R&R 8958 48 July '16 cc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>July</strong> / August 2O16 issue <strong>8958</strong><br />

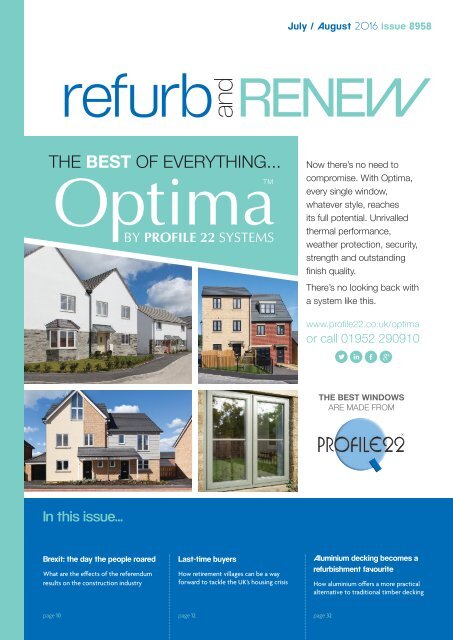

THE BEST OF EVERYTHING...<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

co.uk/optima<br />

<br />

THE BEST WINDOWS<br />

ARE MADE FROM<br />

In this issue...<br />

Brexit: the day the people roared<br />

What are the effects of the referendum<br />

results on the construction industry<br />

Last-time buyers<br />

How retirement villages can be a way<br />

forward to tackle the UK’s housing crisis<br />

Aluminium decking becomes a<br />

refurbishment favourite<br />

How aluminium offers a more practical<br />

alternative to traditional timber decking<br />

page 10 page 12 page 32

R<br />

and<br />

refurb| RENEW<br />

Dear Reader,<br />

Whatever your opinion on the outcome of the European<br />

Referendum, I think you’ll be as pleased as I am that it’s finally behind<br />

us. Perhaps, now, the Government might even consider getting on<br />

with running the country again.<br />

I only hope that the ‘Leaves’ and ‘Remains’ among our MPs will put as<br />

much time and energy into sorting out our housing crisis as they did<br />

in trying to cajole us into voting their way. Because we sure need to<br />

do something about our industry, with just over 40,000 new home<br />

registrations in the rolling quarter (February 2016 – April 2016) - being<br />

nowhere near enough to house our rapidly increasing population.<br />

All the uncertainty surrounding our future in the EU is now over; and<br />

I sincerely hope that this fact alone will be enough for manufacturers<br />

and construction industry professionals to pick up their tools again<br />

with confidence and move on, however difficult.<br />

Whether we have made the right decision regarding the EU,<br />

obviously only time will tell. But I for one intend to get on with my<br />

life and work, in the best way I can – I wish you all good luck and<br />

su<strong>cc</strong>ess post-Referendum.<br />

Articles<br />

Last-time buyers 12<br />

Juliet Woodcock looks at retirement villages as being a way<br />

forward to tackle the UK’s housing crisis.<br />

The foldable system from WeatherFAST 20<br />

Joe Bradbury of R&R Magazine caught up with WeatherFAST’s<br />

Managing Director, Orry White to discuss their new product,<br />

WeatherFOLD.<br />

Aluminium decking - a refurbishment favourite 32<br />

A manufacturer of patented aluminium open grilles has tapped<br />

into the demand in the refurbishment sector by offering a more<br />

practical alternative to traditional timber decking.<br />

Yours sincerely<br />

Juliet Woodcock<br />

Front Cover<br />

The industry has<br />

long-awaited a<br />

window and door<br />

system that can<br />

future-proof product<br />

specification for years<br />

to come. Hailed as<br />

the biggest new<br />

product introduction<br />

in the window<br />

industry for a decade,<br />

Profile 22 has<br />

unveiled Optima.<br />

For more information see page 42<br />

THE BEST OF EVERYTHING...<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

co.uk/optima<br />

<br />

THE BEST WINDOWS<br />

ARE MADE FROM<br />

The silent scream 36<br />

Juliet Woodcock talks to Paul Barrett, Product Manager at<br />

ROCKWOOL Ltd, about acoustic issues in commercial and<br />

educational buildings.<br />

Refurb proves best for flats transformation 38<br />

Three 50-year old blocks of flats had reached the point at<br />

which they either needed significant investment to bring them<br />

up to the current Scottish Housing Quality Standard, or needed<br />

to be demolished and replaced with new build properties.<br />

20 32 38 44<br />

Special Features<br />

Consulting Editor - Juliet Woodcock - juliet@wavcoms.co.uk<br />

Advertising - Paul Barstow - paul@wavcoms.co.uk<br />

- Nasser Agha-Khan - mmc@wavcoms.co.uk<br />

News Desk & Press Releases - Gemma Spilsbury - press@wavcoms.co.uk<br />

Production - Di Smith - di@wavcoms.co.uk<br />

- Ellie Rich - design@wavcoms.co.uk<br />

Circulation - circulation@wavcoms.co.uk<br />

Telephone Enquiries 01827 311800<br />

Publisher’s Statement.<br />

r&r is a bi-monthly publication. Printed in England. All rights reserved. No part of r&r may be reproduced or stored in a retrieval system or<br />

transmitted in any form without prior permission of the publisher. Whilst every effort is made to ensure the a<strong>cc</strong>uracy of editorial<br />

content, the editor and publishers do not a<strong>cc</strong>ept responsibility for errors or loss and damage caused by any statements, claims or<br />

observations made by contributors, authors and their agents.<br />

Waverley Communications Limited Registered Office: Waverley House, 11 Galena Close, Amington Heights, Amington Industrial Estate,<br />

Tamworth, Staffordshire. B77 4AS. Reg. No. <strong>48</strong>05329<br />

20. . . . Roofing, Cladding & Insulation<br />

32 . . . Floors, Walls & Ceilings<br />

38 . . . Doors & Windows<br />

44 . . . Retrofit<br />

<strong>July</strong> / Aug2O16 issue <strong>8958</strong> refurb| RENEW 03

News |<br />

NEWS<br />

Job flexibility ensures tradesmen are the nation’s happiest workers<br />

Over 90% of 1,000 tradespeople are happy in their jobs, with the majority putting it down to the flexibility of mobile working, new research has found.<br />

The study, which was conducted by IronmongeryDirect, found that 91% of mobile working tradesmen are happy in their jobs, with 50% of these claiming they<br />

are very happy.<br />

Tradesmen stated that flexible working (61%) and increased productivity (28%) were the biggest benefits of mobile working. In fact, a massive 98% of tradesmen<br />

said they were happy with the amount of flexibility their job provides.<br />

When asked what they enjoy most about mobile working, the majority (62%) said they liked having flexibility over the hours they work. 42% also took<br />

satisfaction in the fact they are trusted to do their job independently.<br />

Some tradesmen prefer mobile working over being confined to an office as 23% said it helps them to work better as there are fewer distractions than in an<br />

office environment, and a fifth said it ensures they don’t get caught up in office politics. In fact, 16% said mobile working helps them to work with their team<br />

more easily.<br />

The report also found that nearly four fifths of trade professionals (79%) believe that mobile working adds to productivity and improves their job performance.<br />

UK house prices soar 1751% since 1975<br />

European Referendum<br />

The UK housing market has seen a more than eighteen-fold increase<br />

(1751%) in average prices since the last time voters were asked whether<br />

Britain should stay in or out of Europe, a<strong>cc</strong>ording to research by property<br />

crowdfunding platform, Property Partner.<br />

Compared to other investments, residential property has outperformed<br />

all other asset classes including stocks and shares (increased 9.5 times<br />

since 1975) and gold (up by more than 12 times).<br />

Residential property prices in London have risen the most, rocketing by<br />

3200% - almost double the annual UK average house price growth - since<br />

the second quarter of 1975 when Prime Minister Harold Wilson put<br />

forward a referendum on what was then known as the European<br />

Economic Community (EEC) or Common Market.<br />

Today, a little more than four decades on, the average UK house price is<br />

now £198,564. Back in June 1975, house hunters were being asked to fork<br />

out on average £10,728 – today, in real terms, taking into a<strong>cc</strong>ount inflation<br />

that would have been just £99,949.<br />

NHBC reports 17% rise in new registrations in the<br />

year to April<br />

A total of 14,228 new homes were registered to be built in April – a 17 per cent<br />

rise on the same period a year ago, a<strong>cc</strong>ording to the latest figures from the<br />

