You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

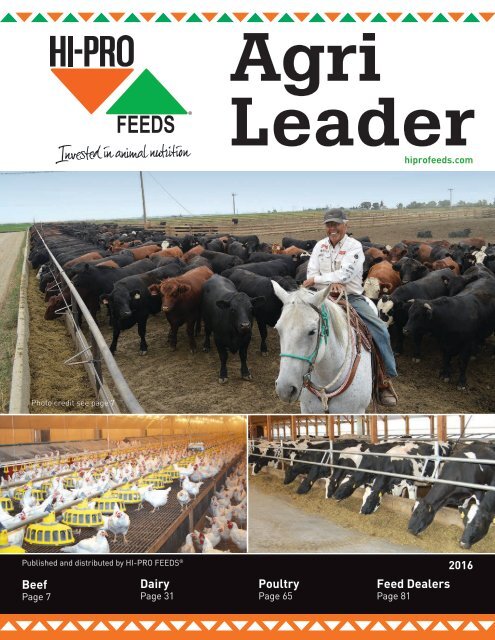

<strong>Agri</strong><br />

<strong>Leader</strong><br />

hiprofeeds.com<br />

Photo credit see page 7<br />

Published and distributed by HI-PRO FEEDS ®<br />

Beef<br />

Page 7<br />

Dairy<br />

Page 31<br />

Poultry<br />

Page 65<br />

Feed Dealers<br />

Page 81<br />

2016

Expect the kind of<br />

service you can only<br />

get from an owner.<br />

When we say we’re invested in animal nutrition we mean that<br />

literally, most Hi-Pro employees are also shareholders. We focus<br />

on helping our customers through quality products, sophisticated<br />

animal nutrition expertise and the highest level of service. We<br />

know what it takes for you to be successful and we go out of our<br />

way to make sure you get what you need, when you need it.<br />

Get the Hi-Pro team working for you.<br />

Visit us today at hiprofeeds.com<br />

HI-PRO FEEDS® and the HI-PRO FEEDS logo are registered trademarks of Hi-Pro Feeds LP. © 2016 Hi-Pro Feeds LP.

<strong>Agri</strong>culture stays strong<br />

in a volatile environment<br />

As we kick off another year, it’s a good time to reflect and<br />

understand the key issues that affected agriculture in<br />

western Canada in 2015. The highlights (in no particular<br />

order) included the following:<br />

• Poultry producers in the BC Fraser Valley battled<br />

a large outbreak of Avian Influenza, contained it,<br />

and then saw many areas of the US (and elsewhere<br />

globally) be devastated by the disease.<br />

• The ghost of Christmas past arrived with another BSE<br />

diagnosis that forced many industry stakeholders to<br />

go back into 9-years of records to ensure safety in the<br />

food chain.<br />

• Ongoing weather volatility with an early spring, and a<br />

summer drought.<br />

• Initial transportation challenges, then improvement<br />

as the railroads became (more) available to<br />

agriculture as petro-products became shut-in with<br />

decade-low oil prices.<br />

• A tumbling Canadian dollar, which will no doubt<br />

change some North/South trade flows, and present<br />

export opportunities.<br />

• Release of long-awaited details of the (somewhat<br />

clandestine) Trans Pacific Partnership (TPP). At<br />

first it created anxiety, but that tailed-off as details<br />

emerged<br />

In the end, the hallmark for managing through 2015 had<br />

to be calmness, an agility to adapt, and a resolute belief in<br />

the ongoing importance of agriculture.<br />

Here at Hi-Pro Feeds, we’ve<br />

put our sights squarely Dean Prevost<br />

on ‘creating and keeping<br />

customers’. We’ve dedicated<br />

ourselves to that mission, and have been investing<br />

heavily, learning and improving since we emerged as<br />

a new company in 2012. We took another big step in<br />

2015 with the acquisition of Champion Feed Services in<br />

Northern Alberta… all customers and employees have<br />

been warmly invited to join the Hi-Pro family that can now<br />

make/deliver high-quality feed across the province.<br />

As you flip through the pages of this issue of the <strong>Agri</strong><br />

<strong>Leader</strong>, you will read about livestock, dairy and poultry<br />

producers that have embraced the change and volatility<br />

in this industry. As an employee-owned business their<br />

entrepreneurial spirit is important to us at Hi-Pro. Our<br />

business wants to be big enough to deliver (a broad range<br />

of feed, with service excellence), but small enough to care<br />

(about our communities, customers and employees). It<br />

is our goal to continuously improve alongside the people<br />

that work hard to look after their animals and produce<br />

high quality, safe food for the people of this growing world.<br />

Sincerely,<br />

<br />

Dean Prevost<br />

CEO, Hi-Pro Feeds<br />

In this issue…<br />

Dean Prevost, CEO ..........3 Daren Kennett, Founder .....4 Editorial Comments ........5<br />

