CatalogueProduceTech2016_Anglais

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

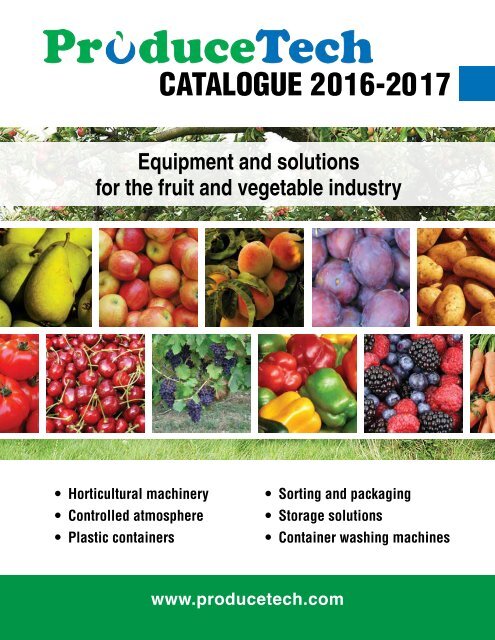

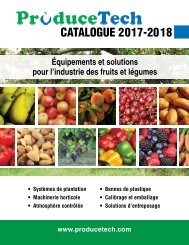

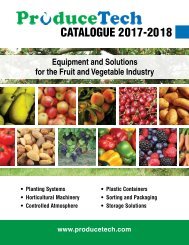

CATALOGUE 2016-2017<br />

Equipment and solutions<br />

for the fruit and vegetable industry<br />

• Horticultural machinery<br />

• Controlled atmosphere<br />

• Plastic containers<br />

• Sorting and packaging<br />

• Storage solutions<br />

• Container washing machines<br />

www.producetech.com

Our company<br />

We are very pleased to present our first product and service catalogue.<br />

ProduceTech continually strives to bring you reliable, top-quality<br />

equipment. In this highly competitive market, every fruit and vegetable<br />

producer, warehouse manager and distributor must be innovative in order<br />

to thrive.<br />

By keeping abreast of new technologies, ProduceTech is ready to help you<br />

and share our knowledge. You are not just our clients, but our business<br />

partners. We encourage you to contact our team with your comments and<br />

questions, and we look forward to working with you!<br />

Eric Deschambault, Eng., President

Summary<br />

This icon lets you know there is a<br />

video available on our website and our<br />

YouTube channel.<br />

Follow us on LinkedIn<br />

Find us on Facebook<br />

Watch our YouTube videos<br />

Are you looking a<br />

particular type of equipment?<br />

Do you need help importing a<br />

special product<br />

or piece of machinery?<br />

Contact us today – it will be our<br />

pleasure to assist you.<br />

Horticultural Machinery ........................................................2<br />

Mechanical rotary hoes and harrows....................................2<br />

Inter-row ridging machines...................................................2<br />

Subsoilers............................................................................3<br />

Root pruners........................................................................3<br />

Rotary mowers.....................................................................4<br />

Expandable deck mowers.....................................................5<br />

Hammer mulching machines.................................................6<br />

Vine-shoot and sucker removers...........................................7<br />

Mechanical pruners and lopping machines....................... 8-9<br />

Pre-pruners........................................................................10<br />

Leaf removers....................................................................10<br />

Mechanical thinners............................................................11<br />

Spreaders...........................................................................12<br />

Harvesting Equipment.........................................................13<br />

Tree shakers......................................................................13<br />

Fruit collectors...............................................................14-15<br />

Platforms for harvesting and pruning.............................16-19<br />

Custom-made harvesting and transport trailers..............20-21<br />

Room Construction.............................................................22<br />

Structural insulated panels.................................................22<br />

Doors for refrigerators and freezers....................................23<br />

High-speed doors...............................................................24<br />

Gas-tight doors ..................................................................25<br />

Gas and Controlled Atmosphere Management...................26<br />

High-purity nitrogen generators..........................................26<br />

Humidification systems.............................................................. 27<br />

Leak testing equipment............................................................. 27<br />

Gas-Tight coatings.................................................................... 27<br />

Grading and Packing Equipment for Produce....................28-29<br />

Plastic Containers...............................................................30<br />

Plastic bins ............................................................................... 30<br />

Container Washing Machines.............................................31<br />

Bin washers........................................................................31<br />

Reusable plastic container (RPC) washers............................... 32<br />

Prestressed Concrete Posts & Complete anti-hail Systems....32<br />

Conversion Tables...............................................................33<br />

And many more…! 1

MECHANICAL ROTARY HOES AND HARROWS<br />

Performance - Innovation - Reliability<br />

Extremely sturdy rotary hoes and harrows with an automatic lateral<br />

movement system, ideal for vineyards and orchards. Features include a<br />

highly responsive sensor so the equipment can also be used on recently<br />

planted crops. The equipment is configured to be installed at the rear of the<br />

tractor, but can also be placed at the front (optional).<br />

Optional: Angle of the hoe unit (operated from the driver’s seat) to follow<br />

ground contours. Manual retraction control in case of emergency. Harrow<br />

unit can be replaced with other equipment using the same frame (ridging<br />

disks, hoe unit, mini tiller).<br />

TYPE<br />

MODEL<br />

WORKING<br />

WIDTH<br />

LATERAL<br />

MOVEMENT<br />

WEIGHT<br />

POWER<br />

REQUIRED<br />

(HP)<br />

DEPTH<br />

DISTANCE FROM<br />

TRACTOR CENTER<br />

MINIMUM DISTANCE<br />

BETWEEN TREES<br />

ROTARY<br />

HARROW<br />

ES 50<br />

ES 75<br />

50 cm<br />

20’’<br />

75 cm<br />

30’’<br />

40 cm<br />

16’’<br />

40 cm<br />

16’’<br />

290 kg<br />

639 lb<br />

330 kg<br />

728 lb<br />

25-50<br />

25-50<br />

0-10 cm<br />

0’’- 4’’<br />

0-10 cm<br />

0’’- 4’’<br />

60 cm<br />

24’’<br />

85 cm<br />

34’’<br />

60 cm<br />

24’’<br />

60 cm<br />

24’’<br />

ROTARY HOE<br />

SI 1-40<br />

SI 1-50<br />

SI 1-80<br />

40 cm<br />

16’’<br />

50 cm<br />

20’’<br />

80 cm<br />

31’’<br />

40 cm<br />

16’’<br />

40 cm<br />

16’’<br />

40 cm<br />

16’’<br />

270 kg<br />

595 lb<br />

280 kg<br />

617 lb<br />

300 kg<br />

661 lb<br />

20-50<br />

20-50<br />

25-50<br />

0-12 cm<br />

0’’- 4’’<br />

0-12 cm<br />

0’’- 4’’<br />

0-12 cm<br />

0’’- 4’’<br />

60 cm<br />

24’’<br />

60 cm<br />

24’’<br />

90 cm<br />

35’’<br />

80 cm<br />

31’’<br />

80 cm<br />

31’’<br />

80 cm<br />

31’’<br />

INTER-ROW RIDGING MACHINES<br />

By gently working the soil, the disks destroy weeds and work the soil’s surface.<br />

This machine’s innovative rotating disks are belt-driven though the power takeoff (PTO),<br />

which allows the machine to work in all conditions and soil types. The machine is<br />

available in a front or rear-mounted version. Minimum distance between trees must be<br />

50 cm (20”). 45 HP tractor required (minimum). Working depth of 3-20 cm (1-8”).<br />

