You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

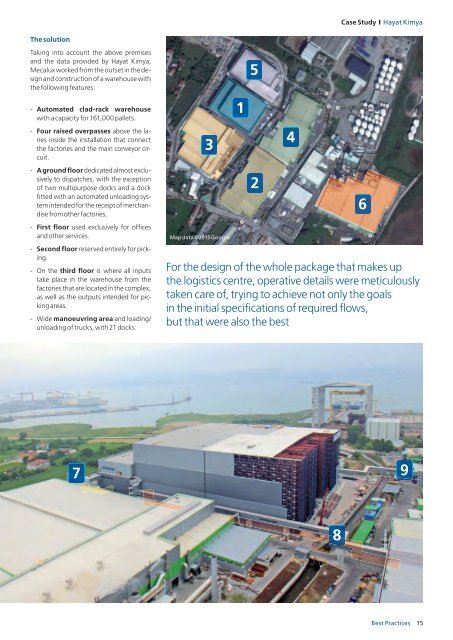

Case Study I Hayat Kimya<br />

The solution<br />

Taking into account the above premises<br />

and the data provided by Hayat Kimya,<br />

Mecalux worked from the outset in the design<br />

and construction of a warehouse with<br />

the following features:<br />

- Automated clad-rack warehouse<br />

with a capacity for 161,000 pallets.<br />

- Four raised overpasses above the lanes<br />

inside the installation that connect<br />

the factories and the main conveyor circuit.<br />

- A ground floor dedicated almost exclusively<br />

to dispatches, with the exception<br />

of two multipurpose docks and a dock<br />

fitted with an automated unloading system<br />

intended for the receipt of merchandise<br />

from other factories.<br />

- First floor used exclusively for offices<br />

and other services.<br />

- Second floor reserved entirely for picking.<br />

- On the third floor is where all inputs<br />

take place in the warehouse from the<br />

factories that are located in the complex,<br />

as well as the outputs intended for picking<br />

areas.<br />

- Wide manoeuvring area and loading/<br />

unloading of trucks, with 21 docks.<br />

3<br />

Map data ©2015 Google<br />

1<br />

5<br />

2<br />

4<br />

For the design of the whole package that makes up<br />

the logistics centre, operative details were meticulously<br />

taken care of, trying to achieve not only the goals<br />

in the initial specifications of required flows,<br />

but that were also the best<br />

6<br />

7<br />

9<br />

8<br />

<strong>Best</strong> <strong>Practices</strong><br />

15