Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

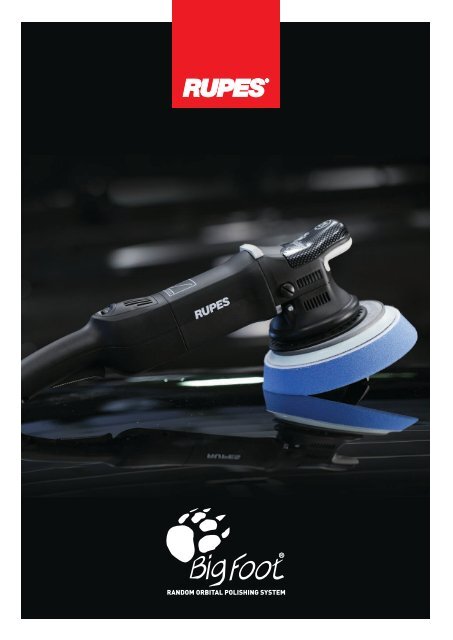

BIGFOOT MarkII<br />

At <strong>RUPES</strong> we produce tools that change the way people work. Our ultimate<br />

goal is helping professionals to work better, faster, and more effectively. We<br />

know that the satisfaction of a job well done is something priceless and we<br />

work hard so you can work easier. The BigFoot random orbital polishing<br />

system is tailored specifically to the professionals who demand the best finish<br />

possible. Based on a large diameter random orbital movement, the BigFoot<br />

system delivers faster paint correction with better finishing than any other<br />

system available. As a result of <strong>RUPES</strong> ongoing research two new machines<br />

are born, two cutting edge orbital polishers that deliver the smoothest<br />

polishing experience ever. Discover the new LHR21 MarkII & LHR15 MarkII,<br />

discover the next level of perfection.

30<br />

+<br />

EFFICIENCY<br />

A more powerful motor, with<br />

less energy consumption and<br />

a higher performance.<br />

MORE SPEED AND TORQUE<br />

Higher RPM and more torque to<br />

guarantee maximum performance on both<br />

flat and curved surfaces.<br />

OPTIMUM BALANCE<br />

The eccentric weight and mechanical parts<br />

have been optimized to obtain an even better<br />

balance than the previous generation.<br />

LOWER VIBRATION LEVEL<br />

Less stress on the user allowing longer<br />

use of the tool and an improved experience.

IMPROVED ERGONOMICS<br />

The rubber cup positioned on the body machine and grip refines<br />

the flawless BigFoot polishers design. The soft-grip material<br />

makes it pleasant and secure to hold. Practical handgrip, silent<br />

mechanics, minimum vibration; These are just some features<br />

that makes BigFoot the industries most versatile and soughtafter<br />

polishing system.<br />

ELECTRONIC SPEED CONTROL MODULE<br />

The variable speed dial provides the ability to adjust speed<br />

for specific applications and thanks to improved electronic<br />

controls the delivery of power is more noticable. Pad orbits<br />

and the resulting rotation are more consistent across the entire<br />

range, maintaining the specified speed under load, from 2500 to<br />

4700 OPM.The BigFoot delivers the right amount of power needed<br />

for the specific task giving users six settings for any polishing<br />

situation.<br />

IMPROVED BALANCE<br />

The perfect balance of the components makes polishng comfortable<br />

and vibration free. This ensures an optimum transfer of<br />

power to the working surface, even on complex or curved<br />

surfaces, and delivers the best polishing results. Additionally,<br />

balance offers effortless to control and maneuverability allowing<br />

operators to work for longer without fatigue.<br />

ON-OFF SWITCH LOCK<br />

The on-off switch button located on the left side of the handgrip<br />

helps the operator to move his hands freely to different<br />

gripping positions while polishing, allowing for continuous<br />

operation and minimal work stoppage for grip or speed changes.<br />

DESIGN<br />

Attention to detail is something more than just attractive<br />

design. Every detail of the BigFoot is carefully considered to<br />

ensure it contributes to improved user experience and results.<br />

The rubber support positioned on the body of the machine has<br />

been added to keep it stable during the non-working stages.<br />

This simple feature is the result of meticulous research aimed<br />

at achieving maximum operator comfort.

