MU March / April 2016

Machinery Update Issue 2 Volume XXVII March/April 2016

Machinery Update Issue 2 Volume XXVII March/April 2016

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Issue 2, Volume XXVII <strong>March</strong>/<strong>April</strong> <strong>2016</strong><br />

The machinery only journal for processing & packaging | www.machineryupdate.co.uk<br />

INSIDE<br />

NEWS<br />

Lorem February ipsum 9, 2019 dolor has sit been<br />

amet, named consectetuer as the day when adipiscing<br />

vast elit, majority sed diam of medicines nonum-<br />

the<br />

my sold nibh in the euismod EU must tincidunt comply<br />

ut with laoreet requirements dolore magna of the EU<br />

Falsified Medicines Directive<br />

NEW MACHINERY<br />

A fully automatic magazine<br />

loading unit suitable for any<br />

high speed case packer<br />

has been developed so that<br />

working conditions can be<br />

improved for operators<br />

Find out more on page 12<br />

INSTALLATIONS<br />

A turnkey filling<br />

line has been<br />

installed in China<br />

to help meet the<br />

growing demand<br />

for party kegs<br />

of Augerta beer<br />

PLUS<br />

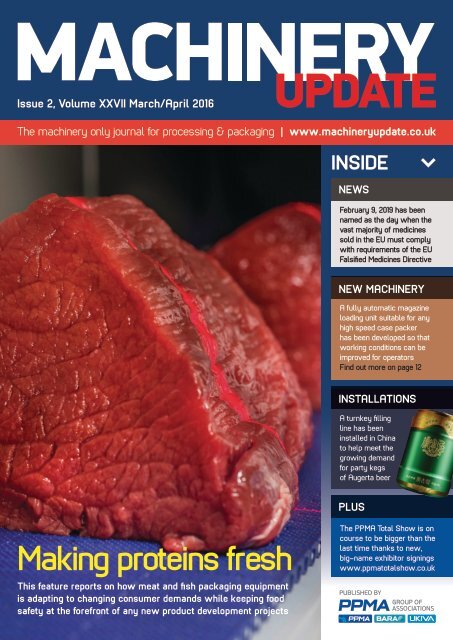

Making proteins fresh<br />

The PPMA Total Show is on<br />

course to be bigger than the<br />

last time thanks to new,<br />

big-name exhibitor signings<br />

www.ppmatotalshow.co.uk<br />

This feature reports on how meat and fish packaging equipment<br />

is adapting to changing consumer demands while keeping food<br />

safety at the forefront of any new product development projects

Much more than simple technology<br />

CAMA UK Ltd - cama3@camagroup.com - Tel. +44 (0) 1793 831111<br />

Utrecht – Netherlands<br />

12 - 14 <strong>April</strong> <strong>2016</strong>

www.machineryupdate.co.uk MARCH/APRIL <strong>2016</strong> MACHINERY UPDATE 3<br />

<strong>March</strong>/<strong>April</strong><br />

Contents<br />

7 NEWS<br />

12 NEW MACHINERY<br />

24 INSTALLATIONS<br />

Sollas <strong>MU</strong> N-D 2014_HR 16/10/2014 10:16 Page 1<br />

25<br />

36 REGULAR FEATURES<br />

20 SPECIAL FEATURE<br />

FOODEX <strong>2016</strong> PREVIEW<br />

This preview details many of the<br />

new product launches that will<br />

feature from PPMA members<br />

during the NEC-based event<br />

36 SPECIAL FEATURE<br />

MEAT, FISH & PROTEINS<br />

This feature reports on the very<br />

latest developments seen in the<br />

meat, fish and other proteins<br />

sectors to meet the changing<br />

retailer and consumer demands<br />

across this dynamic industry<br />

64 VISION<br />

Machine vision software that<br />

is powerful and also versatile<br />

is now available from IDS<br />

66 COMPONENTS<br />

Three pages include flexible<br />

and lean electronics which are<br />

delivering a simple solution for<br />

a machine builder as well as<br />

new pumps, drives and motors<br />

70 REGULATIONS<br />

The final update to ‘Permanent<br />

means of access’ legislation<br />

72 WHO WHAT WHERE<br />

People, events and diary dates<br />

74 CLASSIFIED<br />

Machinery and services<br />

75 BUYERS’ GUIDES<br />

EDITOR:<br />

Gail Hunt<br />

SALES MANAGER:<br />

David Chadd<br />

PUBLISHING MANAGER:<br />

Bill Lake<br />

BUYERS GUIDE CO-ORDINATOR:<br />

Chris Valdes<br />

ARTWORK CONTRIBUTOR:<br />

Barry Heath<br />

PUBLISHING DIRECTOR:<br />

Sarah Ketchin<br />

A PPMA PUBLICATION<br />

PPMA Ltd<br />

New Progress House,<br />

34 Stafford Road,<br />

Wallington,<br />

Surrey SM6 9AA<br />

TEL: +44 (0) 20 8773 8111<br />

FAX: +44 (0) 20 8773 0022<br />

E-MAIL ADDRESSES:<br />

publishing@ppma.co.uk<br />

show@ppma.co.uk<br />

technical@ppma.co.uk<br />

WEBSITE:<br />

www.machineryupdate.co.uk<br />

APPLICATIONS FOR FREE COPIES<br />

of Machinery Update are<br />

considered from specifiers,<br />

managers and purchasers of<br />

processing and packaging<br />

machinery in the UK.<br />

ANNUAL SUBSCRIPTION:<br />

£35 (UK), £50 (Continental<br />

Europe), £65 (rest of world).<br />

ISSN 0969-4145<br />

PRINTED BY:<br />

Manor Group, 7-8 Edison Road,<br />

Highfield Industrial Estate, Hampden Park,<br />

Eastbourne BN23 6PT.<br />

Tel: +44 (0) 1323 514400<br />

The Processing and Packaging Machinery<br />

Association assumes no responsibility for the<br />

statements or opinions, whether attributed<br />

or otherwise, in Machinery Update.<br />

This publication is copyright under the Berne<br />

convention and the International copyright<br />

convention. Apart from any fair dealing for<br />

the purposes of research or private study, as<br />

permitted under the Copyright, Designs and<br />

Patents Act 1988, no part of this publication<br />

may be reproduced, stored in a retrieval<br />

system or transmitted in any form or by any<br />

means in any form without prior written<br />

permission of the publishers.<br />

Publishers: PPMA Ltd

CEIA<br />

The latest technology<br />

in Metal Detection<br />

<strong>MU</strong>LTI-<br />

Technology<br />

SPECTRUM<br />

Technology<br />

THS/MBB MODULAR CONVEYOR BELT SYSTEM<br />

•<br />

Fully compliant with all UK Retailer<br />

requirements including M&S and Tesco<br />

• 2 year warranty on MS21 heads<br />

• IP69K<br />

<strong>MU</strong>LTI-<br />

THS/G21 series FOR FREE-FALLING PRODUCT APPLICATIONS<br />

•<br />

•<br />

• AISI 316L stainless steel construction<br />

High sensitivity to all magnetic and non-magnetic metals, including stainless steel<br />

Designed to inspect powders, liquids, granules and other loose materials in pipes<br />

metal detection services<br />

UK Full Service and Technical Support<br />

24-7 Help Line and Assistance<br />

Metal Detector Validation and Retailer Code of practice training<br />

CEIA Authorised Dealer - Contact us on: 0161 286 8750 (Technical)<br />

0161 286 8755 (Sales)<br />

www.mds.org.uk

www.machineryupdate.co.uk MACHINERY UPDATE 5<br />

PPMA matters<br />

Facing the<br />

health debate<br />

together<br />

Rolling conveyor technology<br />

in the process flow<br />

Grant Jamieson<br />

CHAIRMAN PPMA GROUP OF ASSOCIATIONS<br />

(INCORPORATING PPMA, BARA & UKIVA)<br />

The food sector is very busy facing pressures and<br />

challenges all round just now. The whole obesity and<br />

sugar debate rages on with a sugar tax threatened and<br />

as the doors to Foodex <strong>2016</strong> open in <strong>April</strong> (our preview starts<br />