NHBC.<br />

The figure consists of 11,258 from the private sector and 2,970 public sector<br />

homes, compared to 12,201 (8,988 private sector; 3,213 public sector)<br />

registrations 12 months ago.<br />

Completions were also up four per cent for the month compared to last April<br />

(10,378 in 2016; 10,005 in 2015).<br />

There were 40,399 new home registrations in the rolling quarter (February 2016<br />

– April 2016), NHBC said; a slight decrease of one per cent on last year’s figures<br />

(40,877).<br />

During these three months several regions experienced a “notable growth” in<br />

registrations, compared to 2015, including the North-east (+47%), South-east<br />

(+23%) and Yorkshire & Humberside (+18%).<br />

“April’s new home figures show that the industry enjoyed a su<strong>cc</strong>essful month,<br />

with registration numbers well ahead of this time last year,” said Mike Quinton,<br />

the NHBC’s chief executive.<br />

Councils spend millions on temporary a<strong>cc</strong>ommodation<br />

London councils spent nearly £600m on temporary a<strong>cc</strong>ommodation over the past 18 months.<br />

A 24housing Freedom of Information (FoI) request has uncovered five capital councils alone put out nearly £270m. Overall, the 31 responses reveal London<br />

Councils as spending £558,930,837 on temporary a<strong>cc</strong>ommodation – an average of £31,051,713 per month, or an average of £1,001,668 each month per council.<br />

As rents rise and the housing crisis becomes more severe, the amount spent on temporary a<strong>cc</strong>ommodation by councils is rising.<br />

Birmingham City Council comes closest to the London boroughs, with their spending hitting a handsome £11,096,508.<br />

Manchester City Council, which is facing an ever increasing homelessness crisis, spent £5,345,717 on temporary a<strong>cc</strong>ommodation and Northern Ireland’s Housing<br />

Executive forked out just over £4m.<br />

Bristol City Council’s figure sits at £4.4m, with Reading Borough Council nearing the two million pounds mark.<br />

04<br />

refurb| RENEW <strong>July</strong> / August 2O16 issue <strong>8958</strong>

News |<br />

April’s new home figures show that the industry enjoyed a<br />

su<strong>cc</strong>essful month, with registration numbers well ahead of this time<br />

last year<br />

Mike Quinton, the NHBC’s chief executive.<br />

Tower Bridge to close for three-month repair job<br />

Tower Bridge is to undergo three months of structural repairs later this year, and will close for<br />

three months.<br />

Civils contractor BAM Nuttall will carry out the works, paid for by the Bridge House Estate, the<br />

charitable trust tasked with maintaining five bridges that cross the Thames.<br />

The City of London said that heavy use had taken its toll on the timber decking of Tower Bridge,<br />

which was last refurbished in the 1970s. More than 40,000 people cross over the bridge,<br />

including 21,000 vehicles, each day. The work to the 122-year-old structure will include:<br />

• Replacement of the decking on the bascules (the swinging middle section)<br />

• Corrosion prevention and repair operations<br />

• Replacement of worn expansion joints<br />

• Resurfacing of fixed roads and walkways<br />

• Waterproofing of approach viaducts<br />

• Overhaul and maintenance of key mechanical and lift components<br />

• General cleaning and repairs to the towers<br />

• Replacement of river navigation and traffic signal lights.<br />

The City of London said the bridge will be closed for vehicles, but will remain open to<br />

pedestrians for all but three weekends of the planned works.<br />

Noisy rooms costing hotels millions<br />

The property sector is short-changing itself in the development and construction of hotels.<br />

Owners, developers and investors should look beyond traditional procedures. If you want to<br />

build good hotels which will achieve high profitability, you have to provide comfort and quiet<br />

hotel rooms, a<strong>cc</strong>ording to the Quietroom Foundation.<br />

President Lucas Keizer of the Foundation: “In the coming years, more and more vacant office<br />

buildings will be converted into hotels. In Amsterdam alone there is room for more than 100<br />

hotels. But please make sure they are good hotels and take insulation and sound proofing<br />

standards into a<strong>cc</strong>ount when you convert a building into a hotel. At present, this is often<br />

overlooked.<br />

“The Quietroom Foundation stimulates the world wide development of quieter hotel rooms<br />

and has created the Quietroom label. Experience tells us that hotel guests who book a room<br />

which is really quiet will give the hotel a higher rating. Which obviously is important for the<br />

hotel's reputation and performance in the long run. The recently opened Ramada Hotel in<br />

Amsterdam is a good example of this. It used to be an old office building which has been redeveloped<br />

into a hotel and 434 of its rooms have qualified for the Quietroom label. The<br />

owners have consciously chosen to invest in quality and expect to fully recover their<br />

investment.”<br />

British Steel name returns<br />

The British Steel brand has been revived following the<br />

completion of a deal in which Tata Steel sold its long<br />

products business to Greybull Capital. Greybull, an<br />

investment firm, paid a nominal £1 for the business, which<br />

makes products such as railway tracks and steel sections used<br />

in construction.<br />

The deal will see the safeguarding of over 4,000 jobs as well<br />

as the restoration of the British Steel name which was<br />

discarded in the nineties. The sale includes the steelworks in<br />

Scunthorpe, Lincolnshire, and sites in Teesside, Workington<br />

and York. The brand of the former state-owned industry<br />

disappeared in 1999 with the creation of Corus, which Tata<br />

then bought in 2007.<br />

Mersey Gateway contributes £129m to<br />

North West's economy<br />

Construction of the new Mersey Gateway crossing has<br />

boosted the North-west's economy by £129 million, a<strong>cc</strong>ording<br />

to new figures.<br />

Now in its third year, work has started on the main deck of<br />

the new six-lane toll bridge that will link the towns of<br />

Runcorn and Widnes.<br />

As part of the project, teams will begin to connect the steel<br />

support cables to the deck and upper pylons this summer.<br />

‘Trinity’, the project’s movable scaffolding system (MSS), has<br />

cast the first 250m of the north approach viaduct, and a new<br />

MSS is on its way to Halton to build the south approach<br />

viaduct.<br />

The local road network is undergoing significant<br />

transformation with major junction upgrades taking place<br />

right across the borough, including the redesigned M56<br />

Junction 12 roundabout, which is due for completion in June.<br />

Newly released figures for the first two years of work on the<br />

Mersey Gateway Project show a direct contribution to the<br />

North-west regional economy of some £129million.<br />

The figures a<strong>cc</strong>ount for contracts placed by the Merseylink<br />

Construction Joint Venture with 351 different suppliers and<br />

sub-contractors based within a 30-mile radius of the site in<br />

Halton since work began in May 2014.<br />

®<br />

MAINTENANCE<br />

FREE COATINGS<br />

25 YEARS<br />

EXPERIENCE<br />

plascoat.com<br />

sales@plascoat.com<br />

01252 733777<br />

for str<br />

reet furniture & str<br />

ructural meta<br />

alwork<br />

<strong>July</strong> / August 2O16 issue <strong>8958</strong> refurb| RENEW 05

Product | NEWS<br />

SPV Awarded Family Business of the Year at<br />

The Express and Star Awards<br />

SPV Group, the Walsall based refurbishment specialists are<br />

delighted to announce that we have recently been Awarded<br />

2016 Winner of Family Business of the Year at The Express and<br />

star Business Awards.<br />

Furthermore we are delighted to have received a special<br />

commendation in the category of Community Champions.<br />

The event, one of the highlights of the West Midlands' business<br />

calendar shined a spotlight on the businesses that represent that<br />

whole range of commercial activity across our region.<br />

The judges commented the following with regards to SPV<br />

Group;<br />

“By innovation and exceptional customer service, SPV Group has<br />

become a leading specialist in the UK market place and overseas.<br />

Employing multiple members of other families, as well as their<br />

own, the owners have created a family feel across all<br />

departments.”<br />

Kate Whatley said the achievement is a great a<strong>cc</strong>omplishment for the whole business.<br />

