Pico Of Canada

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

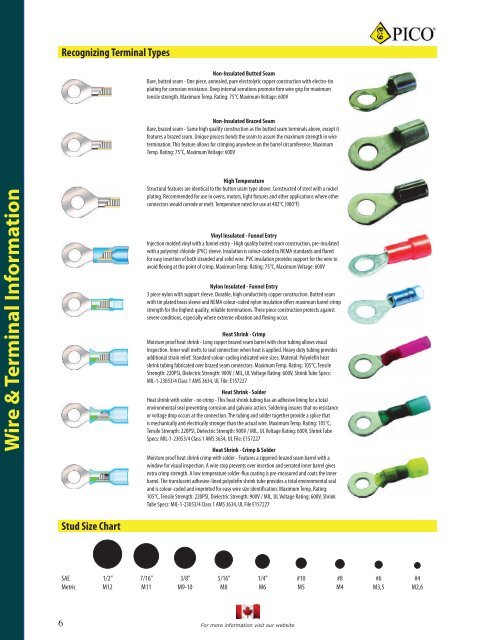

Recognizing Terminal Types<br />

Non-Insulated Butted Seam<br />

Bare, butted seam - One piece, annealed, pure electrolytic copper construction with electro-tin<br />

plating for corrosion resistance. Deep internal serrations promote firm wire grip for maximum<br />

tensile strength. Maximum Temp. Rating: 75°C Maximum Voltage: 600V<br />

Non-Insulated Brazed Seam<br />

Bare, brazed seam - Same high quality construction as the butted seam terminals above, except it<br />

features a brazed seam. Unique process bonds the seam to assure the maximum strength in wire<br />

termination. This feature allows for crimping anywhere on the barrel circumference. Maximum<br />

Temp. Rating: 75°C, Maximum Voltage: 600V<br />

Wire & Terminal Information<br />

High Temperature<br />

Structural features are identical to the button seam type above. Constructed of steel with a nickel<br />

plating. Recommended for use in ovens, motors, light fixtures and other applications where other<br />

connectors would corrode or melt. Temperature rated for use at 482°C (900°F)<br />

Vinyl Insulated - Funnel Entry<br />

Injection molded vinyl with a funnel entry - High quality butted seam construction, pre-insulated<br />

with a polyvinyl chloride (PVC) sleeve. Insulation is colour-coded to NEMA standards and flared<br />

for easy insertion of both stranded and solid wire. PVC insulation provides support for the wire to<br />

avoid flexing at the point of crimp. Maximum Temp. Rating: 75°C, Maximum Voltage: 600V<br />

Nylon Insulated - Funnel Entry<br />

3 piece nylon with support sleeve. Durable, high conductivity copper construction. Butted seam<br />

with tin plated brass sleeve and NEMA colour-coded nylon insulation offers maximum barrel crimp<br />

strength for the highest quality, reliable terminations. Three piece construction protects against<br />

severe conditions, especially where extreme vibration and flexing occur.<br />

Heat Shrink - Crimp<br />

Moisture proof heat shrink - Long copper brazed seam barrel with clear tubing allows visual<br />

inspection. Inner wall melts to seal connection when heat is applied. Heavy duty tubing provides<br />

additional strain relief. Standard colour-coding indicated wire sizes. Material: Polyolefin heat<br />

shrink tubing fabricated over brazed seam connectors. Maximum Temp. Rating: 105°C, Tensile<br />

Strength: 220PSI, Dielectric Strength: 900V / MIL, UL Voltage Rating: 600V, Shrink Tube Specs:<br />

MIL-1-23053/4 Class 1 AMS 3634, UL File: E157227<br />

Heat Shrink - Solder<br />

Heat shrink with solder - no crimp - This heat shrink tubing has an adhesive lining for a total<br />

environmental seal preventing corrosion and galvanic action. Soldering insures that no resistance<br />

or voltage drop occurs at the connection. The tubing and solder together provide a splice that<br />

is mechanically and electrically stronger than the actual wire. Maximum Temp. Rating: 105°C,<br />

Tensile Strength: 220PSI, Dielectric Strength: 900V / MIL, UL Voltage Rating: 600V, Shrink Tube<br />

Specs: MIL-1-23053/4 Class 1 AMS 3634, UL File: E157227<br />

Heat Shrink - Crimp & Solder<br />

Moisture proof heat shrink crimp with solder - Features a zippered-brazed seam barrel with a<br />

window for visual inspection. A wire stop prevents over insertion and serrated inner barrel gives<br />

extra crimp strength. A low temperature solder-flux coating is pre-measured and coats the inner<br />

barrel. The translucent adhesive-lined polyolefin shrink tube provides a total environmental seal<br />

and is colour-coded and imprinted for easy wire size identification. Maximum Temp. Rating:<br />

105°C, Tensile Strength: 220PSI, Dielectric Strength: 900V / MIL, UL Voltage Rating: 600V, Shrink<br />

Tube Specs: MIL-1-23053/4 Class 1 AMS 3634, UL File E157227<br />

Stud Size Chart<br />

SAE<br />

Metric<br />

1/2”<br />

M12<br />

7/16”<br />

M11<br />

3/8”<br />

M9-10<br />

5/16”<br />

M8<br />

1/4”<br />

M6<br />

#10<br />

M5<br />

#8<br />

M4<br />

#6<br />

M3,5<br />

#4<br />

M2,6