on page 20), designers and manufacturers of food and also its<br />

supply chain, are being forced to innovate with new solutions.<br />

Having recently attended ProSweets and ISM in Cologne,<br />

I can say with some certainty that the industry is very much<br />

alive and confident. Evidently there is a great deal of work in<br />

bringing together food preferences with the health benefits of<br />

some or all of the ingredients to make a suitable proposition.<br />

Our industry has been world<br />

leading in process and also<br />

packaging innovations for years<br />

The sweets and snacks line-up provided numerous<br />

alternatives and offers for nutrition-conscious consumers.<br />

These included vegan and sugar-reduced chocolate, lactosefree<br />

biscuits and sugar-reduced filled chocolates. New trend<br />

themes at ISM included Halal, Kosher, organic, Fairtrade, sugarfree,<br />

allergy friendly, functional, artisan, private label, limited<br />

edition, impulse and sharing packs, vegetarian and vegan.<br />

Nuts, got their own section, and chocolate was very well<br />

represented. There were lots of offerings using nuts and coatings<br />

or incorporating them to get the health benefits, but processed<br />

in a way to make them more appealing, more consumer-friendly<br />

and easier to pack and carry while retaining freshness etc.<br />

So the industry is challenged to innovate and meet the newer<br />

more testing expectations now set before them.<br />

As a diverse trade association, the PPMA members covered<br />

in the pages of this magazine each issue, love a technical<br />

challenge. Our industry has been world leading in process and<br />

packaging innovations for generations and this next chapter<br />

is another one we look forward to.<br />

So, just because it hasn’t been done before, doesn’t necessarily<br />

mean it can’t be done in the future. And this is true across all<br />

food categories and beyond.<br />

This issue is full of the latest developments and on page 36,<br />

you’ll find the start of our 28 page meat, fish and proteins<br />

feature which covers a whole host of technologies developed<br />

for this market, but which can be also be transferred to others.<br />

Machinery that has answered the producers’ needs for something<br />

new, as a process or as a packaging choice, is right up our street. n<br />

just a few, easy-to-fit components<br />

adjusts perfectly to the space available<br />

has a flexible, three-dimensional layout<br />

dependable transport operations at temperatures<br />

between 4° and 30 °C<br />

saves on energy due to rolling friction<br />

saves investment costs, and also operating,<br />

service and maintenance costs<br />

UK<br />

WRH Global UK Ltd<br />

Unit 17, Harlow Mill Business Centre<br />

Riverway, Harlow<br />

Essex CM20 2FD<br />

Phone +44 (0) 1279 635 657<br />

Fax +44 (0) 1279 445 837<br />

info@wrh-global-uk.com<br />

www.wrh-global-uk.com<br />

www.denipro.com

Fully integrated machine control<br />

Sysmac Automation Platform<br />

Information<br />

technologies<br />

Smart factory<br />

IT devices<br />

O ffi c e<br />

Sales force<br />

SQL-Database<br />

Information<br />

Motion<br />

Safety<br />

Vision<br />

Robotics<br />

Sensing<br />

Vision<br />

Sysmac is an integrated automation platform that offers complete control<br />

and management of your automation system and delivers simple system<br />

architecture, reduced programming and optimised productivity.<br />

Omron’s FH series vision system is designed to be an integral part of a<br />

Sysmac automation solution, providing seamless integration through<br />

EtherCat connectivity and benefiting from a common software platform.<br />

Inspection or guidance applications can be realised with minimum effort<br />

through the FH’s intuitive programming system. High performance<br />

controllers and a wide range of resolution cameras provide the flexibility<br />

to solve even the most complex of applications.<br />

For further information<br />

+44 (0)1908 258258<br />

uk@eu.omron.com<br />

industrial.omron.co.uk/sysmac

News<br />

www.machineryupdate.co.uk MARCH/APRIL <strong>2016</strong> MACHINERY UPDATE 7<br />

PPMA Total Show is<br />

powering ahead to be<br />

better than ever event<br />

Item-level serialisation is the issue<br />

Last milestone passed<br />

on the way to the EU<br />

FMD being enacted<br />

The recent publication of the<br />

delegated Regulation <strong>2016</strong>/161<br />

associated with the EU Falsified<br />

Medicines Directive (FMD) sets<br />

February 9, 2019 as the date<br />

by which the vast majority of<br />

prescription and some overthe-counter<br />

(OTC) medicines<br />

dispensed or sold within the 28<br />

EU Member States must meet<br />

the requirements of the Acts.<br />

Failure to comply is serious,<br />

as it will render affected<br />

products illegal for sale.<br />

It is the requirement for<br />

item-level serialisation, more<br />

than any other, which is<br />

exercising those responsible<br />

for compliance in the wider<br />

supplier community as well as<br />

in the industry itself.<br />

• See page 10 for analysis<br />

The PPMA Total Show<br />

<strong>2016</strong> this September<br />

will be bigger and better<br />

than the 2013 event following<br />

a host of new contract signings<br />

across industry sectors.<br />

Taking place from<br />

27 – 29 September at the NEC,<br />

Birmingham, this year’s show<br />

will see more space and more<br />

exhibitors gracing Hall 5. The<br />

show incorporates three major<br />

exhibition brands: PPMA,<br />

Pakex and Interphex and takes<br />

place every three years in place<br />

of that year’s PPMA Show.<br />

In essence, the exhibition is<br />

a larger version of the annual<br />

PPMA Show that includes<br />

packaging materials as well<br />

as machinery to become<br />

a total production line<br />

event. From components to<br />

materials, from processing<br />

to packaging machinery,<br />

the three-day show will offer<br />

visitors a comprehensive view<br />

of what manufacturing looks<br />

like in <strong>2016</strong>.<br />

PPMA Total Show <strong>2016</strong> is on course<br />

Group exhibition manager<br />

David Harrison is delighted<br />

that the exhibition is on<br />

course to offer visitors a mix<br />

of machinery for the food and<br />

drink industries as well as the<br />

pharmaceuticals sector.<br />

“We have companies back for<br />

the first time in a while such as<br />

Bosch Packaging Technology<br />

which is exciting,” he tells<br />

Machinery Update.<br />

T 020 8773 8111<br />

W www.ppmatotalshow.co.uk<br />

Academia and industry personnel<br />

New partnership set<br />

to boost skills in the<br />

engineering sector<br />

Siemens has moved to boost skills in<br />

the engineering sector in the North<br />

West via a new partnership with the<br />

higher and further education sectors.<br />

The company, which employs<br />

14,000 people in the UK, has joined<br />

forces with the University of Salford<br />

and Trafford College to develop<br />

education and training programmes<br />

for school leavers to degree level.<br />

The three organisations<br />

have outlined a new Degree<br />

Apprenticeship which would allow<br />

company recruits to study block<br />

release at Trafford College and<br />

the University of Salford, working<br />

seamlessly from Higher National<br />

Certificate/Higher National<br />

Diploma to Bachelor Engineering<br />

level. Degree Apprenticeships allow<br />

people to study while working and<br />

are part government-funded.<br />

Technology forum<br />

for machine vision<br />

presents challenges<br />

THE CONTRIBUTION TO ENGINEERING IS REWARDED<br />

Recognising top engineers<br />

Group operations director at Domino Printing Sciences Rachel Hurst<br />

has been presented with an Achievement Medal, one of the key<br />

prizes of the Institution of Engineering and Technology’s (IET) 2015<br />

achievement awards in recognition of her distinguished contribution<br />

to manufacturing and engineering. “Although the accolade is a<br />

personal one, I owe it to the team at Domino,” she says.<br />

The 370 machine vision experts<br />

and also newbies that attended<br />

the Machine Vision Technology<br />

Forum at Silverstone in <strong>March</strong>,<br />

found the day packed with<br />

useful technical information<br />

and live demonstrations.<br />

Billed as the UK learning<br />

and networking event for<br />

machine vision, the day was<br />

organised by Stemmer Imaging<br />

in conjunction with the<br />

European Imaging Academy.<br />

The seminar programme<br />

featured 50 seminars split<br />

over six parallel tracks while<br />

attendees saw the latest<br />

technology and demonstrations<br />

from 32 manufacturers at the<br />

co-located exhibition.<br />

TÜV SÜD achieves milestone<br />

Firm celebrates its<br />

150th anniversary<br />

TÜV SÜD is celebrating the<br />

company’s 150th anniversary<br />

this year having started out<br />

inspecting steam boilers in<br />

1866. Today, the company has<br />

a global network of operations<br />

including in the UK, which employs<br />

over 600 people providing<br />

testing, inspection, certification<br />

and consulting services.