“We are delighted to be recognised as Family Business of the Year and furthermore<br />

recognised for our work within the local community. The awards were an inspirational evening<br />

recognising some fantastic local businesses.<br />

We would like to thank everyone within the business for all their continued commitment to<br />

the company and hard work as well as our valued clients and supply chain for making this<br />

possible”<br />

www.spv-uk.co.uk<br />

06<br />

West Coast mainline viaduct is back<br />

on track<br />

Underwater<br />

surveys for<br />

client Network<br />

Rail<br />

Infrastructure<br />

Projects (Civils)<br />

confirmed that<br />

the foundations<br />

and stone piers<br />

for a major<br />

viaduct on the<br />

West Coast mainline in Carlisle were being scoured, and required a long<br />

term solution which offered scour protection to the masonry and<br />

foundations.<br />

To repair the stone piers, Story Contracting installed a total of 64<br />

tonnes of permanent interlocking sheet piles around the piers. The piles<br />

were driven to refusal, toeing into the mudstone bedrock. Following<br />

this, 282m3 of Hanson concrete containing Sika® UCS Pak, a specialist<br />

underwater admixture, was poured between the pier and the sheet<br />

piles, with a capping beam formed at cut-off level.<br />

Used for the production of underwater concrete and meeting the<br />

requirements of BS 8443, Sika® UCS Pak prevents the wash out of the<br />

cement paste and increases the cohesion of the concrete. Sika® UCS<br />

Pak is packaged in water soluble bags to enable ease of addition on site.<br />

http://gbr.sika.com/content/united_kingdom/main/en/group.html.<br />

refurb| RENEW <strong>July</strong> / August 2O16 issue <strong>8958</strong><br />

Boilers roll with the times<br />

As part of a<br />

£4m<br />

community<br />

and business<br />

hub<br />

renovation<br />

project, Ideal<br />

Commercial<br />

Boilers have<br />

supplied an Evomax Cascade, consisting of three Evomax 150s and a<br />

multiline flue cascade, to Marble Hall, the former Rolls-Royce engine<br />

factory on Nightingale Road, Derby.<br />

Originally built in 1907, the former factory and office facility has been<br />

fully refitted to provide a brand new managed workspace and<br />

community hub, and has had new boilers, radiators and radiant<br />

panels installed.<br />

The Evomax 150 boilers were chosen specifically for their compact<br />

size and high kW output for a wall mounted boiler, which made<br />

installation easy. The boilers and the frame and header kits were<br />

also easy to carry and manoeuvre within the building as well as<br />

having a small footprint. The BREEAM rating for the boilers installed<br />

is 66% with a classification of 'Very Good', which puts it in the top<br />

25% of new UK buildings.<br />

01<strong>48</strong>2 492 251<br />

www.idealcommercialboilers.com

Conor aims to make a difference in<br />

Jamaica<br />

A Glasgow Caledonian University (GCU) quantity surveying student<br />

has traveled to Jamaica to offer hands-on help with building<br />

projects in some of the country’s poorest areas.<br />

Conor McGread, a fourth-year BSc Quantity Surveying student from<br />

County Tyrone, has received a GCU Magnusson Award, established<br />

in honour of the late broadcaster and former chancellor Magnus<br />

Magnusson KBE, to provide funding and opportunities to help<br />

students and academics in their studies or careers.<br />

Conor will use his award to help improve the infrastructure in<br />

Jamaica by undertaking projects such as upgrading the unhygienic pit<br />

toilets of primary schools. He will also be assisting in the designing<br />

and building of houses for Jamaica’s most poor and those who have<br />

lost their homes due to natural disasters such as hurricanes.<br />

Projects Abroad will help coordinate Conor’s stay by finding him a<br />

local family to stay with throughout his time in Jamaica. On the<br />

building sites, he will be working alongside an experienced<br />

tradesman and other volunteers.<br />

Conor said: “This project would not have been possible without the<br />

funding of a Magnusson Award. It will assist me in almost every<br />

financial factor there is, including my travel to Jamaica, which is not<br />

cheap, and other expenditures such as va<strong>cc</strong>inations and visas.”<br />

Conor left for Jamaica on <strong>July</strong> 4 and will stay in the country for four<br />

weeks.<br />

He added: “My GCU programme has helped me prepare for this<br />

exciting and rewarding project. Throughout my four years at GCU, I<br />

feel I’ve gained certain skills that will enable me to improve the lives<br />

of those in most need in Jamaica.<br />

“The Construction Technology module of my programme, for<br />

example, was one of the more practical, whereby we learned how a<br />

building was constructed from the ground up, along with the various<br />

techniques used. I hope that I can use these skills to educate some<br />

of the local construction workers to create more robust buildings<br />

that are strong enough to withstand the strong wind loads imposed<br />

on them by hurricanes.”<br />

Complacency could get you burned<br />

By Martin Oates – Commercial Director with SE Controls<br />

In <strong>July</strong> 2013 the Construction Products Regulations<br />

(CPR) mandated the CE marking of all products<br />

used within the construction industry that are<br />

covered by a harmonised European standard<br />

(hEN)<br />

Within the European standards, EN12101-2<br />

2003 ‘Smoke and Heat Exhaust Ventilators’<br />

(SHEV’s), both vertical and inclined<br />

ventilators utilised for life safety smoke<br />

ventilation systems, automatically fall within<br />

scope of the CPR. This adds stricter testing<br />

criteria to ensure product performance meets<br />

the required standards and are compliant.<br />

The regulations dictate that the vent and actuator must be<br />

tested together, as a system, to the specifications within the annexes<br />

of the standard, which must be conducted at an a<strong>cc</strong>redited test facility<br />

This process also covers the fabrication of the vent as a SHEV carries a<br />

higher level of classification, ‘System 1’, compared to an EN14351-1<br />

window, which is ‘System 3’. Also, they must be delivered under an<br />

audited process to ensure the detail on site is identical to the<br />

prescriptive test detail.<br />

Contrary to popular<br />

belief, an actuator can<br />

no longer be fitted to<br />

a window and be<br />

compliant unless it is<br />

tested with the<br />

specific vent system<br />

being used. Merely<br />

fitting a tested<br />

actuator to a window<br />

does not prove<br />

Compliance testing is mandatory<br />

compliance and it is<br />

this condition that could catch out those that are unaware of the<br />

standard.<br />

Non-compliance is policed in the main by Approved Inspectors and<br />

Building Control Officers who now look for proof of certification under<br />

the directions of BS7346-8 Code of Practice, which covers provisions<br />

for smoke control throughout the construction process.<br />

Unfortunately, if compliance proof cannot be provided, it is too late to<br />

sign-off the building, resulting in delays and compensation claims under<br />

damage clauses. However, should a non-compliant smoke vent fail<br />

during a fire incident, the consequences are far more severe not only to<br />

the o<strong>cc</strong>upants, but also to the company whose products failed to<br />

meet the standard.<br />

Most leading façade system companies’ products are now tested to<br />

the standard, many in partnership with SE Controls to utilise the<br />

company’s extensive range of UK manufactured actuators. From a<br />

building design perspective, many of SE Controls actuators are now<br />

available as BIM objects, which include extensive product information<br />

and COBie data.<br />

Combined with their delivery qualifications, both on and off site, a<br />

certified solution is provided that includes the vital Declaration of<br />

Performance (DoP) documentation, which verifies compliance.<br />

The DoP contains reference to the Notified Approved Body that<br />

underwrites the process and the test references. It also contains the<br />

performance criteria against the test annexes in the form of declared<br />

essential characteristics and is signed by a Director of the company<br />

placing the SHEV onto the market.<br />

No DoP, no compliance. Don’t let complacency get you burned.<br />

<strong>July</strong> / August 2O16 issue <strong>8958</strong> refurb| RENEW 07

Product | NEWS<br />

Small but mighty<br />

Vectaire’s HREC 1003 single room heat recovery unit is a 3 speed centrifugal fan<br />

for kitchens, bathrooms and shower-rooms up to 40m2. It has an energy<br />

efficient EC motor, which provides low level and continuous ventilation,<br />

combined with high performance and efficiency saving up to 75% of potential<br />

heat loss. The HREC1003 includes an integral summer mode and a frost-stat. It is<br />

