<br />

Dimaco<br />

Hikvision<br />

IDS Imaging Development Systems<br />

Lake Image Systems<br />

Multipix Imaging<br />

OPTEL GROUP<br />

Scorpion Vision<br />

STEMMER IMAGING<br />

Outstanding Customer Service<br />

Clearmark Solutions<br />

Cox & Plant<br />

MDS CEIA<br />

OAL<br />

RMGroup<br />

Russell Finex<br />

Scorpion Vision<br />

Yorkshire Packaging Systems<br />

PPMA BEST Award<br />

Evolution Bottling and<br />

Packaging Solutions<br />

HepcoMotion<br />

METTLER TOLEDO Safeline<br />

SF Engineering<br />

Winkworth<br />

With thanks to our sponsors

12 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Vacuum conveyors help<br />

additive manufacturing<br />

European debut for<br />

new industrial IoT<br />

platform gets smart<br />

Visitors to Fanuc’s stand at<br />

EMO <strong>2019</strong> in Hannover this<br />

<strong>Sep</strong>tember will see its new<br />

industrial internet of things (IIoT)<br />

platform. Called FIELD – Fanuc<br />

intelligent edge link and drive<br />

system, it is designed to help<br />

users take a decisive step towards<br />

Smart factory status.<br />

The system connects a<br />

range of Fanuc’s and thirdparty<br />

production technology<br />

– including both new and<br />

legacy models – to provide<br />

fast, centralised access to all<br />

production data within a factory.<br />

As the system is ‘edge-heavy,’<br />

data is collected and processed<br />

at source on the shop floor,<br />

rather than in the cloud, to give<br />

operators access to much more<br />

accurate real-time data and<br />

analytics. FIELD is also fully<br />

scalable across multiple cells<br />

within a factory.<br />

T 02476 053 000<br />

W www.fanuc.eu<br />

With Piab piFLOWp<br />

SMART vacuum<br />

conveyors, production<br />

powders can be delivered<br />

to the 3D printing systems<br />

without any particulate matter<br />

pollution for employees.<br />

Thanks to the system’s<br />

intelligence and self-learning<br />

features, no tedious setting<br />

and testing is required – just<br />

the press of the start button.<br />

Piab says that while<br />

3D printing/additive<br />

manufacturing sets new<br />

standards in the realisation<br />

of products, many process<br />

steps are still manual.<br />

In particular, the loading of<br />

the production equipment with<br />

the corresponding plastics or<br />

metal powder. An ergonomic<br />

workplace design is needed<br />

to prevent back pain from<br />

employees handling the<br />

weight of the containers<br />

as well as exposure to the<br />

particulate matter itself.<br />

“The use of vacuum<br />

conveying technology<br />

can help to protect people,<br />

the product itself and<br />

the environment,” explains<br />

Ian Hodkinson, technical<br />

sales office manager at Piab.<br />

As a supplier to the<br />

pharmaceutical, chemical<br />

and food industries, the<br />

company also faces this issue<br />

and so developed the vacuum<br />

conveyor as a closed system<br />

to solve this problem.<br />

Filters in the vacuum conveyor<br />

as well as additional exhaust<br />

air filters on the vacuum pump<br />

prevent fine dust from entering<br />

the system in the workspace<br />

and thus causing employees<br />

to come into contact with<br />

any of these substances.<br />

This ensures a clean<br />

The Piab<br />

piFLOWp<br />

SMART<br />

vacuum<br />

conveyors<br />

prevent<br />

any powder<br />

pollution<br />

working environment where<br />

the health burden is reduced<br />

as far as possible. At the same<br />

time, the powder is protected<br />

against contamination by<br />

environmental influences with<br />

corresponding loss of quality.<br />

As it becomes ever more<br />

important to ensure powders<br />

and granulates are conveyed<br />

in a controlled manner to<br />

dosing and mixing equipment,<br />

the autotuning feature of the<br />

new conveyor automates<br />

the process of powder and<br />

bulk conveying.<br />

T 01509 857010<br />

W www.piab.com<br />

Partnership brings new range of detection and also quality<br />

control solutions to thermoformer and traysealer options<br />

Sealpac UK has further<br />

enhanced its end-to-end<br />

traysealer and thermoformer<br />

production line offering<br />

by becoming the sole UK<br />

distributor for Pulsotronic<br />

and its range of detection<br />

and quality control solutions.<br />

Based in Germany, the<br />

company has more than<br />

50 years’ experience within<br />

the food industry and<br />

Sealpac says the addition<br />

of Pulsotronic to its range of<br />

specialist technology partners,<br />

cements the company’s full<br />

Equipment by<br />

Pulsotronic<br />

line capability, providing<br />

a complete ‘one-stop-shop’<br />

solution for fmcg customers.<br />

Pulsotronic offers<br />

solutions for both quality<br />

control and end of line<br />

inspection. Its detection<br />

equipment can check<br />

for any foreign bodies<br />

and contaminants,<br />

while its weighing belt<br />

can identify whether<br />

a product is over or<br />

under the specifications<br />

required. The equipment<br />

helps manufacturers to meet<br />

their obligations in supplying<br />

a product that is safe and<br />

in line with all weights and<br />

measures regulations.<br />

The software also<br />

gives customers traceability<br />

and can provide valuable<br />

insights to help optimise<br />

performance and efficiency.<br />

“Pulsotronic’s machinery<br />

has been developed to<br />

perfectly withstand the<br />

meat, poultry, fish and<br />

dairy factory environment,<br />

making it a valuable addition<br />

to our offering,” says Kevin<br />

Witheford md of Sealpac UK.<br />

T 0845 302 3056<br />

W www.sealpac-uk.com

lightline Pickerline<br />

THE FUTURE CAN<br />

BE THIS EASY.<br />

Easier ordering, shorter delivery times<br />

and an attractive purchase price: With<br />

the new lightline Pickerline pick & place<br />

packaging machine, you’ll profit from many<br />

benefits in no time at all. Take advantage<br />

of our expertise and our experience –<br />

preconfigured and ready to go.<br />

www.schubert.group<br />

SCHU_lightline_Pickerline_210x297_EN_RZ_190226.indd 1 26.02.19 15:06

14 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Automated in-line system for<br />

inspecting filling and capping<br />

ROBO-QCS is an in-line<br />

quality control system<br />

designed to perform<br />

fully automated quality<br />

inspection and in-line<br />

monitoring of the entire<br />

filling and capping process<br />

and is available from FT<br />

System Control & Inspection.<br />

Through a pick and place<br />

system, the ROBO-QCS<br />

withdraws the bottle from<br />

the line and inserts it in<br />

the measurement station to<br />

perform inspections such as<br />

filling volume, torque tests,<br />

closing angle and CO2 content<br />

analysis, internal pressure<br />

measurement, CO2 partial<br />

pressure measurement, CO2<br />

percentage measurement<br />

dissolved in the liquid, angle<br />

application inspection.<br />

Reduce your waste by 50%<br />

Hera, the sustainable choice for your production line:<br />

• Deposits free-flowing ingredients on conveyored products from 1g<br />

• Proven to cut waste by 50% on production lines<br />

• Even, consistent coverage on products<br />

• Stop-start, automatic motion<br />

• Reduces dependency on manual labour<br />

To find out how we can help you reduce your giveaway<br />

contact us on +44 1684 310 000 or email: sales@sparc-systems.com<br />

www.sparc-systems.com<br />

The system is easy to install on a line<br />

After performing the<br />

inspection, the machine<br />

reintroduces the bottle in the<br />

line. Thanks to its integrated<br />

sampling system, it provides<br />

real-time statistical analysis<br />

of production trends, while<br />

the suite of technological tools<br />

integrated into the system<br />

provides a large amount of raw<br />

data that the software returns<br />

as usage data. The ROBO-QCS<br />

can be installed into an<br />

existing bottling line without<br />

any additional conveyor belts<br />

or an accumulation table.<br />

T 07931 336177<br />

W www.ftsystem.com

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2019</strong> MACHINERY UPDATE 15<br />

New jet wash system gives<br />

efficient cleaning for users<br />

Industrial Washing Machines<br />

(IWM) has launched a<br />

new and improved line of<br />

washers suitable for washing<br />

200 and 300 litre Eurobins.<br />

The EC20 comes complete with<br />

integral automatic bin lifting<br />

devices and offers better wash<br />

performance to both internal<br />

and external surfaces of the<br />

widely used wheeled buggy.<br />

Crucially, the latest EC20<br />

machines come equipped<br />

with the motorised and<br />

special IWM ‘TravelJet’<br />

traversing jet wash system<br />

that delivers 100% of the<br />

high power pumped jetting<br />

360 degrees around the soiled<br />

buggies within the wash<br />

compartment. The travelling<br />

jet system ensures there are<br />

no dead spots when cleaning,<br />

including the troublesome lip<br />

and wheel areas. The TravelJet<br />

system incorporates corrosionproof<br />

plastic bayonet-type or<br />

stainless steel jet nozzles.<br />

This EC20 with TravelJet is<br />

ideal for Eurobins as well as<br />

Vemag skips and stainless<br />

steel or plastic buggies; and<br />

where applicable, the EC20-30<br />

The EC20 comes with integral bin lifting devices as standard for ease of use<br />

