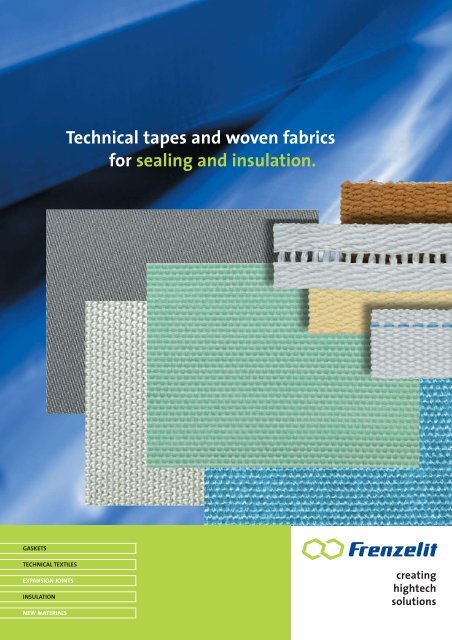

Technical tapes and woven fabrics for sealing and insulation.

Technical tapes and woven fabrics for sealing and insulation.

Technical tapes and woven fabrics for sealing and insulation.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GASKETS<br />

TECHNICAL TEXTILES<br />

EXPANSION JOINTS<br />

INSULATION<br />

NEW MATERIALS<br />

<strong>Technical</strong> <strong>tapes</strong> <strong>and</strong> <strong>woven</strong> <strong>fabrics</strong><br />

<strong>for</strong> <strong>sealing</strong> <strong>and</strong> <strong>insulation</strong>.

<strong>Technical</strong> <strong>tapes</strong> <strong>and</strong> <strong>woven</strong> <strong>fabrics</strong><br />

As a major supplier of technical textiles <strong>for</strong> use in gaskets<br />

<strong>and</strong> thermal <strong>insulation</strong> we help our customers to increase<br />

their competitive edge over their competitors.<br />

Frenzelit has been developing <strong>and</strong> manufacturing textiles<br />

which are capable of withst<strong>and</strong>ing high temperatures <strong>for</strong><br />

more than 50 years. We listen to customer requirements,<br />

<strong>and</strong> give pro-active support throughout the development,<br />

sampling <strong>and</strong> manufacturing processes.<br />

Your advantage: You, the customer, benefit not only from<br />

our technical knowledge but also from our decades of<br />

experience in application engineering.<br />

Photo: photothek<br />

There are seven technical tape <strong>and</strong> <strong>woven</strong> fabric product<br />

lines offered by Frenzelit, each with different temperature<br />

limits <strong>and</strong> numerous product types – perfectly adapted to<br />

their particular application.<br />

Innovations made by Frenzelit<br />

Continuous improvement is essential in order to remain<br />

competitive in today´s market. Frenzelit has extensive<br />

research <strong>and</strong> development facilities where new products<br />

are fully tested prior to introduction to the marketplace.<br />

Where customers provide time constraints we are able to<br />

offer timely customer support to ensure solutions are<br />

found <strong>and</strong> new technologies are implemented on time<br />

<strong>and</strong> within budget. These are the outst<strong>and</strong>ing features of<br />

“innovations made by Frenzelit”.<br />

Application areas<br />

Whether they are a material used <strong>for</strong> heat <strong>and</strong> sound<br />

<strong>insulation</strong> purposes or a substrate <strong>for</strong> coating: <strong>tapes</strong> <strong>and</strong><br />

<strong>woven</strong> <strong>fabrics</strong> from Frenzelit made out of glass fibres <strong>and</strong><br />

processed glass stay impressively cool even at high<br />

temperatures. Our customers also appreciate the very<br />

extensive product range <strong>and</strong> the many different finishing<br />

alternatives, which <strong>for</strong>m the basis together <strong>for</strong> the<br />

outst<strong>and</strong>ing position we hold in the <strong>insulation</strong> field.<br />

Photo: Georg/F1 ONLINE<br />

Photo: Buderus Deutschl<strong>and</strong>

Application areas<br />

Automotive Insulation<br />

Heatproofing<br />

Soundproofing<br />

Heating <strong>and</strong> air conditioning Sealing<br />

Heatproofing<br />

Protection of people<br />

Process industry Insulation of<br />

- Pipes<br />

- Containers<br />

- Equipment<br />

- Heat exchangers<br />

Protection <strong>for</strong> hoses <strong>and</strong> electricity cables<br />

Shipbuilding Protection of property<br />

Power industry Insulation<br />

Heatproofing<br />

Machine manufacturing <strong>and</strong> Insulation of<br />

plant engineering - Pipes<br />

- Containers<br />

- Equipment<br />

- Heat exchangers<br />

Protection <strong>for</strong> hoses <strong>and</strong> electricity cables<br />