LHR 21 Mark II<br />

With its 21mm orbit and its 180mm backing pad, the LHR 21 MarkII random<br />

orbital polisher is the perfect solution for working large surface areas. It<br />

provides a fast correction, clean finishing, and does so without neglecting the<br />

<strong>RUPES</strong> branded quality or user experience. The improved motor efficiency<br />

guarantees more power and torque delivery on any surface.<br />

TECHNICAL DATA<br />

Ø backing pad<br />

Ø orbit<br />

Power<br />

O.P.M.<br />

Weight<br />

Variable Speed<br />

Backing pad thread<br />

mm-in 150 - 6”<br />

mm-in 21-13/16”<br />

Watts 500<br />

2500 - 4700<br />

kg-lbs 2.25 - 4.96<br />

M8

LHR 15 Mark II<br />

Built to handle any detailing situation, the new LHR 15 MarkII is the<br />

new frontier of detailing. The ergonomic design allows for precise paint<br />

correction with complete comfort, including curved surfaces, and<br />

difficult to reach areas. More powerful and 30% more efficient, the 15mm<br />

orbit offers excellent correcting power and finishing ability.<br />

TECHNICAL DATA<br />

Ø backing pad<br />

Ø orbit<br />

Power<br />

O.P.M.<br />

Weight<br />

Variable Speed<br />

Backing pad thread<br />

mm-in 125 - 5”<br />

mm-in 15 - 19/32”<br />

Watts 500<br />

2500-5300<br />

kg-lbs 2.20 - 4.85<br />

M8

BIGFOOT DUETTO<br />

Total paint restoration system

LHR 12E DUETTO<br />

All-in-one sanding and polishing system for painted surfaces<br />

Duetto is equally effective working with soft or interface backing pads teamed with micro-abrasives<br />

during the defect correction step or with foam polishing pads and compounds during the polishing<br />

stage. Extensive research on random orbital dynamics and exhaustive testing resulted in the choice of<br />

a 12mm orbit for Duetto. This orbit length greatly improves the surface rectification abilities of the latest<br />

generation of microabrasive discs. The combination of Duetto and microabrasives is especially effective<br />

when smoothing orange peel or significant defects. The finish generated by this combination is<br />

both homogeneous and predictable, with no deep sanding marks.<br />

1 2<br />

Sanding ...<br />

...<br />

Polishing<br />

The use of microabrasive discs to correct severe defects creates a surface that is easily polished, radically<br />

reducing the overall time of the full correction process. Duetto is so well balanced and low in vibration<br />

that the operator can easily control the sanding step by simply guiding Duetto over the surface.<br />

The ability of the operator to control the tool so efficiently minimizes the chances of creating rough and<br />

uneven surfaces that require time-consuming rework.<br />

Duetto has several design features that make it<br />

uniquely operator friendly.<br />

The anti-spinning device reduces the chances of<br />

operator error even for a novice technician. The front<br />

hand grip allows the operator to place his/her hand at<br />

the virtual balance center of the tool and keeps<br />

vibration to a minimum.<br />

The electronic module has built-in torque control,<br />

reducing the need for the operator to apply significant<br />

downward vertical pressure.<br />

Another unique Duetto feature is the rubber support<br />

that allows the operator to place Duetto on a<br />

workbench without the abrasive disc touching a<br />

surface that might contain contaminants that could<br />

transfer to the workpiece during the sanding process.<br />

Compatible with microabrasive discs and the<br />

appropriate 5” interface pad<br />

Interface<br />

Abrasive<br />

Foam<br />

polishing<br />

pads<br />

Duetto is an amazing polisher due to its precise engineering and concern for operator control and<br />

comfort. Duetto is manageable and comfortable in every situation and quickly provides excellent results.<br />

Duetto has all the features of the BigFoot system, neatly packaged in a compact and maneuverable body.<br />

Duetto’s 12mm orbit places it at the very top of the compact machine category in speed, comfort and<br />

manageability.<br />

Duetto is compatible with BigFoot foam polishing pads and abrasive compounds.<br />