available with 400, 500 or 600mm length tube heat recovery cells (100mm<br />

diameter).<br />

The termination kit incorporates both a weather louvre and a condensate<br />

outlet which enables complete installation from inside. It is available in<br />

standard, timer and humidity control models and is suitable for both new-build<br />

and refurbishment.<br />

www.vectaire.co.uk<br />

Geberit helps stately<br />

home go green<br />

GeberitMapress Carbon Steel has been<br />

chosen for its ease of installation and ‘no<br />

hot works’ credentials to install a biomass<br />

system at Saltram House, a magnificent<br />

National Trust owned stately home in<br />

Plymouth.<br />

One of many National Trust premises to<br />

get a renewable makeover as part of a<br />

general drive to improve the<br />

environmental credentials of its buildings,<br />

Saltram now enjoys heating and hot water<br />

courtesy of a biomass system, consisting<br />

of 220kW and 95kW boilers fuelled by<br />

pellets. A district heating system services<br />

the main house and the majority of other<br />

buildings on the site.<br />

"We use GeberitMapress on 95% of our<br />

jobs," said James Howard, from Dunster<br />

Biomass, which installed the system at<br />

Saltram House. "It's quick to install, easy to<br />

use and reliable. The fact there's no need<br />

for hot works makes it ideal for historic<br />

buildings.”<br />

www.geberit.co.uk<br />

New catalogue and state-of-the-art processing plant<br />

Wykamol, market leader in the development<br />

and supply of remedial treatment products for<br />

damp, insect infestation, and dry rot has<br />

launched a brand new corporate catalogue,<br />

featuring new innovations as well as timehonoured<br />

standards.<br />

Aimed at builders, contractors, specifiers and<br />

local authority purchasing departments, the<br />

compact 100-page booklet features every<br />

product in the current Wykamol portfolio,<br />

alongside technical drawings, product guides,<br />

explanatory diagrams, and illustrations of products in application and in situ.<br />

Insecticides, fungicides and all manner of timber and surface treatments remain a major part of<br />

Wykamol's business, and its comprehensive range is presented in its entirety in the new catalogue.<br />

It is, however, basement conversion, damp proofing and structural waterproofing with which the<br />

Wykamol name is now broadly tied.<br />

Wykamol has invested £850k in 2016, extending its Burnley HQ to house a new powder<br />

processing and bagging plant, where they can also prepare bespoke powder formulations to<br />

customer's exact specifications, such as cement waterproofing powders, thermal renders, and<br />

specialist structural grouts.<br />

www.wykamol.com<br />

Lighting up leisure<br />

This new swimming pool at Immingham<br />

includes some of the best examples of how<br />

the Kalwall® translucent daylighting system is<br />

used for leisure and sport activities. This<br />

stunning £1.45m facility was designed by ENGIE<br />

- Architectural Consultancy for North East<br />

Lincolnshire Council with support from Sport<br />

England. It includes Kalwall cladding for all the<br />

walls in the new fitness suite and exercise studio.<br />

Internally, rooms are bathed with diffused natural daylight which creates a stimulating and healthy<br />

exercising environment. While being translucent, it also offers privacy. Externally, the elevations<br />

appear crisp, simple and inviting. When illuminated at night Kalwall will glow softly presenting a<br />

striking external appearance.<br />

The system also enhances simplicity by eliminating the need for blinds, curtains or solar control. In<br />

addition, the even distribution and deep penetration of light through Kalwall means less artificial<br />

lighting is needed thereby reducing energy costs.<br />

www.structura-uk.com/kalwall<br />

08<br />

refurb| RENEW <strong>July</strong> / August 2O16 issue <strong>8958</strong>

Article |<br />

Brexit: the day the people roared<br />

Juliet Woodcock attempts to assess the effects of the referendum results on the construction industry.<br />