8 MACHINERY UPDATE MARCH/APRIL <strong>2016</strong> www.machineryupdate.co.uk<br />

News<br />

Williamson expands association<br />

roles with the PPMA and VDMA<br />

Iris X-ray Pipeline<br />

Inspection System<br />

Director – corporate<br />

market development<br />

at Stemmer Imaging<br />

Mark Williamson has been<br />

elected as the next chairman<br />

of the PPMA (Processing<br />

& Packaging Machinery<br />

Association). He has also been<br />

elected to serve on the board<br />

of VDMA Machine Vision for<br />

the next three years.<br />

Look what Sparc has in<br />

its Pipeline for you!<br />

Applications<br />

• Muscle Meat<br />

• Ground Meat<br />

• Poultry trims<br />

• Pie Fillings / Slurries<br />

• Ice Cream / Dairy products<br />

Benefits<br />

• Suitable for use in harsh<br />

environments<br />

• Simple and robust design<br />

• Product not compressed<br />

• Servo driven rotary reject<br />

valve diverts product to<br />

reject bin<br />

• Easy to change over<br />

• HACCP compliant<br />

Sparc House, Merebrook Business Park,<br />

Hanley Road, Malvern, Worcestershire,<br />

WR13 6NP England<br />

T: +44 (0)1684 310000<br />

E: sales@sparc-systems.com<br />

Williamson will be new chairman<br />

The PPMA represents<br />

suppliers of processing<br />

and packaging machinery,<br />

vision systems and robotics<br />

equipment to the UK and<br />

overseas markets and includes<br />

over 470 member and affiliate<br />

companies. VDMA Machine<br />

Vision is a subgroup within<br />

the VDMA Robotics +<br />

Automation Association<br />

in Germany, with over<br />

100 member companies<br />

supplying machine vision<br />

components and systems for<br />

both manufacturing and nonmanufacturing<br />

applications<br />

across Europe.<br />

Williamson is a former<br />

chairman of the UKIVA (UK<br />

Industrial Vision Association)<br />

and joined the PPMA board in<br />

2010 when the UKIVA became<br />

a special interest group of the<br />

organisation. He becomes<br />

vice-chair to current PPMA<br />

chairman Grant Jamieson<br />

and will take up his two year<br />

appointment as chairman in<br />

December this year. In 2018,<br />

he will revert to the position<br />

of vice-chair for a further<br />

year to support the then<br />

incoming-chairman.<br />

www.sparc-systems.com

www.machineryupdate.co.uk MARCH/APRIL <strong>2016</strong> MACHINERY UPDATE 9<br />

Sector apprentice wins<br />

top Semta skills award<br />

Packaging Automation<br />

(PA) has received<br />

national recognition<br />

for its long established<br />

apprenticeship scheme as its<br />

employee, electrical engineer<br />

Christopher Eckert, was<br />

named the UK’s top apprentice<br />

at the Semta Skills awards.<br />

PA has trained more than<br />

100 apprentices since the<br />

scheme started 30 years ago<br />

with former apprentices now<br />

holding director, management<br />

and team leader roles in<br />

the current business. The<br />

company needs to continually<br />

recruit to meet growing<br />

demand for its equipment and<br />

has struggled to find engineers<br />

who have the specialist<br />

skills required for the design<br />

and manufacture of food<br />

packaging machinery.<br />

The award was announced<br />

at a gala dinner at London’s<br />

Hilton Hotel on Park Lane<br />

hosted by BBC journalist,<br />

presenter and engineering<br />

advocate Steph McGovern.<br />

Eckert was chosen over the<br />

other finalists who were from<br />

Toyota and Mars.<br />

“I am very shocked – to<br />

Atwell - <strong>MU</strong> M-A <strong>2016</strong>_Layout 1 21/01/<strong>2016</strong> 12:58 Page 1<br />

Christopher Eckert (centre) receives his award at the gala evening in London<br />

be up against apprentices<br />

from enormous companies<br />

like Mars and Toyota, I really<br />

didn’t expect to win,” said<br />

award winner Eckert during<br />

the gala evening.<br />

“My message to other young<br />

people is don’t be deterred.<br />

“My dad didn’t really want<br />

me to become an apprentice<br />

because he felt university was<br />

the best option but if you are<br />

willing to commit and work<br />

hard you can get where you<br />

want to be,” he said.<br />

While working at PA,<br />

Eckert has completed his<br />

HNC in Electrical/Electronic<br />

Engineering with distinction<br />

enabling him to win an<br />

employer sponsored place<br />

to study for a BEng Honours<br />

degree at Manchester<br />

Metropolitan University.<br />

In brief<br />

DRIVES & CONTROLS FOR<br />

AUTOMATION IS IN APRIL<br />

Drives & Controls takes place at the<br />

NEC, Birmingham from 12-14 <strong>April</strong>.<br />

This biennial event is recognised<br />

as the UK’s leading show for<br />

automation, power transmission<br />

and motion engineering and this<br />

time, is co-located with six other<br />

industrial exhibitions.<br />

The exhibition has grown<br />

over the last decade and in 2014<br />

registered over 13,000 visitors.<br />

A live Robotic Demonstration<br />

Area will be featured for the<br />

first time to reflect this dynamic<br />

and fast growing sector in the<br />

industrial landscape. There is also<br />

a full conference programme.<br />

W www.drives-expo.com<br />

MECHANICAL ENGINEERS<br />

GATHER IN NUREMBURG<br />

The mechanical processing<br />

technology community will be<br />

gathering in Nuremburg from<br />

19 to 20 <strong>April</strong>, for POWTECH<br />

<strong>2016</strong>. Greeting visitors will be<br />

about 900 exhibitors showcasing<br />

the latest technical developments<br />

in the manufacturing, processing<br />

and handling of powders, granules<br />

and bulk solids. Technology<br />

featured is suitable for the<br />

chemicals, pharmaceuticals, food<br />

and feed manufacturing sectors.<br />

W www.powtech.de<br />

+44 (0) 1444 239970<br />

sales@atwell-labellers.co.uk<br />

www.Labeller.co.uk<br />

You grow it<br />

We’ll Label it<br />

Label design & bespoke labelling by Atwell’s<br />

Fast, Reliable and Easy to use Semi Automatic<br />

and Bespoke Fully Automatic Labelling Systems.<br />

Introducing Contract Labelling from the Labelling Experts<br />

OVERHEAD<br />

TOP/<br />

BOTTOM<br />

SIDE<br />

FRONT/<br />

BACK<br />

<strong>MU</strong>LTIPLE<br />

FACE<br />

<strong>MU</strong>LTIPLE ROW<br />

CROSS WEB<br />

PRINT &<br />

APPLY<br />

TAPERED<br />

POT<br />

WRAP-<br />

AROUND<br />

BUCKET<br />

LABELLER<br />

PALLET<br />

LABELLER<br />

PUNNET<br />

LABELLER<br />

TAMPER<br />

EVIDENT<br />

18 Bolney Grange Business Park • Hickstead • West Sussex • RH17 5PB • UK

10 MACHINERY UPDATE MARCH/APRIL <strong>2016</strong> www.machineryupdate.co.uk<br />

News<br />

Three years and counting<br />

before FMD compliance<br />

As the last major milestone is passed en route to enactment of the EU Falsified Medicines Directive<br />

(FMD), Machinery Update talks to key players about what this means in practice<br />

