You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

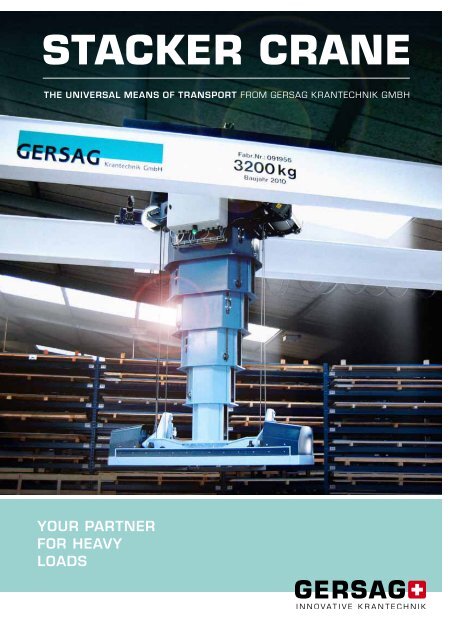

<strong>Stacker</strong> <strong>crane</strong><br />

The universal means of TransporT from GersaG KrantechniK Gmbh<br />

YOUR PARTNER<br />

FOR HEAVY<br />

LOADS

THE STAckER cRANE<br />

5,000 kg stacker <strong>crane</strong> with fast changeover system, fork carrier / vacuum gripper<br />

rubi holzbau aG, Grindelwald<br />

<strong>Stacker</strong> <strong>crane</strong> GersaG KrantechniK Gmbh<br />

3,200 kg stacker <strong>crane</strong> with fully automatic controls<br />

for sheet metal shelving operations, manual lorry unloading<br />

schindler aG, ebikon<br />

transfer table with enclosure: the stacker <strong>crane</strong> picks a sheet metal package automatically one of the touch-screen panels for command input<br />

a stacker <strong>crane</strong> is a universal means<br />

of transport that can be used in<br />

warehousing and production. Unlike<br />

a conventional forklift or side loader,<br />

aisles are not required, as the stacker<br />

<strong>crane</strong> works from above. the telescopic<br />

mast is suspended from the single or<br />

double-girder <strong>crane</strong>, allowing it to cover<br />

the area. even passing over racks and<br />

other obstacles can be done without<br />

difficulty. a further advantage is the<br />

small space requirement. even a forklift<br />

requires an aisle that it is as wide as<br />

the vehicle – but not our stacker <strong>crane</strong>.<br />

since the fork tips can be rotated 90º,<br />

only a minimal aisle is needed to allow<br />

the lifting mast to pass through. the lifting<br />

mast can be continuously rotated<br />

through 360º. to load lorries standing<br />

at an angle, for example, the forks can<br />

be tilted from +7.5º to - 2.5º.<br />

from euro pallets to<br />

wooden beams<br />

a further advantage is the adjustability of<br />

the distance between forks. from 600<br />

mm fork spacing for euro pallets up to<br />

3,600 mm for wooden beams or sheet<br />

steel. this allows the load to be moved<br />

correctly and safely, in accordance with<br />

the goods being transported. the stacker<br />

<strong>crane</strong> can also be fitted with vacuum<br />

or magnetic grippers as an option.<br />

changeover systems for various lifting<br />

means or add-on equipment are possible.<br />

all the way up to a fully<br />

automatic storage<br />

and retrieval machine<br />

the stacker <strong>crane</strong> can be operated with<br />

floor or radio remote control, like normal<br />

hall <strong>crane</strong>s. as an option, it can also be<br />

used in fully automatic mode to service a<br />

pallet rack for example. command input<br />

can be done with touch screen panels.<br />

Distance measuring systems allow the<br />

controls to always know the position of<br />

the <strong>crane</strong>. combinations are also possible.<br />

the rear of the hall can thus be used<br />

as an automatic sheet metal warehouse,<br />

while the manually-controlled <strong>crane</strong> supports<br />

production at the front of the hall.<br />

simply a multi-talented <strong>crane</strong>.