Dear reader, this article has been written just<br />

three days post-referendum thanks to the<br />

inevitable print deadline that all publishing<br />

houses must follow. So, I wish to reassure you<br />

that I have read widely on both sides of the<br />

argument from the Leave and Remain<br />

campaigns and watched the numerous<br />

televised debates before casting my vote.<br />

Therefore I hope that, by combining this<br />

knowledge, along with information received<br />

from manufacturers and professionals in the<br />

construction industry, to provide you with an<br />

honest picture of how Brexit might affect the<br />

sector.<br />

Firstly, pre-Brexit: a friend of nearly 25 years is a<br />

chippie from Bromley in Kent. A skilled<br />

carpenter who underwent traditional<br />

apprenticeship, he asserts that his earnings have<br />

never recovered to the level he enjoyed before<br />

the expansion of the EU due to Eastern<br />

Europeans always being able to undercut him -<br />

they didn't have the expense of his mortgage,<br />

their children back home being fed and housed<br />

at a fraction of the cost of living in the UK. A<br />

lifetime Labour voter, he feels that it was his<br />

party's betrayal of the working class that forced<br />

him to vote Conservative in the last election, as<br />

they were the only ones that offered a<br />

referendum which might reduce foreign labour<br />

import and thus give him a chance to again earn<br />

a decent wage. I know he voted Brexit for a<br />

fact.<br />

The case for staying in the EU came mainly<br />

from manufacturers who export to the<br />

European continent - pre-referendum, most<br />

would not give me, a journalist, an opinion that<br />

I would be allowed to print, from either point<br />

of view. Thus I gave up trying to write an<br />

article on the subject for the December issue<br />

of R&R. For your interest, here are a couple of<br />

the questions I posed:<br />

There were ten home hunters battling it out for<br />

each property in November as the number of<br />

homes available continued to decline, a<strong>cc</strong>ording<br />

to the National Association of Estate Agents<br />

(NAEA). If we stay in the EU and let in EU<br />

workers coming to the UK for jobs, do you<br />

think it would be reasonable to ask Brussels for<br />

a larger rebate to help us address the shortage<br />

of housing?<br />

To what extent does your company depend on<br />

employing foreign workers, including EU<br />

citizens? Would leaving the EU have a negative<br />

impact on your trading in the UK, and if so,<br />

how?<br />

I totally a<strong>cc</strong>ept that we need EU workers; while<br />

Germany has already stated that it will not stop<br />

trading with us, nor impose punitive tariffs.<br />

Encouragingly, Lord Bamford from JCB said: "In<br />

1973, when we joined as its eight member, the<br />

EU a<strong>cc</strong>ounted for 31% of world economic<br />

output. Today with 28 member countries the<br />

figure is just 17%, which underlines the sinking<br />

role of the EU in the world economy." Many<br />

economists admit that unless the Eurozone can<br />

be fixed, this trend is sure to continue.<br />

Despite the result of the vote, the building<br />

industry is still in the same quandary: My friend<br />

remains resentful of the fact that his has<br />

suffered thanks to European workers – while<br />

10<br />

refurb| RENEW <strong>July</strong> / August 2O16 issue <strong>8958</strong>

the fact is, simply, that we need foreign help to<br />

build the number of houses and other<br />

properties required.<br />

Indeed, in 2014, 790,000 Polish people were<br />

resident in the UK – the biggest group of<br />

Europeans living here. After Brexit, new<br />

Europeans eventually lose the automatic right<br />

to work here unless we adopt the Norwegianstyle<br />

position of being outside the EU but<br />

agreeing to free movement. Or we could ‘play<br />

Fact file<br />

Construction Industry Training<br />

Board figures say construction<br />

workers from overseas are broken<br />

down as follows:<br />

Poland: . . . . . . . . . . . . . . . . . . . . . 30,120<br />

Romania: . . . . . . . . . . . . . . . . . . 24,842<br />

Lithuania: . . . . . . . . . . . . . . . . . . . 7,569<br />

India: . . . . . . . . . . . . . . . . . . . . . . . . 7,704<br />

Bulgaria: . . . . . . . . . . . . . . . . . . . . 5,443<br />

Laia: . . . . . . . . . . . . . . . . . . . . . . 3,830<br />

South Africa: . . . . . . . . . . . . . . . . . 1,316<br />

Hungary: . . . . . . . . . . . . . . . . . . . . . ,4<strong>48</strong><br />

Australia: . . . . . . . . . . . . . . . . . . . . . 937<br />

hardball’ and enforce a points based system<br />

similar to Australia.<br />

Reports issued in the last few months from the<br />

CITB and the CIOB state that the UK simply<br />

does not have enough home grown skilled<br />

workers to cope with the volume of<br />

construction growth anticipated over the<br />

coming years. The Construction Industry<br />

Training Board predicts that 230,000<br />

construction jobs will be created in the UK<br />

between now and 2020.<br />

Figures from its Construction Skills Network<br />

report show that of the 44,000 new jobs a year<br />

predicted before 2020, 2,870 will be for<br />

bricklayers, 4,320 for carpenters and interiors<br />

fitters and 2,510 for building envelope<br />

specialists. And while the CITB is pushing to<br />

increase the construction skills base with a<br />

£7.5million investment in training and the<br />

launch of new website Go Construct, in the<br />

short and medium term the skilled<br />

workforce needs to come from elsewhere.<br />

The Chartered Institute of Building, in<br />

its 2015 report: An analysis on<br />

migration in the construction sector,<br />

describes the three options available<br />

to meet the CITB’s employment<br />

forecast. “Import from a ready supply<br />

of foreign talent, invest in training<br />

and development of UK citizens, or<br />

redesign the construction process,”<br />

are their suggestions. Actis’<br />

Matthew King responded, saying: “All three of<br />

these seem a sensible combination – the first<br />

two are self explanatory while the final one<br />

provides an exciting way forward, and one<br />

which is already seeing momentum build. And<br />

that’s moving away from brick and block and<br />

focusing more on off site construction. The<br />

fact that these are quicker to construct, thus<br />

requiring fewer man hours, and have a greater<br />

percentage of elements which require less<br />

highly skilled workers, could ease some of the<br />

burden of having fewer staff on the<br />

ground.”<br />

The report goes on: “Some migration into and<br />

out of the country is both inevitable and<br />

desirable for contractors as it helps to dampen<br />

the volatility in the labour market. While<br />

construction will need to recruit migrant<br />

workers to cope with the upswing in work, the<br />

opportunity is there to train many more UK<br />

youngsters.”<br />

Moving on: regarding the drop in the value of<br />

the Pound, this will be good for UK exports.<br />

This view has very much been echoed by The<br />

Lord Bamford, Chairman of JCB, who wrote an<br />

open letter to all his employees and pensioners<br />

towards the beginning of June whereby he<br />

reassures the reader that “JCB will continue to<br />

trade with Europe, irrespective of whether we<br />

remain in or leave the EU.” He goes on to point<br />

out that EU countries a<strong>cc</strong>ount for 22 per cent<br />

of his company’s turnover. The other 78 per<br />

cent comes from the UK, India, the Americas,<br />

Russia, the Middle East, Africa, Asia Pacific and<br />

the Far East.<br />

At the end of the day, the main factors driving<br />

the relentless increase in property prices are<br />

the rising population, shortage of supply and<br />

record low mortgage rates. Simon Tyler, of<br />

Tyler Mortgage Management, sees little<br />

chance of a housing price crash: “Britain<br />

has a chronic shortage of housing<br />

that will drive up prices for many<br />

years too come.” Regarding<br />

the predicted tumble in<br />

London’s property<br />

market,<br />

: Actis’ Matthew King believes that<br />

offsite construction is the way<br />

forward to bypass the skills<br />

shortage and speed up construction<br />

foreign investors will continue to buy as the<br />

Friday drop in Sterling’s value currently offers<br />

them several per cent more for their money.<br />

Ultimately, it seems that it is disaffected people<br />

like my friend the carpenter – and millions<br />

more in Labour heartlands - who voted to leave<br />

the EU. They want a better life, a chance for<br />

their children to earn a decent wage. Too many<br />

Brits had had enough of competing for<br />

underpaid work, of the government not<br />

listening to and acting on their behalf. In the<br />

end, the only way they could try and make our<br />

establishment listen was, on June 23rd, to join in<br />

protest on the day the people roared.<br />

<strong>July</strong> / August 2O16 issue <strong>8958</strong> refurb| RENEW 11

Article |<br />

Last-time buyers<br />

Juliet Woodcock looks at retirement villages as being a way forward to tackle the<br />

UK’s housing crisis<br />

“This report has identified<br />

substantial demand among older<br />

homeowners to consider rightsizing,<br />

which could have a significant<br />

impact on addressing the UK’s<br />

housing shortage.<br />

Brian Beach, author of the<br />

“Generation Stuck” report<br />

Lime Tree village grounds:<br />

Properties at Lime Tree Village, created by Retirement Villages Group Ltd,<br />

are centred around Cawston House, which has been restored by Retirement Villages<br />

Residents at Lime Tree enjoy communal<br />

facilities including a restaurant, library, bar,<br />

function room, conservatory, games lawn<br />

and more.<br />

We have heard every political party bang on<br />

about the plight of first time buyers for at<br />

least the last decade – and quite rightly so;<br />

there are not enough houses to go around,<br />

while foreign individuals and those who can<br />

afford holiday homes are buying up property<br />

across the UK – both facts mean that house<br />

prices are way too expensive for the young.<br />

We all a<strong>cc</strong>ept that more affordable housing<br />

needs to be built.<br />

But the housing crisis goes much wider; for we<br />

also need to focus on ‘last-time buyers,’ helping<br />

older people to downsize in order to free up<br />

family-sized homes for younger families. It<br />

would be a win-win for both generations.<br />

The ‘Generation Stuck’ report, by the<br />

International Longevity Centre and retirement<br />

housing specialists McCarthy & Stone, found a<br />

third of over-55s were actively considering<br />

downsizing or expecting to do so in future.<br />

More than half of those surveyed said their<br />

main motivation was to move to a property<br />

Polo Field properties:<br />

Retirement Village’s Lime Tree Village is now<br />

being extended to include new homes at The<br />

Polo Field<br />

which was easier to maintain, while two in five<br />

wanted smaller energy bills or felt their home<br />

was too big now their children had left.<br />

Brian Beach, author of the publication, said:<br />

“This report has identified substantial demand<br />

among older homeowners to consider<br />

rightsizing, which could have a significant<br />

impact on addressing the UK’s housing<br />

shortage.<br />

“But it is clear that there remains an inadequate<br />

supply of the kinds of properties that would<br />

serve older households.”<br />

Interestingly, though, the report estimated as<br />

many as 3.5million older people in the UK have<br />

considered moving to a retirement property –<br />

but there are few catering for their needs –<br />

unless you look at a relatively new specialist<br />

developments. And when you go onto the slick<br />

websites of some of the retirement villages, it’s<br />

hard not to understand why the elderly are<br />

tempted – indeed, in another three years, this is<br />

where you might find me when I’m not cooking<br />

in my beautiful cottage: either in the spa pool,<br />

or sipping G&T in the social club with my newfound<br />

friends and neighbours.<br />

With the added comfort of knowing that if my<br />

husband or myself require assistance, as we get<br />

older, this is available from warden-type<br />

supported care in my own home, to a care<br />

home with fully qualified nurses trained in<br />

dementia care. All these facilities are usually on<br />

one site along with amenities such as a village<br />

store, hairdressers, golf clubs and gyms, as well<br />

as organized days out. What is there not to<br />

like?<br />

Indeed, one retirement developer will even sell<br />

a potential buyer’s old house for them through<br />

its ‘Fair Exchange Promise’: “Renaissance Villages<br />

will cover the initial costs associated with<br />

buying a new property, reducing any wait time<br />

you would usually experience in the sales<br />

process. These costs will then be recouped<br />

when your old home is sold and the<br />

completion funds are available, and any balance<br />

is returned to you from the sale of your old<br />

home.”<br />

Another retirement specialist, Retirement<br />

Villages Group Ltd, has 14 developments in its<br />

portfolio, spread across 11 counties in the<br />

southern half of the UK. With a wide range of<br />

leisure facilities and varying service levels or<br />

care, this company offers a ‘Try Before you Buy’<br />

scheme, which enables two people to a free<br />

overnight stay with Continental breakfast at<br />

one of its villages, in order to ‘test drive’ the<br />

lifestyle before committing to it.<br />

Meanwhile, Brian Beach added: “Attention to<br />

the housing needs of older people is extremely<br />

important as 60% of the projected growth in<br />

households over the next two decades will be<br />

amongst those aged 65 and over.<br />

“Alongside this growing demand for suitable<br />

housing options in later life, however, there is a<br />

huge under-supply of homes that have been<br />

built specifically for the particular needs and<br />

aspirations of the older population, whether<br />

specialist in nature, like retirement housing, or<br />

open market housing built with older people in<br />

mind from the outset.”<br />

12<br />

refurb| RENEW <strong>July</strong> / August 2O16 issue <strong>8958</strong>

Vieo. The versatile long-strip solution<br />

for modern roof and wall design.<br />

Attractive, contemporary and innovative. This is an exciting time for building design and construction.<br />