Beef ................. 7<br />

Nelson Family Ranches. . . . . . . . 7<br />

Hi-Pro Cow/Calf Program .....13<br />

U2 Ranch ..................15<br />

Creep Feeding Calves ........21<br />

OB Colony-Beef .............23<br />

Mycotoxins .................27<br />

Advertisers’ Index .... 87<br />

Dairy................ 31<br />

OB Colony-Dairy ............31<br />

From Calf to Calving .........35<br />

Springbank Holsteins ........37<br />

Cottonwood Holsteins ........44<br />

Laingspring Dairy ...........45<br />

Muller Brothers .............45<br />

Silvervale Farm .............57<br />

Poultry.............. 65<br />

Willow Bend Farms ..........65<br />

Top 5 Learnings .............71<br />

Nature’s Farm Eggs ..........73<br />

Functional Gut Integrity ......78<br />

Dealers.............. 81<br />

Purity Farm & Garden ........81<br />

Paradise Hill Farm Supply ....84<br />

Hi-Pro Feeds Directory .......88<br />

AGRI LEADER » 2016<br />

3

Global network<br />

with a local focus<br />

Since the beginning of Hi-Pro Feeds (April, 2012),<br />

our plan progresses in providing high quality, consistent<br />

animal feed products to customers across North<br />

America.<br />

We’ve completely revamped the company that was<br />

previously a part of Viterra, building a strong foundation<br />

of world-class systems, processes and people.<br />

In other words, we’ve established an industry leading<br />

platform that is rigorously invested in animal nutrition.<br />

We have been working hard the last 3 years to be better<br />

each and every day.<br />

Champion Feed Services Acquisition<br />

We announced the acquisition of Champion Feed Services<br />

Ltd in Alberta back in October, 2015. This purchase<br />

extends our business into a broader market,<br />

creating a vast network across the entire province of<br />

Alberta. Adding the Champion feed mills at Barrhead,<br />

Westlock, and Grande Prairie will assist in providing a<br />

greater mix of products and services to the customers<br />

we serve.<br />

This expands our business to 15 feed mills in the US<br />

and western Canada. The assets of Champion Oat Processors<br />

were also acquired in Grande Prairie, which<br />

ties nicely to the Hi-Pro business in Texas, Oklahoma,<br />

New Mexico and Arizona. We are excited to have a facility<br />

that can process, market, and ship double and triple<br />

cleaned oats and oat groats to our US and Canadian<br />

customers. We can now include these high-end products<br />

that fit nicely in our overall offer to clients.<br />

Champion Feed Services has been an industry leader<br />

in Northern Alberta, and has consistently demonstrated<br />

a strong commitment to the livestock industry. Hi-<br />

Pro Feeds and Champion<br />

Feed Services bring<br />

Daren Kennett<br />

together a longstanding<br />

entrepreneurial spirit established by deep roots in the<br />

community and diverse strengths. Together it makes<br />

a great combination for the continued advancement of<br />

the agriculture industry in this region of Canada.<br />

Both companies have helped drive the bottom line<br />

for commercial producers and their livestock. We will<br />

remain committed to this with continued innovation,<br />

investment, and increased milling capacity. The Champion<br />

Feed Services locations will continue to operate<br />

as is, and the employees have job offers with Hi-Pro<br />

Feeds. The deal closed officially at the end of November.<br />

Customer Feedback<br />

As an employee-owned company, we (over 500 employees)<br />

take our jobs very seriously. We know that ‘if<br />

we don’t take care of our customers, someone else<br />

will’. For that reason we have spent a lot of time soliciting<br />

feedback from customers across the many areas of<br />

our business. We have learned a lot, and are investing<br />

in ways to execute the basics, consistently right. Our<br />

priorities are focused on the following:<br />

1. Dependable product availability, and delivery<br />

2. High quality, consistent feed products<br />

3. Personalized service where we communicate, are<br />

responsive, solve problems and go the extra mile<br />

Making feed and rations for various species of animals<br />

is a complex business. We are trying to simplify this and<br />

get the basics right. This is a journey, and we will be<br />

continuously measuring and asking you if we are getting<br />

it right. If we are not, please make sure you tell us.<br />

Respectfully,<br />

Daren Kennett<br />

Founder, Hi-Pro Feeds<br />

Champion Feed Services mill in Westlock, AB<br />

- Hi-Pro Feeds photo<br />

4 AGRI LEADER » 2016

Help tell the real story of Canadian agriculture<br />

Our industry needs more agvocates<br />

To reach its full potential, agriculture needs everyone<br />

in the industry to speak up and speak positively.<br />

<strong>Agri</strong>culture More Than Ever is an industry-driven<br />

cause to improve perceptions and create positive<br />

dialogue about Canadian ag. Together we can share<br />

the facts about this vibrant and modern industry, to<br />

tell the world why we love what we do.<br />

It’s up to all of us to be agvocates and it’s easier<br />

than you think – visit AgMoreThanEver.ca and find<br />

out how you can get involved.<br />

Hi-Pro Feeds is a proud partner of this cause<br />

Editorial Comments<br />

Welcome to the Hi-Pro Feeds <strong>Leader</strong><br />

magazine for 2016 – now the <strong>Agri</strong><br />

<strong>Leader</strong>. Included in this revised and<br />

expanded edition are features from<br />

beef ranches, dairy farms, poultry operations<br />

and feed dealers. As always,<br />

the family human interest stories are<br />

an integral part of the farm descriptions.<br />

We have frequently observed<br />

that farmers like to read about other<br />

farmers’ experiences, and not only in<br />

their area of production.<br />

Throughout the magazine, Hi-Pro<br />

nutritionists describe the relevant<br />

programs and provide technical information<br />

of value to respective producers.<br />

The Beef Section features two southern<br />

Alberta ranches: a large family<br />

company with extensive operations in<br />

cow/calf, feedlot, crop production and<br />

non-ag developments. The second,<br />

is an elite Angus breeder suppling<br />

superior genetics to the industry. A<br />

Colony story includes brief descriptions<br />

of several enterprises, but details<br />

their beef feedlot best practices<br />

and in the next section, their dairy<br />

operation.<br />

In the Dairy Section, a comparative<br />

review of three farms is presented<br />

addressing the question how robotic<br />

milking changed management of<br />

the farm. Two other modern dairies<br />

recently built in new locations are<br />

described.<br />

The Poultry Section features innovation:<br />

in broiler, unique lighting and<br />

sanitation protocols, and innovative<br />

production and marketing of eggs.<br />

Two dealers offer their specialized<br />

experiences as retail operations<br />

providing products and valuable<br />

services to farmer and ranchers in<br />

their communities. They discuss<br />

how their customers’ needs have<br />

changed over the years.<br />

Advertisers continue to strongly<br />

value this publication as a vehicle<br />

to reach producers across Western<br />

Canada with their product and services<br />

information. We appreciate<br />

their participation.<br />

Enjoy the read. We invite your comments<br />

and suggestions about this<br />

publication. Talk to your Hi-Pro<br />

Feeds representative.<br />

Sincerely,<br />

Walter Goerzen,<br />

Managing Editor & Publisher<br />

____________________________<br />

PHOTOGRAPHY by W Goerzen<br />

unless indicated<br />

AGRI LEADER » 2016<br />

5

The Future of YOUR FAMILY FARM:<br />

PLANTING THE SEEDS FOR THE NEXT GENERATION<br />

While the transition of any family business has potential pitfalls, there is no doubt that transferring<br />

a family farm to the next generation has its own unique challenges. For this reason, a detailed farm<br />

succession plan with input from professional advisors will be a valuable tool in meeting the family’s<br />

needs and allowing for an effective and orderly transition.<br />

Let the experienced lawyers at Miller Thomson LLP help you plant and plan for the next generation.<br />

Brian P. Kaliel<br />

Edmonton<br />

bkaliel@millerthomson.com<br />

Jeff N. Grubb<br />

Regina<br />

jgrubb@millerthomson.com<br />

Michael Henley<br />

Guelph<br />

mhenley@millerthomson.com<br />

Wendy Baker<br />

National Co-<strong>Leader</strong><br />

Vancouver<br />

wbaker@millerthomson.com<br />

Carol VandenHoek<br />

National Co-<strong>Leader</strong><br />

Guelph<br />

cvandenhoek@millerthomson.com<br />

Added experience. Added clarity. Added value.<br />

Miller Thomson LLP<br />

millerthomson.com<br />

6 AGRI LEADER » 2016<br />

vancouver calgary edmonton saskatoon regina london kitchener-waterloo guelph toronto markham montréal

