You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

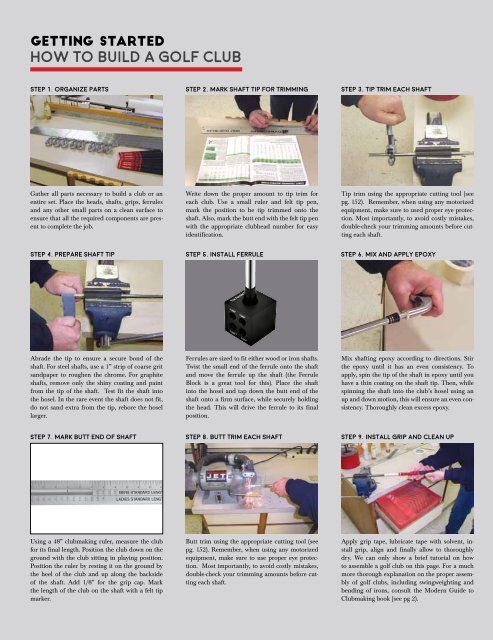

GETTING STARTED<br />

HOW TO BUILD A GOLF CLUB<br />

step 1. Organize parts<br />

step 2. Mark shaft tip for trimming<br />

step 3. Tip trim each shaft<br />

Gather all parts necessary to build a club or an<br />

entire set. Place the heads, shafts, grips, ferrules<br />

and any other small parts on a clean surface to<br />

ensure that all the required components are present<br />

to complete the job.<br />

Write down the proper amount to tip trim for<br />

each club. Use a small ruler and felt tip pen,<br />

mark the position to be tip trimmed onto the<br />

shaft. Also, mark the butt end with the felt tip pen<br />

with the appropriate clubhead number for easy<br />

identification.<br />

Tip trim using the appropriate cutting tool (see<br />

pg. 152). Remember, when using any motorized<br />

equipment, make sure to used proper eye protection.<br />

Most importantly, to avoid costly mistakes,<br />

double-check your trimming amounts before cutting<br />

each shaft.<br />

step 4. Prepare Shaft Tip<br />

step 5. Install ferrule<br />

step 6. Mix and apply epoxy<br />

Abrade the tip to ensure a secure bond of the<br />

shaft. For steel shafts, use a 1” strip of coarse grit<br />

sandpaper to roughen the chrome. For graphite<br />

shafts, remove only the shiny coating and paint<br />

from the tip of the shaft. Test fit the shaft into<br />

the hosel. In the rare event the shaft does not fit,<br />

do not sand extra from the tip, rebore the hosel<br />

larger.<br />

Ferrules are sized to fit either wood or iron shafts.<br />

Twist the small end of the ferrule onto the shaft<br />

and move the ferrule up the shaft (the Ferrule<br />

Block is a great tool for this). Place the shaft<br />

into the hosel and tap down the butt end of the<br />

shaft onto a firm surface, while securely holding<br />

the head. This will drive the ferrule to its final<br />

position.<br />

Mix shafting epoxy according to directions. Stir<br />

the epoxy until it has an even consistency. To<br />

apply, spin the tip of the shaft in epoxy until you<br />

have a thin coating on the shaft tip. Then, while<br />

spinning the shaft into the club’s hosel using an<br />

up and down motion, this will ensure an even consistency.<br />

Thoroughly clean excess epoxy.<br />

step 7. Mark butt end of shaft<br />

step 8. Butt trim each shaft<br />

step 9. Install grip and clean up<br />

Using a 48” clubmaking ruler, measure the club<br />

for its final length. Position the club down on the<br />

ground with the club sitting in playing position.<br />

Position the ruler by resting it on the ground by<br />

the heel of the club and up along the backside<br />

of the shaft. Add 1/8” for the grip cap. Mark<br />

the length of the club on the shaft with a felt tip<br />

marker.<br />

Butt trim using the appropriate cutting tool (see<br />

pg. 152). Remember, when using any motorized<br />

equipment, make sure to use proper eye protection.<br />

Most importantly, to avoid costly mistakes,<br />

double-check your trimming amounts before cutting<br />

each shaft.<br />

Apply grip tape, lubricate tape with solvent, install<br />

grip, align and finally allow to thoroughly<br />

dry. We can only show a brief tutorial on how<br />

to assemble a golf club on this page. For a much<br />

more thorough explanation on the proper assembly<br />

of golf clubs, including swingweighting and<br />

bending of irons, consult the Modern Guide to<br />

Clubmaking book (see pg 2).