Optional: The disks can be replaced with other equipment such as a rotary harrow,<br />

rotary hoe, vine shoot remover, blade or mower.<br />

TYPE MODEL WEIGHT<br />

REAR<br />

FRONT<br />

WIDTH<br />

(WITHOUT ARM)<br />

DISTANCE FROM<br />

TRACTOR CENTER<br />

(WITHOUT ARM)<br />

MINIMUM ROW WIDTH<br />

Compact 450 kg - 992 lb 100 cm - 3’3’’ 105 cm - 3’5’’ 150 cm - 4’11’’<br />

Junior 470 kg - 1036 lb 110 cm - 3’7’’ 115 cm - 3’9’’ 170 cm - 5’7’’<br />

Piccolo 510 kg - 1124 lb 120 cm - 3’11” 125 cm - 4’1’’ 200 cm - 6’7’’<br />

Medio 550 kg - 1213 lb 140 cm - 4’8’’ 155 cm - 5’1’’ 240 cm - 7’10’’<br />

Grande 600 kg - 1323 lb 180 cm - 5’11’’ 190 cm - 6’3’’ 320 cm - 10’6’’<br />

Magnum 660 kg - 1455 lb 205 cm - 6’9’’ 210 cm - 6’11’’ 450 cm - 14’9’’<br />

Piccolo 530 kg - 1168 lb 120 cm - 3’11’’ - 180 cm - 5’11’’<br />

Medio 570 kg - 1257 lb 140 cm - 4’8’’ - 240 cm - 7’10’’<br />

Grande 600 kg - 1323 lb 180 cm - 5’11” - 320 cm - 10’6’’<br />

Magnum 660 kg - 1455 lb 205 cm - 6’9’’ - 450 cm - 14’9’’<br />

2<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

SUBSOILERS<br />

Very robust subsoiler. Thanks to its two curved shares, it lifts the soil<br />

without damaging the grass at the surface. The rear roller restores<br />

the surface. The ability to make a horizontal cut facilitates deep water<br />

penetration, deep aeration of the soil and deep root development.<br />

Adjustable working width and depth.<br />

Optional:<br />

Version with fertilizer spreader. The subsoiler is equipped with<br />

a stainless steel container with a load capacity of 450 liters<br />

(119 USG); fertilizer spreading is controlled from the tractor by a manual<br />

hydraulic control.<br />

MODEL<br />

NUMBER<br />

OF<br />

SHARES<br />

ROLLER<br />

DIAMETER<br />

WEIGHT<br />

POWER<br />

REQUIRED<br />

(HP)<br />

DEPTH<br />

MINIMUM<br />

WORKING<br />

WIDTH<br />

MINIMUM<br />

DISTANCE<br />

BETWEEN<br />

ROWS<br />

DAR 140 2 50 cm - 20’’<br />

650 kg<br />

1433 lb<br />

60 - 90<br />

20-50 cm<br />

8’’-20’’<br />

120 cm<br />

3’11’’<br />

180 cm<br />

5’11’’<br />

DAR 170 2 50 cm - 20’’<br />

730 kg<br />

1609 lb<br />

80 - 100<br />

20-50 cm<br />

8’’-20’’<br />

150 cm<br />

4’11’’<br />

260 cm<br />

8’6’’<br />

DAR 140 C 2 50 cm - 20’’<br />

750 kg<br />

1653 lb<br />

60 - 90<br />

20-50 cm<br />

8’’-20’’<br />

120 cm<br />

3’11’’<br />

180 cm<br />

5’11”<br />

“DAR 170 C 2 50 cm - 20’’<br />

890 kg<br />

1962 lb<br />

80 - 100<br />

20-50 cm<br />

8’’-20’’<br />

150 cm<br />

4’11’’<br />

260 cm<br />

8’6”<br />

ROOT PRUNERS<br />

Slow down tree growth with the root pruner. In the case of rootstocks that are too<br />

vigorous, cutting the roots makes fruit smaller and firmer. This also allows you to<br />

minimize time spent trimming and thinning.<br />

Technical details:<br />

- Adjustable height.<br />

- 3 hydraulic double-effect connections are required to control:<br />

• Horizontal extension of the blade up to 50 cm (20”) to adapt<br />

to various row types.<br />

• Oblique angle of the blade up to 50 cm (20”)<br />

to control the cutting angle.<br />

• Extension of the blade up to 40 cm (16”) to adjust working depth.<br />

- Hardox 500 blade, 1 m long (3’3”).<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

3

Performance - Innovation - Reliability<br />

ROTARY MOWERS<br />

HM mulching machines are compact, work close to the ground and are equipped with<br />

a smooth fiberglass cover that prevents damage to fruit. The cutting blades rotate at<br />

high speed to ensure rapid and precise cutting. Minimal energy consumption allows<br />

for more fuel savings. A wide range of cutting widths is available, from 1.15 m (3’9”)<br />

to 3.55 m (11’8”). Cutting height is also adjustable.<br />

Save steps<br />

Save time<br />

Save money<br />

Lateral disks let you get to hard-to-reach areas that can be a challenge for traditional<br />