The publication in<br />

February of the delegated<br />

Regulation <strong>2016</strong>/161<br />

associated with the EU FMD<br />

sets February 9, 2019 as the<br />

date by which the vast majority<br />

of prescription and some OTC<br />

(over-the-counter) medicines<br />

dispensed or sold within the 28<br />

EU Member States must meet<br />

the requirements of the Acts.<br />

Failure to comply will render<br />

affected products illegal for sale.<br />

UNIQUE PACK IDENTITY<br />

Among these requirements<br />

is the need for every pack to<br />

carry a unique identity in a<br />

standardised format that can<br />

be verified at any point from<br />

manufacture to patient. “It is<br />

this requirement, item-level<br />

serialisation, more than any<br />

other that is exercising those<br />

responsible for compliance, in<br />

the wider supplier community<br />

as well as in the industry<br />

itself,” says Craig Stobie,<br />

director – global sector<br />

management and development<br />

at Domino Printing Sciences.<br />

Craig Stobie is director - global<br />

sector management and<br />

development at Domino Printing<br />

Enactment will ostensibly<br />

mark the culmination of a<br />

decade-long journey for many<br />

in the industry, a journey<br />

which began with the legal<br />

proposal put forward by the<br />

EU Commission in December<br />

2008. “At Domino, we have<br />

characterised item-level<br />

serialisation as the biggest<br />

challenge faced by the<br />

pharmaceutical industry in a<br />

generation and we believe that<br />

its ramifications will continue<br />

to be felt for some time beyond<br />

the compliance deadline,” says<br />

Stobie. “While manufacturers<br />

must become technically<br />

capable of producing<br />

serialised packs over the next<br />

three years, all the evidence<br />

suggests that productivity<br />

may be adversely impacted for<br />

some time beyond that.”<br />

SERIALISATION STEPS<br />

There are steps that can be<br />

taken now to mitigate the ‘side<br />

effects’ of serialisation but<br />

the extent of the impact will<br />

only become apparent when<br />

producers begin serialised<br />

production in earnest: for<br />

many this is still some time<br />

away, he says.<br />

It would be foolish to<br />

underestimate the amount of<br />

work still to be done ahead<br />

of the compliance deadline<br />

Manfred Minich is chief executive<br />

officer at Atlantic Zeiser<br />

and the occasional bout of<br />

serialisation fatigue can<br />

certainly be forgiven.<br />

Manufacturers, suppliers and<br />

other stakeholders recognise that<br />

no organisation can provide a<br />

complete solution singlehandedly<br />

But ceo of Atlantic Zeiser<br />

Manfred Minich believes any<br />

company that has not yet<br />

started the FMD journey is in<br />

real danger of running out of<br />

time. “From our experience<br />

from past projects, the<br />

majority of big international<br />

pharma companies know<br />

what needs to be done<br />

but they still haven’t<br />

implemented all relevant<br />

serialisation workflows,<br />

especially on the enterprise<br />

level,” he says. “However<br />

a multitude of smaller<br />

and medium-sized pharma<br />

manufacturers have been<br />

procrastinating on this issue<br />

for a long time.”<br />

Minich believes the main<br />

reason for this, among others,<br />

is the fact that the directive<br />

was more than 30 pages long<br />

containing some complex<br />

requirements without spelling<br />

out the technical implications.<br />

“Although the technologies<br />

that are necessary to generate,<br />

print and verify codes are<br />

usually common, the reliable<br />

interchange with a database<br />

solution that can administer<br />

workflows and guarantee<br />

the uniqueness of the codes<br />

and safety features seems to<br />

be undiscovered territory for<br />

most players,” he says.<br />

A POSITIVE JOURNEY<br />

Stobie thinks that even though<br />

there is still a long way to go<br />

for some, there are some real<br />

positives to be drawn from<br />

the journey so far. Firstly, the<br />

fact that serialisation will be<br />

a significant line of defence in<br />

protecting all EU Citizens from<br />

the trade in illicit medicines<br />

and secondly, the way the<br />

industry is pulling together to<br />

produce a cohesive response<br />

to the legislation.<br />

“Manufacturers, suppliers<br />

and other stakeholders<br />

recognise that no organisation<br />

can provide a solution<br />

singlehandedly, prompting<br />

a sharing of knowledge and<br />

resource unlike anything we<br />

at Domino have experienced,”<br />

he says. “This spirit of<br />

partnership bodes well for<br />

the sector as it addresses the<br />

challenge of serialisation and,<br />

we hope, far beyond that.”<br />

W www.atlanticzeiseruk.com<br />

W www.domino-uk.com

12 MACHINERY UPDATE MARCH/APRIL <strong>2016</strong> www.machineryupdate.co.uk<br />

New Machinery<br />

Automatic magazine loading<br />

brings cardboard blank gains<br />

Cermex, the case packing<br />

division of Gebo Cermex,<br />

has introduced FlexiLoad<br />

to handle fully automatic<br />

magazine loading for any<br />

high speed case packing<br />

system. This patent pending<br />

solution is designed to<br />

improve working conditions,<br />

and enable operators to devote<br />

their time to other, higher<br />

added value tasks.<br />

Consisting of a 6-axis robot,<br />

a universal gripping tool<br />

and PC-based software,<br />

FlexiLoad can handle<br />

regular slotted containers<br />

(RSCs), wraparound blanks<br />

or trays. It can also enhance<br />

the ergonomics of both new<br />

equipment and also existing<br />

installed machinery, through<br />

a retrofit process.<br />

By automating a task that<br />

requires repetitive efforts<br />

by the operator, FlexiLoad<br />

makes a real improvement to<br />

working conditions and to the<br />

productivity of the line, says<br />

Cermex. Such an improvement<br />

can, in certain countries, lead<br />

to a reduction in mandatory<br />

contributions to state health<br />

insurance, which are indexed<br />

Fortress 3rd LHP_<strong>MU</strong> 19/11/2014 08:47 Page 1<br />

FlexiLoad is compatible with any type of medium to high speed case packer with outputs above 25 boxes per minute<br />

on the number and length of<br />

interruptions for sick leave.<br />

Going from spending 50%<br />

to 80% of their time to less<br />

than 10% (replacing empty<br />

pallets with full pallets) on<br />

stocking up the case packing<br />

system, operators are available<br />

for working on other, higher<br />

added value tasks.<br />

For example, the operator<br />

has more time for performing<br />

quality control operations or<br />

for sample picking.<br />

The positive return on<br />

investment in terms of<br />

organisational improvement<br />

and of productivity gains<br />

comes in addition to the<br />

100% industrial ROI in only<br />

one year for a line operating<br />

continuously round the clock.<br />

FlexiLoad can also<br />

perform additional functions<br />

depending on the needs<br />

of industrial clients, such<br />

as providing a system for<br />

shredding the straps around<br />

the bundles of RSC blanks,<br />

so as to reduce the volume<br />

of the waste, or incorporating<br />

a magazine on wheels for<br />

storing recovered interlayer<br />

sheets.<br />

T 01480 455919<br />

W www.gebocermex.com<br />

www.fortresstechnology.co.uk<br />

A Fortress Metal Detector is for life!<br />

It is NEVER OBSOLETE!<br />

And it is ALWAYS UPGRADABLE.<br />

To find out more contact us...<br />

Exceptional Sales –<br />

Company Growth<br />

The Phantom Building • 7 Beaumont Road • Banbury • OX16 1RH • UK<br />

E: sales-UK@fortresstechnology.com • T: +44 (0)1295 256266

THE HEARTBEAT OF INDUSTRY 4.0<br />

Are you ready for the fourth industrial revolution? Ready for intelligent manufacturing systems that flexibly respond to new demands?<br />

We move products, processes and people, because our intelligent sensors and networking solutions are setting the pace for Industry 4.0<br />

If you want to learn more about how our heart also enlivens your company, visit us at www.balluff.com/industry-4.0<br />

www.balluff.com<br />

Herz_Industrie4.0_210x143_EN.indd 1<br />

1/12/<strong>2016</strong> 11:11:15 AM<br />

Fast, affordable, print &<br />

apply from Logopak<br />

The new Logopak 300 is a simple case<br />

or pack labeller. It has a clean design,<br />

uncompromising German build quality,<br />

a small footprint and a user-friendly<br />

operator interface.<br />

T: 01904 692333<br />

www.logopak.co.uk

Full Service in Place<br />

Easier maintenance and service: Free access to all wearing parts<br />

Advantages:<br />

Possible to complete a full service (Including mechanical seal) and back in full operating condition, within 20 minutes<br />

Suction and discharge pipework can remain in place<br />

Easier manual handling<br />

No special tools required<br />

Integrates into existing installations<br />

Operating flows, pressures etc unaffected<br />

Quick release cartridge joint and seal, removal within seconds – ‘Pro’ version only<br />

Highly versatile for most industries<br />

∙<br />

Environmentally friendly<br />

Conversion kits available to upgrade already installed NEMO® pumps<br />

NEMO® Pump in FSIP® Design<br />

NETZSCH Pumps & Systems Ltd<br />

Horchester, Holywell<br />

Dorchester, Dorset, DT2 0LL<br />

Tel.: 01935 483900<br />

sales.npu@netzsch.com<br />

www.netzsch.com<br />

Lasnek.<br />

Because<br />

Quality Matters<br />

Stainless Steel Cable Management Systems<br />

• The stainless steel containment specialist<br />

• Choice of containment types & finishes<br />

• Bespoke manufacturing service<br />

• Large stock availability<br />

www.lasnek.com • sales@lasnek.com<br />

Lasnek Ltd, 1 President Way, Luton, Bedfordshire LU2 9NR<br />

Tel: +44 (0) 1582 425 777

New Machinery<br />

www.machineryupdate.co.uk MARCH/APRIL <strong>2016</strong> MACHINERY UPDATE 15<br />