model accommodates both<br />

200 litre and 300 litre bins<br />

without the need for any<br />

operator adjustments.<br />

It works by fully inverting<br />

the bin and washing the<br />

insides with a high velocity<br />

rotating spray manifold,<br />

while the outside is washed<br />

simultaneously with a full<br />

surround jetting system.<br />

Typically, a powerful<br />

stainless steel 11 kW pump is<br />

fitted to the machine to ensure<br />

that all the washing actions are<br />

both vigorous and thorough.<br />

These new machines are<br />

equipped with a flexible<br />

control system that provides<br />

a high level of automation<br />

and allows the wash cycle to<br />

be optimally matched to the<br />

user’s requirements across<br />

various industrial sectors.<br />

T 0121 459 9511<br />

W www.indwash.co.uk<br />

Vacuum grippers<br />

are cost-effective<br />

and intuitive in use<br />

RARUK Automation says the big<br />

benefit of the Robotiq grippers it<br />

offers in the UK is they need no<br />

specialist knowledge to install<br />

them. A Plug + Play kit and<br />

intuitive software enables the<br />

gripper to be programmed directly<br />

on the robot’s touchscreen in the<br />

space of just a few minutes.<br />

And this key characteristic applies<br />

to the entire range including two<br />

new vacuum grippers to<br />

the RARUK Automation range –<br />

the AirPick and EPick.<br />

Both are fully customisable<br />

vacuum grippers and compatible<br />

with all top cobots including the<br />

Universal Robots also supplied<br />

by the company. They provide<br />

manufacturers with a versatile<br />

and cost-efficient alternative<br />

to complicated solutions.<br />

The new additions are designed<br />

to give manufacturers full<br />

control of automation processes,<br />

including pick-and-place<br />

assembly, packaging, palletising,<br />

sanding and machine-tending.<br />

T 01462 670044<br />

W www.rarukautomation.com<br />

• All new erector pick up frame<br />

• Ergonomic magazine for easy filling of case blanks<br />

• Small footprint<br />

• Easy size change from one format to another<br />

• Supplied as a hot melt glue option or adhesive tape<br />

• Colour operator touch screen panel<br />

• Can be a stand-alone machine or integrated into other machinery<br />

• Installed and commissioned with after sales support<br />

• Linear style case erector<br />

Lantech modular<br />

case erector capable<br />

of up to 25 erected<br />

cases per minute<br />

CI 1000/CI 2000<br />

case erector<br />

from Lantech<br />

17 Elizabeth Court, St Neots, Cambridgeshire, PE19 8PF<br />

T: 01480 382739 M: 07764 772965 E: andrew@maters.co.uk www.maters.co.uk

16 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Monobloc filler/capper<br />

