IJRI-ME-02-030 FATIGUE FAILURE ANALYSIS OF STEAM TURBINE SHAFT USING FEM TECHNIQUE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

International Journal of Research and Innovation on Science, Engineering and Technology (<strong>IJRI</strong>SET)<br />

Materials AISI 4130<br />

Steel<br />

Temperature<br />

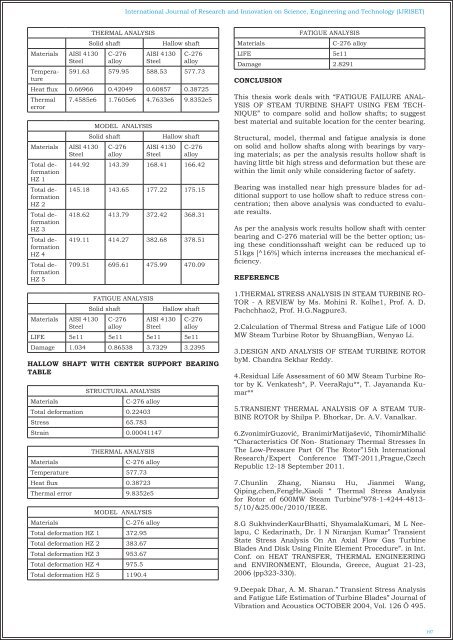

THERMAL <strong>ANALYSIS</strong><br />

Solid shaft<br />

C-276<br />

alloy<br />

AISI 4130<br />

Steel<br />

Hallow shaft<br />

C-276<br />

alloy<br />

591.63 579.95 588.53 577.73<br />

Heat flux 0.66966 0.42049 0.60857 0.38725<br />

Thermal<br />

error<br />

Materials AISI 4130<br />

Steel<br />

Total deformation<br />

HZ 1<br />

Total deformation<br />

HZ 2<br />

Total deformation<br />

HZ 3<br />

Total deformation<br />

HZ 4<br />

Total deformation<br />

HZ 5<br />

Materials AISI 4130<br />

Steel<br />

7.4585e6 1.7605e6 4.7633e6 9.8352e5<br />

MODEL <strong>ANALYSIS</strong><br />

Solid shaft<br />

C-276<br />

alloy<br />

AISI 4130<br />

Steel<br />

Hallow shaft<br />

C-276<br />

alloy<br />

144.92 143.39 168.41 166.42<br />

145.18 143.65 177.22 175.15<br />

418.62 413.79 372.42 368.31<br />

419.11 414.27 382.68 378.51<br />

709.51 695.61 475.99 470.09<br />

<strong>FATIGUE</strong> <strong>ANALYSIS</strong><br />

Solid shaft<br />

C-276<br />

alloy<br />

AISI 4130<br />

Steel<br />

Hallow shaft<br />

C-276<br />

alloy<br />

LIFE 5e11 5e11 5e11 5e11<br />

Damage 1.034 0.86538 3.7329 3.2395<br />

HALLOW <strong>SHAFT</strong> WITH CENTER SUPPORT BEARING<br />

TABLE<br />

Materials<br />

STRUCTURAL <strong>ANALYSIS</strong><br />

C-276 alloy<br />

Total deformation 0.22403<br />

Stress 65.783<br />

Strain 0.00041147<br />

Materials<br />

THERMAL <strong>ANALYSIS</strong><br />

C-276 alloy<br />

Temperature 577.73<br />

Heat flux 0.38723<br />

Thermal error 9.8352e5<br />

Materials<br />

MODEL <strong>ANALYSIS</strong><br />

C-276 alloy<br />

Total deformation HZ 1 372.95<br />

Total deformation HZ 2 383.67<br />

Total deformation HZ 3 953.67<br />

Total deformation HZ 4 975.5<br />

Total deformation HZ 5 1190.4<br />

Materials<br />

LIFE<br />

<strong>FATIGUE</strong> <strong>ANALYSIS</strong><br />

C-276 alloy<br />

5e11<br />

Damage 2.8291<br />

CONCLUSION<br />

This thesis work deals with “<strong>FATIGUE</strong> <strong>FAILURE</strong> ANAL-<br />

YSIS <strong>OF</strong> <strong>STEAM</strong> <strong>TURBINE</strong> <strong>SHAFT</strong> <strong>USING</strong> <strong>FEM</strong> TECH-<br />

NIQUE” to compare solid and hollow shafts; to suggest<br />

best material and suitable location for the center bearing.<br />

Structural, model, thermal and fatigue analysis is done<br />

on solid and hollow shafts along with bearings by varying<br />

materials; as per the analysis results hollow shaft is<br />

having little bit high stress and deformation but these are<br />

within the limit only while considering factor of safety.<br />

Bearing was installed near high pressure blades for additional<br />

support to use hollow shaft to reduce stress concentration;<br />

then above analysis was conducted to evaluate<br />

results.<br />

As per the analysis work results hollow shaft with center<br />

bearing and C-276 material will be the better option; using<br />

these conditionsshaft weight can be reduced up to<br />

51kgs [^16%] which interns increases the mechanical efficiency.<br />

REFERENCE<br />

1.THERMAL STRESS <strong>ANALYSIS</strong> IN <strong>STEAM</strong> <strong>TURBINE</strong> RO-<br />

TOR - A REVIEW by Ms. Mohini R. Kolhe1, Prof. A. D.<br />

Pachchhao2, Prof. H.G.Nagpure3.<br />

2.Calculation of Thermal Stress and Fatigue Life of 1000<br />

MW Steam Turbine Rotor by ShuangBian, Wenyao Li.<br />

3.DESIGN AND <strong>ANALYSIS</strong> <strong>OF</strong> <strong>STEAM</strong> <strong>TURBINE</strong> ROTOR<br />

byM. Chandra Sekhar Reddy.<br />

4.Residual Life Assessment of 60 MW Steam Turbine Rotor<br />

by K. Venkatesh*, P. VeeraRaju**, T. Jayananda Kumar**<br />

5.TRANSIENT THERMAL <strong>ANALYSIS</strong> <strong>OF</strong> A <strong>STEAM</strong> TUR-<br />

BINE ROTOR by Shilpa P. Bhorkar, Dr. A.V. Vanalkar.<br />

6.ZvonimirGuzović, BranimirMatijašević, TihomirMihalić<br />

“Characteristics Of Non- Stationary Thermal Stresses In<br />

The Low-Pressure Part Of The Rotor”15th International<br />

Research/Expert Conference TMT-2011,Prague,Czech<br />

Republic 12-18 September 2011.<br />

7.Chunlin Zhang, Niansu Hu, Jianmei Wang,<br />

Qiping,chen,FengHe,Xiaoli “ Thermal Stress Analysis<br />

for Rotor of 600MW Steam Turbine”978-1-4244-4813-<br />

5/10/&25.00c/2010/IEEE.<br />

8.G SukhvinderKaurBhatti, ShyamalaKumari, M L Neelapu,<br />

C Kedarinath, Dr. I N Niranjan Kumar” Transient<br />

State Stress Analysis On An Axial Flow Gas Turbine<br />

Blades And Disk Using Finite Element Procedure”. in Int.<br />

Conf. on HEAT TRANSFER, THERMAL ENGINEERING<br />

and ENVIRON<strong>ME</strong>NT, Elounda, Greece, August 21-23,<br />

2006 (pp323-330).<br />

9.Deepak Dhar, A. M. Sharan.” Transient Stress Analysis<br />

and Fatigue Life Estimation of Turbine Blades” Journal of<br />

Vibration and Acoustics OCTOBER 2004, Vol. 126 Õ 495.<br />

197