Beef<br />

Section<br />

Photo credit Nelson Family Ranches<br />

Nelson Family Ranches Ltd<br />

Diversification and Innovation<br />

An often lamented trend in agriculture is the transition<br />

from family farms to corporate ownership. Nelson<br />

Family Ranches is a fine example of a family enterprise<br />

that has grown large enough to take advantage of the<br />

economies of scale, certainly to the scale of corporate<br />

operations.<br />

Overview of Operations<br />

The family company is managed by four brothers and<br />

a brother-in-law with a number of other family members<br />

involved. Jeff Nelson, the eldest son of his generation,<br />

oversees the entire organization as CEO. His<br />

wife, Angie, serves as administrator and office manager.<br />

Jeff’s brother Jimmy manages the cattle side of<br />

the business. With 3000 Black Angus and a few Black<br />

Simmental pairs on 11,000 acres of grazing land plus a<br />

feedlot with 12,000 capacity, there is plenty to manage.<br />

(Details follow)<br />

Another brother, Kevin, handles the crop farming. Of<br />

12,000 acres, 4000 are irrigated growing canola, silage<br />

corn, barley (both silage and grain), and alfalfa. The balance<br />

of cropland<br />

is farmed<br />

using the usual<br />

dry-land techniques<br />

to produce<br />

barley and<br />

canola. Some<br />

of the barley is<br />

malt; the rest<br />

is used in the<br />

feedlots. Grain fields are all fenced for winter grazing<br />

and feeding grounds for the beef herd.<br />

The third division of Nelson Family Ranches is two<br />

fully equipped gravel-pits and related construction enterprise.<br />

Included in the gravel operations are aggregate<br />

crushing, sorting and a full line of construction<br />

equipment such as graders, loaders, excavators and<br />

(right) Jeff Nelson, CEO Nelson Family Ranches with Doug Holt,<br />

Hi-Pro Beef Sales & Service Rep, Alberta South<br />

Cover photo – Bob Gibb at age 81 continues to ride the feedlot<br />

and monitor the cattle almost every day at Nelson Family<br />

Ranches. He is a cousin to Grant Nelson.<br />

Beef Section title photo above – cattle on range at Nelson Family<br />

Ranches<br />

AGRI LEADER » 2016<br />

7

<strong>Agri</strong>culture is our way of life too<br />

Meet Justin<br />

With a lifetime of experience in ag,<br />

Justin helps Canadian producers<br />

build their dreams. Like everyone on<br />

your FCC team, Justin knows your<br />

industry and he’ll get to know you.<br />

1-800-387-3232 fcc.ca<br />

Justin Vuignier<br />

FCC Relationship Manager<br />

8 AGRI LEADER » 2016

trucks. They deliver or haul whenever possible. This<br />

division is managed by a fourth Nelson brother, Shawn.<br />

A brother-in-law, Josh, an accountant, serves as CFO<br />

of the company ensuring the company records, operational<br />

analysis and financial management are well<br />

taken care of.<br />

“Yes, we are diversified,” says Jeff. “Dad said diversification<br />

was essential. There will be times when grain<br />

or canola pay well, other times cow/calf, sometimes<br />

feedlot. Good advice.”<br />

“Dad said diversification<br />

was essential…<br />

good advice.”<br />

Family History<br />

At the turn of the previous century, a group of Mormon<br />

pioneers came to the area south of Lethbridge<br />

from Utah with a plan to develop a community irrigation<br />

system for farmland they purchased. They had developed<br />

similar irrigation infrastructure in the Utah Valley.<br />

Jeff Nelson’s great-grandfather, Alonso, came with<br />

his family and a brother in 1904 settling on a quarter<br />

section of land raising a modest flock of sheep. They<br />

missed the first run of homestead land-grants so they<br />

purchased privately owned land, mostly from the railroad.<br />

Almost immediately the group built the community<br />

irrigation system. The Ridge Reservoir for the irrigation<br />

district borders on Nelson farm-land. The ranch<br />

is near the town of Stirling, about 30 minutes southeast<br />

of Lethbridge.<br />

Alonso’s son, Farrell, began the transition to cattle<br />

and that was continued and expanded by his son Grant,<br />

Jeff’s father. Grant and Connie have four sons, as mentioned,<br />

and four daughters who all but one live in the<br />

region.<br />

“I was very fortunate being the eldest to work side by<br />

side with my father and learn the business from him,”<br />

says Jeff. “I still run things by him. I talk to him every<br />

day.”<br />

After handing over the management of the farm to his<br />

sons, Grant didn’t exactly sit back and relax. As the local<br />

Lions Club president, Grant spearheaded the planning,<br />

financing and construction of a new community<br />

centre in Stirling. “Our father taught us to be involved<br />

in the community, “says Jeff. “He believes that he was<br />

given many blessings with our farm and wanted to give<br />

back. We’re carrying on that tradition. We are all heavily<br />

involved in our community and our church.”<br />

In fact, the family’s commitment is to support local,<br />

in retail and as volunteers in the community. In addition<br />

the Lions Club as mentioned, family members are<br />

involved in organizing a children’s choir and five grandchildren<br />

are in 4-H. Jeff has been a Scout leader for 15<br />

years. A Nelson coaches every local sports team from<br />

elementary through high school ages – basketball,<br />

hockey, soccer, football and baseball.<br />

The next generation of Nelsons is growing – 36 children<br />

and young people currently. Jeff says his eldest<br />

son, the oldest of the next generation, now 18, is starting<br />

to help out on the farm and about 20 others provide<br />

various levels of summer help. The farm employs almost<br />

50 workers besides the family.<br />

The extended Nelson family. Parents Grant and Connie, just<br />

right of centre, with their 8 children and spouses, and 36 grandchildren<br />

– Photo credit Nelson family<br />

AGRI LEADER » 2016<br />

9

The Nelson family was honored at the Calgary Stampede<br />

two years ago when they were presented the BMO<br />

Farm Family Award for the County of Warner. A welldeserved<br />

recognition for their community participation<br />

and their outstanding farm operations.<br />

Cow Calf Herd<br />

The cow herd has expanded in the past three to four<br />

years from 2000 to the current 3000 head. Jeff explains,<br />

“Today the cow/calf business is the best it has ever<br />

been. However, during the BSE period when prices<br />

were low, we saw the opportunity to grow our herd. We<br />

bought low and now prices are high. To use Hi-Pro’s<br />

slogan, we invested in animal agriculture.<br />

“…prices were low,<br />

we saw the opportunity<br />

to grow our herd.”<br />

“My philosophy besides diversification, my father’s<br />

mantra, is innovation,” he continues. “Never cut back,<br />

but adapt to changing realities.”<br />

The 3,000 cow herd includes pure-bred cows allowing<br />

Nelsons to sell into the bull market in addition to the 90<br />

they run on their herd. In addition, they raise about 500<br />

pure bred replacement heifers. They track all breeding<br />

stock; calves are tagged, birth and weaning weights are<br />

recorded. Records from calving books are transferred<br />

to Excel spread sheets for analysis. Ultra sound is used<br />

on bulls. Some creep feed is provided, not a common<br />

management practice of commercial herds in the region.<br />

Cows on range are in groups of 300 to 400, but some<br />

as low as 50. Horseback is used for doctoring and moving<br />

cattle, but ATVs are preferred for all equipment related<br />

work such as fence maintenance.<br />

About 75% of the range is improved pasture, reseeded<br />

to orchardgrass, brome, alfalfa and timothy. For consistency<br />

Nelsons grow all their own feed. It is unusual<br />

to be able to do so. “We do enjoy economy of scale.” Hay<br />

growth this season (2015) was excellent – all irrigated.<br />

Three cuts are usual.<br />

“Never cut back, but adapt<br />

to changing realities.”<br />

Feedlot<br />

The ranch’s feedlot of 12,000 head are all owned, from<br />

the Nelson cow herd or purchased by private deals directly<br />

from area ranches. The source varies consider-<br />

We start with performance trials and testing programs to develop proprietary forage products. We then contract our forage seed needs<br />

with highly skilled Canadian seed growers, who work closely with our experienced field representatives to ensure our seed crops are of<br />

top quality. Our expert sales and technical staff are always ready to support and assist with forage product choices and agronomic needs.<br />

More milk …<br />

We are the Forage <strong>Leader</strong>s.<br />

In forage, fibre digestibility is one of the most important quality measures. The main benefit of<br />

high fibre digestibility is an increase in milk production.<br />

1% increase in fibre digestibility (DNDF) =<br />

+0.25 litres milk per cow per day<br />

The importance of high fibre digestibility is supported by independent research work that is well<br />

acknowledged throughout the world. Fibre digestibility is a key focus of the DLF global research<br />

platform.<br />

Forage for Beef<br />

We offer a wide selection of legumes, grasses and designed forage mixtures to meet your needs for beef and:<br />

Increase the daily gains of calves and yearlings<br />

Supply all of the energy and protein needs, as well as nearly all of the minerals and vitamins<br />