cutting systems.<br />

Optional:<br />

100 L (26 USG) or 200 L (52 USG) tank<br />

to spray herbicide between rows.<br />

Hydraulic side shift.<br />

MODEL<br />

NO DISK 1 DISK 2 DISKS<br />

115 150 160 175 200 265 161 201 221 251 301 202 222 252 302<br />

BASE SPECIFICATIONS<br />

MAIN BODY<br />

CUTTING WIDTH<br />

- - - - - -<br />

115 cm<br />

3’9”<br />

155 cm<br />

5’1’’<br />

175 cm<br />

5’9”<br />

200 cm<br />

6’7”<br />

265 cm<br />

8’8”<br />

155 cm<br />

5’1’’<br />

175 cm<br />

5’9”<br />

200 cm<br />

6’7”<br />

255 cm<br />

8’4”<br />

CUTTING WIDTH<br />

115 cm<br />

3’9”<br />

155 cm<br />

5’1’’<br />

160 cm<br />

5’3”<br />

175 cm<br />

5’9”<br />

200 cm<br />

6’7”<br />

265 cm<br />

8’8”<br />

165 cm<br />

5’5”<br />

205 cm<br />

6’9”<br />

225 cm<br />

7’5”<br />

250 cm<br />

8’2”<br />

315 cm<br />

10’4”<br />

255 cm<br />

8’4”<br />

275 cm<br />

9’ 0”<br />

300 cm<br />

9’10”<br />

355 cm<br />

11’8”<br />

TOTAL WIDTH<br />

123 cm<br />

4’0”<br />

163 cm<br />

5’4”<br />

168 cm<br />

5’6”<br />

183 cm<br />

6’0”<br />

208 cm<br />

6’10”<br />

273 cm<br />

8’11”<br />

173 cm<br />

5’8”<br />

213 cm<br />

7’0”<br />

233 cm<br />

7’8”<br />

258 cm<br />

8’6”<br />

323 cm<br />

10’7”<br />

268 cm<br />

8’10”<br />

288 cm<br />

9’5”<br />

313 cm<br />

10’3’’<br />

368 cm<br />

12’1”<br />

WEIGHT<br />

250 kg<br />

550 lb<br />

290 kg<br />

640 lb<br />

300 kg<br />

660 lb<br />

330 kg<br />

730 lb<br />

370 kg<br />

815 lb<br />

470 kg<br />

1035 lb<br />

300 kg<br />

660 lb<br />

340 kg<br />

750 lb<br />

380 kg<br />

840 lb<br />

420 kg<br />

925 lb<br />

520 kg<br />

1150 lb<br />

420 kg<br />

925 lb<br />

440 kg<br />

970 lb<br />

480 kg<br />

1060 lb<br />

680 kg<br />

1499 lb<br />

MINIMUM TRACTOR HP 18 20 22 22 25 35 20 22 25 30 35 30 33 35 40<br />

NUMBER OF BLADES 2 3 2 3 3 4 2+1 3+1 3+1 3+1 4+1 3+2 3+2 3+2 5+2<br />

NUMBER OF WHEELS 3 1 - 2 2 2 3 2 2 2 2 2 2 2 2<br />

NUMBER OF<br />

REAR ROLLERS<br />

ADAPTABLE FOR<br />

FRONT PTO OUTPUT<br />

- 1 3 1 1 2 - 1 1 1 2 1 1 1 1<br />

OPTIONAL<br />

X X <br />

WIDER DISKS X X X X X X <br />

4<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

EXPANDABLE DECK MOWERS<br />

FISARMONICA rotary mulching machines cut grass with<br />

horizontal rotating blades. The left and right sections can be<br />

expanded and controlled independently to adapt to different<br />

row widths in orchards, vineyards and other plantations. This<br />

machine is suitable for tractors from 50 to 110 HP and provides<br />

a high speed grass cutting solution. 2 hydraulic double-effect<br />

connections are required. Grass cuttings can be ejected into<br />

the middle or to the sides of the row. Rollers are height and<br />

width adjustable.<br />

Optional:<br />

100 L (26 USG) or 200 L (52 USG) tank available<br />

to spray herbicide between rows.<br />

Kombi version for front and back linkage.<br />

MODELS 125 145 160 175 235<br />

MIN. CUTTING WIDTH<br />

MAX. CUTTING WIDTH<br />

TOTAL WIDTH<br />

(RETRACTED)<br />

LENGTH<br />

125 cm<br />

4’1”<br />

175 cm<br />

5’9”<br />

130 cm<br />

4’3”<br />

150 cm<br />

4’11”<br />

BASE SPECIFICATIONS<br />

145 cm<br />

4’9”<br />

190 cm<br />

6’3”<br />

150 cm<br />

4’11”<br />

170 cm<br />

5’7”<br />

160 cm<br />

5’3”<br />

215 cm<br />

7’1”<br />

165 cm<br />

5’5”<br />

180 cm<br />

5’11”<br />

HEIGHT 1 m (3’3”)<br />

175 cm<br />

5’9”<br />

235 cm<br />

7’9”<br />

180 cm<br />

5’11”<br />

190 cm<br />

6’3”<br />

235 cm<br />

7’9’’<br />

295 cm<br />

9’8’’<br />

240 cm<br />

7’10’’<br />

225 cm<br />

7’5’’<br />

PTO ROTATION SPEED 540 RPM (if KOMBI: 540 or 1000 RPM) 540 RPM<br />

WEIGHT<br />

SPEED<br />

MAX. GRASS HEIGHT<br />

HERBICIDE TANK<br />

100 L (26 USG) /<br />

200 L (52 USG)<br />

450 kg<br />

990 lb<br />

87 cm<br />

2’10”<br />

100 L (26 USG)<br />

only<br />

540 kg<br />

1190 lb<br />

600 kg<br />

1320 lb<br />

620 kg<br />

1365 lb<br />

4 - 10 km/h ≈ 2.5 – 6.2 mph (depending on conditions)<br />

97 cm<br />

3’2”<br />

OPTIONAL<br />

100 L (26 USG)<br />

only<br />

110 cm<br />

3’7”<br />

120 cm<br />

3’11”<br />

910 kg<br />

2006 lb<br />

120 cm<br />

3’11”<br />

<br />

KOMBI: FRONT OR REAR<br />

PTO OUTPUT<br />

X<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

5

Performance - Innovation - Reliability<br />

HAMMER MULCHING MACHINES<br />

The CASTOR is a universal mulching machine that mows, chops,<br />

shreds and destroys cut branches. Robust construction with an<br />

electronically balanced blade holder. The transmission works with<br />

4 or 5 belts (depending on the model) which guarantees an optimal<br />

use of power. Interchangeable hammers with double-sided blades.<br />

Durability guaranteed; low maintenance. Can be equipped with<br />

1 or 2 lateral disks (35/45/55 cm – 14”/18”/22” diameter).<br />

Optional:<br />

• 100 L (26 USG) or 200 L (52 USG) tank available<br />

to spray herbicide between rows.<br />

• Kombi version for front and back linkage.<br />

• Hydraulic side shift (except for C11 model).<br />

MODEL<br />

CUTTING WIDTH<br />

NO DISKS<br />

C11 C13 C15 C16 C18 C20 C22 C25 C28<br />

1.10 m<br />

3’7”<br />

1.25 m<br />

4’1’’<br />

1.50 m<br />

4’11”<br />

1.60 m<br />

5’3”<br />

1.75 m<br />

5’9”<br />

2.02 m<br />

6’8”<br />

2.20 m<br />

7’3”<br />

2.50 m<br />

8’2”<br />

2.75 m<br />

9’0”<br />

TOTAL WIDTH<br />

1.30 m<br />

4’3”<br />

1.43 m<br />

4’8”<br />

1.68 m<br />

5’6”<br />

1.78 m<br />

5’10”<br />

1.93 m<br />

6’4”<br />

2.20 m<br />

7’3”<br />

2.40 m<br />

7’10”<br />

2.70 m<br />

8’10”<br />

2.95 m<br />

9’8”<br />

WEIGHT<br />

MIN. HP TRACTOR<br />

REQUIRED<br />

NUMBER<br />

OF HAMMERS<br />

340 kg<br />

750 lb<br />

390 kg<br />

859 lb<br />

420 kg<br />

925 lb<br />

440 kg<br />

970 lb<br />

470 kg<br />

1036 lb<br />

520 kg<br />

1147 lb<br />

560 kg<br />

1235 lb<br />

620 kg<br />

1366 lb<br />

650 kg<br />

1433 lb<br />

20 - 25 20 - 25 20 - 25 25 - 30 25 - 30 30 - 40 40 - 50 45 - 55 50 - 60<br />

12 12 16 16 20 24 24 28 28<br />

1 DISK<br />

MODEL<br />

C131 C151 C161 C181 C201 C221 C251 C281<br />

CUTTING WIDTH 1.25 m - 4’1’’ 1.50 m - 4’11” 1.60 m - 5’3” 1.75 m - 5’9” 2.02 m - 6’8” 2.20 m - 7’3” 2.50 m - 8’2” 2.75 m - 9’0”<br />

CUTTING WIDTH D.35 1.55 m - 5’1’’ 1.80 m - 5’11’’ 1.90 m - 6’3’’ 2.05 m - 6’9’’ 2.32 m - 7’7’’ 2.50 m - 8’2’’ 2.80 m - 9’2’’ 3.05 m - 10’0’’<br />

CUTTING WIDTH D.45 1.65 m - 5’5’’ 1.90 m - 6’3’’ 2.00 m - 6’7’’ 2.15 m - 7’0’’ 2.42 m - 7’11’’ 2.60 m - 8’6’’ 2.90 m - 9’6’’ 3.15 m -10’4’’<br />

CUTTING WIDTH D.55 1.75 m - 5’9’’ 2.00 m - 6’7’’ 2.10 m - 6’11’’ 2.25 m - 7’5’’ 2.52 m - 8’3’’ 2.70 m - 8’10’’ 3.00 m - 9’10’’ 3.25 m - 10’8’’<br />

TOTAL WIDTH 1.43 m - 4’8” 1.68 m - 5’6” 1.78 m - 5’10” 1.93 m - 6’4” 2.20 m - 7’3” 2.40 m - 7’10” 2.70 m - 8’10” 2.95 m - 9’8”<br />

WEIGHT 440 kg - 970 lb 490 kg - 1080 lb 520 kg - 1147 lb 540 kg - 1191 lb 570 kg - 1256 lb 620 kg - 1366 lb 660 kg - 1455 lb 720 kg -1588 lb<br />