ADVANTAGES OF THE STAckER cRANE<br />

the stacker <strong>crane</strong> is often compared with the forklift. there are several factors<br />

that speak in favour of the forklift. however, the stacker <strong>crane</strong> is superior<br />

in several respects. thanks to the moveable forks, it can also be compared with<br />

the side loader. We want to show you a few advantages of the stacker <strong>crane</strong>,<br />

compared with the forklift and side loader.<br />

aisles are not required<br />

a stacker <strong>crane</strong> works from above.<br />

this means that it is not dependent<br />

upon a traversable aisle. crowded warehouse<br />

floors are no obstacle for the stacker<br />

<strong>crane</strong>.<br />

blocked aisle – an obstacle for the forklift<br />

blocked aisle – no problem for the stacker <strong>crane</strong><br />

Closer stacks – more<br />

storage volume in<br />

the same floor area<br />

for example, a stack distance of only the<br />

width of the telescopic mast is required<br />

to access the stack in a roof frame<br />

warehouse, thanks to the rotating fork<br />

tips. the fork carrier moves between<br />

the empty spaces, swivels the forks out<br />

and lifts the top frame.<br />

example: stacked wooden beams<br />

thanks to the rotating forks, only narrow aisles<br />

are required<br />

moving around<br />

on different levels<br />

if a fabrication building includes different<br />

levels, such as a loading ramp, this does<br />

not present an obstacle for the stacker<br />

<strong>crane</strong>. even storage racks that stand in<br />

a depression are not a problem for our<br />

multi-talented <strong>crane</strong>!<br />

fork tilt<br />

the fork tips can be tilted just as with a<br />

forklift or side loader. for example, this<br />

allows loading and unloading of lorries<br />

standing at an angle.<br />

Loading ramp – different levels<br />

Lorries standing at an angle – the stacker <strong>crane</strong><br />

can tilt its forks<br />

Different add-on equipment<br />

forks are not always the fastest handling<br />

equipment. Different add-on equipment<br />

is available for such situations. from vacuum<br />

equipment to client-specific grippers,<br />

we have the solution for your material<br />

handling problem! You need the<br />

fork carrier to unload lorries, but prefer<br />

to supply your machines using vacuum<br />

equipment? We can equip the stacker<br />

<strong>crane</strong> with a fast-change system and<br />

you can use the stacker <strong>crane</strong> as a universal<br />

machine in your production!<br />

fast changeover system – example:<br />

fork carrier / vacuum gripper<br />

economic benefit<br />

You will obtain considerable cost benefits<br />

from the 30–40% increase in<br />

warehouse capacity. numerous automation<br />

options bring additional benefits.<br />

We would be happy to show you how<br />

your company can achieve an optimal<br />

cost-benefit relationship.<br />

GersaG KrantechniK Gmbh <strong>Stacker</strong> <strong>crane</strong>

TEcHNIcAL DATA<br />

TeChniCal DaTa<br />

span Double girder up to 40 m<br />

Working speeDs<br />

Lifting up to 16 m/min. (cont. variable)<br />

traverse up to 32 m/min. (cont. variable)<br />

<strong>crane</strong> travel up to 63 m/min. (cont.variable)<br />

360° rotation 1-2 rotations/min. (cont. variable)<br />

aDD-on equipmenT<br />

fork carrier<br />

• carrying capacity up to 5000 kg<br />

• fork spread 600 – 3600 mm<br />

(or client-specific)<br />

• fork length 1150 mm<br />

(load centre of gravity 500 mm)<br />

• fork tilt range + 7.5°, - 2.5°<br />

• 90°fork rotation<br />

vacuum traverse<br />

• carrying capacity up to 1,000 kg (or client-specific)<br />

• Girder length 3 – 16 m<br />

• suction area dimensions dependent upon loaded material<br />

• Plunge depth 200 mm<br />

• suction surface rotates 90° yes<br />

• suction chambers are individually closable<br />

opTions<br />

• freely programmable control<br />

• Distance measurement system, all axes<br />

• scale<br />

• second cable hoist for load transport<br />

• changeover system for other add-on equipment<br />

aDvanTages<br />

• Logistics independent of the floor<br />

• high flexibility<br />

• minimal space requirements for rack access<br />

• nor aisles required<br />

• high operating speed<br />

• high level of available automation<br />

90°<br />

600 – 3600 mm<br />

Gersag is your partner for heavy loads. We can advise you in the planning of your <strong>crane</strong> installation and<br />

find the ideal solution for your material handling problems – with innovative ideas and a tailored response.<br />

We will also support you in all areas of <strong>crane</strong> technology after the installation: from maintenance and repair<br />

to conversion, modernisation and <strong>crane</strong> operation training in our own expertise centre.<br />

GerSaG<br />

KrantechniK Gmbh<br />

industriestrasse 22<br />

6260 reiden, sWitzerland<br />

PhOne +41 (0)62 749 11 11<br />

Fax +41 (0)62 749 11 12<br />

inFO@GersaG-Kran.ch<br />

WWW.GersaG-Kran.ch<br />

fork Carrier<br />

suCTion Traverse<br />

+ 7.5°<br />

– 2.5°