FLEXIBLE

Modernizing Pipelines - Flexpipe Systems

Modernizing Pipelines - Flexpipe Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

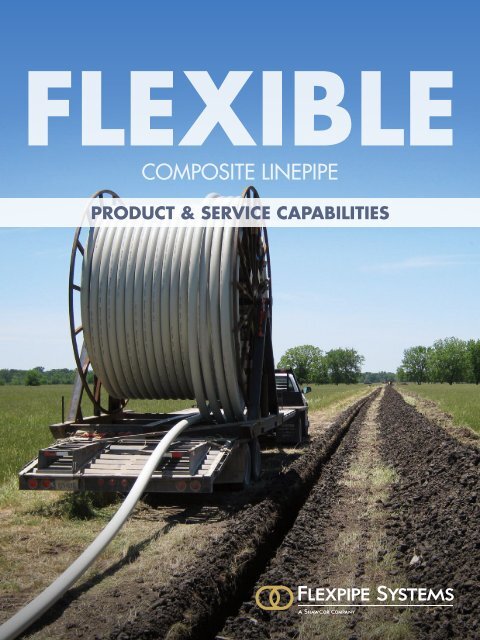

<strong>FLEXIBLE</strong><br />

COMPOSITE LINEPIPE<br />

PRODUCT & SERVICE CAPABILITIES

<strong>FLEXIBLE</strong> PROVEN<br />

COMPOSITE LINEPIPE<br />

It Pays to be Flexible<br />

Flexpipe Systems manufactures and distributes a flexible, composite<br />

pipeline solution for the energy sector. Our corrosion resistant, highpressure<br />

pipeline products help drive down installation costs while<br />

increasing productivity. With over 65 million feet (19 million meters)<br />

of Flexpipe Systems’ patented Linepipe technology and 90,000<br />

fittings successfully installed throughout North America, Latin<br />

America and Australia, our team of technical experts, engineers,<br />

and field personnel will find the right solution for your next pipeline<br />

project.<br />

Modernizing pipelines in the field<br />

All Flexpipe Systems products use the same principle: a<br />

thermoplastic liner, a helically wound reinforcement layer and an<br />

external thermoplastic jacket.<br />

Our composite linepipe solutions are used in a wide range of<br />

applications in which a corrosion resistant pipeline is beneficial,<br />

including:<br />

• Oil and gas gathering<br />

• Water transfer, disposal, and injection<br />

• CO 2 injection<br />

2001<br />

• Flexpipe Incorporated – began as an R&D initiative to<br />

design a composite pipeline system<br />

2003<br />

• First commercial sale in April 2003

Product Lines<br />

FlexPipe Linepipe (FPLP)<br />

STRUCTURAL LAYERS<br />

(Fiber Reinforcement)<br />

THERMOPLASTIC LINER<br />

THERMOPLASTIC JACKET<br />

Our onshore solution that eliminates<br />

corrosion, speeds installation and reduces<br />

operational costs. Available in 2", 3"<br />

and 4" internal diameter sizes with 300,<br />

750, and 1,500 psi pressure ratings<br />

and a maximum continuous operating<br />

temperature of 140°F (60°C). The<br />

patented unbonded fiber design is suitable<br />

for a broad range of options including<br />

oil, gas, water, H 2 S and CO 2 and offers<br />

industry leading impact resistance and<br />

flexibility for ease of handling around<br />

corners and bends.<br />

FP150 FP301 FP601<br />

Maximum Operating Pressure @ 60°C or 140°F 2,068 kPa/300 psi 5,171 kPa/750 psi 10,342 kPa/1,500 psi<br />

Nominal Size 3" 4" 2" 3" 4" 2" 3" 4"<br />

Outside Diameter<br />

Inside Diameter<br />

Weight<br />

Min. Bend Radius<br />

(operational)<br />

Length/Reel*<br />

Reel Diameter<br />

Reel Width<br />

Reel Weight – Full*<br />

Reel Weight – Empty<br />

Fitting Outside Diameter**<br />

Fitting Inside Diameter**<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (kg/m)<br />