MIN. HP TRACTOR<br />

REQUIRED<br />

20 - 25 20 - 25 25 - 30 25 - 30 30 - 40 40 - 50 45 - 55 50 - 60<br />

NUMBER OF HAMMERS 12 16 16 20 24 24 28 28<br />

2 DISKS<br />

MODEL<br />

C152 C162 C182 C202 C222 C252 C282<br />

CUTTING WIDTH 1.50 m - 4’11” 1.60 m - 5’3” 1.75 m - 5’9” 2.02 m - 6’8” 2.20 m - 7’3” 2.50 m - 8’2” 2.75 m - 9’0”<br />

CUTTING WIDTH D.35 2.10 m - 6’11’’ 2.20 m - 7’3’’ 2.35 m - 7’9’’ 2.62 m - 8’7’’ 2.80 m - 9’2’’ 3.10 m - 10’2’’ 3.35 m - 10’12’’<br />

CUTTING WIDTH D.45 2.30 m - 7’7’’ 2.40 m - 7’10’’ 2.55 m - 8’4’’ 2.82 m - 9’3’’ 3.00 m - 9’10’’ 3.30 m - 10’10’’ 3.55 m - 11’8’’<br />

CUTTING WIDTH D.55 2.50 m - 8’2’’ 2.60 m - 8’6’’ 2.75 m - 9’0’’ 3.02 m - 9’11’’ 3.20 m - 10’6’’ 3.50 m - 11’6’’ 3.75 m - 12’4’’<br />

TOTAL WIDTH 1.68 m - 5’6” 1.78 m - 5’10” 1.93 m - 6’4” 2.20 m - 7’3” 2.40 m - 7’10” 2.70 m - 8’10” 2.95 m - 9’8”<br />

WEIGHT 590 kg - 1300 lb 620 kg -1366 lb 640 kg - 1410 lb 670 kg - 1477 lb 720 kg - 1588 lb 760 kg - 1676 lb 820 kg - 1807 lb<br />

MIN. HP TRACTOR<br />

REQUIRED<br />

20 - 25 25 - 30 25 - 30 30 - 40 40 - 50 45 - 55 50 - 60<br />

NUMBER OF HAMMERS 16 16 20 24 24 28 28<br />

6<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

VINE-SHOOT AND SUCKER REMOVERS<br />

SPL800 model:<br />

A vine-shoot remover designed to work in vineyards with high<br />

stems. Made of rubber whips reinforced with canvas. Suitable for<br />

all plantations and soil types. Height and width are hydraulically<br />

adjustable. Head rotation is controlled by the hydraulic flux<br />

regulator supplied with the machine. Ideal for delicate work<br />

around tree trunks thanks to its adjustable-speed rotor.<br />

CUCCHI vine-shoot removers are dual-purpose, able<br />

to eliminate grass growing underneath trees and to<br />

cut off vine-shoots just by varying the rotor speed and<br />

changing the head angle. Its double feelers protect<br />

trees when the machine is used for weeding. Arm<br />

lengths are adjustable to adapt to different row widths.<br />

• Wire diameter: 8 mm (5/16”)<br />

• Wire length: 40 to 80 cm (16” to 31”)<br />

• Rotor length: 50 cm (20”)<br />

• Oil flow rate: 30 L/min (7.9 USG/min) for one head;<br />

60 L/min (15.8 USG/min) for two heads. Ability to increase<br />

oil flow rate with an independent hydraulic unit.<br />

DS model:<br />

• Single head, right side<br />

• Front or rear connection<br />

• Manually adjustable arm length<br />

DSB model:<br />

• Single head, right side<br />

• Front or rear connection<br />

• Hydraulically adjustable arm length<br />

DS2 model:<br />

• Double heads<br />

• Front or rear connection<br />

• Two hydraulically adjustable<br />

arm lengths<br />

Optional:<br />

Interchangeable heads for rotary hoes, harrows or inter-row hoers.<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

7

MECHANICAL PRUNERS AND LOPPING MACHINES<br />

Performance - Innovation - Reliability<br />

These robust trimmers and pruners have been developed to provide<br />

modern orchards and vineyards with efficiency and productivity.<br />

There are many advantages to mechanical trimming:<br />

- Reduces manpower;<br />

- .Promotes air circulation (“Fruit Set”) and increases exposure<br />

to sunlight (fruit color);<br />

- Improves maneuverability for agricultural equipment;<br />

- Allows for more uniform application of chemical products;<br />

- Facilitates the application of fertilizer and herbicide on the ground;<br />

- Increases productivity.<br />

For fruit walls:<br />

• Equipment positioned in front of the tractor.<br />

• Trimmers are equipped with disks for winter trimming<br />

and blades for summer trimming.<br />

• Automatic retraction of the head to avoid posts.<br />

• Disk cutting diameter: up to 10 cm (4”).<br />

• Blade cutting diameter: up to 3 cm (1”).<br />

All models are equipped with 4 hydraulic movements:<br />

horizontal, vertical, arm rotation and head angle.<br />

MODEL<br />

FL200PC<br />

DIMENSIONS<br />

NUMBERS<br />

OF BLADES<br />

A B C A B C<br />

35 cm<br />

1’2”<br />

190 cm<br />

6’3’’<br />

66 cm<br />

2’2”<br />

Winter trimming<br />

NUMBER OF<br />

MOTORS<br />

1 6 2 4<br />

Summer trimming<br />

WEIGHT<br />

270 kg<br />

595 lb<br />

C<br />

35 cm<br />

1’2”<br />

221 cm<br />

7’3”<br />

66 cm<br />

2’2”<br />

1 7 2 4<br />

280 kg<br />

617 lb<br />

B<br />

35 cm<br />

1’2”<br />

252 cm<br />

8’3”<br />

66 cm<br />

2’2”<br />

1 8 2 4<br />

290 kg<br />

639 lb<br />

A<br />

35 cm<br />

1’2”<br />

283 cm<br />

9’3”<br />

66 cm<br />

2’2”<br />

1 9 2 4<br />

300 kg<br />

661 lb<br />

FL800P<br />

C<br />

116 cm<br />

3’10”<br />

154 cm<br />

5’1”<br />

78 cm<br />

2’7”<br />

3 4 2 3<br />

340 kg<br />

750 lb<br />

B<br />

A<br />

116 cm<br />

3’10”<br />

154 cm<br />

5’1”<br />

116 cm<br />

2’7”<br />

3 4 3 3<br />

350 kg<br />

772 lb<br />

BMV machines have various options available, such as an inclinable cutting bar (to reach the tops of trees) and adjustable<br />

height for the cutting head (to adapt to different tree heights).<br />

8<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

For classic fruit trees:<br />

FL600P model<br />

• Equipment positioned in front of the tractor.<br />

• Equipped with disks for winter trimming and blades for summer trimming:<br />

- Disk cutting diameter: up to 10 cm (4”)<br />

- Blade cutting diameter: up to 3 cm (1”)<br />

• 4 hydraulic movements:<br />

- Diagonal<br />

- Vertical<br />

- Cutting bar rotation<br />

- Top angle from 0º to 90º<br />

• Weight: 360 kg (794 lb).<br />

• Equipped with independent hydraulic unit of 80 liters (21 USG) – 190 kg (419 lb).<br />

• Max. height of vertical work: 6.5 m (21’4”).<br />

• Max. height of horizontal work: 4.5 m (14’9”).<br />

• Work capacity with disks: 0.6 ha/h or 1.5 acres/h, depending on plant density.<br />

• Work capacity with blades: 1.5 ha/h or 3.7 acres/h, depending on plant density.<br />