Tube fillers can be supplied<br />

for any effervescent tablets<br />

Loma’s finger print access device<br />

New access device<br />

offers greater line<br />

inspection security<br />

Loma Systems has launched<br />

a biometric finger print access<br />

device which has been specially<br />

designed for its range of CW3<br />

combination metal detector<br />

and checkweigher units to offer<br />

quality assurance & technical<br />

managers greater security for<br />

CCP (critical control point).<br />

The new device automatically<br />

recognises or confirms the identity<br />

of an individual based on their<br />

fingerprint. The level of access to<br />

the CW3 Combo’s touch screen<br />

depends on the status of the<br />

operator, however the system has<br />

been developed primarily to ensure<br />

only service personnel and quality<br />

assurance and technical managers<br />

are able to change settings.<br />

T 01252 893300<br />

W www.loma.co.uk<br />

Following the acquisition<br />

of Swedish manufacturer<br />

Medipac in November<br />

last year, Romaco is now in a<br />

position to offer tube filling<br />

systems for effervescent<br />

tablets for the first time.<br />

These systems for the<br />

primary packaging of<br />

effervescent tablets will now<br />

be sold worldwide under<br />

the umbrella brand Romaco<br />

Siebler and three different<br />

tube filling systems in different<br />

performance classes are<br />

currently available in the MF<br />

series. With a maximum output<br />

of 120 tubes per minute, the<br />

Siebler MF 120 is designed for<br />

very high production speeds.<br />

The mid-range MF 70 is<br />

currently the top-selling model<br />

while the semi-automatic<br />

Siebler MF 20 achieves up to<br />

20 tubes per minute.<br />

All series MF machines apply<br />

the rotation principle to fill<br />

tubes with effervescent tablets.<br />

In operation, the effervescent<br />

The Siebler MF 120 tube filling machine for effervescent tablets is available<br />

tablets are first guided through<br />

up to eight channels, where<br />

they are counted still lying<br />

flat and then fed to the filling<br />

station. They then pass through<br />

filling tubes which rotate at<br />

high speed. The resulting forces<br />

cause the tablets to stand up<br />

automatically and slide upright<br />

into the waiting tubes, which<br />

are also rotating quickly.<br />

The suction effect of this<br />

rotation creates air cushions,<br />

which centre the tablets and<br />

prevent them from hitting<br />

the tube walls. The fragile<br />

effervescent tablets are thus<br />

processed gently.<br />

T 01252 444334<br />

W www.pharmamachinery.co.uk<br />

Continuous ink jet printers, and their inks,<br />

can be fully integrated with egg graders<br />

The line overview is easy to use<br />

Easy line control<br />

and also monitoring<br />

With just a few mouse clicks,<br />

a line monitoring system can be<br />

implemented using the Aprol<br />

process and factory automation<br />

system from B&R Automation. The<br />

system provides information to help<br />

eliminate any problems early which,<br />

in turn, helps to increase efficiencies<br />

and boost production output.<br />

T 01733 371320<br />

W www.br-automation.com<br />

Coding and marking systems<br />

from Domino Printing<br />

Sciences can be fully<br />

integrated with Moba and<br />

Sanovo graders on egg<br />

processing lines.<br />

By combining continuous<br />

ink jet (cij) printers with new<br />

High contrast codes are achieved by A-Series i-Tech printing systems<br />

EU and FDA compliant direct<br />

food contact inks, Domino’s<br />

A-Series i-Tech systems are<br />

capable of printing high<br />

contrast codes on brown and<br />

white eggs.<br />

Domino’s i-Tech cij range<br />

of printers has been designed<br />

in partnership with grader<br />

manufacturers to ensure<br />

performance as well as<br />

reliability and ease of use,<br />

are maintained throughout<br />

production. They allow<br />

direct connection to the latest<br />

Moba egg graders, with<br />

no additional interface<br />

necessary.<br />

T 01954 782551<br />

W www.domino-uk.com

16 MACHINERY UPDATE MARCH/APRIL <strong>2016</strong> www.machineryupdate.co.uk<br />

New Machinery<br />

High speed print and apply is<br />

available, even at entry level<br />

Logopak International<br />

has extended its product<br />

range with a new<br />

high speed print and apply<br />

machine for case and also<br />

pack labelling.<br />

The new Logopak 300<br />

is a cost effective solution<br />

for simple, high speed<br />

applications but the price<br />

point does not mean that<br />

quality has been compromised.<br />

The development team in<br />

Germany took the opportunity<br />

to improve or simplify every<br />

aspect of the machine; with<br />

a particular emphasis on<br />

improving ease of use, says<br />

the company.<br />

Speeds of up to 80 packs a<br />

minute can be achieved on<br />

this uncomplicated labeller.<br />

Just the three most common<br />

applicators – top, front and side<br />

are offered which makes its<br />

availability much quicker, too.<br />

The new design is clean,<br />

hygienic, curved and<br />

sleek, and meets the latest<br />

machinery safety directives.<br />

The reduced footprint<br />

maximises the available space<br />

on a line, and the 15in display<br />

is mounted on the machine<br />

YPS <strong>MU</strong> N-D 2014_<strong>MU</strong> 16/10/2014 09:38 Page 1<br />

Performance and speed are offered by the Logopak 300 print and apply unit<br />

itself for optimal positioning.<br />

The display shows current<br />

label view and will give the<br />

operator immediate fault<br />

diagnosis messages on screen.<br />

Meanwhile, a single plate<br />

allows easy access to the<br />

internal drive system for<br />

maintenance while the height<br />

adjustable support frame is<br />

now standard to allow for<br />

variable height labelling.<br />

The more ergonomic design<br />

has simplified the consumable<br />

web path, with threading<br />

directions engraved onto<br />

the machine body, openended<br />

rollers, and tool-less<br />

collapsible label rewind<br />

for fast, easy threading.<br />

Inside core gripping of the<br />

consumables means there are<br />

no drive location pegs to line<br />

up, and a new quick-release<br />

aluminium mandrel disc<br />

makes changing the 400m<br />

media rolls even quicker.<br />

“Standard features that<br />

have always made Logopak’s<br />

machines stand out have<br />

been preserved in the 300,<br />

including matched labels<br />

and ribbons, refurbishable<br />

printheads for easy ‘plug<br />

and play’ replacement in less<br />

than 30 seconds, and the ‘test<br />

label’ button to print a label<br />

for documentation or audit<br />

purposes,” confirms UK<br />

sales director at Logopak<br />

Howard Jagger.<br />

The new printheads utilise<br />

the latest long life HD print<br />

plates from Rohm. They are<br />

available in 100 or 150mm<br />

widths and are compatible<br />

with older PL3 printheads.<br />

The impressive speed is due<br />

to the label roll having a<br />

new perfectly pre-tensioned<br />

mechanical unwind while<br />

the barcode label has<br />

excellent print quality as<br />

it is printed ‘picket fence’<br />

fashion, as per GS1 guidelines,<br />

says Logopak.<br />

T 01904 692333<br />

W www.logopak.co.uk<br />

SHRINK WRAPPING solutions you can TRUST<br />

Yorkshire Packaging Systems exclusive distributors for the range<br />

of high speed shrink wrappers<br />

YPS will offer full spares and<br />

service backup to existing<br />

UK and Ireland based<br />

Hugo Beck installations.<br />

High Speed Side Sealers<br />

High Speed Feeders<br />

Form, Fill and Seal Machines<br />

High Efficiency Shrink Tunnels<br />

CUSTOMER SERVICE<br />

Woodkirk Freight Terminal, Quarry Lane, Woodkirk, Dewsbury, West Yorkshire, WF12 7JJ, UK<br />

T: +44(0)1924 441355 F: +44(0)1924 440686 E: enquiries@yps.co.uk www.yps.co.uk

www.machineryupdate.co.uk MARCH/APRIL <strong>2016</strong> MACHINERY UPDATE 17<br />