Imperial (lbs/ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (mm)<br />

Imperial (inches)<br />

95<br />

3.75<br />

77<br />

3.02<br />

2.6<br />

1.7<br />

1.8<br />

6<br />

760<br />

2,495<br />

3.7<br />

12<br />

1.2<br />

4<br />

2,760<br />

6,100<br />

680<br />

1,500<br />

110.7<br />

4.36<br />

63.5<br />

2.50<br />

122<br />

4.80<br />

99<br />

3.90<br />

4.0<br />

2.7<br />

2.1<br />

7<br />

750<br />

2,460<br />

3.7<br />

12<br />

2.4<br />

8<br />

4,283<br />

9,430<br />

1,150<br />

2,530<br />

139.7<br />

5.50<br />

85.9<br />

3.38<br />

69<br />

2.73<br />

54<br />

2.12<br />

1.7<br />

1.1<br />

1.2<br />

4<br />

1,100<br />

3,610<br />

3.7<br />

12<br />

1.2<br />

4<br />

2,635<br />

5,800<br />

680<br />

1,500<br />

81.5<br />

3.21<br />

44.5<br />

1.75<br />

97<br />

3.80<br />

77<br />

3.02<br />

3.0<br />

2.0<br />

1.8<br />

6<br />

760<br />

2,495<br />

3.7<br />

12<br />

1.2<br />

4<br />

3,100<br />

6,800<br />

680<br />

1,500<br />

110.7<br />

4.36<br />

63.5<br />

2.50<br />

124<br />

4.89<br />

99<br />

3.90<br />

4.9<br />

3.3<br />

2.1<br />

7<br />

735<br />

2,410<br />

3.7<br />

12<br />

2.4<br />

8<br />

5,013<br />

11,030<br />

1,150<br />

2,530<br />

139.7<br />

5.50<br />

85.9<br />

3.38<br />

73<br />

2.86<br />

54<br />

2.12<br />

2.4<br />

1.6<br />

1.2<br />

4<br />

1,100<br />

3,610<br />

3.7<br />

12<br />

1.2<br />

4<br />

3,450<br />

7,600<br />

680<br />

1,500<br />

85.1<br />

3.35<br />

44.5<br />

1.75<br />

101<br />

3.96<br />

77<br />

3.02<br />

4.3<br />

2.9<br />

1.8<br />

6<br />

700<br />

2,300<br />

3.7<br />

12<br />

1.2<br />

4<br />

3,820<br />

8,400<br />

680<br />

1,500<br />

115.6<br />

4.55<br />

63.5<br />

2.50<br />

130<br />

5.11<br />

99<br />

3.90<br />

6.9<br />

4.6<br />

2.1<br />

7<br />

570<br />

1,870<br />

3.7<br />

12<br />

2.4<br />

8<br />

5,493<br />

12,130<br />

1,150<br />

2,530<br />

144.3<br />

5.68<br />

85.9<br />

3.38<br />

*Length and reel weights are approximate as they may vary depending on the manufacturing run.<br />

**Fitting dimensions do not include O.D. of flange provided for Flanged End Fittings.<br />

**Fitting O.D. and I.D. apply to Flanged End, Weld-neck and Pipe-to-Pipe Coupling fittings.<br />

FlexPipe Linepipe High Temperature (FPLP HT)<br />

WOUND DRY FIBERGLASS<br />

Utilizes advanced materials capable of<br />

continuous operation up to 180°F (82°C).<br />

Suitable for temperature excursions up to<br />

500 hours at 200°F (93°C) eliminating the<br />

need for cooling systems. Available in 2",<br />

3" and 4" internal diameter sizes with a<br />

maximum operating pressure of 1,500 psi.<br />

HDPE-RT LINER<br />

The patented design delivers the most<br />

HDPE-RT JACKET<br />

flexible, high pressure composite linepipe<br />

available; high impact resistance during<br />

installation, and no axial elongation when<br />

pressurized.<br />

FP301 HT<br />

FP601 HT<br />

Maximum Operating Pressure @ 82°C or 180°F 5,171 kPa/750 psi 10,342 kPa/1,500 psi<br />

