Reciprocators_en

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

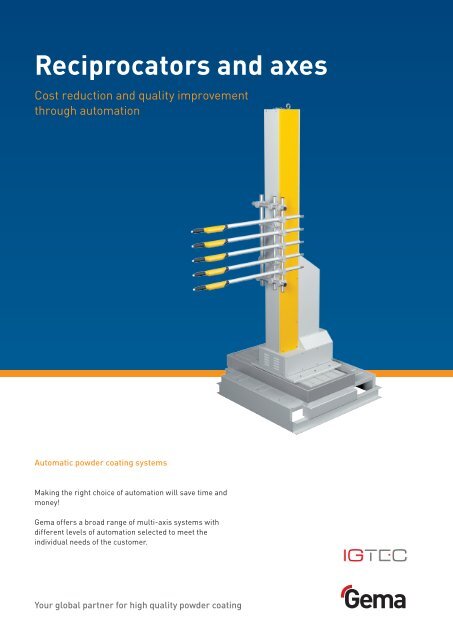

<strong>Reciprocators</strong> and axes<br />

Cost reduction and quality improvem<strong>en</strong>t<br />

through automation<br />

Automatic powder coating systems<br />

Making the right choice of automation will save time and<br />

money!<br />

Gema offers a broad range of multi-axis systems with<br />

differ<strong>en</strong>t levels of automation selected to meet the<br />

individual needs of the customer.<br />

Your global partner for high quality powder coating

The base for all motion<br />

Reliable and precise<br />

Quiet running, individual programming options and stability<br />

combined with high loading capacity are indisp<strong>en</strong>sable for uniform<br />

powder coating. The reciprocators of the ZA series meet these<br />

requirem<strong>en</strong>ts perfectly and feature a solid and maint<strong>en</strong>ance-fri<strong>en</strong>dly<br />

design. They constitute the base for all automation, from simple<br />

vertical strokes to complex and multidim<strong>en</strong>sional processes.<br />

B<strong>en</strong>efits of the ZA reciprocators<br />

– Long-stroke and short-stroke operation<br />

– Tooth belt transmission for quiet running<br />

– Maint<strong>en</strong>ance-free AC-motor<br />

– Narrow column design for space-saving gun configurations<br />

OptiMove Control<br />

The OptiMove axis control unit is user-fri<strong>en</strong>dly, allowing ease of<br />

programming. Each control module controls a single axis. Despite its<br />

compact design, OptiMove offers many functions normally found in<br />

more complex control units.<br />

Features:<br />

– Programming via touch panel<br />

– Up to 255 programs<br />

– Segm<strong>en</strong>t operation and stroke adjustm<strong>en</strong>t<br />

– Cycle times displayed<br />

– Integrated DigiBus / CAN-bus

Detection of gaps,<br />

height and width<br />

Gap detection<br />

The gap control turns off the guns where a gap is detected. For this<br />

application a light barrier detects the object to be coated at the booth<br />

<strong>en</strong>trance and the guns are activated just before the object passes<br />

through. In case of a gap, the guns are turned off after the object has<br />

passed.<br />

Height detection<br />

For the height detection a light grid is used, which automatically<br />

triggers the required guns. With horizontal gun arrangem<strong>en</strong>t, the<br />

reciprocator stroke l<strong>en</strong>gths are automatically adapted to the object<br />

heights.<br />

Width detection<br />

In addition to the gap and height detection systems, the width detection<br />

automatically adjusts the reciprocators via X-axis to variable object<br />

widths. Ideally the guns are arranged vertically, so that the object<br />

contour can be scanned exactly.<br />

Standard axes for all applications<br />

Z-axis:<br />

This is the standard axis. It moves the guns in<br />

a vertical direction.<br />

X-axis:<br />

This axis moves the reciprocator horizontally<br />

for the width adjustm<strong>en</strong>t. The X-axis is also<br />

used for the automatic gun cleaning via<br />

blow-off nozzles.<br />

X-axis<br />

Z-axis

Multidim<strong>en</strong>sional<br />

solutions<br />

Synchronization with conveyor (Y-axis)<br />

This option is used for the inner coating of hollow bodies such as ov<strong>en</strong>s<br />

and control cabinets. A shaft <strong>en</strong>coder synchronizes the reciprocators<br />

to the chain speed, guaranteeing accurate coating of edges, recessed<br />

parts and internal features. The ideal coating data is calculated<br />

beforehand and stored in a database, where it can be recalled at any<br />

time.<br />

Infeed axes (U-axis)<br />

For special object geometries and applications, there are differ<strong>en</strong>t<br />

axes available (with rotating axes if required). These are equipped with<br />

an indep<strong>en</strong>d<strong>en</strong>t drive, which accurately moves the gun in and out of<br />