FLHD900 model – best-selling, most versatile model<br />

• Equipment positioned in front of the tractor.<br />

• Equipped with disks for winter trimming and blades for summer trimming:<br />

- Disk cutting diameter: up to 15 cm (6”)<br />

- Blade cutting diameter: up to 3 cm (1”)<br />

• 4 hydraulic movements to adapt to all types of plantation.<br />

• 7 versions available to cut from 2.02 to 3.13 m (6’8” to 10’3”) in length.<br />

• Weight: from 350 kg (772 lb) to 410 kg (904 lb) depending on the model.<br />

• Equipped with independent hydraulic unit of 80 liters (21 USG) – 190 kg (419 lb).<br />

• Work capacity with disks: 1 ha/h or 2.5 acres/h, depending on plant density.<br />

• Work capacity with blades: 2 ha/h or 4.9 acres/h, depending on plant density.<br />

For vineyards:<br />

The E600 model trims the sides and top of a single row.<br />

• Equipment positioned in front of the tractor.<br />

• Work capacity: 0.8 ha/h (2 acres/h) depending on the vineyard configuration.<br />

• Oil flow rate:<br />

- 20 to 22 L/min (5.3 to 5.8 USG/min) with mechanical distributor<br />

- 35 L/min (6.6 USG/min) with electro-hydraulic distributor<br />

• Quickly and easily set up.<br />

The DE800 model trims both sides and the top of a single row.<br />

• Equipment positioned in front of the tractor.<br />

• The external cutting bar is equipped with a spring that allows for retraction<br />

in case of an obstacle.<br />

• Work capacity: 1.2 ha/h (3 acres/h) depending on the vineyard configuration.<br />

• Oil flow rate:<br />

- 20 to 22 L/min (5.3 to 5.8 USG/min) with mechanical distributor<br />

- 25 L/min (6.6 USG/min) with electro-hydraulic distributor<br />

• Quickly and easily set up.<br />

• Available with adjustable horizontal cutting bar<br />

to adapt to row height.<br />

A gathering attachment can be added to vine trimmers to straighten fallen<br />

branches and direct them to the blades.<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

9

Performance - Innovation - Reliability<br />

PRE-PRUNERS<br />

The PR3000 is a very robust machine for pruning vines in winter.<br />

• Positioned in front of the tractor.<br />

• Working capacity: 0.3 to 0.5 ha/h (0.7 to 1.2 acres/h) depending on the vineyard configuration.<br />

• Speed: 2.5 km/h (1.5 mph).<br />

• Oil flow rate:<br />

- 20 L/min (5.3 USG/min) with mechanical distributor<br />

- 25 L/min (6.6 USG/min) with electro-hydraulic distributor<br />

• Weight: Between 350 kg (772 lb) and 380 kg (838 lb) depending on the model.<br />

• Quickly and easily set up.<br />

• 4 hydraulic movements: vertical/inclination/transversal/disk opening.<br />

Optional:<br />

Sensors for automatic opening near the posts.<br />

NUMBER OF DISKS<br />

PRUNING HEIGHT<br />

5 32 cm / 1’1’’<br />

6 40 cm / 1’4’’<br />

7 47 cm / 1’7’’<br />

8 55 cm / 1’10’’<br />

9 62 cm / 2’0”<br />

10 70 cm / 2’4’’<br />

11 77 cm / 2’6’’<br />

LEAF REMOVERS<br />

The DFR430 leaf removal machine removes leaves from the vine, exposing the grapes<br />

to the sun and increasing air circulation so that they reach optimal ripeness more quickly.<br />

Mechanical leaf removal reduces work time by 70% compared to manual removal.<br />

• Positioned in front of the tractor.<br />

• Oil flow rate:<br />

- 25 L/min (6.6 USG/min) with mechanical distributor<br />

- 30 L/min (7.9 USG/min) with electro-hydraulic distributor<br />

• Working capacity: 0.8 ha/h or 2 acres/h depending on vineyard configuration.<br />

Optional:<br />

A cutting bar can be installed in front of the leaf remover to cut branches.<br />

Accessories for BMV equipment<br />

10<br />

Mandatory protection for<br />

tractors without a cab<br />

Joystick to control<br />

5 hydraulic circuits<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

Hydraulic tank, capacity of 40 L (10.5 USG) /<br />

80 L (21.1 USG) / 120 L (31.7 USG)

Sales - Installation - Maintenance - Repairs<br />

MECHANICAL THINNERS<br />

• There are many advantages to mechanical thinning:<br />

- Significant reduction in manpower required.<br />

- Reduced use of chemical products.<br />

- Positive impacts on the quality and size of fruit.<br />

• Fully equipped including whips, hydraulic hoses<br />

and electronic rotation control.<br />

• Positioned in front of the tractor.<br />

TECHNICAL INFORMATION<br />

WHIP LENGTH 60 cm (24”)<br />

MAXIMUM HEIGHT FROM GROUND 4 m (13’1”)<br />

WORKING CAPACITY<br />

OIL FLOW RATE (depends on model)<br />

1.5 ha/h to 2.5 ha/h (3.7 to 6.2 acres/h)<br />

TH500E and TH500A: 20 L/min (5.3 USG/min)<br />

TH500B: 36 to 40 L/min (9.5 to 10.6 USG/min)<br />

Electronic console with<br />

graphic display to control whip<br />

rotation speed independently<br />

from the tractor speed.<br />

TH500E<br />

WORKING HEIGHT MOTOR WEIGHT<br />

220 cm - 7’3" 1 215 kg - 474lb<br />

250 cm - 8’2" 1 220 kg - 485 lb<br />

280 cm - 9’2" 1 225 kg - 496 lb<br />

Economical model; lightweight<br />

frame with fixed height.<br />

310 cm - 10’2" 1 230 kg - 507 lb<br />

Hydraulic movements included: lateral and inclination<br />

TH500A<br />

WORKING HEIGHT MOTOR WEIGHT<br />

220 cm - 7’3” 1 220 kg - 485 lb<br />

250 cm - 8’2” 1 225 kg - 496 lb<br />

Robust model with vertical hydraulic<br />

movement to work at various heights.<br />

280 cm - 9’2” 1 230 kg - 507 lb<br />

310 cm - 10’2” 1 235 kg - 518 lb<br />

Hydraulic movements included: lateral, vertical and inclination<br />

B<br />

A<br />

TH500B<br />

WORKING HEIGHT<br />

MOTOR WEIGHT<br />

A<br />

B<br />

125 cm - 4’1” 95 cm - 3’1” 2 230 kg - 507 lb<br />

125 cm - 4’1” 125 cm - 4’1” 2 235 kg - 518 lb<br />

155 cm - 5’1” 125 cm - 4’1” 2 240 kg -529 lb<br />

Model with 2 independent sections<br />

(with different rotation speeds) to adjust thinning<br />

between the top and bottom of the tree. In certain<br />

instances it is preferable to thin the top of the tree<br />

more because the bottom may be subject to frost,<br />

and will therefore thin more naturally.<br />

155 cm - 5’1” 155 cm - 5’1” 2 245 kg - 540 lb<br />

Hydraulic movements included: lateral, vertical, and inclination<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

11

Performance - Innovation - Reliability<br />

SPREADERS<br />

ProduceTech offers a range of spreaders adapted for use<br />

in orchards and vineyards. They will allow you to quickly<br />

and evenly apply the product of your choice: manure,<br />

pressing residue, straw, soil, lime, etc.<br />

The F.V.S. TOP spreader is designed to spread<br />

product between rows at the base of the trees.<br />

MODEL VOLUME EMPTY WEIGHT WIDTH<br />

MINIMUM ROW<br />

WIDTH<br />

F.V.S. 25 TOP VIGNERON 2.5 m³ - 88 ft³ 1380 kg - 3042 lb 145 cm - 4’9” 180 cm - 5’11”<br />