Electrical appliance industry Insulation<br />

Heatproofing<br />

Protection <strong>for</strong> electricity cables<br />

Protection against fire<br />

Protection of people<br />

Protection of property<br />

Safety engineering Protection against fire<br />

Protection of people<br />

Protection of property<br />

Do you have any questions about your application?<br />

The technical textiles in<strong>for</strong>mation service will help you:<br />

textile@frenzelit.de

Product lines<br />

isoTHERM®<br />

S/ST<br />

Application temperature limit<br />

1050 °C (1100 °C <strong>for</strong> a short time)<br />

Special SiO 2 glass fibres that<br />

withst<strong>and</strong> high temperatures<br />

are the basic material <strong>for</strong><br />

these products.<br />

Their characteristic properties<br />

are low thermal conductivity,<br />

minimum heat storage <strong>and</strong><br />

absolute incombustibility.<br />

isoTHERM® S/ST does not<br />

irritate the skin, is absolutely<br />

harmless to health <strong>and</strong> has<br />

excellent chemical resistance<br />

properties.<br />

• Filament diameter 6–9 µm<br />

• Incombustible<br />

(based on DIN 4102)<br />

• Loss due to shrinkage/version S

isoGLAS®<br />

Application temperature limit<br />

450 °C (550 °C <strong>for</strong> a short time)<br />

E-glass is the basic material.<br />

Texturing guarantees a large<br />

storage volume <strong>and</strong> thus<br />

good <strong>insulation</strong> properties.<br />

isoGLAS® products are extremely<br />

textile <strong>and</strong> harmless to<br />

health.<br />

• Filament diameter 6–11 µm<br />

• Incombustible<br />

(based on DIN 4102)<br />

• Loss due to shrinkage < 1,5 %<br />

• SBG approval <strong>for</strong> all <strong>woven</strong> <strong>fabrics</strong><br />

novaTEX®<br />

Application temperature limit<br />

250 °C (380 °C <strong>for</strong> a short time)<br />

Synthetic fibres like m-aramide,<br />

p-aramide or blends with Preox<br />

etc. are the basic material <strong>for</strong> our<br />

novaTEX® textiles.<br />

novaTEX®<br />

GOLD<br />

Application temperature limit<br />

450°C (Decomposition temp. 650°C)<br />

High-per<strong>for</strong>mance fibres with<br />

outst<strong>and</strong>ing properties <strong>for</strong>m<br />

the basis <strong>for</strong> this product<br />

family.<br />

The main characteristics of<br />

novaTEX® GOLD are high<br />

strength <strong>and</strong> excellent wear<br />

properties combined at the<br />

same time with high temperature<br />

resistance.

Coatings<br />

<strong>and</strong> finishes<br />

The properties of textile substrates can be changed very specifically by coating, impregnating or laminating them:<br />