developed for E-liquid<br />

The pilot project is underway<br />

Automating<br />

cell and gene<br />

therapeutics<br />

In a pilot project, Optima Pharma<br />

is co-operating with Charité –<br />

Universitätsmedizin Berlin to<br />

develop a production platform<br />

for automatic manufacturing<br />

and filling of cell and gene<br />

therapeutics.<br />

These new types of medication<br />

pave the way for personalised<br />

medicine and are considered a<br />

promising new therapy possibility<br />

for hereditary and metabolic<br />

diseases, neurodegenerative<br />

disorders, and cancer. These<br />

medications depend on the<br />

patient’s cells and are still<br />

produced manually, for each<br />

individual patient, which is very<br />

expensive. This new project is<br />

financed by the Berlin Institute of<br />

Health (BIH).<br />

ISOLATOR TECHNOLOGY<br />

Optima Pharma is working<br />

together with Charité on a<br />

production platform based on<br />

isolator technology that will<br />

allow the manufacturing of these<br />

medications in an automated<br />

process and according to GMP<br />

guidelines (Good Manufacturing<br />

Practice) of the pharmaceutical<br />

industry. The production platform<br />

offers the possibility to map the<br />

necessary processes required<br />

to manufacture different cell<br />

and gene therapy products. The<br />

objective is to speed up the process<br />

of clinical projects like this one and<br />

bring them to a faster and a more<br />

promising application.<br />

After the development and<br />

build process, the machine will be<br />

installed and validated.<br />

T 01962 620898<br />

W www.optima-packaging.co.uk<br />

Adelphi Manufacturing<br />

has developed a<br />

Monobloc filler to<br />

meet with the E-liquid<br />

and CBD industry’s<br />

requirements for accuracy<br />

and hygiene while also<br />

providing space saving<br />

benefit for users.<br />

Part of Adelphi’s<br />

Response range of<br />

filling equipment, which<br />

includes the same basic<br />

filler, delivers accuracy<br />

of ± 0.25% when, says the<br />

company, the industry<br />

average is ± 0.1%.<br />

When blending<br />

consumable medicinal or<br />

recreational oils, having<br />

a filler that meets or<br />

exceeds industry hygiene<br />

requirements is vital, says<br />

Dean Willis, sales director at<br />

Adelphi Manufacturing.<br />

He believes E-liquid<br />

manufacturers should therefore<br />

look for the maximum possible<br />

hygiene levels.<br />

“Our Response Monobloc<br />

filler was originally designed<br />

to meet pharmaceutical<br />

standards and will therefore<br />

SMI packers from the MP ERGON<br />

series create cardboard packs<br />

with all-over graphics and<br />

strong visual impact, to attract<br />

consumer attention to fmcg<br />

brands on shelf.<br />

This continuous motion<br />

packaging system guarantees<br />

a fluid production process<br />

that preserves the integrity<br />

and quality of the product,<br />

says the company.<br />

The MP ERGON series can<br />

be equipped with bespoke<br />

solutions to pack containers<br />

with an out-of-standard<br />

Adelphi Manufacturing’s Monobloc filler<br />

delivers the hygiene required for users<br />

adhere to any new regulations<br />

that may be created around<br />

the mixing and blending of<br />

E-liquids,” he says.<br />

All “wetted” parts that come<br />

into contact with product are<br />

manufactured in hygienic<br />

pharmaceutical 316L grade<br />

stainless steel, PTFE and Viton.<br />

An all-stainless monocoque<br />

Conical packs can be packed<br />

securely for on-shelf impact<br />

shape like conical jars, that,<br />

precisely because of their<br />

shape, are more unstable.<br />

During the packaging<br />

Various formats can be handled<br />

construction, with curved<br />

and sloping surfaces, meets<br />

GMP requirements.<br />

The Monobloc also offers<br />

space saving benefits to<br />

users. The starwheel design<br />

centralises and synchronises<br />

processes; each index of<br />

the starwheel moves the<br />

container to the next stage,<br />

ensuring it remains aligned<br />

during all processes.<br />

The Monobloc’s compact<br />

design comes in contrast<br />

to the packaging machinery<br />

of the past, when all<br />

processes were arranged in<br />

a linear way.<br />

Willis recognises that<br />

customers looking to<br />

automate in the E-liquid<br />

and CBD oil products<br />

markets have many choices,<br />

but he believes a Monobloc<br />

system can provide many<br />

advantages compared with<br />

a traditional inline filling<br />

system, including precision,<br />

consistency, production<br />

speeds and less wastage<br />

through human error.<br />