F.V.S. 35 TOP VIGNERON 2.9 m³ - 102 ft³ 1500 kg - 3307 lb 145 cm - 4’9” 180 cm - 5’11”<br />

F.V.S. 40 TOP VIGNERON 3.3 m³ - 117 ft³ 1680 kg - 3704 lb 155 cm - 5’1” 300 cm - 9’10”<br />

F.V.S. 45 TOP VIGNERON 3.6 m³ - 127 ft³ 1750 kg - 3858 lb 155 cm - 5’1” 300 cm - 9’10”<br />

F.V.S. 25 TOP 3.0 m³ - 106 ft³ 1470 kg - 3241 lb 165 cm - 5’5” 210 cm - 6’11”<br />

F.V.S. 35 TOP 3.3 m³ - 117 ft³ 1550 kg - 3417 lb 165 cm - 5’5” 210 cm - 6’11”<br />

F.V.S. 40 TOP 4.5 m³ - 159 ft³ 1800 kg - 3968 lb 185 cm - 6’1” 300 cm - 9’10”<br />

F.V.S. 45 TOP 5.5 m³ - 194 ft³ 2000 kg - 4409 lb 185 cm - 6’1” 300 cm - 9’10”<br />

The A.F.O. spreader is designed to spread product in the<br />

middle of each row, without affecting the leaves on the trees.<br />

MODEL VOLUME EMPTY WEIGHT MINIMUM ROW WIDTH<br />

A.F.O. 10 1.5 m³ - 53 ft³ 1000 kg - 2204 lb 130 cm - 4’3’’<br />

A.F.O. 15 2.2 m³ - 78 ft³ 1160 kg - 2557 lb 170 cm - 5’7’’<br />

A.F.O. 25 3.3 m³ - 117 ft³ 1250 kg - 2756 lb 190 cm - 6’3’’<br />

A.F.O. 35 4.4 m³ - 155 ft³ 1350 kg - 2976 lb 230 cm - 7’7’’<br />

Various versions of this model are also available:<br />

- The A.F.O. LP model spreads only towards<br />

the bottom, only in the row.<br />

- The A.F.O. PL model allows product to be<br />

spread towards the bottom within the row<br />

as well as inter-row.<br />

A.F.O. LP<br />

A.F.O. PL<br />

12<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

TREE SHAKERS<br />

We offer a wide range of tree shakers to help you harvest fruit<br />

efficiently without damaging your trees.<br />

The VHM model is a mechanical shaker adapted for use in wide<br />

rows. This simple and efficient machine has rubber-covered<br />

clamp to avoid damaging the tree trunk.<br />

Technical specifications:<br />

• Trunk diameter must be between 5 and 40 cm (2-16”).<br />

• Minimum tractor power required: 30 HP.<br />

• Minimum row width: 3.8 m (12’6”).<br />

• Can shake up to 360 trees/hour.<br />

• PTO speed required: 540 RPM.<br />

LENGTH WIDTH HEIGHT WEIGHT<br />

1.12 m - 3’8’’ 3.69 m - 12’1’’ 0.74 m - 2’5’’ 450 kg - 992 lb<br />

The VHP model is a high-performance hydraulic shaker designed<br />

for narrow rows. Well suited for younger plantations and more<br />

fragile mature trees. It is completely controlled from the tractor cab.<br />

Technical specifications:<br />

• Trunk diameter must be between 5 cm and 40 cm (2”-16”).<br />

• Gripping of the tree trunk occurs from 0.3 m to 1.3 m<br />

(1’0” to 4’3”) from the ground.<br />

• Minimum tractor power required: 70 HP.<br />

• Two hydraulic motors.<br />

• Shaker width including tractor: 2.5 m (8’2”).<br />

• Can shake up to 400 trees/hour.<br />

LENGTH WIDTH HEIGHT<br />

WEIGHT WITHOUT<br />

REAR BALANCE<br />

WEIGHT WITH<br />

REAR BALANCE<br />

OIL TANK<br />

2.80 m - 9’2’’ 1.27 m - 4’2’’ 1.15 m - 3’9’’ 812 kg - 1790 lb 1190 kg - 2623 lb 140 L - 37 USG<br />

The Push Fruit 1201 is a fruit blower connected to the rear of the<br />

tractor (PTO) to blow fruit to the ground to facilitate collection or<br />

to tidy rows.<br />

LENGTH BLOWING WIDTH WEIGHT<br />

1280 kg<br />

1.5 m - 4’11’’ 1.7 m - 5’7’’<br />

2822 lb<br />

MIN. TRACTOR POWER<br />

REQUIRED<br />

70 HP<br />

Two versions available: left or right output.<br />

Blowing nozzle can be extended to increase range.<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

13

Performance - Innovation - Reliability<br />

FRUIT COLLECTORS<br />

We offer a range of Feucht-Obsttechnik fruit collecting machines to harvest drops. These<br />

German-made machines are equipped with a cleaning mechanism to separate leaves, grass<br />

and pebbles from the fruit. Differential suspension allows these machines to adapt to all types<br />

of terrain.<br />

MODEL: OB 80 OR OB 100 (A)*<br />

Width 1.29 m (4’3”) 1.75 m (5’9”)<br />

Length 3.21 m (10’6”) 4.2 m (13’9”)<br />

Height 1.41 m (4’8”) 1.25 m (4’1”)<br />

Weight ≈ 300 kg (661 lb) ≈ 500 kg (1102 lb)<br />

Motor Briggs & Stratton Vanguard 16 HP Briggs & Stratton V-twin 18 HP<br />

Speed 0 - 15 km/h (0 - 9.3 mph) 0 - 15 km/h (0 - 9.3 mph)<br />

Collecting capacity Up to 4 tonnes/h (12 bins/h) Up to 8 tonnes/h (24 bins/h)<br />

Hopper capacity 250 L - 66 USG (7 bushels) 700 L - 185 USG (20 bushels)<br />

Max. unloading height 2.45 m (8’) 2.55 m (8’4’’)<br />

Length of standard arm 1.53 m (5’) 1.73 m (5’8’’)<br />

Length of longer arm (optional) 2.16 m (7’1’’) 2.5 m (8’2’’)<br />

A. Maximum distance between arms<br />

(2 conventional arms)<br />

A. Maximum distance between arms<br />

(1 conventional arm + 1 longer arm)<br />

B. Maximum distance on right of machine<br />

(with conventional arm)<br />

B. Maximum distance on right of machine<br />

(with longer arm)<br />

2.5 m (8’2’’) 3.8 m (12’6’’)<br />

2.95 m (9’8’’) 4.25 m (13’11’’)<br />

1.17 m (3’10’’) 1.34 m (4’5’’)<br />

1.62 m (5’4’’) 1.79 m (5’10’’)<br />

Fuel consumption ≈ 4 L/h (1.0 USG/h) ≈ 5 L/h (1.3 USG/h)<br />

Optimal grass height when collecting fruit 15 - 25 cm (8” - 9.5”) 15 - 25 cm (8” - 9.5”)<br />