Nominal Size 2" 3" 4" 2" 3" 4"<br />

Outside Diameter<br />

Inside Diameter<br />

Weight<br />

Min. Bend Radius<br />

(operational)<br />

Length/Reel*<br />

Reel Diameter<br />

Reel Width<br />

Reel Weight – Full*<br />

Reel Weight – Empty<br />

Fitting Outside Diameter**<br />

Fitting Inside Diameter**<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (kg/m)<br />

Imperial (lbs/ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (mm)<br />

Imperial (inches)<br />

69<br />

2.73<br />

54<br />

2.12<br />

1.7<br />

1.1<br />

1.2<br />

4<br />

1,120<br />

3,675<br />

3.7<br />

12<br />

1.2<br />

4<br />

2,635<br />

5,800<br />

680<br />

1,500<br />

81.5<br />

3.21<br />

44.5<br />

1.75<br />

97<br />

3.80<br />

77<br />

3.02<br />

3.0<br />

2.0<br />

1.8<br />

6<br />

760<br />

2,495<br />

3.7<br />

12<br />

1.2<br />

4<br />

3,100<br />

6,800<br />

680<br />

1,500<br />

110.7<br />

4.36<br />

63.5<br />

2.50<br />

124<br />

4.89<br />

99<br />

3.90<br />

4.9<br />

3.3<br />

2.1<br />

7<br />

735<br />

2,410<br />

3.7<br />

12<br />

2.4<br />

8<br />

5,013<br />

11,030<br />

1,150<br />

2,530<br />

139.7<br />

5.50<br />

85.9<br />

3.38<br />

73<br />

2.86<br />

54<br />

2.12<br />

2.4<br />

1.6<br />

1.2<br />

4<br />

1,120<br />

3,675<br />

3.7<br />

12<br />

1.2<br />

4<br />

3,450<br />

7,600<br />

680<br />

1,500<br />

85.1<br />

3.35<br />

44.5<br />

1.75<br />

101<br />

3.96<br />

77<br />

3.02<br />

4.3<br />

2.9<br />

1.8<br />

6<br />

700<br />

2,300<br />

3.7<br />

12<br />

1.2<br />

4<br />

3,820<br />

8,400<br />

680<br />

1,500<br />

115.6<br />

4.55<br />

63.5<br />

2.50<br />

130<br />

5.11<br />

99<br />

3.90<br />

6.9<br />

4.6<br />

2.1<br />

7<br />

570<br />

1,870<br />

3.7<br />

12<br />

2.4<br />

8<br />

5,493<br />

12,130<br />

1,150<br />

2,530<br />

144.3<br />

5.68<br />

85.9<br />

3.38<br />

*Length and reel weights are approximate as they may vary depending on the manufacturing run.<br />

**Fitting dimensions do not include O.D. of flange provided for Flanged End Fittings.<br />

**Fitting O.D. and I.D. apply to Flanged End, Weld-neck and Pipe-to-Pipe Coupling fittings.<br />

2007<br />

• Introduction of the first FP601 1,500 psi linepipe<br />

2005<br />

• Implementation of the crimp fitting system<br />

2008<br />

• Purchased by ShawCor Ltd. in June 2008

PRODUCT & SERVICE CAPABILITIES<br />

FlexCord Linepipe (FCLP)<br />

STRUCTURAL LAYERS<br />

(Galvanized Steel Cords)<br />

BARRIER LAYER<br />

THERMOPLASTIC LINER<br />

THERMOPLASTIC JACKET<br />

Designed to handle severe pressure<br />

cycles and pulsations such as those<br />

generated by piston pumps. Patent<br />

pending high strength steel-cord<br />

reinforced design delivers a pressure<br />

rating up to 2,250 psi and is available<br />

in 2", 3" and 4" internal diameter sizes,<br />

with a maximum continuous operating<br />

temperature of 140°F (60°C).<br />

FC901*<br />

FC801<br />

Maximum Operating Pressure @ 60°C or 140°F 15,510 kPa/2,250 psi 13,790 kPa/2,000 psi<br />