predefined zones.<br />

Special axes for complex applications<br />

Z-axis<br />

U-axis:<br />

The U-axis moves the single guns horizontally,<br />

one by one, into the recessed areas of the object.<br />

R-axis<br />

R-axis:<br />

Rotates the spray gun around its own axis.<br />

Y-axis:<br />

Moves the reciprocator synchronized with the<br />

conveyor along the booth.<br />

U-axis<br />

Y-axis<br />

X-axis

Robots and rotating axes<br />

Rotating axes (R-axis)<br />

Rotating axes are ideally suited for the coating of inner edges and<br />

recessed parts (for example on control cabinets and rotating parts).<br />

They accurately trace the rounded geometries and guarantee optimum<br />

coating results ev<strong>en</strong> on difficult-to-reach areas.<br />

Robots<br />

Wh<strong>en</strong> the highest flexibility and free programming are required,<br />

robots offer the perfect solution. The programming is done via<br />

“teach-in”. The geometry and motion sequ<strong>en</strong>ces are tracked with the<br />

spray gun, whereas the robot stores the data for the coating process.<br />

Special axes – Solutions for<br />

complex applications<br />

Special application cases need<br />

special solutions. Thanks to our<br />

vast experi<strong>en</strong>ce and wide range<br />

of products, we will find, in close<br />

collaboration with you, the ideal<br />

axis geometry for your specific<br />

needs.

MagicControl ® CM30<br />

All parameters under control<br />

MagicControl CM30 module controls all parameters of the powder<br />

coating plant. The individual application layout is shown on the scre<strong>en</strong>,<br />

and all operations and functions are transmitted in real-time.<br />

Individual programming<br />

You program all parameters directly on the scre<strong>en</strong>. With clear<br />

symbols, the touch scre<strong>en</strong> displays the action messages. Differ<strong>en</strong>t<br />

security levels prev<strong>en</strong>t programs and parameters being modified by<br />

mistake.<br />

Storing with maximum security<br />

To maintain security, coating programs and parameters can be stored<br />

onto memory cards.<br />

What is CAN-Bus?<br />

A bus system allows the<br />

data exchange betwe<strong>en</strong> the<br />

hardware compon<strong>en</strong>ts and<br />

the control module CM30/<br />

CM22, controlling the powder<br />

coating system.<br />

The bidirectional Data<br />

exchange betwe<strong>en</strong> the<br />

hardware compon<strong>en</strong>ts<br />

<strong>en</strong>sures a comfortable and<br />

process-safe Data exchange.<br />

PLC control units for fully automated coating<br />

MagicControl is a fully<br />

programmable, c<strong>en</strong>tral control<br />

module for controlling the booth,<br />

the gun control units, the<br />

reciprocators, the axes and the<br />

powder supply. MagicControl<br />

allows for interlocking and data<br />

exchange with higher-level plant<br />

control units.<br />

The control and command of height, width and depth detection are<br />

easily executed via monitor with touch-scre<strong>en</strong> function and large display.<br />

Clear symbols offer a simple and intuitive operation. The coating<br />

programs and production data are stored on CompactFlash cards and<br />

can be recalled at any time.

Cost reduction and quality<br />

improvem<strong>en</strong>t with Gema<br />

reciprocators and axes<br />

B<strong>en</strong>efits of the ZA reciprocators<br />

– Long-stroke and short-stroke operation<br />

– Tooth belt transmission for quiet running<br />

– Maint<strong>en</strong>ance-free AC-motor<br />

– Narrow column design for space-saving<br />

gun configurations<br />

– Broad assortm<strong>en</strong>t of axes<br />

– Wide range of control options<br />

– Positioning accuracy within a millimeter<br />

– Vast program diversity<br />

The powder coating world of<br />

Gema

Gema Switzerland<br />

Your global partner for high quality<br />

powder coating<br />

Take advantage of our expertise and experi<strong>en</strong>ce from<br />

more than 40 years of electrostatic powder coating<br />

applications. From simple hand coating through to fully<br />

automated powder coating, we offer solutions that meet<br />

the demands and requirem<strong>en</strong>ts of customers around<br />

the world in a wide range of industrial sectors. A global<br />

service network <strong>en</strong>sures you always get professional<br />

support, at any time and any place!<br />

Gema is part of Graco Inc. Our goal is to help our<br />

customers to increase their productivity while creating<br />

attractive, long-lasting products. Our experts<br />

continually set new standards in the surface coating<br />

industry.<br />

009675-EN-06-2016<br />

Gema Switzerland GmbH reserves the right to make technical modifications without<br />

notice. Illustrations in brochures may contain special options and do not necessarily<br />

correspond to the standard version. OptiC<strong>en</strong>ter, MagicC<strong>en</strong>ter, OptiSpeeder,<br />

MagicCompact, MagicCylinder, OptiFlex, OptiStar, OptiGun, OptiSelect, MagicControl,<br />

OptiControl and OptiFlow are trademarks of Gema Switzerland GmbH.<br />

Gema Switzerland GmbH<br />

Möv<strong>en</strong>strasse 17 | 9015 St.Gall<strong>en</strong> | Switzerland<br />

T +41 71 313 83 00 | F +41 71 313 83 83<br />

www.gemapowdercoating.com