*Also available as diesel version (width 1.98 m / 6’6”)<br />

HOPPER FOR MECHANICAL UNLOADING TRAILER FOR 2 BINS TRAILER FOR 3-4 BINS<br />

14<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

The OB Future II fruit collecting machine is a high-performance option<br />

for large-scale orchards.<br />

Technical specifications:<br />

• 50 HP diesel motor<br />

• Can collect up to 20 tonnes/ha (440 bushels/acre)<br />

• Hopper capacity of 2900 liters (82 bushels)<br />

• Hopper can be raised up to 3 m (9’10”)<br />

• Can adapt to orchards with a lateral slope of 5%<br />

• Can climb slopes of up to 38% incline (without rotors)<br />

• Minimum row width: 3.5 m (11’6”)<br />

• Maximum speed: 16 km/h (10 mph)<br />

Length Width Height Weight Working width<br />

5.70 m<br />

18’8’’<br />

1.80 m<br />

5’11’’<br />

1.70 m<br />

5’7’’<br />

2600 kg<br />

5732 lb<br />

1.80 – 3.50 m<br />

5’11’’ – 11’6’’<br />

Use the FC fruit cleaning table in combination with a fruit collecting<br />

machine to remove bruised fruit or pebbles directly while working in the<br />

orchard. This cleaning table is easy to maneuver thanks to its trailertype<br />

construction. It is also equipped with lights for road transport.<br />

Technical specifications:<br />

• Hydraulic foot and conveyor orientation mechanism<br />

• Powered by 5.5 HP Honda gas motor<br />

• Maximum transport speed: 40 km/h (25 mph)<br />

• Number of workers required to operate the equipment: 2<br />

Length<br />

Width<br />

Working<br />

height<br />

Transport<br />

height<br />

Weight<br />

Hopper<br />

volume<br />

5.1 m<br />

16’9’’<br />

2.1 m<br />

6’7’’<br />

3 m<br />

9’10’’<br />

2.5 m<br />

8’2”<br />

990 kg<br />

2183 lb<br />

1600 L<br />

423 USG<br />

Also available in single FCS model without motor, connected to the tractor’s<br />

PTO (power takeoff).<br />

The Front Sweeper attachment is installed in front of the tractor to clear<br />

orchard rows, thus avoiding damage to fruit and ensuring the way is<br />

clear for pick your own.<br />

Sweeping width Weight Oil flow rate<br />

2.1 - 3 m<br />

6’7’’ - 9’10’’<br />

450 kg<br />

992 lb<br />

20 - 50 L/min<br />

5 -13 USG/min<br />

Min. tractor<br />

power required<br />

30 HP<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

15

PLATFORMS FOR HARVESTING AND PRUNING<br />

Performance - Innovation - Reliability<br />

TECNOFRUIT harvesting and pruning platforms from FRUMACO are among the most flexible available on the<br />

market. This equipment is more than just a platform for picking fruit; it is a true work center that will serve you all<br />

year round. Once the conveyors are removed from the machine (a simple process – just 3 bolts to remove, with<br />

lifting hoist eyelet in place), the platform can be used for pruning trees or for installing hail nets.<br />

Platform for installation<br />

and maintenance of nets<br />

13 LED lights for<br />

nighttime work<br />

6 adjustable lateral conveyors to<br />

carry fruit without damaging it<br />

Trailer with capacity for<br />

16 bins (3 full)<br />

Joystick or<br />

power-assisted steering<br />

16<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

Automatic container filling Central conveyor Container for<br />

second-quality fruit<br />

Automatic ultrasonic<br />

guidance eliminates<br />

need for a driver<br />

Drawbar to tow the platform by<br />

truck over long distances<br />

Pneumatic compressor with<br />

air tank for trimming equipment<br />

4-wheel drive<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

17

PLATFORMS FOR HARVESTING AND PRUNING<br />

Performance - Innovation - Reliability<br />

The Frumaco platform is<br />

available in two models to<br />

adapt to different row widths.<br />

MODEL: TECNOFRUIT CF 105 TECNOFRUIT CF 110<br />

BASE SPECIFICATIONS<br />

Row width Between 3 m and 4 m / 9’10’ and 13’1’’ Between 3.6 m and 4.5 m / 11’10’’ and 14’9’’<br />