Provide a more even seasonal distribution of forage<br />

Provide a higher level of herd health<br />

Produce surplus hay and additional income<br />

pickseed.com<br />

10 AGRI LEADER » 2016

ably. “We know the herds well and some buy Nelson<br />

bulls,” says Jeff. “The feedlot tracks each individual<br />

herd’s calves using Fusion feedlot soft-ware. This provides<br />

a herd-by-herd health and growth status for us to<br />

compare and to use for future cattle purchases.”<br />

“Our objective is to reduce stress at all stages,” continues<br />

Jeff. “We follow Temple Grandin’s guidelines<br />

whenever applicable.”<br />

The first 21 days after weaning are critical. When<br />

calves arrive, they are given a full vaccination shot right<br />

off the truck and moved onto feed and water. Weather<br />

is a factor. If wet, especially if bedding is wet, or dusty<br />

conditions prevail, calves suffer. Calves that have only<br />

been on natural-source water may have difficulty adjusting<br />

to water troughs. If the mothers had access to<br />

water troughs, calves observe and learn. They come<br />

looking for water and adjust much faster. Similarly, if<br />

the mothers have been at a feed bunk, or if calves have<br />

had access to creep-feed, they come looking for feed.<br />

The Nelson ranch has many different water sources<br />

– springs and lakes, spring fed waterers and solar powered<br />

pumps into troughs. Across the range, water quality<br />

is excellent.<br />

The various conditions of herds means a diverse<br />

weight range in the feedlot, from 450 to 700lb. Calves<br />

are grouped and fed by weight, so the farm is able to<br />

sell fat cattle year round.<br />

A background ration of mostly silage is fed initially<br />

with a daily gain of 1.5 to 2.0lb. They feed for a slower<br />

growth initially to push out at a later date. On full feed,<br />

a 3.0 to 3.5ADG yields a 1350 to 1500lb market-ready<br />

steer. “Huge improvements have been made in genetics<br />

and nutrition in the past 20 years to push the finished<br />

weights to these levels from 1100 to 1200lb at<br />

that time,” says Jeff.<br />

Fat cattle are marketed by pen groups for uniformity<br />

and weight. Most are shipped to Cargill. Grade-out has<br />

been Prime 2-5%, 65% AAA, and 25% AA, and a few at<br />

A-Standard grade.<br />

Feed rations for the feedlot have been developed by<br />

Hi-Pro nutrition staff for many years. With the purchase<br />

of New Life Feeds by Hi-Pro Feeds in December<br />

of 2014, Doug Holt, the sales representative who has<br />

been the rep for the Nelson cow/calf herd for about 20<br />

years, has moved over to Hi-Pro and assumed responsibility<br />

for the feedlot as well.<br />

“The transition to Hi-Pro with all our feed business<br />

was seamless,” says Jeff. “The same people, now more<br />

support with more nutritionists on staff. We have appreciated<br />

our relationship with Doug and his great service<br />

for many years and look forward to many more at<br />

Hi-Pro.”<br />

(top photo) The feed mill, forage and commodity storage with a<br />

corner of the feedlot in the foreground<br />

Fall roundup with the next generation helping the cowboys<br />

process calves<br />

Photo credits Nelson Family<br />

AGRI LEADER » 2016<br />

11

The feedlot uses 10 different rations, all custom formulated<br />

for the requirements of each specific group<br />

– from backgrounding, transitioning to finishing, plus<br />

separate diets for cow/calf, creep, and breeding stock.<br />

The background ration is based on 80% silage (corn,<br />

alfalfa and barley) and 20% grain (barley, millrun, and<br />

or wheat). Hay is only fed in the first week to background<br />

the calves.<br />

The ration adjusts in 10% increments to the 80%<br />

grain/commodity finisher diet for the last 100 days –<br />

the length of time required to achieve the maximum<br />

AAA grade out.<br />

Jeff explains, “Our mill has capacity for many ingredients,<br />

allowing for the use of least-cost ration formulation<br />

giving us the best price advantage, adding to<br />

profitability.”<br />

Doug points out, “Jeff does more market research<br />

and speculation than most, following all markets to<br />

find the best value on any commodities. He has the industry<br />

information and is seen as a commodity market<br />

specialist. Neighbours seek his advice.”<br />

“We must align<br />

ourselves to where<br />

the future is.”<br />

Future<br />

When asked about future plans, Jeff points back to<br />

the fundamentals, “Diversification and innovation.<br />

Cattle numbers were and still are down across the industry,<br />

so we expect good opportunity. Five years ago<br />

we expanded the herd. Seven years ago we identified<br />

opportunity to develop our gravel resource and added<br />

construction equipment. Ten years ago we grew the<br />

grain farm. I believe these decisions fit together well<br />

in terms of labour, equipment and land-base. Remember<br />

the future of agriculture looks good. We must align<br />

ourselves to where the future is. That is our business<br />

model.”<br />

Recently the Nelson family developed recreation<br />

properties on the Ridge Reservoir Lake that borders<br />

their land. They built roads, put in water, sewer and<br />

power. The first lots sold in the summer of 2015, and<br />

the venture looks positive.<br />

“<strong>Agri</strong> tourism has possibilities, and with a large family<br />

with lots of youth coming on, we ask, how can we<br />

include the next generation in the family operations.<br />

Our motto continues to be: family and community, work<br />

hard, play well, and get the work done when needed,”<br />

concludes Jeff.<br />

With their many resources, the diversified operations<br />

and their strong family and community commitment, be<br />

assured Nelson Family Ranches Ltd will continue to be<br />

a successful family company well into the future.<br />

12 AGRI LEADER » 2016<br />

Grain and silage corn harvests<br />

– Photo credit Nelson Family

Custom Cow/Calf<br />

Feeding Program<br />

Raylene Boehmer, B.Sc.A., Senior Nutritionist, Hi-Pro Feeds, Lethbridge, AB<br />

Raylene Boehmer<br />

The beef industry is facing unique challenges in<br />

western Canada. With low cow inventories, feeder calf<br />

and replacement prices are high. However, with the<br />

drought that affected much of the cow/calf regions of<br />

western Canada, forage supplies are low. This has left<br />

many ranches scrambling for alternatives to feeding<br />

forages or programs that will stretch out the limited<br />

supplies available.<br />

Feeding straw is always an option for wintering beef<br />

cows but requires proper supplementation. Cows cannot<br />

eat or digest enough straw to meet their nutritional<br />

requirements. Providing degradable protein is essential<br />

for the digestion of the high fiber, low protein straw.<br />

The supplemental protein must be available to the rumen<br />

microbes to encourage microbial growth. It is<br />

these microbes that play an essential role in breaking<br />

down the fiber and converting it to energy for the cow.<br />

The fiber digestion is also important to prevent impaction.<br />

Without enough rumen microbes to digest the<br />

fiber, impaction can occur. A properly balanced program<br />

of free choice straw and 5 to 7lbs of supplement<br />

works well for wintering cows, but should be adjusted<br />

at about 6 weeks prior to calving. A program of free<br />

choice straw and 5 to 7lbs of supplement works well for<br />

wintering cows, however this program does not provide<br />

enough energy for the increased demands on the cow<br />

for fetal growth and lactation. It should be adjusted at<br />

about 6 weeks prior to calving.<br />

The best quality forages should be saved for feeding<br />

cows in the last month of gestation and through calving<br />

and lactation. Supplies can be stretched out by limit<br />

feeding through the winter and providing either straw<br />

or other high fiber byproducts. Forage replacement<br />

pellets can be economically included to supplement<br />

limited forage supplies. Pellets can be formulated to<br />

provide all nutrients that are deficient in a limited forage<br />

program. Energy, protein, minerals, vitamins and<br />

even ionophores can be included in the pellet.<br />

Customized feeding programs are very important for<br />

cow/calf operations. The program needs to be put together<br />

for the type and amount of forage available on<br />

each ranch. Hi-Pro has tools that look at the economics<br />

of feeding options. This helps to make optimal purchasing<br />

and feeding decisions for maximum profitability<br />

and success.<br />

This program looks at each stage of production to<br />

see where available forages can best fit. Nutrient requirements<br />

change through the reproductive cycle. It<br />

is important to meet the requirements but it is costly to<br />

exceed the requirements.<br />

Hi-Pro offers a wide range of products to provide<br />

proper nutrition to balance with available forages.<br />

Products vary from a complete mineral feeding program,<br />

to cubes for feeding on the ground, to textured<br />

or pelleted creep feeds, to beef supplements and premixes,<br />

to bull rations, to forage replacement pellets, to<br />

feedstuff commodities. Hi-Pro is committed to provide<br />

support and products that can help to make the cow/<br />

calf operator a success.<br />

An example of a report generated from this tool looks<br />

like the chart on the next page. A summary is below.<br />

AGRI LEADER » 2016<br />

13

The size of Canada’s cattle herd is still in decline and almost a<br />

quarter smaller than its peak in 2005, Statistics Canada reports.<br />

The federal statistics agency on Thursday released estimates<br />

showing the herd at 13 million cattle on farms on July<br />

1 this year, down 2.1 per cent from the same date in 2014.<br />

Total cattle inventories at July 1 showed their greatest declines<br />

in Saskatchewan and Alberta, down three per cent at<br />

2.715 million and down 2.8 per cent at 5.3 million respectively,<br />

compared to July 1, 2014.<br />

Except for steers, up four per cent at 65,400 head, overall<br />

cattle inventories declined compared to July 1 last year, with<br />

the number of beef cows on Canadian farms down 3.4 per<br />

cent at 3.8 million head, and beef heifers held for breeding<br />

down 0.6 per cent at 612,600 head, StatsCan said.<br />

Canada’s farmers had 1.4 million dairy cows and heifers<br />

on their farms, down 2.2 per cent. Overall, the number of Canadian<br />

farms reporting inventories of cattle and calves sat at<br />

82,050, down 0.6 per cent.<br />

Both slaughter and exports fell during the first half of<br />

2015 compared with the same period in 2014, StatsCan said.<br />

“While cattle prices remain strong so far in 2015, limited cattle<br />

supplies mean that there are fewer animals available to<br />

market.”<br />

January-to-June cattle slaughter decreased 13.5 per cent,<br />

to 1.4 million head, compared with the first six months of<br />

2014, while exports fell 21.4 per cent, to 491,500 head.<br />

Canada’s total inventory of cattle and calves on July 1 was<br />

23 per cent below its peak level recorded in 2005, StatsCan<br />

noted.<br />

Alberta Ag News August 21, 2015<br />

14 AGRI LEADER » 2016

U2 Ranch Ltd – Joanne & Darren Unger<br />

One Couple’s Journey<br />

to Elite<br />

Genetics<br />

Darren and Joanne Unger have developed<br />

an elite herd of pure-bred Angus<br />

over the past 20 years to establish<br />

a North American wide reputation for<br />

superior genetics. Their bulls - and<br />

semen and embryos - have been sold<br />

across Canada, into the US and recently<br />

into South America.<br />

They operate U2 Ranch just north<br />

of Coaldale, Alberta, with the ranch<br />

head-quarters and cropland located<br />

on river-bottom land along the Oldman<br />

River. The pure bred herd of 650<br />

cows, about two-thirds Red Angus, is<br />

the result of years of selection, growth<br />

and development beginning with a<br />

foundation of 20 pure bred cows.<br />

However their journey into the cattle<br />

business faced major challenges.<br />

Darren and Joanne Unger with Joe McLean, Hi-Pro Beef Specialist, Alberta South.<br />