And with high performing projects, such as Ice Arena Wales (pictured), we’re excited to be part of the<br />

modern industrial revolution.<br />

As a UK manufacturer with a culture of innovation we’re continually developing and refining our roof and wall products<br />

to meet the changing and challenging design and project management requirements facing today’s construction<br />

professionals.<br />

Vieo is an exciting roof and wall product that transcends industrial cladding to provide a flexible, high performance<br />

solution that is visually impressive. Vieo can combine exceptional thermal and acoustic efficiency with trusted fire<br />

performance and minimal environmental impact.<br />

A culture of innovation is present throughout our supply chain, with Colorcoat HPS200 Ultra ® and Colorcoat Prisma ®<br />

pre-finished steel from Tata Steel being highly recommended for Vieo roof and wall construction. These Colorcoat ®<br />

products come with the Confidex ® Guarantee for the weatherside of industrial and commercial buildings, offering<br />

extended cover for up to 40 years. Colorcoat ® products are certified to BES 6001 Responsible Sourcing standard.<br />

If you‘re looking for genuine innovation, discover Vieo.<br />

Euroclad Limited · Wentloog Corporate Park · Cardiff · CF3 2ER<br />

029 2201 0101 · www.euroclad.com · @eurocladuk<br />

Colorcoat HPS200 Ultra, Colorcoat Prisma and Confidex<br />

are registered trademarks of Tata Steel UK Limited.

Article |<br />

Energy efficient retrofit and the art of<br />

teaching an old dog new tricks<br />

A common misconception made when considering energy efficiency incentives is that older or outdated buildings need to be replaced<br />

entirely with a more modern counterpart in order to achieve any tangible results. In actuality, a building doesn’t need to be new to be<br />

efficient. Joe Bradbury of R&R investigates the crucial role of retrofit, industry behavioural change and an open mind if the commercial<br />

building sector is to lower its carbon footprint.<br />

14<br />

There are some wonderful<br />

innovations happening within<br />

architecture and construction.<br />

We have marvelled at a host of<br />

exciting, brand new smartstructures<br />

of late, which are<br />

built to passivhaus standard or<br />

better. The Crystal, in London, for<br />

example, was built by Siemens as<br />

an urban sustainable landmark and<br />

draws thousands of visitors each<br />

year. Aside from being an<br />

architectural marvel in terms of<br />

aesthetics and design, The Crystal also boasts<br />

the impressive title of being one of the greenest<br />

buildings ever built by mankind and is allegedly<br />

the most sustainable venue in the world. It uses<br />

natural light, smart lighting technology,<br />

photovoltaic solar panels, rainwater harvesting<br />

and black water recycling. The Pixel Building in<br />

Melbourne, Australia is another perfect example<br />

of modern building efficiency. The carbon<br />

produced each year by the building is<br />

compensated by renewable energy and carbon<br />

consuming materials, which are utilised in the<br />

structure throughout, resulting in a truly 100%<br />

carbon-free building.<br />

These are just two of a myriad of examples of<br />

some of the fantastic things that are happening<br />

within construction today. Good news, right?<br />

Well, yes… but with a few caveats. The bad news<br />

for the retrofit sector is that all of these stunning<br />

new buildings have started to breed a culture of<br />

construction professionals, building specifiers,<br />

architects and contractors who believe that new<br />

= better. However, the true unsung heroes of the<br />

energy efficiency game are building owners who<br />

make efforts to retrofit older buildings to meet<br />

modern demand in both an ethical and<br />

economical way.<br />

By improving the usage of energy in existing<br />

buildings and improving the behaviour of its<br />

o<strong>cc</strong>upants, many older structures are steadily<br />

being converted one by one into true models of<br />

sustainability. Take CoRE in Stoke-on-Trent as an<br />

example; the wholesale refurbishment of one of<br />

Stoke on Trent's most derelict pottery factories<br />

was completed in 2013. By tackling one of the<br />

hardest to treat properties possible, the design<br />

and build team created something not only<br />

spectacular but also educational and inspirational.<br />

CoRE is a true testament to the potential of<br />

retrofit, showing how with effort and a little<br />

refurb| RENEW <strong>July</strong> / August 2O16 issue <strong>8958</strong><br />

elbow grease, a derelict building can go on to<br />

achieve a BREEAM Excellent rating. This was done<br />

with careful consideration and implementation of<br />

sensitive yet striking additions to the site was<br />

needed, along with thermal and air tightness<br />

improvements to the existing building. Technical<br />

innovation played a large part in order to<br />

incorporate sustainable materials, plant and<br />

construction methods into a building with<br />

different construction materials, ages and<br />

techniques.<br />

Time for change<br />

Commercial properties make up an enormous<br />

portion of the built environment. They serve as a<br />

platform for most of the country’s major<br />

industries and provide the general public with<br />

areas in which to work, shop, socialise and relax.<br />

Needless to say, commercial buildings play a<br />

crucial role in 21st century Britain. However,<br />

despite investment in this booming sector being<br />

ever on the rise, commercial buildings are<br />

amongst some of the poorest performing<br />

buildings in terms of energy efficiency.<br />

A<strong>cc</strong>ording to the Committee on Climate Change,<br />

the commercial sector is a<strong>cc</strong>ountable for<br />

approximately 26% of all greenhouse gas<br />

emissions from buildings in the UK. The world’s<br />

population is currently consuming the equivalent<br />

of 1.6 planets resources a year. The Global<br />

Footprint Network estimates that if we continue<br />

to consume at current rates we'll blow the global<br />

carbon budget and lock in more than 2C of<br />

global warming in approximately 17 years.<br />

This is frankly una<strong>cc</strong>eptable and most are now in<br />

agreement that changes need to be made in both<br />

our practices and the products that we use.<br />

Retrofit will play an enormous part in<br />

implementing this change. The EU is currently<br />

reviewing its EU 2030 energy efficiency targets,<br />

with buildings in general highlighted as having<br />

great potential to reduce global emissions if<br />

efforts are made to make them more energy<br />

efficient. This ultimately means that more<br />

investments will be made in retrofitting buildings<br />

with efficient technology going forward. Retrofit<br />

is the future.<br />

Retrofit needn’t cost the earth<br />

While many building owners often pursue single<br />

technology improvements, such as heating or<br />

lighting alone, it is actually a multifaceted<br />

approach that is needed long term in order to<br />

enhance savings. Whilst the initial outlay will be<br />

higher by utilising multiple technologies and<br />

techniques within a refurbishment, the upgrades<br />

are ultimately paid for through energy savings<br />

over time.<br />

Take lighting for example - the amount your<br />

facility will save by performing a lighting retrofit<br />

only will often reduce energy costs by over 50%.<br />

Considering that lighting is typically a<strong>cc</strong>ountable<br />

for 30-40% of a commercial building’s electric bill,<br />

it’s easy to see where money is saved. If other<br />

energy efficient practices were in place, these<br />

savings would be even more pronounced.<br />

7 steps to efficiency<br />

Here are 7 key areas to look at which, if steps are<br />

taken to improve them, will result in an old<br />

building becoming as efficient (if not more) as its<br />

newer architectural counterparts:<br />

1. Insulation - primarily look at the roof, ceiling<br />

and loft space followed by walls and flooring<br />

2. Heating – Consider replacing outdated<br />

systems with heating pumps, electric boilers,<br />

smart controls etc. Savings of 30–80% can<br />

be made with products such as these.<br />

3. Air tightness - Plug air leaks and perhaps<br />

install new windows and doors. After all,<br />

why pay for heating if most of it is lost to<br />

poor indoor air control?<br />

4. Lighting – Switching to compact fluorescent<br />

light bulbs and/or LED light bulbs. This is<br />

cheap, easy and provides immediate<br />

improvements.<br />

5. Lower energy usage – Try to specify<br />

appliances and products with low energy<br />

consumption only.<br />

6. Go green – There’s a lot to be said for solar<br />

energy and biomass boilers!<br />

In short, retrofit is a modern solution to present<br />

and future problems. The construction industry<br />

has all too often been described as being stuck in<br />

its ways and therefore an unattractive career<br />

prospect for the younger people. In reality, this<br />

couldn’t be further from the truth. We are<br />

diverse, exciting and ever-changing as an industry,<br />

but retrofitters need to start re-educating<br />

industry peers and stressing the true value of<br />

retrofit if we are to improve our image overall,<br />

lower our carbon footprint and attract the next<br />

generation of budding professionals.