T 01444 472300<br />

W wwww.adelphi.uk.com<br />

process, an empty space<br />

is created on the lower<br />

base of the containers to<br />

accommodate the top’s larger<br />

diameter. In order to reduce<br />

the gap at the bottom part of<br />

the package, the overlapping<br />

sleeves can be equipped with<br />

productstopping<br />

flaps,<br />

to block<br />

containers<br />

and protect<br />

them from<br />

falling out. This<br />

means no additional<br />

side protection such as top<br />

or bottom flaps are required.<br />

T 0161 277 7840<br />

W www.smigroup.net

www.boschpackaging.com<br />

19-08-16_bosch_AD_Service-Campagne_210x297mm_<strong>Machinery</strong><strong>Update</strong>_de_en.indd 1 12.08.<strong>2019</strong> 15:01:25

18 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Stretch pallet wrappers<br />

now available in the UK<br />

Hazel 4D has become the<br />

official UK distributor of<br />

semi-automatic stretch<br />

pallet wrappers from Atlanta<br />

Stretch, one of the largest<br />

stretch wrapping machine<br />

manufacturers in Europe.<br />

Hazel 4D’s technicians<br />

will install and service the<br />

Atlanta pallet wrappers and<br />

programme them to ensure<br />

they’re stretching the<br />

film and wrapping<br />

pallets in the<br />

most stable and<br />

cost-effective<br />

way. The UK<br />

company says<br />

it specialises in saving<br />

company’s money on stretch<br />

film while improving their<br />

pallet load stability.<br />

“We’re excited to partner<br />

with this progressive company<br />

that shares our desire to<br />

revolutionise the way pallets<br />

are wrapped,” says Kevin<br />

Oliver, technical sales<br />

manager at Hazel 4D. “These<br />

results that can be achieved by<br />

using the Atlanta equipment<br />

and our Extremus stretch film,<br />

coupled with our technical<br />

The range<br />

is designed<br />

to meet all<br />

wrapping<br />

needs<br />

expertise to ensure pallets are<br />

wrapped at the lowest cost,<br />

using the minimum weight<br />

of polythene and providing<br />

superior load stability.”<br />

Hazel 4D’s range of Atlanta<br />

machines includes turntable,<br />

robot, mobile and rotating arm<br />

stretch wrappers.<br />

The Mytho Easy is an<br />

advanced turntable wrapper<br />

and the high-tech film<br />

carriage has the same rollers<br />

that Atlanta use on its<br />

automatic wrappers.<br />

It can stretch film up to<br />

400% on application.<br />

With customisable<br />

password protected<br />

programmes, the<br />

Mytho Easy is great<br />

for high volume<br />

wrapping, whereas<br />

the Eva core brake<br />

turntable wrapper<br />

is perfect for<br />

operations with<br />

low volume<br />

requirements.<br />

The Synthex<br />

is a power prestretch<br />

turntable machine<br />

with six customisable<br />

programmes and the Lybra is<br />

a reliable power pre-stretch<br />

rotating arm wrapper with<br />

99 storable programmes.<br />

The compact SFERA Easy<br />

Touch robot is flexible and<br />

can be used anywhere in the<br />

warehouse. It can wrap any<br />

size and shape of pallet and<br />

doesn’t need to be plugged in<br />

when wrapping. The mobile<br />

Marathon can replace manual<br />

pallet wrapping.<br />

T 0113 242 6999<br />

W www.hazel4d.com<br />

The lab gives practical advice<br />

New PouchLab can<br />

help to design more<br />

waste-free packaging<br />

Volpak, the manufacturer<br />

of horizontal form, fill and<br />

seal machines for flexible<br />

pouches, has developed a new<br />

R&D Excellence Centre called<br />

the ‘PouchLab’, to support<br />

customers and stakeholders in<br />

developing sustainable pouch<br />

solutions by combining product<br />

knowledge with machinery<br />

expertise and materials.<br />

PouchLab is dedicated to brand<br />

owners who need to optimise<br />

pack size, down-gauge packaging<br />

or exploring new materials for<br />

their products. The Lab can also<br />

compare the behaviour of different<br />

material structures, test suitability<br />

for automation, double check the<br />

performance of their film, develop<br />

new sustainable solutions or new<br />

re-closable features for flexible<br />

packaging. Volpak’s UK agent<br />

is Engelmann & Buckham.<br />

T 01420 593680<br />

W www.buckham.co.uk<br />

The Trusted Metal Conveyor Belt Manufacturer<br />

The Trusted Metal Conveyor Belt Manufacturer<br />

‘NEW’ Hygienic Conveyor Solutions<br />

Flex-Turn ® Conveyor Ladder-Flex Conveyor Straight Conveyor<br />

• NEW open leg frame • NEW simplified wash through design<br />

• Easy to clean & maintain • High density blue plastic components<br />

Wire Belt Company Ltd, Castle Road, Eurolink Industrial Centre, Sittingbourne, Kent ME10 3RF<br />