(below) U2 cattle on irrigated pasture along the river bottom land of Old Man River<br />

“The first year, cattle prices dropped dramatically,”<br />

says Joanne. “Calf prices were 80 to 85 cents! Yet<br />

somehow we survived.” “Barely,” adds Darren. “It was<br />

Photo credit U2 Ranch<br />

AGRI LEADER » 2016<br />

15

a stressful time. We’ve been through ups and downs<br />

and sometimes it seemed like mostly downs.”<br />

However, later when the BSE crisis hit, Joanne explains,<br />

“As a pure bred herd selling breeding stock, the<br />

pain was not as great as many ranchers faced.”<br />

Both Joanne and Darren grew up in the region; Darren<br />

on a row-crop farm growing peas, sugar beets, and<br />

beans. Joanne’s family ran a mixed farming operation<br />

that consisted of a cow-calf herd, farrow to finish<br />

hog operation, feedlot and crop production. “We both<br />

learned the hard work of farming and were anxious to<br />

acquire our own place after we married in 1992,” says<br />

Darren. “We bought our first ranch the next year at<br />

Wrentham, with 350 heifers. Twenty of that group we<br />

purchased were pure bred.”<br />

In 1997 they sold that first ranch and bought a farm<br />

more geared to crop production. It wasn’t the perfect<br />

place for the beef operation but was part of their expansion<br />

plans. At this time they sold all their commercial<br />

cattle. That core group of 20 pure bred cattle, 60 at<br />

the time, became the foundation of the U2 herd today.<br />

“The core group was mostly 10 year old mature cows<br />

with excellent genetics,” says Darren. “Over the first 15<br />

years we kept our quality females to grow the numbers<br />

so our cow herd has been mainly a closed herd since<br />

1997.”<br />

For the expansion period, they used AI (artificial insemination),<br />

bought some herd bulls and used AI from<br />

their own bulls. In fact now they collect semen from the<br />

best bulls and use AI on about 500 cows, almost 80% of<br />

the herd.<br />

Herd Management<br />

Calving at U2 is in January and February with breeding<br />

beginning April 1st. During breeding, Joanne and<br />

Darren make a fine team. She watches for heats, and<br />

Darren does the AI. First service conception rate is an<br />

impressive 70%.<br />

Calving occurs outside, often in extreme cold. “We<br />

have less than five minutes to bring the calf and dam<br />

into the calving barn. Here the calf is weighed, given<br />

first vaccinations, and after ensuring the calf is off to a<br />

good suck and is fully dry, mother and calf will be back<br />

to an outside pen, usually within 24 hours.”<br />

The fresh cow diet in winter is silage based with either<br />

corn or barley silage, mixed with a large portion<br />

of straw. No baled hay is fed on the ranch. In spring,<br />

cows are managed the same as a commercial herd with<br />

strict culling practices. Cows are usually turned out on<br />

range by June 1st onto native pasture.<br />

Bull calves, weaned at the end of August, average<br />

around 750lb, and heifers a month later average about<br />

700lb. “We like to see the bull calves in pens, settled<br />

16 AGRI LEADER » 2016

on feed, as at this weight, they would not be growing<br />

enough on milk even with creep feed.” Note that the U2<br />

herd is on the early calving regime in Jan and Feb. We<br />

believe in weaning early as these calves are already 6-7<br />

months of age.”<br />

Darren explains their philosophy about raising bulls,<br />

“We’ve built a strong genetics base with the AI program<br />

and purchased select bulls. Our observations as breeders<br />

are essential. If I don’t like it, how can I sell it? We<br />

are told by buyers that our bulls are very quiet, and<br />

easy to manage. We feel this is a direct result of genetic<br />

selection and proper management.”<br />

“If I don’t like it,<br />

how can I sell it?”<br />

All calves are registered as required before 6 months<br />

on the Angus Association program that includes birth<br />

weight (averaging 80lb), weight at 205 days and as a<br />

yearling at 365 days. Weights range mostly from 1350<br />

to 1500lb with a few below and several above 1600.<br />

Bull Sales<br />

“Since 2004, the main event for marketing our cattle<br />

has been the annual U2 Ranch Bull Sale held every<br />

March. This year marks the 20th sale to be held Tuesday,<br />

March 22, 2016 at Foothills Auctioneers in Stavely,<br />

AB. There will be 170 U2 bulls on offer featuring ‘high<br />

end’ bulls in volume and in everyone’s price range,”<br />

Darren explains. “We firmly believe and take pride in<br />

the fact that our customers get the most bull for their<br />

dollar at our sale”<br />

“…our customers get the<br />

most bull for their dollar…”<br />

In past years the Ungers have participated in cattle<br />

shows such as the <strong>Agri</strong>bition in Regina, the Canadian<br />

Red Roundup in Red Deer and the Edmonton Farm Fair.<br />

But as the ranch and related work grew, and the U2<br />

brand became well known, travelling to shows has declined.<br />

A bull sale catalogue is available from the Ungers<br />

– 1600 copies were produced last year. Further information<br />

as a down-loadable sale catalogue is available<br />

through their web site – U2ranch.ca.<br />

“Our philosophy related to bull sales is establishing<br />

buyer confidence with strong customer service, the<br />

same as any other customer based business,” says<br />

Joanne. “We deliver any bull to the purchaser, we fea-<br />

Cattle at U2 Ranch (top to bottom), on pasture and in corals, buyers<br />

looking over the fine crop of yearling bulls, and mature bulls<br />

in a straw bedded pen - Photo credit all three photos U2 Ranch<br />

AGRI LEADER » 2016<br />

17

ture injury replacement, and we invite potential buyers<br />

to come and look at the ranch, and then go to the sale.<br />

We build relationships with our buyers.”<br />

“We build relationships<br />

with our buyers.”<br />

Darren offers, “Joanne is a great support as my ranch<br />

partner who is passionate about customer service with<br />

a keen marketing sense.” To which Joanne replies, “It‘s<br />

mutual.”<br />

It is obvious that Darren and Joanne are a great egalitarian<br />

team, evident in the U2 Ranch success.<br />

He continues the business philosophy discussion, “A<br />

good bull is the best and most economical investment<br />

for any herd. A poor bull eats the same feed and requires<br />

the same attention. That’s what I’ve learned over<br />

the years. We buy bulls too.<br />

“Over two thirds of sales are repeat customers. The<br />

bulls sell themselves, especially if the customer has<br />

seen the performance of a U2 bull on his or a neighbour’s<br />

ranch and experienced the customer service of<br />

U2. This is probably more important than the EPD numbers<br />

provided for every bull. It is network marketing. It<br />

is repeat business.<br />

“Recently heifer sales have been an opportunity as<br />

U2’s own herd expansion has leveled off.” Darren continues.<br />

“There is a demand for PB females down in<br />

the States with cows selling for herd expansion and<br />

as donors. We have sold groups of females to breeders<br />

in Colorado, Texas, Oklahoma, Nebraska and the<br />

Dakotas. Show heifer prospects have sold to breeders<br />

all over the U.S and have proudly represented us at<br />

Denver, Fort Worth, Kentucky, Houston and Louisville<br />

Stock Shows.”<br />

The family home near the Old Man River, pivot irrigated alfalfa<br />

field, and forage harvest at U2 – Photo credit harvest photos U2<br />

18 AGRI LEADER » 2016

Crop Farming<br />

In addition to 700 acres of native pasture, and a considerable<br />

amount of leased grazing land, U2 Ranch<br />

farms 300 acres silage corn and about 60ac barley under<br />

three pivots. Corn silage yields are typically 20 to<br />

22 ton per acre but with the weather conditions of 2015,<br />

yields were up to 25 ton.<br />

This crop acreage utilizes all the manure the cattle<br />

provide with room for more cattle. About a third of the<br />

farm receives manure applications each season.<br />

The ranch operates a full line of equipment for their<br />

own crops and as a custom silaging enterprise – planting,<br />

chopping, bagging – mostly for dairy farms in the<br />

area. Their harvester is a Claas Model 900 and bagging<br />

equipment is AgBag.<br />

Family and Labour<br />

The Ungers have two children. Son Cole, 21, who is<br />

keen on a future in ranching, has completed an engineering<br />

diploma and is accepted in a professional engineering<br />