BIGFOOT Duetto is perfect for:<br />

- Restoring lustre<br />

- Final polishing after the sanding phase<br />

- Removing wear and medium-light scratch<br />

marks<br />

- Removing holograms generated by previous<br />

polishing that used traditional rotary<br />

methodology<br />

BIGFOOT Duetto guarantees excellent results in:<br />

- Eliminating orange peel and other paint defects<br />

- Removing medium-depth scratches<br />

- Removing surface contaminations chemically<br />

resistant to normal detergents<br />

The attention to detail is not limited to just the innovative and attractive design. The modern lines<br />

and exceptional technical quality are combined with a number of details that are the result of<br />

meticulous research aimed at achieving maximum operator comfort. The non-slip rubber inserts<br />

are numerous and have many functions. In particular, the insert on the machine body is used to<br />

support the polisher when placed on a surface. With its nonslip rubber inserts in the front cover, the<br />

LHR 12E is perfect for all polishing operations in difficult to reach zones. The operator can work in<br />

comfort to produce the best results possible.

BIGFOOT MINI<br />

Polishing system

efore<br />

after<br />

LHR 75E MINI<br />

The LHR 75E is the polisher for difficult shapes and for spot<br />

repair operations.<br />

The LHR 75E is a must for any detailer wishing to<br />

obtain perfect results, even in the most difficult areas.<br />

The 12 mm orbit, combined with <strong>RUPES</strong> accessories and<br />

consumables, achieves quick results on areas such as<br />

mudgards, front panels, headlights, bumpers and more.<br />

The attention to detail is not limited to just the innovative and attractive design. The modern lines and exceptional<br />

technical quality are combined with a number of details that are the result of meticulous research aimed at achieving<br />

maximum operator comfort. The non-slip rubber inserts are numerous and have many functions. In particular, the<br />

insert on the machine body is used to support the polisher when placed on a surface. With its nonslip rubber inserts<br />

in the front cover, the LHR 75E is perfect for all polishing operations in difficult to reach zones. The operator can<br />

work in comfort to produce the best results possible.

LHR 12E Duetto Technical data<br />

Ø backing pad mm-in 125 - 5”<br />

Ø orbit mm-in 12 - 1/2”<br />

Power Watts 400<br />

O.P.M. 4000-5500<br />

Weight kg-lbs 2.6 - 5.73<br />

Variable Speed<br />

•<br />

Backing pad thread<br />

M8<br />

LHR 75E Mini Technical data<br />

Ø backing pad mm-in 75 - 3”<br />

Ø orbit mm-in 12 - 1/2”<br />

Power Watt 400<br />

Weight kg-lbs 2.3-5.07<br />

Variable Speed<br />

•<br />

Backing pad thread<br />

M6

BIGFOOT FOAM POLISHING PADS<br />

<strong>RUPES</strong>’ expanded resin foam polishing pads are specially designed for the random<br />

orbital polishing system. They produce excellent results with substantial time<br />

saving and reduced compound consumption. BigFoot’s large random orbital<br />

movement creates high mechanical stresses on the foam polishing pads, generating<br />

an increase in internal temperature. The innovative “open cell” structure of the<br />

BigFoot foam polishing pads prevents the build-up of heat generated during the<br />

polishing process. In addition, this particular structure provides maximum<br />

efficiency in the polishing process with minimum downward vertical pressure<br />

from the operator. The center hole creates superior ventilation and heat<br />

dispersion through special channels in the backing pad. The innovative design of the<br />

truncated cone shape optimizes the performance of the large diameter orbit, and at<br />

the same time protects against accidental contact between the backing pad and the<br />

work surface.

COARSE<br />

The large dimension of the cells dissipates any heat build-up, allowing the<br />

compounds to work at optimum levels. The oscillating movement of the<br />

BigFoot systems is a perfect partner for the porous structure. The abrasive<br />

compound is not retained inside the sponge but is continuously applied to the<br />

work surface, providing a constant layer of lubricated abrasive between the<br />

surface and the foam polishing pad. The use of Zephir abrasive compound is<br />

recommended.<br />

MEDIUM<br />

The oscillating movement of the BigFoot systems is a perfect partner for the<br />

porous structure. The abrasive compound is not retained inside the sponge but is<br />

continuously applied to the work surface, providing a constant layer of lubricated<br />

abrasive between the surface and the foam polishing pad.<br />

Following are recommended compound/medium foam pad combinations:<br />

- Quarz abrasive compound for optimum results on any type of surface;<br />

- Zephir abrasive compound to decrease correction time and still produce a good finish;<br />