Biscuits and cracker line offers<br />

upkeep and hygiene time gains<br />

whluk_adver16_machup_0304_d1b5_eoc.pdf 1 2/23/16 12:57 AM<br />

Baker Perkins has<br />

upgraded its range<br />

of sheet forming and<br />

cutting lines for hard sweet<br />

biscuits and crackers to<br />

TruClean standards, offering<br />

benefits in maintenance and<br />

hygiene with lower costs and<br />

faster changeovers.<br />

These lines comprise either a<br />

3-roll sheeter or a laminator to<br />

take a bulk feed of dough and<br />

form it into a sheet, ready to<br />

pass through gauge rolls which<br />

achieve the chosen thickness,<br />

and then a rotary cutter before<br />

baking. But the market was<br />

demanding a higher standard<br />

which is why the radical<br />

redesign has taken place to<br />

achieve reduced maintenance<br />

needs and make access much<br />

easier where it is needed.<br />

Visit W H Leary<br />

and Robatech<br />

Hall 6<br />

Stands D60 & D62<br />

TIME FOR A CLEANING<br />

C<br />

ROUTINE IS REDUCED BY<br />

40%<br />

on the upgraded sheet forming<br />

and cutting lines for biscuits<br />

Improving visibility and CMY<br />

access for cleaning, simplifying<br />

K<br />

removal and replacement of<br />

components and assemblies,<br />

cutting the number of<br />

components, and reducing<br />

accumulation of debris were<br />

the principle design requirements.<br />

Baker Perkins says it has<br />

achieved all of this without<br />

compromising any fundamental<br />

process performance<br />

parameters and attributes such<br />

as output and weight control.<br />

As well as time gains, it is<br />

now possible to clean a line<br />

more thoroughly than previously<br />

as allergen-level cleaning can<br />

be achieved between product<br />

runs, a requirement on which<br />

an increasing number of<br />

companies insist.<br />

T 01733 283000<br />

W www.bakerperkins.com<br />

M<br />

Y<br />

CM<br />

MY<br />

CY

18 MACHINERY UPDATE MARCH/APRIL <strong>2016</strong> www.machineryupdate.co.uk<br />

New Machinery<br />

Latest horizontal flow<br />

wrapper provides gain<br />

Ulma Packaging is now<br />

offering the UK market<br />

a high tech version of<br />

its Atlanta range of horizontal<br />

flow wrapping<br />

machines.<br />

The Atlanta<br />

Hi-tech can<br />

produce a three<br />

seal pillow pack<br />

and is designed<br />

to improve<br />

efficiencies<br />

across many sectors.<br />

Key target markets include<br />

bakeries, dairies, fresh produce,<br />

confectionery, biscuits and pies,<br />

medical sachets, hardware and<br />

even stationery.<br />

This latest model includes<br />

as standard the ‘no product,<br />

no bag’ feature, misplaced<br />

product detection and access<br />

to a bespoke software ‘UDAQ’<br />

allowing integration with<br />

remote line monitoring and<br />

data capture. Designed for<br />

the most demanding<br />

applications, the machine<br />

can be installed as part of an<br />

automatic packing line or as<br />

a standalone manual feeding<br />

solution.<br />

Versatility and flexibility is a<br />

Versatility and flexibility is a key feature with all Atlanta models<br />

key feature with all the<br />

Atlanta models and the<br />

Hi-tech takes this even further<br />

thanks to the integration<br />

of a multi-axis servo motor<br />

solution where all three<br />

motors can be synchronised<br />

through an electronic control<br />

panel and simple to use colour<br />

graphics screen, says the<br />

company. The 10 inch colour<br />

touch screen has built-in<br />

fault finding diagnostics<br />

and an icon menu to make<br />

it easy to use for operators.<br />

The operator language format<br />

can be changed easily via the<br />

screen interface, and comes<br />

as standard with the new<br />

horizontal machine.<br />

Pack length, size and<br />

cutting speed are all<br />

controlled from the touch<br />

screen, which has a built-in<br />

memory allowing the<br />

parameter storage of up to<br />

50 products. Capable of up<br />

to 400 packs a minute where<br />

speed is the important factor,<br />

or if versatility is required, the<br />

model can handle products up<br />

to 500mm in length.<br />

T 01909 506504<br />

W www.ulmapackaging.co.uk<br />

Changeover times are quicker<br />

Label manufacturer<br />

has installed an<br />

updated Kama unit<br />

Kama has updated its compact<br />

die-cutting and finishing machine<br />

which is now available with a new<br />

sheet feeder, a modern touch<br />

panel and new software.<br />

The latest ProCut 58 is capable<br />

of handling format sizes up to<br />

580 mm x 400 mm, 50 mm<br />

more than previously, says UK<br />

agent Friedheim International.<br />

Indeed, Kama has already<br />

delivered the first of the new<br />

generation ProCut 58 die-cutters<br />

to a company in Belgium that<br />

produces labels and folding<br />

boxes for pharmaceuticals and<br />

cosmetics – a market with an<br />

increasing demand for short runs<br />

and small formats.<br />

Changeover from die-cutting<br />

to hot foil stamping or back again<br />

takes about ten minutes.<br />

T 01442 206100<br />

W www.friedheim.co.uk

Source new solutions at Foodex <strong>2016</strong><br />

Whatever part of the industry you represent, at Foodex and its<br />

co-located shows you’ll find a show-floor full of ideas to enhance<br />

productivity, improve efficiency and boost your business.<br />

Held every two years, the shows bring together over 1200 suppliers<br />

plus over 100 informative sessions from more than 250 experts.<br />

By registering for Foodex you’ll also gain free access to Food & Drink Expo, Farm Shop<br />

& Deli Show and National Convenience Show<br />

foodex.co.uk<br />

@foodex #FDX<strong>2016</strong><br />

foodex.co.uk/LinkedIn<br />

bakery beverage dairy fresh ingredients logistics meat seafood<br />

CO-LOCATED WITH<br />

MEDIA PARTNERS<br />

This is a trade event. No under 16s will be admitted

20 MACHINERY UPDATE MARCH/APRIL <strong>2016</strong> www.machineryupdate.co.uk<br />

Preview<br />

Over 100 sessions<br />

and 250 speakers<br />

deliver rich content<br />

As well as showcasing the<br />

latest trends across the food<br />

manufacturing sectors, Foodex<br />

<strong>2016</strong>, will include over 100 sessions<br />

and 250 confirmed speakers<br />

so visitors can hear from the<br />

industry’s leading experts on a<br />

wide range of topics including food<br />

and drink fraud, protecting supply<br />

chains and opportunities and<br />

threats in exporting.<br />

The sugar debate will also<br />

be covered in regard to diet<br />

and obesity, as an issue that<br />

manufacturers have a key role<br />

to play, while other subjects<br />

include practical ways to combat<br />

campylobacter.<br />

Highlighting one of the biggest,<br />

ongoing issues facing the industry,<br />

the skills gap will be addressed at<br />

the Foodex Future Skills Summit.<br />

A number of leading experts will<br />

gather to address the challenges<br />

facing the industry and what can be<br />

done to encourage fresh talent to<br />

climb the ranks. Key spokespeople<br />

will join the panel from the Institute<br />

of Food Science and Technology<br />

(IFST) and National Skills Academy<br />

with further keynote speakers still<br />

to be announced.<br />

Food and drink industry<br />

will gather at the NEC<br />

Foodex, the trade event<br />

for the food and drink<br />

processing, packaging,<br />

ingredients and logistics<br />

industries, has sold out more<br />

than two months ahead of<br />

kick-off in <strong>April</strong>.<br />

The biennial show at the<br />

NEC, Birmingham from<br />

18-20 <strong>April</strong>, will represent<br />

eight sectors of the industry<br />

comprising bakery, beverage,<br />

dairy, fresh, ingredients,<br />

logistics, meat and seafood.<br />

About 60% of the 350<br />

exhibitors at the three-day<br />

event will be new for <strong>2016</strong>,<br />

with 40% of companies<br />

returning to the show following<br />

success at the 2014 exhibition.<br />

The UK food and drink<br />

manufacturing and processing<br />

industry is set for growth of<br />

between 3-4% in the short to<br />

medium term while reaching a<br />

value of about £113bn in 2018-<br />

2019 according to a Research<br />

and Markets report. There<br />

are over 9500 manufacturing<br />

sites and factories in this<br />

sector, with the bakery, meat<br />

processing and dairy industry<br />

operating the largest number<br />

of processing sites.<br />

Adpak <strong>MU</strong> M-A <strong>2016</strong> V3_Layout 1 23/02/<strong>2016</strong> 13:03 Page 1<br />

www.adpak.co.uk<br />

Foodex runs from 10am, Monday 18 <strong>April</strong> until 4pm on Wednesday 20 <strong>April</strong><br />