program. “Education is essential and provides<br />

a good fallback position,” Darren reminds him. Daughter<br />

Jordy, 18, has just entered pharmacology studies in<br />

Calgary looking forward to a career in pharmacy.<br />

The ranch employs three full-time workers. In addition<br />

more help is employed during crop season to help<br />

with the custom silage operations.<br />

“When we talk about our team of people, an important<br />

member of the team is Joe McLean, [beef sales<br />

rep from Hi-Pro Feeds], who has been our contact for<br />

most of our years in the business,” says Darren. “He<br />

and their nutrition staff are an essential part of our operation”.<br />

Joanne adds, “We relate to the Hi-Pro Feeds slogan<br />

that says, ‘Invested in animal nutrition’. We as their<br />

customer are invested in animal agriculture in partnership<br />

with them. Joe has been a great support to us; he<br />

is knowledgeable, service oriented and a good friend.”<br />

Future<br />

When asked about future plans, Darren was quick to<br />

reply, “We do not have expansion plans as more cows<br />

means more land that is simply not available. We already<br />

lease a lot of grazing land. Also, the present work<br />

load is more than enough, so we are focused on innovation<br />

and continuous improvement of the quality of the<br />

herd we have.”<br />

In conclusion he adds, “There will always be room for<br />

good cattle, and we position our business for people<br />

who recognize the value of excellent genetics. Local<br />

commercial customers are still our priority, our main<br />

concern and our focus. At the same time in the past<br />

three years, we have built good relationships with customers<br />

in the US. We are excited to see that market<br />

develop as well.”<br />

“There will always<br />

be room for good cattle”<br />

The U2 herd is already<br />

considered an elite genetics<br />

source for ranchers<br />

across western<br />

Canada, into the US and<br />

beyond. Recently they<br />

sold the first semen and<br />

embryos into Argentina.<br />

The future is always<br />

bright for quality, backed<br />

by excellent service and<br />

strong relationships.<br />

Everyone recognizes<br />

the U2 name, some because<br />

of the well-known<br />

rock group, but more importantly,<br />

many because<br />

of the quality genetics<br />

from the U2 Ranch operated<br />

by 2 Ungers.<br />

Darren, Cole, Jordy and<br />

Joanne Unger – Photo credit<br />

Unger family<br />

AGRI LEADER » 2016<br />

19

SERVICE<br />

Expect the kind of customer service that you can only get from an owner.<br />

At Hi-Pro Feeds, we act like owners because we are. Most Hi- Pro employees<br />

are also shareholders. Like you, we are invested in this industry and<br />

committed to providing the support you need to keep your operation running<br />

smoothly. Our word means something—we do what we say and stand behind<br />

our products. We know what it takes for you to be successful in your business<br />

and we go out of our way to make sure that you get what you need, when you<br />

need it.<br />

EXPERTISE<br />

Quite simply, our animal nutrition expertise will help you to get the most out of your feed, and more importantly,<br />

your operation. It all starts with our animal nutrition specialists. We work with our customers to understand their<br />

needs and develop the optimum feed formulation for their application. We bring the latest in animal nutrition<br />

knowledge and experience to your operation so that you can focus on running your business. Our nutrition specialists<br />

work closely with our manufacturing team to ensure that your feed is produced and delivered to specification—every<br />

time.<br />

NUTRITION<br />

Not all feed is created equal. At Hi-Pro Feeds, we produce only the highest performing feed products to the most<br />

stringent standards and with an unwavering focus on consistent quality. Our animal nutrition experts work with<br />

you to make sure that we provide the optimum feed formulation for your application. Our tight manufacturing standards<br />

ensure that we continue to meet that specification over time. We offer a complete range of animal nutrition<br />

products across a wide range of species and our feed products have contributed to many award winning animals.<br />

Animal Health & Nutrition<br />

www.robinsonbioproducts.com<br />

Tel: 403-938-0556 Toll Free: 888-968-0556 Fax: 403-938-0022<br />

20 AGRI LEADER » 2016

Creep Feeding<br />

Beef Calves<br />

Raylene Boehmer, B.Sc.A, Senior Nutritionist, Hi-Pro Feeds, Lethbridge, AB<br />

Creep feeding is to provide beef calves with supplemental<br />

feed and nutrients before weaning. Calves typically<br />

only receive nutrients from milk and grass in the<br />

pre-weaning period. Supplemental feed can be provided<br />

in a creep feeder that will only allow calves access<br />

to the feed and not the cows. Providing a creep<br />

feed makes it possible to increase weaning weights, increase<br />

stocking density and decrease weaning stress.<br />

Increased Weaning Weights – calves of most beef<br />

breeds are capable of growing at a rate of 2 lbs per<br />

day from birth to weaning. However, by the time the<br />

calf is 3 months old, the cow’s milk will generally not<br />

supply enough nutrients for this level of growth. As an<br />

example, a 200 lb calf requires about 25 lbs of milk to<br />

gain 2 lbs per day. If the cow is only producing 15 lbs of<br />

milk, the calf must consume about 5 lbs of good quality<br />

pasture dry matter to maintain growth. If the pasture<br />

is in poor condition, which is likely what is causing<br />

the poor milk production in the cow, the calf<br />

cannot consume enough nutrients to maintain<br />

the 2 lb growth rate. However, a creep feed can<br />

supply the necessary nutrients for this growth.<br />

Increases in weaning weights associated with<br />

creep feeding are quite variable due to variability<br />

in pasture conditions. There are limited increases<br />

with good quality pasture that supports<br />

milk production and calf growth. However, if<br />

the pasture is dry and in poor condition, there<br />

can be significant gains in weaning weights.<br />

Research has shown an average increase of 40<br />

lbs in weaning weights of creep fed calves, with<br />

most calves increasing anywhere from 25 to 60<br />

lbs, depending on pasture conditions.<br />

Increased Pasture Stocking Rate - calves<br />

tend to consume creep feed rather than forage.<br />

Therefore, pasture stocking rates can be<br />

increased when a creep feed is provided. It is<br />

estimated that for every 1.0 lb of creep feed consumed,<br />

forage dry matter intake will decrease<br />

by 0.5 lb to 1.0 lb. This can represent an additional<br />

10 cow/calf pairs for every 40 calves that<br />

are creep fed.<br />

Decreased Weaning Stress - calves with access<br />

to creep feed will be accustomed to eating<br />

grain and will be less dependent on milk from<br />

the cow. Weaning can take place with reduced stress<br />

as calves easily transition onto a diet without milk.<br />

Creep fed calves are easier to start on feed and quicker<br />

to regain shipping weight losses.<br />

Economics must be considered when making the decision<br />

to creep feed. When grain prices are high relative<br />

to calf prices, it may not be profitable to provide<br />

creep feed. Feed conversions are highly variable and<br />

yet have a big impact on the economics. Research has<br />

shown that the creep feed to gain ratios can range from<br />

5:1 on poor quality pasture to 15:1 on high quality pasture.<br />

Hi-Pro has developed tools to help in the decision<br />

on providing a creep feed. Based on expected weaning<br />

weights, calf price, feed conversion and creep feed<br />

price, it is possible to determine the return (or loss)<br />

from providing a creep feed.<br />

ECONOMICS OF CREEP FEEDING<br />

NO CREEP<br />

WITH CREEP<br />

Weaning Weight (lb) 500 550<br />

Calf Price at Weaning ($/lb) $2.00 $2.00<br />

Value of Calf at Weaning ($/head) $1,000.00 $1,100.00<br />

Lb Creep Required/Lb Extra Gain 8<br />

Lbs Creep Required/Head 400<br />

Price of Creep Feed ($/MTD) $300.00<br />

Notes:<br />

Total Cost of Creep Feed ($/Head) $54.45<br />

Net Value of Calf ($/head) $1,000.00 $1,045.55<br />

RETURN FROM CREEP FEEDING ($/head) $45.55<br />

1. Research shows the average increase in weaning weight from creep feeding is 40 lbs, with most<br />

calves falling in the range of 25 to 60 lbs, depending on pasture condiYon.<br />