- Keramik abrasive compound for one-step applications.<br />

FINE<br />

This most versatile of BigFoot pads adapts to the type of compound used. Its fine<br />

cell structure has a medium/hard consistency. Produced from superior grade<br />

resins, the fine pad heightens the “gloss level” of the compounds while offering<br />

excellent speed of correction.<br />

Following are recommended compound/medium foam pad combinations:<br />

- Quarz abrasive compound for an excellent finish in one-step applications;<br />

- Keramik abrasive compound for excellent results on difficult surfaces/this<br />

combination will easily remove light swirls and holograms;<br />

- Diamond abrasive compound to obtain extremely high levels of gloss on hard surfaces.<br />

EXTRAFINE<br />

Manufactured from a high-density resin that results in a particularly soft consistency<br />

with a very fine cell structure, this foam pad adapts itself beautifully to convex<br />

surfaces and irregular shapes typically found on sports cars and vintage vehicles. Its<br />

unique soft density makes it ideal for attaining an ultragloss surface finish. The use<br />

of Diamond abrasive compound is recommended for a “show car” finish.

BIGFOOT MICROFIBER<br />

POLISHING PADS<br />

The innovative <strong>RUPES</strong> PATENTED microfiber polishing pads are manufactured using a<br />

polyurethane resin directly injected into the structure between the velcro interface and<br />

the microfiber fabric. The resin adheres directly to both materials to provide a stable<br />

and secure bond without the use of adhesives. Due to the unique moulding technique,<br />

<strong>RUPES</strong> is able to offer a pad with an beveled, allowing easy conformabiliity to convex<br />

shapes during the polishing process. In addition to helping dissipate heat, the centre<br />

hole also helps to correctly fit the microfiber polishing pad onto the backing plate.<br />

CUTTING AND FINISHING<br />

The microfiber fabric is manufactured in two versions, blue for the correction step to enhance the<br />

cutting capacity of the abrasive, and yellow for light action to promote the gloss level.<br />

MAIN ADVANTAGES<br />

Quick defect correction on high solids or ceramic clears coat.<br />

High efficiency on clear coat and one stage surfaces.<br />

Greatly reduced polishing cycle times.<br />

Less dust on the surface during polishing process.<br />

Comfortable and easy to use.<br />

BLUE CUTTING PAD<br />

The Blue Microfiber Cutting Pads are designed for removing heavy<br />

swirl marks, scratches and oxidation from any color paintwork. The<br />

cutting version features a short and dense microfiber and is perfect<br />

for use with heavy cutting BigFoot polishing compound.<br />

The special microfiber allows for the true correction power of the<br />

product used and for maximum product coverage to achieve the<br />

highest quality results on ceramic laquer.<br />

YELLOW FINISHING PAD<br />

The Yellow Microfiber Finishing Pads are designed to restore the depth<br />

and clarity to your vehicle’s paintwork. The long and soft microfiber is<br />

perfect for removing light swirl marks, holograms using fine and ultra<br />

fine BigFoot polishing compounds. The Yellow Microfiber Finishing<br />

Pads eliminate light imperfections delivering a perfect optical grade<br />

finish.

SPIRAL SLOTS, A REAL INNOVATION<br />

The innovative spiral slots represent an important technical<br />

improvement with an unique design. Developed for use with<br />

BigFoot random orbital polishers, the new spiral slots guarantee:<br />

- Heat dissipation<br />

- Lighter weight for a better balance of the machine<br />

- Controlled and measured spreading of the polishing compounds on<br />

the surface

BIGFOOT ABRASIVE<br />

COMPOUNDS<br />

BigFoot abrasive compounds are the result of in-depth studies and research and<br />

consist of high quality abrasive mixes, all silicone free. The compounds are specifically<br />

designed for random orbital polishing. Random orbital polishing compounds require<br />

a unique formula to assure that the product has the perfect combination of viscosity<br />

and aggressiveness. These unique compositions result in a product whose consistency<br />

delivers the best possible solution for uniform distribution on the foam polishing pad.<br />

Four different types of compounds are available, each satisfying a particular polishing need.<br />

COARSE<br />

ZEPHIR GLOSS is a high-performance compound recommended for first step<br />

polishing. Its grain is the most “aggressive” of the BigFoot abrasives and is<br />

used for the rapid removal of marks and scratches. At the same time Zephir<br />

is highly effective in restoring paints and creating a high degree of gloss.<br />