: The Centre of Refurbishment Excellence (CoRE) was<br />

completed in April 2013 following an investment of<br />

£12.4 million in to the wholesale refurbishment of one<br />

of Stoke on Trent's most derelict pottery kilns. It is a<br />

physical embodiment of sustainability and a true<br />

testament to the amazing capabilities of retrofit.<br />

: Core Interior<br />

refurb| RENEW 15

www.spv.co.uk Refurbishment and Maintenance of Buildings Issue No. 6<br />

e Randolph Hotel, Oxford<br />

SPV Group, the nationwide<br />

refurbishment contractors have<br />

recently undertaken the fire<br />

refurbishment works at e 5 *<br />

Macdonald Randolph Hotel, Oxfordthe<br />

leading 5 star Hotel in Oxford.<br />

e heritage building is located in the<br />

centre of Oxford on Beaumont St<br />

o<strong>cc</strong>upying a corner site with the<br />

Ashmolean Museum opposite the<br />

main entrance, with the other side<br />

fronting onto St Giles and colleges and<br />

the Playhouse eatre a few doors up.<br />

SPV were initially appointed to carry<br />

out the emergency works to get the<br />

Hotel back up and running following a<br />

devastating fire which started within<br />

the kitchen area.<br />

On completion of these works, SPV<br />

were then appointed to carry out the<br />

external and internal fire<br />

refurbishment contract.<br />

Works involved the rebuilding of the<br />

Tower of the Hotel all as per Heritage<br />

requirements, flat roofing works, slate<br />

roofing works and remedial works to<br />

the windows.<br />

SPV were most recently appointed to<br />

create the new Acanthus Dining<br />

Experience at the Hotel which offers<br />

the people of Oxford an exciting new<br />

dining experience as well as e<br />

Cartoon Bar- the most stylish new bar<br />

in Oxford City Centre.<br />

St Aidens School, Ilford<br />

SPV are currently undertaking the roofing works at St Aidens School, Ilford.<br />

e bespoke design and build contract involves the design, supply and installation of all<br />

labour, plant and materials to the roof of the new modular classroom block.<br />

e classroom is constructed off site then delivered to site for SPV to carry out the flat to<br />

pitched roof conversion using a<br />

liner panel, rigid insulation and<br />

a standing seam roof sheeting<br />

system.<br />

Modular construction can<br />

reduce waste and site<br />

disturbance compared to site<br />

built structures.<br />

Once completed, the building<br />

will be entirely transformed<br />

and ready for use by the school.<br />

SPV Team members<br />

save the day<br />

AHuge well done to Lewis Male and Carl<br />

Petch of SPV for their courageous efforts<br />

in saving the Lady Mayor of Tiverton<br />

from an awful mugging experience.<br />

http://m.middevongazette.co.uk/Ladymayor-80-saved-mugging-mobilityscooter/story-29102953-detail/story.html<br />

SPV are delighted to have<br />

been awarded with a<br />

Performance Beyond<br />

Compliance Certificate by<br />

Considerate Constructors.<br />

e Award celebrates our Company's<br />

achievement of outperforming the Scheme's<br />

Company Code of Considerate Practice by<br />

achieving a score of 7 points or above in each of<br />

the five sections.<br />

: David Cameron has ‘rebooted’ Margaret<br />

Thatcher’s Right to Buy of the eighties<br />

David Watson<br />

Chairman, Considerate Constructors Scheme Ltd.<br />

<br />

Reg No: C1234 Member Since: February 2015<br />

Issue Date: 06 April 2016<br />

Presented to<br />

SPV Group<br />

For membership period<br />

March 2015 to March 2016

New residential air con range<br />

launched by LG<br />

LG has launched its new range of<br />

residential air conditioning<br />

equipment,<br />

the Econo, (ref: E09EM / E12EM),<br />

the Libero-S, (ref: P09EN / P12EN /<br />

P28EN / P24EN), and<br />

the Libero-R, (ref: D09RN / D12RN<br />

/ D18RN / D24RN).<br />

All have had an upgrade and now<br />

come with Wifi options and a tenyear<br />

smart inverter compressor warranty, reflecting the reliability of<br />

LG units, as well as a stylish redesign to add to its su<strong>cc</strong>essful<br />

ARTCOOL Stylist, the Mirror and the Prestige units.<br />

These new energy efficient units are simple to install and come with<br />

easy to use controls and a large magic display allowing you to check<br />

the unit’s energy usage. They’re easy to open and simple to clean<br />

which lengthens the units’ lifespan. Features include very low noise<br />

levels – just 19dB for the 9k and 12k models, fast cooling and heating,<br />

smart control - with Wifi option- and Gold-finTM coating protecting<br />

the surface of the outdoor heat exchanger from wear and corrosion.<br />

These new units incorporate high pressure blade fans which provide<br />

indoor air flow rates 15% higher than conventional systems. The<br />

outdoor unit features high efficiency wings that create high<br />

efficiency cooling and heating and a 9m long power airflow corridor<br />

that provides a cooling response that is faster and more powerful.<br />

Brochures can be downloaded from partner.lge.com/uk,<br />

or you can email LG HVAC.marketing@lge.com for<br />

more information.<br />

L G Electric<br />

First Call<br />

First Call offer the complete property maintenance solution.<br />

As a fully insured company with over 30 years' experience,<br />

we offer our clients a wide variety of interior/exterior<br />

services and solutions. These include extensions, building<br />

work, fencing, landscape gardening, UPVC windows, painting<br />

and decorating; whatever the challenge, we aim to exceed<br />

your expectations, every time.<br />

Give us a call - we do it all! 07517 635479<br />

www.handrailsuk.co.uk/<br />

/stargard<br />

Tel: 01473 240055<br />

Email:sales@sgsystems.co.uk<br />

l<br />

Stargard<br />

The original<br />

“Warm to the touch” handrail<br />

4mm (4,000 microns) thick PVC<br />

over<br />

galvanised<br />

steel<br />

tube<br />

ro<br />

r argard - warm to the touch handrai<br />

- structural glass balustrad e<br />

lassrail<br />

- stainless steel balustrad e<br />

entinel<br />

S<br />

G<br />

S<br />

<strong>July</strong> / Aug2O16 issue <strong>8958</strong> refurb| RENEW 17

Product | NEWS<br />

Raising awareness of lung disease with Breathe Easy Week<br />

Leading British fan manufacturer Vent-Axia was delighted to support Breathe Easy Week in June, the annual<br />

awareness week which focuses on lung health and is run by the British Lung Foundation (BLF).<br />

“Vent-Axia was delighted to support Breathe Easy Week this year. The British Lung Foundation’s aim is that one day<br />

everyone will breathe clean air with healthy lungs. At Vent-Axia we support this and are committed to helping to<br />

achieve this by providing effective, energy efficient ventilation to help provide good indoor air quality in our<br />

homes,” says Jenny Smith, Marketing Manager at Vent-Axia.<br />

Designed to work with the natural air infiltration, continuous ventilation systems control the air path through the<br />

home. As a result, they prevent the migration of damaging humidity and pollutants, providing near silent energy<br />

efficient ventilation. There are a number of options available, both for new builds and for retrofitting and the latest<br />

continuous ventilation systems also offer heat recovery.<br />

www.vent-axia.com<br />

New Catalogue from ACE Fabreeka UK<br />

ACE and Fabreeka have come together to become the new ACE Fabreeka UK. Both of these well recognised, market leading brands are available<br />

from one highly experienced team focused on the UK motion and vibration control market.<br />

