CERTIFIED

15-10_Shaft_Wall_Brochure_Web

15-10_Shaft_Wall_Brochure_Web

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

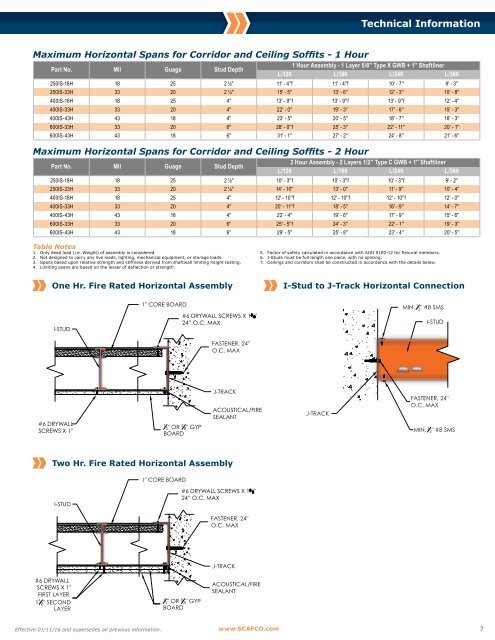

Technical Information<br />

Maximum Horizontal Spans for Corridor and Ceiling Soffits - 1 Hour<br />

Part No. Mil Guage Stud Depth<br />

1 Hour Assembly - 1 Layer 5/8'' Type X GWB + 1'' Shaftliner<br />

L/120 L/180 L/240 L/360<br />

250IS-18H 18 25 2 ½" 11' - 4''f 11' - 4''f 10' - 7'' 9' - 3''<br />

250IS-33H 33 20 2 ½" 15' - 5'' 13' - 6'' 12' - 3'' 10' - 8''<br />

400IS-18H 18 25 4" 13' - 9''f 13' - 9''f 13' - 9''f 12' - 4''<br />

400IS-33H 33 20 4" 22' - 0'' 19' - 3'' 17' - 6'' 15' - 3''<br />

400IS-43H 43 18 4" 23' - 5'' 20' - 5'' 18' - 7'' 16' - 3''<br />

600IS-33H 33 20 6" 28' - 0''f 25' - 3'' 22' - 11'' 20' - 1''<br />

600IS-43H 43 18 6" 31' - 1'' 27' - 2'' 24' - 8'' 21' - 6''<br />

Maximum Horizontal Spans for Corridor and Ceiling Soffits - 2 Hour<br />

Part No. Mil Guage Stud Depth<br />

2 Hour Assembly - 2 Layers 1/2'' Type C GWB + 1'' Shaftliner<br />

L/120 L/180 L/240 L/360<br />

250IS-18H 18 25 2 ½" 10' - 3''f 10' - 3''f 10' - 3''f 9' - 2''<br />

250IS-33H 33 20 2 ½" 14' - 10'' 13' - 0'' 11' - 9'' 10' - 4''<br />

400IS-18H 18 25 4" 12' - 10''f 12' - 10''f 12' - 10''f 12' - 0''<br />

400IS-33H 33 20 4" 20' - 11''f 18' - 5'' 16' - 9'' 14' - 7''<br />

400IS-43H 43 18 4" 22' - 4'' 19' - 6'' 17' - 9'' 15' - 6''<br />

600IS-33H 33 20 6" 25' - 5''f 24' - 3'' 22' - 1'' 19' - 3''<br />

600IS-43H 43 18 6" 29' - 5'' 25' - 8'' 23' - 4'' 20' - 5''<br />

Table Notes<br />

1. Only dead load (i.e. Weight) of assembly is considered.<br />

2. Not designed to carry any live loads, lighting, mechanical equipment, or storage loads.<br />

3. Spans based upon relative strength and stiffness derived from shaftwall limiting height testing.<br />

4. Limiting spans are based on the lesser of deflection or strength.<br />

5. Factor of safety calculated in accordance with AISI S100-12 for flexural members.<br />

6. I-Studs must be full length one piece, with no splicing.<br />

7. Ceilings and corridors shall be constructed in accordance with the details below.<br />

One Hr. Fire Rated Horizontal Assembly<br />

I-Stud to J-Track Horizontal Connection<br />

#6 DRYWALL SCREWS X 1 5/8"<br />

24” O.C. MAX<br />

#6 DRYWALL<br />

SCREWS X 1"<br />

Two Hr. Fire Rated Horizontal Assembly<br />

#6 DRYWALL SCREWS X 1 5/8"<br />

24” O.C. MAX<br />

#6 DRYWALL<br />

SCREWS X 1"<br />

Effective 01/11/16 and supersedes all previous information.<br />

www.SCAFCO.com<br />

7