MEDIUM<br />

QUARZ GLOSS is a medium grain abrasive compound that easily repairs<br />

minor surface scratches and minor scoring from sources such as car wash<br />

brushes. Quarz can be used with full confidence that it will not leave halos<br />

or holograms.<br />

FINE<br />

KERAMIK GLOSS is the ideal composition for perfect finishes on particularly<br />

hard clear coats. This fine water-soluble abrasive compound is ideal for<br />

totally eliminating paint defects and for a hologram-free final step of spot<br />

repair, following the microabrasive nib removal process.<br />

EXTRAFINE<br />

DIAMOND is specifically formulated for the final finishing pass and its ultra-fine<br />

abrasive generates a deep lustre and color depth. The product is water soluble,<br />

allowing for easy removal of any residue. The extreme lustre and gloss that all<br />

professionals have sought for years are finally easily within reach!

UHS<br />

UHS EASY GLOSS<br />

High Solids Clear Coat Correction Compound<br />

UHS FOAM POLISHING PAD<br />

High Solids Clear Coat Polishing Pad<br />

Designed for scratch resistant and high solid ceramic paints, but works equally as well on all clear coat surfaces, the<br />

<strong>RUPES</strong> UHS Polishing System removes imperfections and leaves a high-gloss finish in just 1-step. The UHS foam<br />

pads also performs well with the <strong>RUPES</strong> Zephir (Blue), Quarz (Green) and Keramik (Yellow) compounds in heavy<br />

correction and gloss enhancement applications with most types of clear coat paints.<br />

Code<br />

Description<br />

9.BFUHS250/6 MEDIUM<br />

• 9.BFUHS/8 MEDIUM<br />

Size<br />

Unit<br />

Code Description Ø mm Ø in Unit<br />

250 ml 1 carton with 6 bottles<br />

9.BF100U/4 MEDIUM 80-100 3”-4” 1 carton with 4 pads<br />

1000 ml 1 carton with 8 bottles 9.BF100U/32 MEDIUM 80-100 3”-4” 1 carton with 32 pads<br />

9.BF100U/50 MEDIUM 80-100 3”-4” 1 carton with 50 pads*<br />

9.BF150U/2 MEDIUM 130-150 5”-6” 1 carton with 2 pads<br />

9.BF150U/16 MEDIUM 130-150 5”-6” 1 carton with 16 pads<br />

9.BF150U/50 MEDIUM 130-150 5”-6” 1 carton with 50 pads*<br />

9.BF180U/2 MEDIUM 150-180 6”-7” 1 carton with 2 pads<br />

9.BF180U/16 MEDIUM 150-180 6”-7” 1 carton with 16 pads<br />

•<br />

9.BF180U/50 MEDIUM 150-180 6”-7” 1 carton with 50 pads*<br />

* 50 UHS Foam polishing pads in 1 bulk

SKORPIO II<br />

EXPERIENCE THE EXCELLENCE<br />

The Skorpio II is what every random orbital sander<br />

operator needs-an extremely quiet tool that has<br />

tremendous power and low vibration!<br />

The newly designed pneumatic Skorpio II is the quietest<br />

random orbital sander in its class. Further, it comes in a<br />

choice of orbit sizes to fit your particular application.<br />

The body is coated with an anti-slip rubber for better<br />

handling, the throttle lever is designed to support the<br />

operator’s wrist during operation and actually fits perfectly<br />

into the tool body to eliminate “pinch points”, the internal<br />

balancing of the components results in extremely low<br />

vibration and the double row bearings insure greater life<br />

and smoother operation.<br />

ø 3 mm<br />

ORBIT<br />

ø 6 mm<br />

ORBIT<br />

ø 9 mm<br />

ORBIT<br />

SKORPIO II - 3 mm: The 3mm orbit is<br />

designed for finishing applications<br />

that use grade P320 and higher<br />

abrasives. The small orbit, combined<br />

with the high rpm and proper<br />

abrasives, delivers a high quality<br />

finish that is perfectly prepared for<br />

paints and other coatings.<br />

SKORPIO II -6 mm: Following several<br />

years of on-site research, Rupes R&D<br />

department found that a 6mm orbit is<br />

ideal for creating the best combination<br />

of material removal/ surface finish.<br />

The 6mm orbit is 20% more time<br />

efficient than the traditional 5mm orbit<br />

and, when used with the suggested<br />

abrasive grades between P120 and<br />

P320, generates the same high quality<br />

finish.<br />

SKORPIO II - 9 mm: The 9mm orbit<br />

tool is designed primarily for roughing<br />

and material removal applications.<br />

The tool is aggressive, but light in<br />

weight and ergonomically designed.<br />

The suggested range of abrasives is<br />

P60 to P120.