Sector uplift is clear to see as<br />

Foodex continues to grow.<br />

In addition to a wealth of<br />

insight, debate and exposure<br />

to the latest innovations,<br />

visitors will be able to enjoy<br />

a host of competitions.<br />

The Great New Idea is new<br />

to the <strong>2016</strong> show whereby<br />

exhibitors will put forward<br />

their best innovation. Entrants<br />

will be whittled down to three<br />

through voting online ahead<br />

of the event, before judges<br />

will choose a winner during<br />

live presentations at the<br />

show itself.<br />

Foodex <strong>2016</strong> is co-located<br />

with the Farm Shop & Deli<br />

Show, National Convenience<br />

Show and Food & Drink Expo.<br />

To register for free, receiving<br />

entry to all co-located shows,<br />

visit W www.foodex.co.uk<br />

Let Adpak Provide your<br />

Perfect Packaging Solution<br />

• Suitable for food and non-food products • Designed and built to European machinery standards<br />

• Manufactured in stainless steel • Competitively priced • Reliable bespoke solutions • Space saving design<br />

3 Pendleside, Lomeshaye Ind Estate, Nelson, Lancs, BB9 6RY Tel: 01282 601444 Fax: 01282 612201 info@adpak.co.uk

www.machineryupdate.co.uk MARCH/APRIL <strong>2016</strong> MACHINERY UPDATE 21<br />

Seal testing along with<br />

pack stacking and UV<br />

UV Torpedo conveyor from JenAct can be discussed on the Jenton International stand at the three-day event in <strong>April</strong><br />