Tel: +44 (0) 1795 421771 | Fax: +44 (0) 1795 428905 | Email: sales@wirebelt.co.uk | www.wirebelt.co.uk<br />

Wire Belt advert PPMA.indd 1 18/02/<strong>2019</strong> 12:29

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2019</strong> MACHINERY UPDATE 19<br />

New technological developments<br />

on show support label production<br />

At Labelexpo Europe <strong>2019</strong>,<br />

Meech International will<br />

be presenting its latest<br />

technological developments<br />

to support label production<br />

including; CyClean R,<br />

Hyperion IonCharge 50-75w<br />

and IonCharge 30, and the<br />

Hyperion 960IPS.<br />

The company will also<br />

be displaying its other wellestablished<br />

static control and<br />

web cleaning products.<br />

UK MANUFACTURED PACKAGING MACHINERY EXCELLENCE<br />

Turnkey solutions – Filling, Capping, Labelling – Automation – Bespoke, special purpose design<br />

Pharmaceutical – Food and Beverage – Chemical – Aromatherapy – Medical –<br />

Diagnostics – Industrial – Ecig – Adhesives<br />

The IonCharge 50 upgrade is shown<br />

“Labelexpo is a major<br />

event in Meech’s calendar –<br />

it provides the perfect platform<br />

for us to demonstrate how<br />

our products prevent problems<br />

and improve productivity<br />

within label production,”<br />

says Ralph Simon, sales<br />

director at Meech International.<br />

“We’re delighted to be<br />

presenting four new products<br />

this year, each of which has<br />

been designed following<br />

close consultation with our<br />

customers within the labelling<br />

and packaging industry.”<br />

An enhanced version of<br />

Meech’s original CyClean,<br />

CyClean R is a single or doublesided<br />

non-contact web cleaner<br />

and will be launched, the<br />

Hyperion IonCharge 30 and<br />

IonCharge 50 are upgrades of<br />

Meech’s 992V3 30kV and 50kV<br />

generators respectively, and<br />

they will both be on the stand.<br />

The new mid-range, Pulsed DC<br />

Ionising Bar, Hyperion 960IPS<br />

can also be discussed.<br />

STAND 6C34<br />

W www.meech.com<br />

Fully modular machinery<br />

Clean room ready<br />

Latest interface technology<br />

Full after-care service<br />

To discover more about the machines that could transform your company<br />

please visit:<br />

www.capcoder.com<br />

Tel: 01865 891466 Email: sales@capcoder.com<br />

Cap Coder JP MU M-J <strong>2019</strong>.indd 1 18/04/<strong>2019</strong> 12:58

20 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Affordable checkweigher<br />

offers versatile operation<br />

Food traps are now eliminated<br />

Minebea Intec has<br />

launched Essentus,<br />

a new dynamic<br />

checkweigher that offers a<br />

wide range of options and so<br />

can be tailored to individual<br />

application profiles, easily.<br />

For instance, it can handle<br />

heavy or light products in the<br />

food or chemical industry, and<br />

customers can choose exactly<br />

the checkweigher that suits<br />

their specific application.<br />

The Essentus checkweigher<br />

is the latest addition to<br />

Minebea Intec’s inspection<br />

portfolio. In operation, it<br />

ensures precise monitoring of<br />

weight and completeness and<br />

has been specially developed<br />

to better meet the different<br />

needs of customers now and<br />

in the future. Many users have<br />

clearly defined requirements<br />

and need a simple and<br />

affordable checkpoint on their<br />

production line. Others are<br />

looking for an inexpensive<br />

entry-level model to take<br />

advantage of 100% sampling.<br />

Initially, the in-line<br />

checkweigher is available in<br />

two versions: the Essentus<br />

Simmatic MU J-A <strong>2019</strong> ARTWORK<br />

The Essentus range is currently available in two versions – light and heavy<br />

