Polyurethane Foam Field Joint Infill Systems - PIH - Pipeline ...

Polyurethane Foam Field Joint Infill Systems - PIH - Pipeline ...

Polyurethane Foam Field Joint Infill Systems - PIH - Pipeline ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

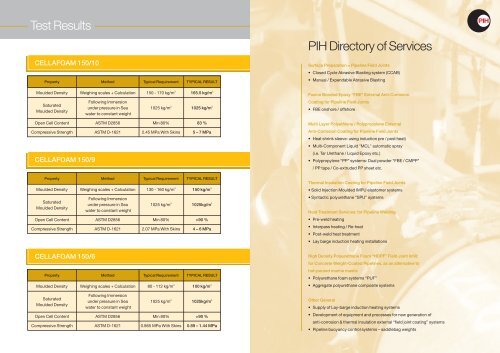

Test Results<br />

CELLAFOAM 150/10<br />

Property Method Typical Requirement TYPICAL RESULT<br />

Moulded Density Weighing scales + Calculation 150 - 170 kg/m 3<br />

Saturated<br />

Moulded Density<br />

Following Immersion<br />

under pressure in Sea 1025 kg/m 3<br />

water to constant weight<br />

165.5 kg/m 3<br />

1025 kg/m 3<br />

Open Cell Content ASTM D2856 Min 80% 83 %<br />

Compressive Strength ASTM D-1621 2.45 MPa With Skins 5 – 7 MPa<br />

CELLAFOAM 150/9<br />

Property Method Typical Requirement TYPICAL RESULT<br />

Moulded Density Weighing scales + Calculation 130 - 160 kg/m 3<br />

Saturated<br />

Moulded Density<br />

Following Immersion<br />

under pressure in Sea 1025 kg/m 3<br />

water to constant weight<br />

150 kg/m 3<br />

1025kg/m 3<br />

Open Cell Content ASTM D2856 Min 80% >90 %<br />

Compressive Strength ASTM D-1621 2.07 MPa With Skins 4 – 6 MPa<br />

CELLAFOAM 150/6<br />

Property Method Typical Requirement TYPICAL RESULT<br />

Moulded Density Weighing scales + Calculation 80 - 112 kg/m 3<br />

Saturated<br />

Moulded Density<br />

Following Immersion<br />

under pressure in Sea 1025 kg/m 3<br />

water to constant weight<br />

100 kg/m 3<br />

1025kg/m 3<br />

Open Cell Content ASTM D2856 Min 80% >90 %<br />

Compressive Strength ASTM D-1621 0.865 MPa With Skins 0.89 – 1.44 MPa<br />

<strong>PIH</strong> Directory of Services<br />

Surface Preparation = <strong>Pipeline</strong> <strong>Field</strong> <strong>Joint</strong>s<br />

• Closed Cycle Abrasive Blasting system (CCAB)<br />

• Manual / Expendable Abrasive Blasting<br />

Fusion Bonded Epoxy “FBE” External Anti-Corrosion<br />

Coating for <strong>Pipeline</strong> <strong>Field</strong> <strong>Joint</strong>s<br />

• FBE onshore / offshore<br />

Multi Layer Polyethlene / Polypropylene External<br />

Anti-Corrosion Coating for <strong>Pipeline</strong> <strong>Field</strong> <strong>Joint</strong>s<br />

• Heat shrink sleeve: using induction pre / post heat)<br />

• Multi-Component Liquid "MCL" automatic spray<br />

(i.e. Tar Urethane / Liquid Epoxy etc.)<br />

• Polypropylene “PP” systems: Dual powder “FBE / CMPP”<br />

/ PP tape / Co-extruded PP sheet etc.<br />

Thermal Insulation Coating for <strong>Pipeline</strong> <strong>Field</strong> <strong>Joint</strong>s<br />

• Solid Injection Moulded IMPU elastomer systems<br />

• Syntactic polyurethane “SPU” systems<br />

Heat Treatment Services: for <strong>Pipeline</strong> Welding<br />

• Pre-weld heating<br />

• Interpass heating / Re-heat<br />

• Post-weld heat treatment<br />

• Lay barge induction heating installations<br />

High Density <strong>Polyurethane</strong> <strong>Foam</strong> “HDPF” <strong>Field</strong> <strong>Joint</strong> <strong>Infill</strong>:<br />

for Concrete Weight-Coated <strong>Pipeline</strong>s, as an alternative to<br />

hot-poured marine mastic<br />

• <strong>Polyurethane</strong> foam systems “PUF”<br />

• Aggregate polyurethane composite systems<br />

Other General<br />

• Supply of Lay-barge induction heating systems<br />

• Development of equipment and processes for new generation of<br />

anti-corrosion & thermal insulation external “field joint coating” systems<br />

• <strong>Pipeline</strong> buoyancy control systems – saddlebag weights