2. Expected Feed Conversions depend on pasture condiYon & milk producYon:<br />

-‐ Excellent pasture & above average milk producYon 14:1 to 18:1<br />

-‐ Average pasture & average milk producYon 8:1 to 10:1<br />

-‐ Poor quality pasture & poor milk producYon 4:1 to 6:1<br />

3. Return is only over cost of creep feed. It does not include cost of the creep feeder or added labor.<br />

AGRI LEADER » 2016<br />

21

Electronic Sow Feeding System<br />

Product Features and Advantages:<br />

SOW CARE SOLUTIONS<br />

- 24/7 Service<br />

- 60 - 70 sows per station.<br />

- Group size from 40 to 400 sows.<br />

- Static or dynamic groups.<br />

- Computer-Controlled feeding.<br />

- Feed up to three types of feed.<br />

- Can eat meals on own schedule.<br />

- Protected from other sows.<br />

- Automatically sorted - selection data.<br />

Rondomat 3S Feeder<br />

STORAGE BINS<br />

CALL US TODAY!<br />

Grain Handling Equipment & Storage Systems<br />

Custom Automation & Blending Control Panels<br />

Poultry & Swine Barns: Equipment & Accessories<br />

Construction, Fabrication & Design Services<br />

Feed Milling & Oil Seed Processing<br />

Government Applications & Local Permits<br />

Call TOLL FREE: 1-866-893-3302<br />

18 Burnt Valley Avenue, Red Deer, AB T4P 0M5<br />

Email: norag@noragltd.ca

OB Colony – Marwayne, AB<br />

Many Enterprises at OB Colony<br />

Beef Feedlot and<br />

Dairy are Featured<br />

OB Colony was established in 1957 as a division<br />

of Thompson Colony, Fort MacLeod. They are located<br />

near Marwayne, AB, only 30 minutes northwest<br />

of the City of Lloydminster. The interesting<br />

name, OB, is derived from Mr O’Brian, a Texan,<br />

from whom the first 3000 acres were purchased<br />

in 1954.<br />

Sam Hofer, who manages the carpentry shop<br />

and all construction (and there has been a lot of<br />

building recently), describes the farming operations.<br />

“Today OB Colony owns 9800 acres with<br />

about 8600ac seeded in crops – 3000 in wheat,<br />

3000 canola, 700 peas, 1750 in barley (both grain<br />

and silage), 70 to 80 in potatoes and 160 in silage<br />

corn. The corn and potatoes are irrigated but the balance<br />

is dryland farming. The rest of the land is pasture<br />

with a generous amount of lakes and marshes.”<br />

The potatoes supply the Cold Lake, AB air-force base<br />

and are also sold to local grocery stores.<br />

“The Colony’s two crop sprayers led naturally to custom<br />

spraying in the region, now up to about 20,000 acres<br />

total spring and fall. However, the labour requirement<br />

for this operation is high and custom spraying may be<br />

reduced.”<br />

The operations traditionally were beef – a cow/calf<br />

herd of 500 cows, all pure bred Hereford, and a feedlot<br />

with 1400 capacity (the feedlot and the 160 lactating<br />

cow dairy enterprise are featured later). The beef cow<br />

herd was sold about six years ago. “An unfortunate decision<br />

with today’s beef prices,” states Sam. “Diversification<br />

is essential as rarely can we predict the future<br />

accurately.”<br />

(right) Sam Hofer and Robert Kassian, Hi-Pro Colony Sales Manager.<br />

The fine wolf skin on the wall was hunted and tanned by Sam.<br />

Below, the OB Colony at Marwayne, AB<br />

Other livestock include a flock of 110 ewes where<br />

the Colony made major feeding changes recently. Sam<br />

explains, “We went to complete feed starting with Hi-<br />

Pro’s 18% Lamb Creep right through the grower and<br />

finisher stage instead of our on-farm mixing. Lambs<br />

achieved market weight a month earlier! Also, we have<br />

seen many fewer problems since we used the Hi-Pro 1<br />

to 1 Mineral. Foot rot was an issue on our alkaline soils<br />

but it is gone.”<br />

“…rarely can we predict<br />

the future accurately.”<br />

The Colony’s poultry enterprises were dealt a serious<br />

blow when a Salmonella out-break spread through<br />

the central and northern region of Alberta in February<br />

2015. It affected many producers, including six Colonies.<br />

AGRI LEADER » 2016<br />

23

“The depopulation of our flocks, both layer and pullets,<br />

did provide an opportunity to rebuild aging facilities<br />

originally built in 1977,” explains Sam. “We tore<br />

down the entire building and are rebuilding with a modern<br />

structure and equipment.”<br />

They have one year to complete the reconstruction<br />

without loss of quota, and that will be a challenge to<br />

get it done in that period. Acquiring all necessary permits<br />

and ordering equipment from Europe takes 6 to 8<br />

months.<br />

The new layer facility, 225 by 50 feet, will feature the<br />

Big-Dutchman Enriche Colony cages that hold 70 birds<br />

per cage in a three tier configuration, including dry manure<br />

belts and egg collection system.<br />

The Colony holds 6000 bird quota but are building for<br />

10,000 capacity. They plan to lease quota and buy additional<br />

when available. The pullet barn will be built later<br />

when the construction pressure is past, as pullets are<br />

available for purchase from other producers.<br />

Other poultry raised at OB includes broilers (4000 per<br />

8 week placement), 1200 ducks, 300 geese, plus 350<br />

turkeys for the Thanksgiving period only. All poultry are<br />

self-butchered on site.<br />

In closing, Sam adds, “We greatly appreciate Hi-Pro<br />

Feeds’ products, their nutritional advice, but above all,<br />

our representative, Robert Kassian who has been our<br />

contact and friend for many, many years.”<br />

Water supply, both quality and quantity, was historically<br />

a major problem for OB. About 35 years ago,<br />

they made the difficult decision to spend a million dollars<br />

to install a water system with a 12 inch water line<br />

pumped from the North Saskatchewan River. The water<br />

is pumped a distance of 3 kilometers into a reservoir<br />

on a high point on the property. Then another line<br />

was installed to gravity flow to the Colony site – another<br />

3 kilometers. The result has been excellent.<br />

A non-agricultural enterprise that has developed in<br />

the past two years is the refitting of propane tanks for<br />

the Superior Propane Company. The refurbishing includes<br />

sand-blasting the tanks, painting and refitting<br />

all valves and lines. Colony men are now fully certified<br />

to completely refit the tanks to final certification as new.<br />

Tanks are mostly 500 and 1000lb sizes, but 100lb and<br />

20’s or 30’s are also refitted. Six men are the propane<br />

crew: two for sand-blasting, two for painting and two<br />

for refitting. The business has grown to an inventory on<br />

site of about 1000 tanks. It meant the Colony needed to<br />

construct a new building to accommodate this growing<br />

and profitable enterprise. It is 200 by 90 feet completed<br />

in time to work inside this winter.<br />

Tabletop Stone Mill EM-25/250 UL/CSA approved<br />

Capacity up to 150lbs/hr<br />

DanSon-SKIOLD Inc, Edmonton AB<br />

708-432-6313 or danvas@shaw.ca<br />

The Right Solution for Whole Wheat Flour<br />

24 AGRI LEADER » 2016

Beef Feedlot<br />

One of two operations to be featured at OB is the beef<br />

feedlot. Gideon Hofer is the manager and his assistant<br />

manager is Steven. The lot capacity is about 1400 feeders<br />

plus 600 yearlings. The cow herd of 500 was sold<br />

five years ago.<br />

“The grazing land has been rented out since the herd<br />

was sold but we are planning to get back into cow/calf,”<br />

says Gideon. “The acres are available, and with yearlings<br />

the dollar gain is only on the difference in prices<br />

from fall to spring. We think the diversification of our<br />

beef enterprise is important.<br />

“Previously the herd was on early calving in January<br />

and February, but we would probably go back to traditional<br />

March/April calving.”<br />

Calves are currently purchased in fall directly from<br />

area ranchers, right off the range. The mix is typically<br />

half British and half exotic breeds. The Colony’s dairy,<br />

(featured later) also supplies all the bull calves as<br />

steers to the feedlot. After the dairy calves are weaned<br />

at 11 weeks, including being held in a group pen for a<br />

couple of weeks, they are transported to the feedlot and<br />

managed in separate pens from the main groups. Up to<br />

90 Holstein steers are fed each year.<br />

When asked about their best practices to achieve top<br />

results, Gideon and Steven described many factors.<br />

“First of all, we must pay attention to all the small details.<br />

There is not one big issue, but many small things<br />

make up the big one.”<br />

Here is a list of the small ‘things’ according to Gideon<br />

and Steven:<br />

--<br />

Recognize that each group of cattle is different<br />

from the next<br />

--<br />

Remember when you are buying you are also selling<br />

– think and plan ahead to market<br />

--<br />

Understand that for calves fresh off range the<br />

most critical issue is to get them on feed and water<br />