• Mechanical resistance (abrasion, tear strength)<br />

• Insulating capacity<br />

• Water <strong>and</strong> gas barrier<br />

• Heat resistance<br />

Finishing processes <strong>and</strong> their heat resistance levels<br />

Coating<br />

Treatment with different agents<br />

applied to the surface:<br />

• Clean-cut STF 3-059* 200 °C<br />

• Slip-resistant SBF 3-088* 200 °C<br />

• Alufix 3-071* 200 °C<br />

• Alugrau 200 °C<br />

• Vermiculite 750 °C<br />

• Natural rubber, silicone,<br />

Hypalon, elastomer coatings<br />

200 °C<br />

• Mtex ® (aluminium) 600 °C<br />

* with SGB approval<br />

Impregnation<br />

• Simple care<br />

• Visual impact<br />

• Easy installation<br />

• Better processability<br />

Treatment with low-viscosity agents<br />

that penetrate the material:<br />

• Graphitised 200 °C<br />

• Black 200 °C<br />

• HT finishing 700 - 800 °C<br />

Lamination<br />

Bonding of two or more layers of the<br />

same or different structures:<br />

• Self-adhesive film 150 °C<br />

• Aluminium foil 650 °C<br />

• Aluminium sheet 650 °C<br />

• Aluminised polyester film 180 °C

Product types<br />

isoTHERM® S/ST<br />

Version Fabric pattern Weight (g/m 2 ) Thickness(mm) Width(mm)<br />

S Atlas 600 0.7 920<br />

S Atlas 1100 1.3 920<br />

ST Atlas 600 0.7 840<br />

ST Atlas 1100 1.3 840<br />

ST Linen 1000 2.0 1000<br />

ST Twill 1800 3.8 1000<br />

ST V4A Twill 730 1.3 1000<br />

ST V4A Linen 730 1.4 1000<br />

ST Tape* 2-3 10-120<br />

ST Tape* 4-10 30-120<br />

isoTHERM® 1000<br />

Version Fabric pattern Weight (g/m 2 ) Thickness(mm) Width(mm)<br />

E Linen 1200 2.0 1000<br />

Tape* 2-3 10-120<br />

isoTHERM® 800<br />

Version Fabric pattern Weight (g/m 2 ) Thickness(mm) Width(mm)<br />

E Linen 650 1.0 1000<br />

E Twill 830 1.4 1000<br />

E Linen 1000 1.6 1000<br />

E V4A Linen 1200 1.8 1000<br />

E Double linen 2000 3.0 1000<br />

Tape* 2-3 10-120<br />

Tape* 4-10 30-120<br />

isoTHERM® HT<br />

Version Fabric pattern Weight (g/m 2 ) Thickness(mm) Width(mm)<br />

E Leinw<strong>and</strong> 1150 1.5 1000<br />

E Twill 1480 2.4 1000<br />

E Double linen 2000 3.0 1000<br />

Do you have any questions about your application?<br />

The technical textiles in<strong>for</strong>mation service will help you:<br />

textile@frenzelit.de<br />

isoGLAS®<br />

Version Fabric pattern Weight (g/m 2 ) Thickness(mm) Width(mm)<br />

E Twill 420 0.5 1000<br />

E Twill 450 1.0 1600<br />

E Linen 600 1.0 1000<br />

E Atlas 630 0.65 1000<br />

E Linen 1000 1.6 1000<br />

E V4A Linen 1250 1.6 1000<br />

E Double linen 2000 3.0 1000<br />

Tape* 2-3 10-120<br />

Tape* 4-10 30-120<br />

novaTEX®<br />

Version Fabric pattern Weight (g/m 2 ) Thickness(mm) Width(mm)<br />

50% Preox<br />

50% aramide Linen 630 2 1000<br />

100% aramide Linen 450 1.8 1000<br />

Tape* 2-3 10-120<br />

novaTEX® GOLD<br />

Version Fabric pattern Weight (g/m 2 ) Thickness(mm) Width(mm)<br />

Gold Linen 730 2.4 1000<br />

Gold Twill 750 2.6 1000<br />

Tape* 2-3 10-120<br />

*All the dimensions are available with self-adhesive film too.<br />

Different grades, versions, dimensions <strong>and</strong> ladder <strong>tapes</strong><br />

as well as finished parts are available on request.

Good <strong>for</strong> people <strong>and</strong> environment.<br />

GASKETS<br />

TECHNICAL TEXTILES<br />

EXPANSION JOINTS<br />

INSULATION<br />

Frenzelit has obtained certification that the company complies with the requirements<br />

of both ISO/TS 16949 <strong>and</strong> ISO 14001.This means complete transparency in<br />

all areas <strong>and</strong> a high degree of security <strong>for</strong> our customers.<br />

Further <strong>sealing</strong> <strong>and</strong> insulating<br />

products from Frenzelit<br />

<strong>Technical</strong> needlemats<br />

<strong>for</strong> thermal <strong>and</strong> acoustic<br />

<strong>insulation</strong> <strong>and</strong> the filtration<br />

industry<br />

Solutions<br />

<strong>for</strong> acoustic <strong>and</strong><br />

heat <strong>insulation</strong><br />

NEW MATERIALS<br />

<strong>Technical</strong> cords<br />

<strong>and</strong> braids<br />

<strong>for</strong> <strong>sealing</strong> <strong>and</strong> <strong>insulation</strong><br />

Thermal blankets<br />

to protect people <strong>and</strong><br />

property<br />

novaSEAL®<br />

Boiler <strong>and</strong> tank rings<br />

Frenzelit-Werke GmbH & Co. KG<br />

P.O.Box 11 40 · 95456 Bad Berneck · Germany<br />

Phone: +49 9273 72-0 · Fax: +49 9273 72-344<br />

info@frenzelit.de · www.frenzelit.com<br />

Quality management<br />

ISO/TS 16949<br />

Environmental management<br />

ISO 14001<br />

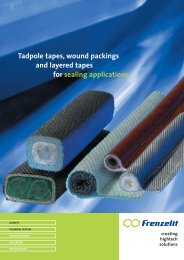

Tadpole <strong>tapes</strong>, wound<br />

packings <strong>and</strong> layered <strong>tapes</strong><br />

<strong>for</strong> <strong>sealing</strong> applications<br />

All previous versions of this prospectus cease to apply. Subject to technical amendment.<br />

FL/2/07.07/02/FL