NEW MOTOR<br />

The new high performance motor is designed to provide the best power to weight ratio with<br />

a lower air consumption. Designed to minimize tool noise and to low vibration level, the new<br />

motor reduces internal friction for a higher power transfer ratio, simplified maintenance and<br />

longer tool life.<br />

DOUBLE ROW-BALL BEARINGS<br />

A new double-row ball bearing system, designed specifically by the <strong>RUPES</strong> R&D team, results<br />

in longer bearing life, greater motor stability and lower vibration levels.<br />

ANTI SPINNING SYSTEM<br />

The presence of the rubber shroud prevents the tool from operating in free rotation mode.<br />

This eliminates the risk of damage to the work surface from a true rotary motion.<br />

Further, the shroud allows for more efficient dust extraction by sealing the area between the<br />

tool’s housing and the backing pad. (Not available on “NO VACUUM” models).<br />

ERGONOMIC LEVER WITH RUBBER INSERT<br />

The new throttle lever design, exclusive to <strong>RUPES</strong>, slides the throttle lever fulcrum forward<br />

when the lever itself is depressed. This action lifts the back end of the throttle lever and<br />

places it in a neutral position creating a stable and ergonomic support for the operator’s<br />

hand. Improved handling and reduced vibration are results of the new design.<br />

EXTREMELY WELL BALANCED<br />

<strong>RUPES</strong> R&D team dedicated significant time and effort to create a tool whose internal<br />

components are perfectly balanced. The result is a tool that is very low in vibration and ideal<br />

for high time-exposure applications.<br />

INTERCHANGEABLE BACKING PAD<br />

The internal components of the Skorpio II are so well balanced that operators can actually<br />

change the size of the backing pad without compromising the low vibration level of the tool.<br />

It is now possible to choose the backing pad diameter that you need Ø 125 mm or Ø 150 mm,<br />

without changing tools!<br />

NON VACUUM CENTRAL VACUUM SELF VACUUM<br />

No dust extraction capability<br />

Configured for external<br />

dust extraction systems<br />

Integral dust extraction<br />

system (venturi)

SKORPIO II TECHNICAL DATA<br />

SKORPIO II Ø 125 mm<br />

Ø orbit Ø backing pad Holes Velcro Vinyl Working Air consumption R.P.M. Weight Speed Spindle Vacuum<br />

pressure max control thread<br />

mm mm/in bar/PSIG kg/lbs<br />

RH223 3 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

RH226 6 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

RH229 9 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

Backing pad included 980.035N<br />

RH223/S 3 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

RH226/S 6 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

RH229/S 9 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

Backing pad included 980.035N<br />

RH223A 3 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Central<br />

RH226A 6 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Central<br />

RH229A 9 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Central<br />

RH223T 3 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Self generated*<br />

RH226T 6 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Self generated*<br />

RH229T 9 125 / 5 MULTIHOLE • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Self generated*<br />

Backing pad included 980.035N<br />

SKORPIO II Ø 150 mm<br />

ACCESSORIES<br />

FILTER CARTRIDGE ASSEMBLY<br />

Complete filtering KIT including:<br />

• FILTER UNIT<br />

• HOSE Ø 20 mm - 2 m (6.5ft)<br />

FILTER UNIT<br />

• The filter unit is transparent, allowing the<br />

operator to visually check the level of dust/dirt in<br />

the filter itself;<br />

• The fitting diameter is 29 mm/;<br />

•The unit features a clip to fix the cable/hose of<br />

power tools;<br />

• The unit contains a quick release safety feature.<br />

FILTER CARTRIDGE<br />

•The material is washable polyester, resulting in<br />

long life if the filter is maintained properly;<br />

• Fins create cyclonic air movement that creates<br />

less clogging of the filter and extends product life<br />

significantly.<br />

Ø orbit Ø backing pad Holes Velcro Vinyl Working Air consumption R.P.M. Weight Speed Spindle Vacuum<br />

