You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Amongst the benefits he highlighted for the<br />

landmark social housing scheme and other<br />

predominantly timber based builds were the<br />

lightness, speed of erection and the reduced<br />

reliance on heavy equipment. Andrew Waugh<br />

commented as he ran through his slides that<br />

"These are robust buildings." However he<br />

explained how they went together without the<br />

use of tower cranes, while the erectors mainly<br />

made use of cordless screwdrivers or other<br />

hand-held tools for assembling the<br />

components.<br />

Furthermore, while nail guns tended to be the<br />

noisiest feature of the construction cycle, the<br />

acoustic performance of the finished structure<br />

was addressed using a variety of insulation<br />

materials and a pumped screed flooring<br />

system. The latter feature also offers a ready<br />

answer to timber framing's widely recognized<br />

lack of thermal mass. In fact such screeds can<br />

both provide a feeling of substance under foot -<br />

even a<strong>cc</strong>ommodating disability buggies indoors<br />

- and create a heat sink to flatten out spikes<br />

from the daily heating and cooling cycle.<br />

For his contribution to the evening's<br />

proceedings, Metsä Wood's Head of Technical,<br />

Engineering and Design, Frank Werling, opted<br />

not to expand on the details of the Plan B<br />

process, but to explain some of the potentials<br />

for the manufacturer's extensive product<br />

range; including Kerto.<br />

He explained how Kerto Q offers different<br />

properties to Kerto S through having some 20<br />

per cent of the wood grains orientated<br />

crossways in the manner of plywood. The<br />

sophistication of the production processes not<br />

only enable the characteristics of the timber<br />

elements to be fine-tuned, but these can of<br />

course be reassembled into I-beams or box<br />

sections to allow widely differing load<br />

conditions to be a<strong>cc</strong>ommodated.<br />

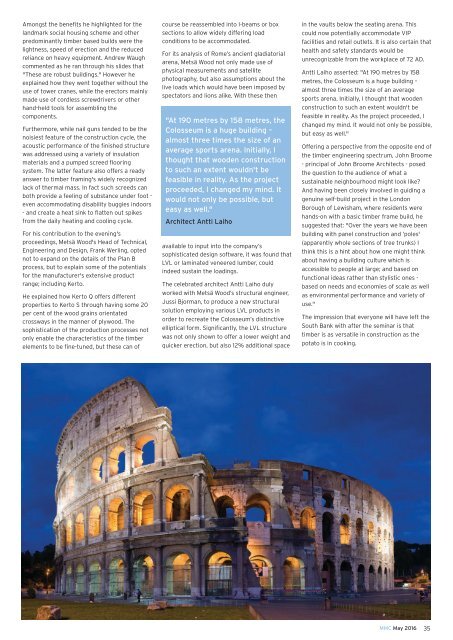

For its analysis of Rome’s ancient gladiatorial<br />

arena, Metsä Wood not only made use of<br />

physical measurements and satellite<br />

photography, but also assumptions about the<br />

live loads which would have been imposed by<br />

spectators and lions alike. With these then<br />

"At 190 metres by 158 metres, the<br />

Colosseum is a huge building –<br />

almost three times the size of an<br />

average sports arena. Initially, I<br />

thought that wooden construction<br />

to such an extent wouldn't be<br />

feasible in reality. As the project<br />

proceeded, I changed my mind. It<br />

would not only be possible, but<br />

easy as well."<br />

Architect Antti Laiho<br />

available to input into the company’s<br />

sophisticated design software, it was found that<br />

LVL or laminated veneered lumber, could<br />

indeed sustain the loadings.<br />

The celebrated architect Antti Laiho duly<br />

worked with Metsä Wood’s structural engineer,<br />

Jussi Bjorman, to produce a new structural<br />

solution employing various LVL products in<br />

order to recreate the Colosseum’s distinctive<br />

elliptical form. Significantly, the LVL structure<br />

was not only shown to offer a lower weight and<br />

quicker erection, but also 12% additional space<br />

in the vaults below the seating arena. This<br />

could now potentially a<strong>cc</strong>ommodate VIP<br />

facilities and retail outlets. It is also certain that<br />

health and safety standards would be<br />

unrecognizable from the workplace of 72 AD.<br />

Antti Laiho asserted: "At 190 metres by 158<br />

metres, the Colosseum is a huge building –<br />

almost three times the size of an average<br />

sports arena. Initially, I thought that wooden<br />

construction to such an extent wouldn't be<br />

feasible in reality. As the project proceeded, I<br />

changed my mind. It would not only be possible,<br />

but easy as well."<br />

Offering a perspective from the opposite end of<br />

the timber engineering spectrum, John Broome<br />

- principal of John Broome Architects - posed<br />

the question to the audience of what a<br />

sustainable neighbourhood might look like?<br />

And having been closely involved in guiding a<br />

genuine self-build project in the London<br />

Borough of Lewisham, where residents were<br />

hands-on with a basic timber frame build, he<br />

suggested that: "Over the years we have been<br />

building with panel construction and ‘poles'<br />

(apparently whole sections of tree trunks) I<br />

think this is a hint about how one might think<br />

about having a building culture which is<br />

a<strong>cc</strong>essible to people at large; and based on<br />

functional ideas rather than stylistic ones -<br />

based on needs and economies of scale as well<br />

as environmental performance and variety of<br />

use."<br />

The impression that everyone will have left the<br />

South Bank with after the seminar is that<br />

timber is as versatile in construction as the<br />

potato is in cooking.<br />

<strong>MMC</strong> <strong>May</strong> 2016 35