Efficiency offers basic<br />

features, while the Essentus<br />

Performance offers advanced<br />

functions. Both devices are<br />

also available for different<br />

weight classes: one is the<br />

L version, which is suitable for<br />

light products weighing up to<br />

6 kg. The other is the H version,<br />

which can be used to weigh<br />

products of up to 60 kg.<br />

Both versions offer weighing<br />

precision and robustness,<br />

simple and intuitive operation<br />

as well as reliability thanks to<br />

the latest generation of strain<br />

gauge technology. There is<br />

also a choice of conveyor belt<br />

lengths from 300 mm to<br />

2,100 mm and conveyor<br />

belt widths from 50 mm<br />

to 900 mm, making the<br />

checkweighers suitable for<br />

many applications.<br />

T 0121 779 3131<br />

W www.minebea-intec.com<br />

Hygienic conveyor<br />

enhances the food<br />

quality and safety<br />

Tray sealing company Proseal<br />

has developed a new ultrahygienic<br />

conveyor to help food<br />

manufacturers meet the highest<br />

food quality and safety standards.<br />

The next generation OC Conveyor<br />

incorporates several special<br />

features that avoid potential<br />

food traps, together with an<br />

enhanced design which ensures<br />

fast and thorough cleaning<br />

during wash down.<br />

The new fully folded<br />

construction of the conveyor<br />

has removed any box sections or<br />

tubing, and open wiring looms<br />

have replaced the more common<br />

wire bundles, removing another<br />

potential food trap and providing<br />

easier access for the cleaning<br />

of individual cables.<br />

A further significant feature is<br />

the replacement of moving belts<br />

with a new wash-through chain<br />

transport system.<br />

T 01625 856600<br />

W www.proseal.com<br />

Meet the next generation 7 axis cobots<br />

Supplied with touch screen tablet pendant and CPU with rapid and<br />

simple deployment, no prior experience needed.<br />

Collision detection, European safety equipment and adherence.<br />

Redundant 7th axis for true obstacle avoidance.<br />

Currently available with either a vacuum or pneumatic end effector<br />

for immediate payback.<br />

Simmatic Automation, UK Sole agent of Siasun Cobots,<br />

China’s largest robot manufacturer www.siasun.com<br />

T: +44 (0) 1299 877770 www.simmatic.co.uk E: sales@simmatic.co.uk

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2019</strong> MACHINERY UPDATE 21<br />

Safety light curtain is resistant to<br />

any aggressive cleaning regimes<br />

Conveyor Advert Flyer B.pdf 1 10/06/<strong>2019</strong> 10:31:17<br />

With an hygienic stainlesssteel<br />

housing developed<br />

to meet stringent<br />

pharmaceutical industry<br />

requirements, the TWINOX4<br />

safety light curtain from Sick<br />

UK is resistant to aggressive<br />

cleaning and decontamination<br />

regimes. The TWINOX4 is a Type<br />

4 device (IEC 61496-1) with 14 mm<br />

beam resolution and can be<br />

used in safety applications<br />

requiring PLe (EN ISO 13849)<br />

and SIL3 (EN 62061).<br />

The safety light curtain<br />

protects operating personnel<br />

when interventions are<br />

required in the hazardous<br />

areas around machines that<br />

are subject to stringent hygiene<br />

requirements. It is ideal for use<br />

in Restricted Access Barrier<br />

System areas such as primary<br />

packing and filling stations.<br />

C<br />

PHARMACEUTICAL USE<br />

Rugged, resistant to harsh M<br />

cleaning media and designed<br />

Y<br />

without edges or gaps, the<br />

TWINOX’s 20 mm x 40 mm CM<br />

cross-section dimensions<br />

MY<br />

make it suitable for<br />

CY<br />

integration in machinery<br />

when space is limited.<br />

CMY<br />

“The SICK TWINOX4 offers<br />

K<br />

pharmaceutical manufacturers<br />

the twin protection of<br />

hygienic design together with<br />

technology-leading machinery<br />

safety,” explains Dr Martin<br />

Kidman of Sick UK.<br />

Machine integration<br />

flexibility for both machine<br />

builders and end-users is<br />

assured with a choice of<br />

300 mm, 420 mm and 600 mm<br />

light curtain heights, over<br />

a width range of up to<br />

4.5 metres. Operating<br />

temperatures range from<br />

-20deg C to +55deg C, hygienic<br />

and chemical resistant<br />

PUR cable is supplied with<br />

standard industrial M12 5-pin<br />

connections for the devices.<br />

T 01727 831121<br />

W www.sick.co.uk<br />

The people for conveyor components<br />

In partnership with<br />

Oadby Plastics are a leading supplier of<br />

Conveyor Components, Chains & Modular Belting<br />

We stock a comprehensive range of levelling feet, bipods, tripods,<br />

inserts and associated products to support your conveyor equipment.<br />

• Machined Parts • Conveyor Chains • Sprockets • Levelling Feet • Modular Belt<br />

Bipods & Tripods • Threaded Inserts • Guide Rails • • Roller Guides • Brackets<br />

Clamps • Handles • Hinges • Transfer Rollers • Bearings • Wear Strips • Wear Bends • Chain Guides<br />

people and products you can rely on<br />

Please visit our website<br />

www.oadbyplastics.co.uk<br />

sales@oadbyplastics.co.uk 0116 232 1010 @oadbyplasticsltd @oadbyplastics

22 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Thermal transfer printer<br />