quickly. They require special attention<br />

--<br />

Body score all calves on arrival and sort into uniform<br />

groups<br />

--<br />

Recognize that creep-fed calves will score higher<br />

and will transition better onto full feed<br />

--<br />

Handle cattle gently, be quiet and content to develop<br />

calm animals<br />

--<br />

Anything out of the ordinary equals stress<br />

--<br />

Make animals as comfortable as possible<br />

--<br />

Maintain a routine, same time of every day to walk<br />

the pens, to feed, to push up<br />

--<br />

Initially, walk pens three times a day to acclimatize<br />

the calves to you<br />

The propane tank re-fitting enterprise at OB Colony, Gideon and<br />

Steven Hofer with Robert Kassian, (middle), Hi-Pro Colony Sales<br />

Manager, at the feedlot with feed mill in background<br />

AGRI LEADER » 2016<br />

25

--<br />

Walk pens first thing in the morning to observe<br />

and treat those that do not get up<br />

--<br />

Ensure feed rations are consistent as well as<br />

amount fed. Do not over feed<br />

--<br />

Feed twice a day initially<br />

--<br />

Clean bunks regularly<br />

--<br />

Check rolling of barley periodically for consistency<br />

and quality<br />

--<br />

Short cut silage eliminates sorting<br />

--<br />

Pay attention to silage face management<br />

--<br />

Ensure cattle have access to feed and water<br />

--<br />

Clean away manure from bunk area as needed<br />

--<br />

Float the pens regularly, especially after a rain<br />

--<br />

There is not one big issue, but many small things<br />

make up the big one.”<br />

“There is not one big<br />

issue, but many<br />

small things make up<br />

the big one.”<br />

live weight at shipping,” explains Gideon. “We target up<br />

to 1600lb so that at a 60% carcass weight, this is just<br />

below the maximum of a 1000lb carcass. If the carcass<br />

weight is over this limit, a heavy penalty of 35 cents per<br />

pound is deducted. Another point, we don’t strive for<br />

Prime grade as there is no price advantage.”<br />

In conclusion, Gideon repeats an earlier comment,<br />

“We must remember that when we are buying calves<br />

we are also selling. We must think and plan ahead to<br />

market because that is the end game. And in the meantime,<br />

we focus on the small details of the operation.<br />

They make up the big things.”<br />

“We must think and<br />

plan ahead to market…<br />

the end game.”<br />

OB Colony Dairy<br />

continued on page 29<br />

The feed rations for newly arrived calves off the range<br />

are based on 65% corn silage (at about 66% moisture).<br />

The balance is grain plus a Hi-Pro Custom pre-mix<br />

containing minerals, yeast, and medication. No hay is<br />

fed except to yearlings. Intake at 2% of body weight is a<br />

guideline for highly nutritious feed.<br />

Mid-way in the feeding period, at the 900lb stage,<br />

the silage/grain ratio is 50/50. At the finisher feeding<br />

phase, the ration is 20% corn silage, 75% grain and 5%<br />

supplement. At any given time, four different rations<br />

are used depending on the condition and weight of the<br />

animals.<br />

Beef breed calves are expected to gain 3.3lb/day from<br />

start to finish. The Holstein steers gain 3.0 and are<br />

ready for market at 1200lb, and Steven adds, “They are<br />

good for filling the truck to exactly the maximum total<br />

weight allowed. The dairy steers at 1200lb still achieve<br />

AA grade.”<br />

Over a six month period, fat cattle are shipped to market<br />

about every other month, 300 at a time. OB Colony<br />

has its own cattle liner, making the non-stop trip to JBS<br />

in Brooks in approximately five hours.<br />

Grade out has been consistent at 45 to 50% AAA and<br />

the balance AA with a few A. “Our average is 1530lb<br />

MS Topfoam<br />

MS Megades<br />

MS<br />

Greenline<br />

Mobile<br />

Cleaning<br />

Let the foam work for you!<br />

• A powerful alkaline soaking fluid<br />

• Clings better and lasts longer<br />

• Adhesion properties for removal of slurry,<br />

fats and feed residues<br />

• Economic to use, concentration of only 2%<br />

• 1 kg gives more than 100 m2 foamed surface<br />

• Very effective for of heavy soiling<br />

• Saves time and water<br />

Clean,<br />

Thorough &<br />

Fast<br />

Mycotoxins<br />

Mary Lou Swift, Ph.D., Director of Nutrition, and<br />

Jenilee Peters Tarasoff, B.Sc., Quality Assurance Manager<br />

Mary Lou Swift<br />

Jenilee Peters Tarasoff<br />

A mycotoxin is defined as “a secondary metabolite<br />

produced by organisms of the fungi kingdom” commonly<br />

known as mold. The term “mycotoxin” is relatively<br />

new (1962) and evolved after a large number of<br />

turkeys died in England (Bennett and Klich, 2003). The<br />

cause of death was determined to be aflatoxins in peanut<br />

meal. This incident spurred the scientific community<br />

into producing a large body of research on mycotoxins.<br />

Today, some 300 to 400 mycotoxins have been<br />

identified, but in practice, only 13 are of primary concern<br />

to animal health.<br />

While molds are easy to see, mycotoxins are not,<br />

and unfortunately, the presence of mold does not always<br />

indicate the presence of mycotoxins. Fungi that<br />

produce molds fall into two groups: those that invade<br />

before harvest and those that invade after harvest.<br />

Pre-harvest invaders include Fusarium. graminearum,<br />

F. moniliform and sometimes Aspergillus. flavus. Fusarium<br />

graminearum can produce a mycotoxin known<br />

commonly as DON (deoxynivalenol).<br />

In Western Canada, we normally are concerned about<br />

the level of this mycotoxin in grain, but we should not<br />

forget that small grain silages can test positive for DON<br />

as well as other mycotoxins in this family. Similarly,<br />

fungi growth on corn grown for silage can produce mycotoxins.<br />

Extreme mold growth can have obvious negative<br />

effects including changes in color, consistency and<br />

odor, which can lead to undesirable feeds. Nutritionally,<br />

mold growth can reduce the energy, protein and<br />

vitamin content potentially resulting in decreased performance,<br />

in high producing or growing animals. It<br />

is essential to minimize any mold growth during the<br />

growing season and while in storage.<br />

Nutritionally, mold growth<br />

can reduce the energy,<br />

protein and vitamin content<br />

There are many field conditions that influence the<br />

growth of molds and the production of mycotoxins,<br />

including moisture, temperature and the presence of<br />

fungal spores. Additionally, stress factors like drought,<br />

poor fertilization, high plant density, weeds, insects or<br />

mechanical damage from events like hail or lodging<br />

can weaken the plant’s natural defense and promote<br />

mold colonization and growth.<br />

While the mechanism of resistance is not well understood,<br />

one strategy employed for reducing mycotoxin<br />

levels in small grain crops such as barley is the<br />

development of resistant cultivars through breeding<br />

programs. Another strategy is the use of fungicides.<br />

These strategies have proven effective in the case of<br />

DON contamination.<br />

Other management practices include minimizing<br />

lodging, and careful management of crop residues<br />

and crop rotation. Crop residues may be of significant<br />

importance as increased DON concentrations have<br />

been documented in no-till or reduced tillage systems<br />

in comparison to clean tillage systems. Additionally,<br />

crops rotations that include small grains following corn<br />

or small grains planted continually can also increase<br />

the risk.<br />

Moisture and storage<br />

temperature are crucial<br />

Moisture content at harvest can be critical as moisture<br />

can facilitate the growth of fungi such as Penicillium<br />

and Aspergillus. After harvest, storage conditions<br />

dictate whether fungi will continue to grow and/or produce<br />

mycotoxins. Storage temperature is crucial as<br />

increasing temperature (improper fermentation) can<br />

result in the growth of other fungi causing further degradation.<br />

It is very difficult for fungi to in properly preserved<br />

feeds. Careful ensiling will prevent further mold<br />

development, although it will not destroy any mycotoxin<br />

already present. Good ensiling practices include harvesting<br />

at the proper moisture content, chopping to a<br />

uniform length, filling the silo/bunk rapidly, packing<br />

sufficiently, using an effective fermentation aid and<br />

covering completely. Essentially the goal is to reduce<br />

the pH quickly and eliminate oxygen effectively to reduce<br />

mold growth and mycotoxin production.<br />

AGRI LEADER » 2016<br />

27

Mold can grow in hay at moistures of 13% to 15%<br />

making it difficult to make hay dry enough to prevent<br />

mold growth. Dry down can be improved by increasing<br />

ventilation, leaving air spaces between bales, reducing<br />