pressure max control thread<br />

mm mm/in bar/PSIG kg/lbs<br />

RH253 3 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

RH256 6 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

RH259 9 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

Backing pad included 981.320N<br />

RH253/S 3 150/6 - • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

RH256/S 6 150/6 - • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

RH259/S 9 150/6 - • 6.2/90 340 0-11,000 0.8/1.76 • M8-F -<br />

Backing pad included 981.145N<br />

RH253A 3 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Central<br />

RH256A 6 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Central<br />

RH259A 9 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Central<br />

RH253T 3 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Self generated<br />

RH256T 6 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Self generated<br />

RH259T 9 150/6 MULTIHOLE SLIM • 6.2/90 340 0-11,000 0.8/1.76 • M8-F Self generated<br />

Backing pad included 981.320N<br />

ANTISTATIC HOSE ASSEMBLY<br />

Description Size Tools Code<br />

Antistatic hose assembly 5m/16.5ft pneumatic 9GAT02004/AS<br />

Antistatic hose assembly 8m/26.25ft pneumatic 9GAT02002/AS<br />

HOSE ASSEMBLY<br />

Due to its constant desire to improve its products, <strong>RUPES</strong> S.p.A. reserves the right to make any technical or design modification to its products without prior notice.<br />

The manufacturer shall not be responsible for printing errors. This document voids and replaces previous ones.<br />

Description<br />

Code<br />

Filter cartridge assembly<br />

80.400/KIT<br />

Filter unit<br />

80.400/C<br />

Filter cartridge 88.400<br />

Hose Ø 20 mm - 2m<br />

9.1255/C<br />

Description Size Ømm Tool Code<br />

Hose assembly 5m/16.5ft 29 pneumatic 9GAT02004/C<br />

Hose assembly 8m/26.25ft 29 pneumatic 9GAT02002/C<br />

Evaflex hose (in roll) 30m/100ft 29 - 9.1264/30<br />

Evaflex hose (in roll) 30m/100ft 25 - 9GT03047/30

S 145L<br />

Professional dust extractraction with connections for electric and pneumatic tools

S.C.S. SMART CONTROL SYSTEM<br />

Power and function selector<br />

The blue backlighting indicates that the<br />

extractor is ready to be started. Selection<br />

of the manual or automatic mode is<br />

effortless.<br />

Air cycle during operation<br />

Multifunction LED<br />

The led lights up each time extraction is<br />

activated. The silent operation of the<br />

extractor makes this type of signal<br />

valuable, even in loud working<br />

environments.<br />

Tool Connections<br />

Connection for electric<br />

or a pneumatic tools. The<br />

S 145L can automatically<br />

detect the tools<br />

operation and begin<br />

extraction.

EFFICIENCY AND ORGANIZATION<br />

CONNECTED HOSE<br />

Thanks to the new connector attachment with<br />

an air regulator patented by <strong>RUPES</strong>, the hose for<br />

connection with pneumatic tools ensures maximum<br />

extraction efficiency. In fact, the regulator makes it<br />

possible to obtain the correct air flow rate and thus to<br />

optimize extraction based on the type of application.<br />

The positioning of the tool directly on the connector<br />

attachment is also ergonomic and provides for easy use.<br />

FILTERS AND FILTER BAGS<br />

The different types of filters and filter bags available<br />

allow for use of the S1 Series extractors in all types<br />

of work. Thanks to the technical features and<br />

composition of the filtering material they guarantee<br />

extraction of all types of dust, from the most common<br />

types to the most hazardous ones, in compliance with<br />

current regulations and to safeguard the health of the<br />

user.<br />

Grip with toolholder<br />

The practical grip is available on<br />

request for the S 145 series.<br />

The practical toolholder turns the<br />

extractor into a convenient and<br />

functional work station.<br />

Tool management<br />

The top of the S 145L extractor<br />

features a convenient multipurpose<br />

shelf where tools and related<br />

attachments can be stored.<br />

Attachment storage compartment<br />

The rear includes a capacious<br />

attachment storage compartment<br />

where the power cord and the<br />

extraction hose can be stored after<br />

use.