gives higher throughput<br />

6-axis robot<br />

is a compact<br />

and light unit<br />

ABB has launched its smallest,<br />

lightest robot yet as part of its<br />

growing offering of solutions for<br />

small parts assembly.<br />

The IRB 1100 was designed<br />

to meet the challenges of<br />

semiconductor, pharmaceutical and<br />

electronics manufacturers needing<br />

to handle small and often delicate<br />

parts while working at speed<br />

without compromising productivity<br />

or quality. This new robot offers<br />

up to 35% faster cycle times to<br />

maximise productivity, and says<br />

ABB, repeatable accuracy.<br />

Powered by ABB’s new<br />

OmniCore controller, it is<br />

equipped with advanced motion<br />

control capabilities, making<br />

it ideal for supporting rapid<br />

assembly, pick and place and<br />

materials handling applications.<br />

With a 10% smaller footprint<br />

and a 20% lighter, slimmer body<br />

compared to previous robot<br />

generations, the IRB 1100 can<br />

be deployed in confined spaces<br />

and existing automation lines.<br />

In addition to improving production<br />

space flexibility, the IRB 1100<br />

also allows more flexible handling<br />

for heavy-load operations with<br />

complex tools or end effectors.<br />

“Today’s manufacturers need<br />

to squeeze every drop of value<br />

out of their factories – from their<br />

automation systems and even<br />

their floor space,” says Per Vegard<br />

Nerseth, md of Robotics at ABB.<br />

“The IRB 1100 is designed to<br />

support both these imperatives<br />

and create opportunities to get the<br />

most out of every last centimetre<br />

of production.”<br />

T 01908 350300<br />

W www.abb.com<br />

Clearmark Solutions has<br />

launched the ICE Zodiac<br />

Eagle, a next generation<br />

107 mm thermal transfer<br />

printer that is designed to<br />

deliver higher throughputs<br />

and support longer length 1200<br />

metre ribbon for larger prints.<br />

The ICE Zodiac Eagle, an<br />

evolution of the popular ICE<br />

Zodiac HS 107 mm printer,<br />

now features an airless all<br />

electronic design, which allows<br />

for more precise control of the<br />

printhead and can help boost<br />

line throughput by up to 25 %.<br />

Engineering out the<br />

requirement for compressed<br />

air has also helped to reduce<br />

the printer’s total cost of<br />

ownership, by helping to<br />

reduce operational and<br />

maintenance costs, says the<br />

company.<br />

The printer also features<br />

a full colour touchscreen, with<br />

the proven CLARiTY operating<br />

system, while being fully<br />

modular allows for up to four<br />

printers to be operated from<br />

a single screen.<br />

“This printer has been<br />

specifically engineered<br />

The new TruBake HiCirc<br />

convection oven launched by<br />

Baker Perkins brings higher<br />

rates of convection, higher<br />

heat flux, and a broader range<br />

of product capability than<br />

its predecessors. The new<br />

oven is a development of the<br />

well-proven HiCirc oven with<br />

improvements in flexibility,<br />

efficiency and hygiene and, for<br />

the first time, the ability to be<br />

integrated into a hybrid oven.<br />

The stable and predictable<br />

baking environment is suitable<br />

for a wide variety of products,<br />

Clearmark has engineered out any printer requirement for compressed air in use<br />

to incorporate a series of<br />

breakthroughs in coding<br />

technology to help customers<br />

achieve larger prints with<br />

longer ribbon, which in turn<br />

helps to reduce frequency of<br />

changeover, while continuing<br />

to drive down total cost of<br />

ownership,” explains Chris<br />

Simpson, managing technical<br />

director at Clearmark.<br />

The ICE Zodiac Eagle follows<br />

the introduction of the ICE<br />

Latest convection oven offers broader range<br />

of product capability than its predecessors<br />

The design of the new modular oven allows it to become a hybrid option<br />

from brownies, cookies and<br />

bars up to crackers and pet<br />

treats; it has already been<br />

applied to other products<br />

Zodiac Hawk, the only thermal<br />

transfer printer with a built-in<br />

print checking system.<br />

This machine reports on the<br />

quality of each code it produces,<br />

largely removing the need to<br />

invest in costly add-on vision<br />

systems and operator training<br />

in order to meet increasing<br />

demand from retailers for code<br />

quality checks.<br />

T 0115 964 0144<br />

W www.interactivecoding.co.uk<br />

including baked granola and<br />

ingredients.<br />

T 01733 283000<br />

W www.bakerperkins.com

PFM MU S-O <strong>2019</strong> ARTWORK<br />

Flexible packaging machinery<br />

not New up <strong>Machinery</strong> to speed?<br />

Let PFM boost your production<br />

PPMA<br />

Total Show<br />

Stand C20<br />

<strong>Machinery</strong><br />

n Horizontal flowrappers<br />

n Vertical form fill seal<br />

bag makers<br />

n Horizontal form fill<br />

seal pouch machinery<br />

n Multihead weighers<br />

Bag Styles<br />

n Pillow packs<br />

n Stand up bags<br />

n Pouches<br />

n Recloseable packs<br />

n MAP<br />

PFM Packaging <strong>Machinery</strong> Ltd, PFM House, 2 Pilgrim Way, Stanningley, LEEDS LS28 6LU<br />

T: +44 (0)113 239 3401 E: sales@pfmuk.com W: www.pfmuk.com<br />

Meech Cabinet Cooler Systems<br />

... for enhanced, efficient cooling<br />

• Low cost replacement for traditional<br />

systems used to cool cabinets and<br />

panels<br />

• Running solely on compressed air, with<br />

no moving parts, the Meech Cabinet<br />

Cooler requires no electricity and is<br />

virtually maintenance free<br />

• Innovative design and compact<br />

dimensions allow for installation into<br />

applications with limited space<br />

• EX Cabinet Cooler is also available<br />

with ATEX and IECEX certification for<br />

hazardous locations<br />

sales@meech.com<br />

+44(0)1993 706 700<br />

www.meech.com<br />

Untitled-1 1 05/01/2018 15:34:08

24 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2019</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Enhanced conveyors are<br />