Nominal Size 2" 3" 4"<br />

Outside Diameter<br />

Inside Diameter<br />

Weight<br />

Min. Bend Radius<br />

(operational)<br />

Length/Reel**<br />

Reel Diameter<br />

Reel Width<br />

Reel Weight – Full**<br />

Reel Weight – Empty<br />

Fitting Outside Diameter***<br />

Fitting Inside Diameter***<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (kg/m)<br />

Imperial (lbs/ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (mm)<br />

Imperial (inches)<br />

75.1<br />

2.955<br />

53.8<br />

2.12<br />

4.82<br />

3.24<br />

1.2<br />

4<br />

750<br />

2,460<br />

3.7<br />

12<br />

2.4<br />

8<br />

4,778<br />

10,535<br />

1,150<br />

2,530<br />

87.1<br />

3.43<br />

44.5<br />

1.75<br />

99<br />

3.91<br />

77<br />

3.02<br />

5.1<br />

3.5<br />

1.8<br />

6<br />

575<br />

1,890<br />

3.7<br />

12<br />

1.2<br />

4<br />

3,817<br />

8,415<br />

680<br />

1,500<br />

115.6<br />

4.55<br />

63.5<br />

2.50<br />

128<br />

5.03<br />

99<br />

3.90<br />

8.6<br />

5.8<br />

2.1<br />

7<br />

485<br />

1,590<br />

3.7<br />

12<br />

2.4<br />

8<br />

7,036<br />

15,479<br />

1,150<br />

2,530<br />

144.3<br />

5.68<br />

85.9<br />

3.38<br />

*FC901 does not have a barrier layer.<br />

**Length and reel weights are approximate as they may vary depending on the manufacturing run.<br />

***Fitting dimensions do not include O.D. of flange provided for Flanged End Fittings.<br />

***Fitting O.D. and I.D. apply to Flanged End, Weld-neck and Pipe-to-Pipe Coupling fittings.<br />

FlexCord Linepipe Anti-Buoyant (FCLP AB)<br />

STRUCTURAL LAYERS<br />

(Galvanized Steel Cords)<br />

THERMOPLASTIC LINER<br />

THERMOPLASTIC JACKET<br />

Our anti-buoyant solution is for shallow<br />

water applications with a maximum<br />

depth of 100 feet (30 meters). Available<br />

in 2" internal diameter size with<br />

a maximum operating pressure of<br />

2,250 psi and a maximum continuous<br />

operating temperature of 140°F (60°C).<br />

Flow Coefficients*<br />

Hazen & Williams 150<br />

Darcy Weisbach<br />

e = 0.000005 ft or 0.0015 mm<br />

Manning 0.009<br />

*For all product lines.<br />

FC901 AB<br />

Maximum Operating Pressure @ 60°C or 140°F<br />

15,510 kPa/2,250 psi<br />

Nominal Size 2"<br />

Outside Diameter<br />

Inside Diameter<br />

Weight<br />

Min. Bend Radius (operational)<br />

Length/Reel*<br />

Reel Diameter<br />

Reel Width<br />

Reel Weight – Full<br />

Reel Weight – Empty<br />

Length/Coil*<br />

Coil Weight**<br />

Fitting Outside Diameter***<br />

Fitting Inside Diameter***<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (kg/m)<br />

Imperial (lbs/ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (m)<br />

Imperial (ft)<br />

Metric (kg)<br />

Imperial (lbs)<br />

Metric (mm)<br />

Imperial (inches)<br />

Metric (mm)<br />

Imperial (inches)<br />

*Length may vary. All specifications are subject to change depending on product-specific requirements.<br />