A new 104-page Fabreeka Vibration Control core products catalogue is now available, giving designers, architects and structural engineers a<br />

comprehensive, technical overview of products to solve vibration and isolation problems.<br />

Since 1936, Fabreeka has been providing these solutions to a diverse customer base across numerous end-markets, such as test and measurement,<br />

industrial machinery, building and construction, oil and gas, power generation, steel, automotive, precision equipment,<br />

aerospace and defence.<br />

The original fabric reinforced, elastomeric Fabreeka Pad and the nitrile rubber Fabcel Pad are the two core<br />

Fabreeka branded products supported by a wide array of other supporting vibration and isolation materials,<br />

shock mounts, mounting feet and levelling mounts.<br />

In addition to a very extensive range of products, ACE Fabreeka UK will also be able to offer a<strong>cc</strong>ess to added<br />

value design and customer support services when more than just a product is necessary and a total vibration<br />

control solution is required.<br />

www.ace-controls.co.uk www.fabreeka.co.uk<br />

NEW to the UK market – the E-valve by Sainte Lizaigne<br />

Groundbreaker Systems is delighted to announce that the company can now offer the NEW E-valve by French manufacturing giant Sainte<br />

Lizaigne. This fully remote controllable system is ideal for water network management, opening possibilities for off peak water supply, and sale<br />

of water to remote locations by time or volume.<br />

With scheduled maintenance and a<strong>cc</strong>ess to historical data the E- valve<br />

can add to BREEAM scores by water management. Operated via smart<br />

phone app connected to the valve via Bluetooth low energy, the benefits<br />

for water operators and consumers are far reaching.<br />

Remote billing facilities are invaluable to avoid waste of water resources<br />

such as after-hours management of water to “non domestic” properties<br />

such as office blocks, schools, supermarkets, Holiday Parks or remote<br />

locations, and where action can be taken remotely without incurring<br />

travel time and costs. Ideal for high value locations with poor a<strong>cc</strong>ess,<br />

examples of which are airports or shopping malls. The E-valve also<br />

enables the sale of water by volume via credit card or a<strong>cc</strong>ount<br />

payments.<br />

The E –valve facilitates efficient use of resources with no fuss to<br />

the consumer, is easy to install on existing or new water services;<br />

in addition the E-valve is alarmed for unspecified use, leakage<br />

identification and damage limitation. E-valve is available in the<br />

UK exclusively though Groundbreaker Systems.<br />

www.groundbreaker.co.uk<br />

18<br />

refurb| RENEW <strong>July</strong> / August 2O16 issue <strong>8958</strong>

Changing the options for a<strong>cc</strong>essible toilets<br />

Making ‘reasonable adjustments’ to the built<br />

environment to ensure compliance with the<br />

Equality Act is being made easier with the launch<br />

of a new solution for ‘away from home’ a<strong>cc</strong>essible<br />

toilets.<br />

Space To Change toilets plug the gap between<br />

conventional (Building Regulations Approved<br />

Document M 2013) wheelchair-a<strong>cc</strong>essible toilets,<br />

and the ‘desirable’, additional, larger and better<br />

equipped Changing Places+ toilets.<br />

The concept enables venues that are limited<br />

financially and/or on space to meet the needs of<br />

up to three million British children and adults* who<br />

need changing and lifting facilities for their<br />

personal hygiene. It encompasses a 7m2+ (3m x<br />

2.5m min) wheelchair-a<strong>cc</strong>essible toilet that further<br />

includes an adult-sized changing bench and a hoist.<br />

Space To Change has been developed with leading<br />

Changing Places campaigners and Clos-o-Mat<br />

(Britain’s leading supplier of disabled toilet solutions<br />

at home and away). Firefly Community, an online special needs community, will drive the campaign, supporting campaigners and raising awareness<br />

of the need for a<strong>cc</strong>essible toilets that include height adjustable changing benches and hoists.<br />

Clos-o-Mat<br />

Full details of the Space To Change concept, plus technical support, CAD blocks etc, can be found at<br />

www.clos-o-mat.com<br />

Mapei products specified to create a<br />

distinctly British feel in luxury apartments<br />

Mapei’s products were specified<br />

to help represent the epitome of<br />

sophisticated city living in an<br />

apartment redevelopment. Mapei<br />

products were distributed by<br />

Boyden Tiles, Croydon with the<br />

project being led by WB<br />

Simpsons.<br />

Keraquick and Latex Plus were<br />

used on approx. 340m2 of<br />

flooring to lay the Domus<br />

porcelain 600 x 600 tiles in all the main and ensuite bathrooms plus all of<br />

the balconies within the apartment block.<br />

800m2 of wall tiling were fixed using Mapei’s Ultralite S2 – a high<br />

performance, lightweight cementitious adhesive with very low emissions<br />

of volatile organic compounds. The adhesive, specifically developed for<br />

large size tiles to be laid on large surfaces without back buttering, was<br />

used to bond Domus Tiles 3m x 1m ‘Kerlite Slim’ porcelain tiles to the walls<br />

of the apartments luxury bathrooms and ensuites.<br />

Mapei’s Topcem, was specified as a screed for an area of 120m2 onto<br />

external balconies. The quick setting screed allowed the installation of<br />

Domus Tiles 200 x 800mm ‘Wood Sense’ porcelain tiles just 24 hours after<br />

application.<br />

For more information on Mapei resilient products, other products or<br />

training days, please visit www.mapei.co.uk, email info@mapei.co.uk or tel.<br />

+44 (0)121 508 6970.<br />

www.mapei.co.uk<br />

MODULAR SHOWERING SOLUTIONS<br />

<br />

<br />

<br />

l<br />

l<br />

l<br />

l<br />

l<br />

l<br />

l<br />

l<br />

l<br />

l<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

TAPLANES<br />

R<br />

S H O W E R I N G S O L U T I O N S<br />

<strong>July</strong> / August 2O16 issue <strong>8958</strong> refurb| RENEW 19

Roofing, Cladding & Insulation |<br />

The foldable system from WeatherFAST<br />

WeatherFAST have been supplying a wide range of high performance Fatra PVC membrane steel in sheet or coil form for many years. By<br />

constantly innovating and designing quality products for use on commercial and industrial gutter systems, they have earned the reputation of<br />

being market leaders within this field and their business has flourished. Joe Bradbury of R&R Magazine caught up with WeatherFAST’s Managing<br />

Director, Orry White to discuss their new product, WeatherFOLD - which offers clients a smart and effective way of re-lining old, leaky<br />

valley/boundary wall gutters.<br />

Q) Can you tell us a little bit more about your new foldable system and<br />

how people who specify it in their build can expect to benefit?<br />

A) Certainly! In all honesty, we believe our new folding gutter system is<br />

the best looking and performing product on the market. The simplicity<br />

and effectiveness of its design should really appeal to architects looking<br />

for valley/boundary gutter solutions. The gutters include 3 hinges and<br />

come in 3000mm lengths, with widths up to 1250 wide and come<br />

complete with a 75mm built-in flap that joins onto the next gutter via a<br />

single weld. Due to its unique design, we don't actually need to know the<br />

exact degree of the wings prior to fitting. In our experience this alone<br />

reduces installation times by up to 50% and makes our clients’ lives a lot<br />

easier overall. Instead of having to go back and forth with information on<br />

the existing roof gutter system or having to make costly amendments<br />

prior to installation of the new product, our system simply follows the<br />

lines of the existing gutters. No fuss.<br />

Q) How big a role do you think a folding gutter system can play in helping<br />

a building achieve its maximum potential?<br />

A) Commercial and industrial building owners are always looking for a<br />

gutter solution that is good value, good quality, quick to install and<br />

preferably BBA a<strong>cc</strong>redited. They want to fit something reliable that they<br />

can trust – so they can forget about it; safe in the knowledge that it is<br />

doing its job in the background.<br />

With a 0.6mm steel substrate/1.2mm Fatra PVC chequer plate slip<br />

prevention membrane & 25 year guarantee, we believe our new system<br />