offering hygiene benefits<br />

System is a self-contained unit<br />

An ultra heavy-duty<br />

bulk bag filler has<br />

an integral conveyor<br />

A new ultra-heavy-duty bulk<br />

bag filling system from Flexicon<br />

Europe receives abrasive,<br />

high-density solids and other<br />

difficult-to-handle bulk materials<br />

from upstream processes or<br />

storage vessels, and fills the<br />

material by weight into bulk<br />

bags. Intended for demanding<br />

industrial applications, the<br />

system comprises heavy-gaurge<br />

variants of the company’s<br />

patented Twin-Centrepost filler<br />

and flexible screw conveyor<br />

consolidated on a robust skid<br />

with integral forklifting tubes<br />

for easy mobility.<br />

The filler is equipped with<br />

fill head height adjustment to<br />

accommodate all popular bag<br />

sizes, pneumatically retractable<br />

bag hooks and an inflatable<br />

connector to seal the bag inlet<br />

spout.<br />

T 01227 374710<br />

W www.flexicon.co.uk<br />

Wire Belt has launched<br />

a range of conveyor<br />

systems that the<br />

company says set ‘a new<br />

benchmark’ in hygienic<br />

control and ‘cleanability’.<br />

The Enhanced Hygienic<br />

Conveyors meet or exceed<br />

the latest hygiene design<br />

guidelines, using special<br />

features to make cleaning easier.<br />

“A key challenge facing<br />

production facilities is the<br />

prevention of contamination,”<br />

says Ben Thomason of Wire<br />

Belt. “Our new range marks<br />

a step change in the design<br />

and manufacture of conveyors<br />

and we believe it sets a new<br />

standard in hygienic design.”<br />

The new conveyors are<br />

designed for any production<br />

facility where contamination<br />

is a prime concern, especially<br />

in industries such as food<br />

processing, pharmaceuticals<br />

and cosmetics.<br />

At the forefront of the new<br />

design is the facilitation of<br />

cleaning. That is why the<br />

new conveyors include<br />

an open, wash-through<br />

construction and open leg<br />

The hygienic conveyors from Wire Belt meet guidelines set by the EHEDG<br />

frames, so there are no hidden<br />

areas. The conveyors are also<br />

designed to eliminate crevices<br />

and ‘bug traps’, while surfaces<br />

are self-draining.<br />

Components such as<br />

footpads are all made from<br />

food-approved materials.<br />

Even the standard control<br />

panel is hygienically<br />

designed, with a sloped top<br />

for drainage, IP66 ingress<br />

protection and fully stainless<br />

steel construction.<br />

In common with Wire<br />

Belt’s established lines, these<br />

Enhanced Hygienic Conveyors<br />

use standard components<br />

across the range, ensuring<br />

shorter lead times, simpler<br />

servicing and a ready supply<br />

of spare parts.<br />

The new conveyors will<br />

also reduce running costs.<br />

“Cleaning is a significant<br />

expense in any production<br />

facility, especially where<br />

preventing contamination<br />

is a priority,” says Thomason.<br />

“By making the cleaning<br />

process simpler and quicker,<br />

we have reduced running<br />

costs, improved efficiency<br />

and increased profitability.”<br />

T 01795 421771<br />

W www.wirebelt.co.uk<br />

Latest in-line identification unit delivers beverages, foods<br />

and also pharmaceutical containers with no closure faults<br />

The Heuft FinalView II<br />

CAP is said to take the<br />

in-line identification<br />

of beverage, food<br />

and pharmaceutical<br />

containers with any<br />

closure faults to<br />

a new level and can<br />

be easily integrated<br />

into existing filling<br />

and packaging lines.<br />

This new generation<br />

compact detection<br />

unit carries out complete<br />

in-line inspection of closures<br />

at speeds of up to 100,000<br />

The all-round colour inspection sees no ‘blind spots’ in identifying deformation, damage or leaks<br />

containers an hour, using<br />

a wide variety of optics<br />

and the Heuft reflexx²<br />

real-time image processing.<br />

In operation, closures are<br />

examined continuously from<br />

all sides – including all<br />

the components and<br />

safety elements: the topdown<br />

inspection with<br />

high-resolution colour<br />

camera technology<br />

finds deviating closure<br />

colours, designs and lid<br />

logos just as reliably as<br />

any cracks so that the<br />

properties of the final<br />

goods are guaranteed<br />

just as the integrity and<br />

purity of the product.<br />

T 01827 255800<br />

W www.heuft.com

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2019</strong> MACHINERY UPDATE 25<br />

De-stacker for the food industry<br />

handles common retailer crates<br />

ILS JP MU S-O <strong>2019</strong>.qxp_MU 08/08/<strong>2019</strong> 16:52 Page 1<br />

LAC Conveyor Systems<br />

& Automation’s new<br />

stainless-steel crate<br />

de-stacker for the food<br />

industry accommodates<br />

the most commonly used<br />

supermarket crates.<br />

The company has developed<br />

this de-stacker in response to<br />

a growing requirement from<br />

the food industry, and it<br />

delivers the rapid output<br />

modern food production<br />

facilities require. Manufactured<br />

to a robust design, it provides<br />

a cost-effective solution for<br />

food producers while reducing<br />

manual handling.<br />

The crate de-stacker<br />

handles the two most<br />