**Also available in coils for sea containers with pipe length/coil up to 890 meters (2,920 feet).<br />

***Fitting dimensions do not include O.D. of flange provided for Flanged End Fittings.<br />

***Fitting O.D. and I.D. apply to Flanged End, Weld-neck and Pipe-to-Pipe Coupling fittings.<br />

75.1<br />

2.955<br />

53.8<br />

2.12<br />

4.82<br />

3.24<br />

1.2<br />

4.0<br />

750<br />

2,460<br />

3.7<br />

12<br />

2.4<br />

8<br />

4,778<br />

10,535<br />

1,150<br />

2,530<br />

750<br />

2,460<br />

3,615<br />

7,970<br />

87.1<br />

3.43<br />

44.5<br />

1.75<br />

2011<br />

• Introduced FlexCord as a new 2,000 psi high-pressure linepipe<br />

• Launched FPLP HT to be used in high temperature applications<br />

up to 180°F (82°C)<br />

2013<br />

• FlexCord Linepipe Anti-buoyant is developed for use in<br />

shallow water applications<br />

2012<br />

2012<br />

• Reel-less (coiled) pipe packaging is introduced as an<br />

alternative to reels<br />

• First field trial of 6" FlexFlow larger diameter linepipe

Flexible Composite Linepipe Solutions<br />

Proven reliability<br />

• Over 65 million feet (19 million meters)<br />

of Flexpipe products have been installed<br />

• Extremely thorough pipe qualification<br />

exceeds the requirements of CSA, API,<br />

and ASTM standards<br />

• Engineering application review process<br />

ensures correct product selection for<br />

specific applications<br />

• Fitting and coupling installation is strictly<br />

controlled with custom equipment for<br />

high repeatability<br />

• Impact resistance greater than 10 times<br />

that of traditional thermoset composite pipe<br />

Unmatched corrosion protection<br />

• High density polyethylene liner eliminates<br />

corrosion<br />

• Mechanical fittings are available in carbon<br />

steel with high-phosphorus electroless<br />

nickel plating or in stainless steel<br />

• Minimizes high costs of corrosion<br />

inhibition programs<br />

Simplified installation<br />

• Rapid installation gets production on-line<br />

faster than traditional materials<br />

• Smaller crew size and ease of handling<br />

reduces installation costs by up to 30%<br />

• Environmental impact is reduced due to<br />

small right-of-ways and minimal ground<br />

disturbance<br />

• Flexpipe products are available spooled<br />

on reels or coiled in reel-less packaging<br />

format<br />

Services<br />

• Engineering application reviews to<br />

confirm product suitability<br />

• Train and certify contractors in joining<br />

procedures, handling, and deployment<br />

• Delivery of pipe and fittings to location<br />

• Installation equipment rentals<br />

• Offer onsite expert installation assistance<br />

• Regional solution and deployment centers<br />

providing support, rentals, and materials

Head Office & Manufacturing Facility<br />

3501 54 Avenue SE<br />

Calgary, AB T2C 0A9, Canada<br />

Tel: +1 403 503 0548<br />

Manufacturing Facility<br />

195, 1820 100 Avenue NE<br />

Calgary, AB T3J 0P7, Canada<br />

Tel: +1 403 503 0548<br />

Canada Sales Office<br />

600, 520 5 Avenue SW<br />

Calgary, AB T2P 3R7, Canada<br />

Tel: +1 403 503 0548<br />

U.S. Head Office<br />

1155 Dairy Ashford, Suite 450<br />

Houston, TX 77079, USA<br />

Tel: +1 281 670 2105<br />

Australia<br />

Brisbane, Australia<br />

M: +61 0458 000 209<br />

Global Strategic Partners<br />

To see a complete list of our global strategic partner<br />

locations please visit our website.<br />

For additional information, please contact:<br />

info@flexpipesystems.com<br />

or call toll free: 1 888 359 7473<br />

Solution Centers<br />

Canada<br />

11511 95 Avenue<br />

Grande Prairie, AB T8V 5P7, Canada<br />

Tel: +1 780 882 1213<br />

PO Box 1807<br />

Estevan, SK S4A 2X8, Canada<br />

Tel: +1 306 861 0509<br />

U.S.<br />

2304 Interstate Avenue<br />

Grand Junction, CO 81505, USA<br />

Tel: +1 970 243 0067<br />

2420 N County Road 1120<br />

Midland, TX 79706, USA<br />

Tel: +1 432 685 0865<br />

180 25th Avenue East<br />

Dickinson, ND 58601, USA<br />

Tel: +1 701 483 8684<br />

Deployment Centers<br />

U.S.<br />

Big Wells, TX, USA<br />

George West, TX, USA<br />

Canadian, TX, USA<br />

Carthage, TX, USA<br />

Myton, UT, USA<br />

Bakersfield, CA, USA<br />

flexpipesystems.com