Jenton Ariana is expanding<br />

its range of products for<br />

food manufacturers this<br />

year as vistors will see.<br />

In addition to its range of<br />

seal testers for gas flushed<br />

thermoformed packs (typically<br />

for bakery), the company has<br />

developed and sold several<br />

seal testers for ready meals<br />

applications with random<br />

infeed up to 140 per minute.<br />

“We see this market growing<br />

because of the conflicting<br />

demands of long shelf life<br />

delivered by barrier films<br />

with perfect seals contrasting<br />

with the need for easy peel,”<br />

says Richard Little, managing<br />

director of Jenton.<br />

For <strong>2016</strong>, Jenton Ariana has<br />

also introduced a new high<br />

speed pack stacker which has<br />

already been sold for food as<br />

well as non-food applications.<br />

It can be combined with auto<br />

banding for shelf loading/easy<br />

handling applications.<br />

The design team at Jenton<br />

has also been busy with<br />

revising the equipment offered<br />

for the picking and placing<br />

of cut pads for fresh fish.<br />

Scrolling denesters from the<br />

range will be at the show.<br />

JenAct Ltd is the subsidiary<br />

of Jenton that specialises in<br />

UV disinfection. In the food<br />

industry, applications include<br />

the treatment of HVAC coils<br />

and air ducts and surface<br />

applications such as conveyor<br />

belts as well as the direct<br />

treatment of food. JenAct has<br />

ten granted patents on this<br />

technology and can act in a<br />

consultative role to help advise<br />

what UV can actually achieve<br />

in any given application<br />

before then advising which<br />

the most appropriate<br />

equipment for the job is.<br />

STAND G299<br />

W www.jenton.co.uk<br />

Themed focus areas will reflect the current<br />

retail and production trends for food packs<br />

This year Multivac will be<br />

showcasing a number of focus<br />

areas reflecting current retail<br />

and production trends. These<br />

areas will have themes such<br />

as increased efficiency, low<br />

investment and maintenance<br />

cost and high flexibility<br />

as well as head to head<br />

comparisons of skin tray vs<br />

skin thermoformed packs.<br />

A fully integrated line<br />

will demonstrate that<br />

thermoforming machines<br />

are anything but inflexible<br />

or expensive and with the<br />

introduction of the new R 085,<br />

investment and real estate<br />

requirements are low<br />

while flexibility is very high.<br />

“The R 085 is the best of both<br />

worlds: the low pack cost<br />

of a thermoformer and the<br />

flexibility of a tray sealer,”<br />

explains Laura Affleck,<br />

marketing manager at<br />

Multivac UK.<br />

Also on the stand will be a<br />

Laska KU130 bowl chopper<br />

and a Risco RS110 filler as<br />

well as the recently launched<br />

Baseline range of chamber<br />

machines, which are value<br />

driven models designed and<br />

built to exacting specifications<br />

but without the complexity<br />

of the existing range.<br />

Of particular interest to<br />

many visitors will be the<br />

T300 and R105MF comparison<br />

area, where the two<br />

technologies capable of<br />

producing skin packs for the<br />

protein markets can be seen<br />

head to head (see more details<br />

on page 50).<br />

STAND P200<br />

W www.multivac.co.uk<br />

In brief<br />

INNOVATION IN STYLE<br />

FOR FOOD FLEXPACKS<br />

An automatic system to produce<br />

sandwich ‘grab-bags’, stand-up<br />

bags with pockets and a series of<br />

reclosable bag options are among<br />

the latest flexible packaging<br />

options for food that will be<br />

featured by Italian machinery<br />

manufacturer PFM.<br />

In addition, there is the latest<br />

version of PFM’s servo flow<br />

wrapper, the Pearl, developed<br />

to provide smaller or start-up<br />

operations with all the efficiency<br />

advantages of multi-axis servo<br />

drive, but at an entry level cost.<br />

STAND P260<br />

W www.pfmuk.com<br />

ENERGY SAVING DOORS<br />

PROVIDE EFFICIENCIES<br />

Efaflex UK will be showcasing<br />

a range of door options and<br />

demonstrations will show the<br />

benefits such as reduced energy<br />

costs and increased productivity.<br />

On show will be the S Series with<br />

its patented design and opening<br />

speeds of up to 4m a second.<br />

Installing a door has shown<br />

to save costs across sectors<br />

with one customer saving<br />

4,600 litres of heating oil per<br />

heating period.<br />

STAND N229<br />

W www.efaflex.com<br />

VERTICAL BAGGERS ARE<br />

A HIGH SPEED OPTION<br />

Ulma Packaging will unveil the<br />

latest addition to its range of<br />

high speed bagging equipment as<br />

well as demonstrating an<br />

upgraded flow wrapping model<br />

with improved productivity as<br />

well as automatic tray sealers.<br />

The new VTI 640 vertical<br />

bagger is designed for a wide<br />

variety of food products and will<br />

share the spotlight with the VTC<br />

840 VFFS continuous motion<br />

baggers. The Sienna flow<br />

wrapper on show is ideal for<br />

wrapping loose, irregular shaped<br />

products such as fresh fruit<br />

and vegetables.<br />

STAND M250<br />

W www.ulmapackaging.co.uk

22 MACHINERY UPDATE MARCH/APRIL <strong>2016</strong> www.machineryupdate.co.uk<br />

Preview<br />

Latest automated case<br />

loading methods shown<br />

Increased handling<br />

capabilities, flexibility<br />

and output have pushed<br />

automation to the forefront<br />

for many food manufacturers<br />

which is why Pacepacker<br />

Services will showcase new<br />

automated case loading<br />

systems at the show.<br />

Three new inventions using<br />

Fanuc and Festo robots will<br />

demonstrate how Pacepacker<br />

has successfully automated<br />

laborious manual retail case/<br />

crate loading tasks found in<br />

many food factories.<br />

With a fast ROI, the<br />

Cartesian case loader cell can<br />

pick and place an array of<br />

packaged foods – from trays<br />

of fresh meat to punnets of<br />

fruit – with precision and<br />

efficiency. The robot cell<br />

incorporates a Cartesian style<br />

robot and a multi-purpose<br />

Fanuc M20-iA/35M articulated<br />

robot arm to harmoniously<br />

load and palletise retail crates<br />

simultaneously.<br />

“For the first time we will<br />

reveal to Foodex visitors two<br />

different options for case<br />

loading – using Cartesian<br />

and articulated systems.<br />

Using robots from Fanuc/Festo, Pacepacker is automating onerous tasks<br />

By bringing these two robot<br />

types together we are showing<br />

that there is more than one<br />

way to achieve the same end<br />

result,” says Paul Wilkinson,<br />

Pacepacker’s business<br />

development manager.<br />

Incorporating Festo<br />

mechatronic motion, the<br />

twin-axis Cartesian case<br />

loader robot picks individual<br />

products from a single line<br />

or entire layers and packs<br />

them into secondary trays or<br />

cases. Capable of speeds in<br />

the region of 120-180 packs<br />

per minute, the system allows<br />

users to pick and place with<br />

different accelerations,<br />

decelerations and an infinite<br />

number of positions which,<br />

says the company, proves that<br />

there are cost efficient options<br />

for high speed pick and place<br />

applications beyond a delta or<br />

six-axis robot.<br />

STAND L229<br />

W www.pacepacker.com<br />

High speed print and apply labeller launch<br />

joins integrated barcode verifier on stand<br />

Logopak International will<br />

be demonstrating a range of<br />

equipment including the new<br />

Logopak 300 print and apply<br />

machine (see more details<br />

on page 16), and Vericoder,<br />

the first integrated barcode<br />

verifier for checking every<br />

label to ISO or ANSI standards<br />

which removes the need for<br />

manual intervention.<br />

The Logopak 300 is a high<br />

speed case and pack labeller<br />

for entry level applications that<br />

has a simple and clean design<br />

The Vericoder is among exhibits<br />

with German build quality.<br />

Speeds of up to 80 packs a<br />

minute can be achieved<br />

on this uncomplicated<br />

labelling unit.<br />

Logopak says its<br />

machines offer<br />

mechanical reliability<br />

as they are optimised<br />

for speed as well as<br />

productivity, while<br />

its thermal transfer<br />

labels and foils are<br />

manufactured to provide<br />

excellent print quality.<br />

STAND G289<br />

W www.logopak.co.uk<br />

Weighing<br />

solutions for<br />

foodstuffs<br />

Yamato Scale Dataweigh will<br />

demonstrate the vital role that<br />

checkweighers, multihead<br />

weighers and table top weighers<br />

play throughout the food<br />

packaging process. The company<br />

will be exhibiting both its<br />

table top semi-automatic<br />

Dataweigh range and its I-Series<br />

checkweighers at the event.<br />

Yamato’s I-Series checkweigher<br />

is a high performance, resilient<br />

piece of weighing machinery<br />

that has applications across the<br />

food and non-food industries,<br />

with several bespoke options<br />

available to provide the optimised<br />

solution for the handling and rapid<br />

weighing of products.<br />

If products are delicate, or<br />

fragile in nature, then a low impact<br />

solution such as the table top<br />

semi-automatic Dataweigh may<br />

provide the perfect solution,<br />

says the company.<br />

This combination scale<br />

allows fixed weight packages<br />

of vegetables and meat to be<br />

manually checked and weighed at<br />

up to 30 packs per minute.<br />

“We’re excited to be<br />

showcasing our equipment at the<br />

exhibition,” says Andrea Spencer,<br />

commercial operations manager<br />

for Yamato Scale Dataweigh UK.<br />

“Many customers are<br />

interested in the process and<br />

machinery that keeps their lines<br />

running behind the scenes,” she<br />

continues. “This event gives us a<br />

valuable opportunity to engage<br />

with them and discuss how they<br />

can best achieve their objectives<br />

with Yamato’s checkweighers and<br />

our range of weighing machines.”<br />

STAND P290<br />

W www.yamatoscale.co.uk<br />

Yamato will show its equipment

www.machineryupdate.co.uk MACHINERY UPDATE 23<br />

QA expertise will<br />

be tested at show<br />

Durable, Easy Clean<br />

& Anti-Slip<br />

Resin Flooring for<br />

Processing & Packaging<br />

Ishida Europe will literally<br />

be putting its quality<br />

control expertise to the test<br />

by inviting visitors to bring<br />

their own packs to the stand<br />

to be tested for contaminants,<br />

leakages or other QC issues.<br />

A competition on the stand<br />

will also be running, with<br />

visitors invited to select a<br />

box of confectionery to run<br />

through the Ishida x-ray<br />

machine. Anyone choosing a<br />

box with a contaminant will<br />

then be entered into a prize<br />

draw to win an iPad.<br />

Equipment demonstrated<br />

includes its recently-launched<br />

AirScan leak detector and<br />

its IX-GA-4075 x-ray system,<br />

while the company will<br />

also be showing a 14 head<br />

multihead weigher from its<br />

RV series of equipment.<br />

The new Ishida AirScan<br />

minimises spoilage in a wide<br />

variety of pre-packed retail<br />

food products, including<br />

fresh, cooked and cured<br />

meat, poultry, seafood, fruit,<br />

vegetables, cheeses and also<br />

ready meals.<br />

STAND K279<br />

W www.ishidaeurope.com<br />

Foodex<br />

H291<br />

Leaks in sealed MAP packs are identified at speeds up to 180 packs a minute<br />

Meeting demand for efficient<br />

and sustainable tray seals<br />

The ability to meet food<br />

manufacturers’ demands for<br />

efficiency, flexibility and quality<br />

in their tray sealing operations<br />

will be demonstrated on the<br />

Proseal stand, where the<br />

company will showcase its<br />

electric heat seal technology<br />

that also delivers valuable<br />

environmental benefits.<br />

The Proseal GT2e is a high<br />

speed tray sealer capable of in<br />

excess of 120 trays per minute,<br />

which combines its E-seal<br />

electric sealing technology<br />

with the functional and<br />

reliability benefits of Proseal<br />

equipment.<br />

One benefit of the ‘e’ design<br />

is the machine’s flexibility in<br />

being able to handle any type<br />

of tray including atmospheric,<br />

MAP, vacuum MAP, skin,<br />

skin plus and skin deep.<br />

Customers can select the<br />

format types they require<br />

and these can be added or<br />

removed easily.<br />

STAND H300<br />

W www.prosealuk.com<br />

~ British Manufactured ~ Full Installation in UK & Abroad ~<br />

For floors that need to be anti-slip, durable, chemical or<br />

temperature resistant, decorative, hygienic or all the above;<br />

John Lord has the expertise to offer the complete flooring<br />

package for both industrial and commercial environments.<br />

S PECIALIST FLOORING<br />

| +44 (0)161 764 4617<br />

| john-lord.com

24 MACHINERY UPDATE MARCH/APRIL <strong>2016</strong> www.machineryupdate.co.uk<br />

Installation News<br />

Flexible and gentle handling<br />

is a key ingredient for bakery<br />

Switching to servos has resulted in a super-efficient 60sq m machine that can now be manned by a single operator<br />

At the New Jersey-based bakery, two F44 robots on the Schubert system fill the carton trays with product that has previously been packed in flow wrap bags<br />

Schubert has developed<br />

a TLM final-packaging<br />

system for individually<br />

packaging croissants and<br />

Danish pastries produced by<br />

International Delights in New<br />

Jersey, USA. Thanks to the<br />

Schubert scanner, the highly<br />

flexible system works in a way<br />

that is very gentle on these<br />

products as well as being able<br />

to handle other products and<br />

tray formats easily.<br />

Nine different layouts and<br />

approaches were developed<br />

with the customer before the<br />

ideal solution was found.<br />

For the most part, space<br />

requirements, ease of use<br />

and considerations regarding<br />

possible future products and<br />

packaging formats played<br />

an important role. As is quite<br />

common with American<br />

companies, the machines for<br />

manufacturing and packaging<br />

products were developed<br />

simultaneously. Both the<br />

space requirements for the<br />

Schubert system as well<br />

as the packaging process,<br />

including packaging speed,<br />

had to be altered several<br />

times in the project design<br />

phase and adapted to the<br />

changing parameters of the<br />

manufacturing process.<br />

The Schubert line, which<br />

eventually proved successful,<br />

receives the baked products –<br />

croissants, Danish pastries and<br />

pains au chocolat – from the<br />

cooling or freezing coils and<br />

places them on a conveyor belt<br />

at predetermined intervals<br />

with three F4 robots. This<br />

feeds the products into a flow<br />

wrapping machine.<br />

Subsequently, another<br />

robot distributes the packaged<br />

baked goods on two belts.<br />

The dual-lane transport<br />

reduces the belt speed of the<br />

Picker robots place the products on the belt at predetermined intervals<br />

line, so that a large amount of<br />

products can be packaged in a<br />

gentle manner. An F2 and an<br />

F3 robot are used to form the<br />

trays, while the F3 robot takes<br />

the flat tray blanks from the<br />

magazine and transfers them<br />

to the F2 robot. This leads the<br />

blanks over gluing nozzles,<br />

presses the blank through the<br />

folding unit and setting the<br />

finished erected carton tray on<br />

a Transmodul’s size part.<br />

Two F44 robots then fill<br />

the cardboard trays with the<br />

products packed in flow wrap<br />

bags or, optionally, unwrapped.<br />

DIFFERENT FORMATS<br />