Maximum tree height 3.6 m / 11’10’’ 3.8 m / 12’6’’<br />

Motor Kubota 3 cyl, diesel, 24.8 HP Lombardini 4 cyl, diesel, 33.3 HP<br />

Front wheels (diameter x width) ≈ 10’’ x 5’’ ≈ 10’’ x 5’’<br />

Rear wheels (diameter x width) ≈ 10’’ x 5’’ ≈ 12’’ x 6’’<br />

Auxiliary power 12V – 15A 12V – 15A<br />

Speed 0-8 km/h / 0-5 mph 0-18 km/h / 0-11 mph<br />

Dimensions (retracted) (W x L x H)<br />

Dimensions (deployed) (W x L x H)<br />

4.18 m x 1.8 m x 2.42 m<br />

3’9’’ x 5’11’’ x 7’11’’<br />

4.18 m x 3 m x 2.91 m<br />

13’9’’ x 9’8’’ x 9’7’’<br />

4.9 m x 2.07 m x 2.4 m<br />

16’1’’ x 6’9’’ x 7’10’’<br />

4.9 m x 3.47 x 2.87 m<br />

16’1’’ x 11’5’’ x 9’5’’<br />

Empty weight 2060 kg / 4542 lb 2355 kg / 5192 lb<br />

Lateral platforms<br />

2 rear platforms: 126 cm x 36 cm / 4’2’’ x 1’2’’<br />

2 front platforms: 80 cm x 36 cm / 2’7’’ x 1’2’’<br />

4 platforms: 138 cm x 40 cm / 4’6’’x 1’4’’<br />

Lateral picking belts 4 6<br />

Compressor Optional 650 liters/min - 23 cfm<br />

Turning radius 3.80 m / 12’6’’ 4.20 m / 13’9’’<br />

Options<br />

Lateral picking belts 2 additional belts Standard<br />

Lights and service brake kit No Yes<br />

4-wheel drive Yes Yes<br />

Automatic steering with ultrasound<br />

(only for 4x4 models)<br />

Yes<br />

Yes<br />

Container for second-quality fruit Yes Yes<br />

Compressor 481 liters/min - 17 cfm Standard<br />

4x4 wheels ≈ 10’’ x 6’’ ≈ 12’’ x 6’’<br />

Nighttime work lights Yes Yes<br />

TRAILER<br />

Dimensions (W x L x H) 6.3 m x 1.9 m x 2.5 m / 20’8’’ x 6’3’’ x 8’3’’<br />

Bin capacity<br />

16 (including 3 full)<br />

Number of hydraulic functions 5<br />

18<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

The Frumaco platform is a work center<br />

that will serve you all year long!<br />

Economy, productivity<br />

and quality improvement<br />

Trimming trees in winter<br />

Hail net maintenance<br />

and tree trellising<br />

• The platform allows you to improve harvesting<br />

efficiency and reduce labor costs. Picking ability<br />

per person is significantly increased, by about 77%,<br />

allowing 6 workers to accomplish the work of 11.<br />

Reducing labor costs by more than a third translates<br />

likewise to reduced staff management costs.<br />

• Allows you to quickly pick fruit that is ripening,<br />

providing for better conservation.<br />

• Fruit remains high quality and uniform thoughout the<br />

work shift, which is not always the case with manual<br />

labor. Your employees will be less tired, and therefore<br />

will perform better.<br />

• Rapid return on investment, usually within 3 years,<br />

but sometimes less than 2 years!<br />

Tecnofruit platforms are the most modern on the<br />

market, and more importantly, the most versatile<br />

– they are equipped with the latest innovations<br />

from over 30 years of experience and collaboration<br />

between two of the largest European fruit harvesting<br />

equipment manufacturers.<br />

Today, hundreds of platforms are used in more than 20<br />

countries around the world.<br />

Harvesting<br />

Contact us today to calculate<br />

the potential return on your investment.<br />

You might be surprised!<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

19

Performance - Innovation - Reliability<br />

CUSTOM-MADE HARVESTING AND TRANSPORT TRAILERS<br />

ProduceTech offers a full range of trailers adapted for your needs.<br />

All trailers are made to order according to your specifications.<br />

HARVESTING TRAILERS<br />

Trailers can hold from 3 to 6 bins, depending on the model. They<br />

can hold loads of 1500-5000 kg (3307-11023 lb). Trailer width is<br />

adapted according to the space between rows in the orchard or<br />

vineyard.<br />

The unloading ramps fold onto the bins to ensure secure<br />

transportation and stop the load from shifting.<br />

The unloading ramps are equipped with running boards to help<br />

pickers fill the bins quickly.<br />

Upon request, security features such as turn signals or pneumatic<br />

or hydraulic brakes can also be installed.<br />

Trailers include:<br />

- Rollers to facilitate bin loading and unloading.<br />

- A smart drawbar fixed to the thee-point connection for turning<br />

tight corners and easily lifting the trailer from the cab.<br />

The TEL model is a telescoping trailer which can pick up full bins<br />

from the ground. No need for a forklift in the orchard, pick up the<br />

bins directly with the trailer.<br />

It is the perfect option to integrate with a picking platform to<br />

optimize harvests.<br />

This model can also be equipped with running boards for pickers.<br />

TRANSPORT TRAILERS<br />

The PCR25 model is designed to transport harvesting bins from<br />

the field. It can transport between 3 and 5 bins, depending on the<br />

model. Its maximum width is 125 cm (4’1”), allowing it to circulate<br />

easily between rows.<br />

The PBC/3 model is designed to facilitate transport of plastic crates<br />

from the field. They can be loaded and unloaded from both sides.<br />

Transport is secure thanks to the aluminum frame on both sides and<br />

at the back. A double axle ensures stability during transport.<br />

Both the PCR25 and PBC/3 models can be equipped with<br />

a smart drawbar.<br />

20<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

STAINLESS STEEL TRAILERS<br />

Stainless steel ASI 304 trailers are designed to transport<br />

fruit destined for processing, particularly grapes from the<br />

vineyard. Stainless steel has the advantage of being easy<br />

to clean and is ideally suited for food products. These<br />

trailers can transport liquid content without spilling.<br />

The SCISSORS trailer is designed to transport grapes<br />

directly from the vineyard to the winery. Grapes can be<br />

harvested by machine or by hand. Lifting and opening of<br />

the trailer is done from the tractor cab. The trailer includes<br />

fixed drawbar and adjustable jack.<br />

MODEL CONTAINER LENGTH WIDTH HEIGHT MAXIMUM HEIGHT CAPACITY<br />

D/DF 13 300 cm / 10’11’’ 130 cm / 4’3’’ 130 cm / 4’3’’ 300 cm / 10’11’’ 1 700 kg / 3 748 lb<br />

D/DF 16 300 cm / 10’11’’ 160 cm / 5’3’’ 130 cm / 4’3’’ 300 cm / 10’11’’ 2 500 kg / 5 512 lb<br />

The AF RR stainless steel trailer is also designed to transport grapes or fruit from the field. Lifting and opening is done<br />

from the tractor cab. For transporting more liquid material, a PARA FLUIDS option can be added to avoid the contents<br />

spilling over the top of the trailer.<br />

MODEL LENGTH OF BED WIDTH HEIGHT CAPACITY<br />

AF RR INOX 35x18 350 cm / 11’6’’ 180 cm / 5’11’’ 170 cm / 5’7’’ 5.5 m³ / 194 ft³<br />

AF RR INOX 38x18 380 cm / 12’6’’ 180 cm / 5’11’’ 170 cm / 5’7’’ 6.5 m³ / 230 ft³<br />

AF RR INOX 38x18 TANDEM* 380 cm / 12’6’’ 180 cm / 5’11’’ 170 cm / 5’7’’ 7.5 m³ / 265 ft³<br />

AF RR INOX 40x20* 400 cm / 13’1’’ 200 cm / 6’7’’ 170 cm / 5’7’’ 8.5 m³ / 300 ft³<br />

AF RR INOX 45x20* 450 cm / 14’9’’ 200 cm / 6’7’’ 170 cm / 5’7’’ 10 m³ / 353 ft³<br />

AF RR INOX 50x20* 500 cm / 16’5’’ 200 cm / 6’7’’ 170 cm / 5’7’’ 12 m³ / 424 ft³<br />

AF RR INOX 50x23* 500 cm / 16’5’’ 230 cm / 7’7’’ 170 cm / 5’7’’ 13.5 m³ / 477 ft³<br />

*Double axle<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

21

Performance - Innovation - Reliability<br />

STRUCTURAL INSULATED PANELS<br />

Floors for freezers<br />

Modular floor sections insulated with urethane and<br />

covered with a galvanized steel plate or slip-resistant<br />

aluminum plate. Allows you to transform your existing<br />

warehouse into a freezer without having to install a<br />

ventilated concrete base.<br />

Insulated panels<br />

Norbec insulated panels are equally well suited to new construction as to the conversion of existing warehouse<br />

space into cold storage, controlled atmosphere rooms or freezers. They can be used as an exterior wall covering or<br />

as an interior partition. The painted galvanized steel finish means they are easy to maintain as well as being robust.<br />

Norbec’s range of products adapt to all types of application and are available in a variety of colors to meet your<br />

project’s requirements.<br />

Norlam: Insulated panels with polystyrene core (Styrofoam)<br />

Economical solution<br />

INSULATION FACTOR*<br />

THICKNESS<br />

WIDTH<br />

LENGTH<br />

R4/inch of thickness<br />

3, 4, 5, 6, 7 ½ and 10 inches<br />

45.5 inches<br />

6 to 49 feet<br />

* With type I polystyrene (standard)<br />

Norex: Insulated panels with polyisocyanurate core (polyurethane)<br />

NOREX-S<br />

Straight joint<br />

for interior<br />

partitions<br />

INSULATION FACTOR<br />

THICKNESS<br />

WIDTH<br />

LENGTH<br />

R7.35/inch of thickness<br />

2, 3, 4 or 5 inches<br />

44 inches<br />

8 to 48 feet<br />

High insulation factor<br />

NOREX-L<br />

Offset<br />

joint with<br />

concealed<br />

fasteners<br />

INSULATION FACTOR<br />

THICKNESS<br />

WIDTH<br />

LENGTH<br />

R7.35/inch of thickness<br />

2, 3, 4, 5 or 6 inches<br />

42.5 inches<br />

8 to 48 feet<br />

Noroc: Insulated panels with mineral wool core<br />

INSULATION FACTOR<br />

R4/inch of thickness<br />

4 inches (3/4 hour fire resistance)<br />

THICKNESS<br />

5 inches (1 hour fire resistance)<br />

6 inches (2 hour fire resistance)<br />

WIDTH<br />

42.5 inches<br />

LENGTH<br />

8 to 35 feet<br />

Ideal for firewalls<br />

22<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

DOORS FOR REFRIGERATORS AND FREEZERS<br />

Custom built to your specifications, Norbec refrigerator and freezer doors are efficient<br />

solutions for your needs. Combining efficiency and durability, Norbec doors are a must in<br />

the cold room and refrigerated warehouse industry.<br />

SLIDING DOORS<br />

ACCESS DOORS<br />

STAINLESS STEEL<br />

DOORS<br />

ACCESS RAMPS<br />

HEATED<br />

THRESHOLDS<br />

INTELLIGENT MANAGEMENT<br />

CONSOLES<br />

THERMAL WINDOWS<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

23

Performance - Innovation - Reliability<br />

HIGH-SPEED DOORS<br />

Automatic fast-opening doors allow you to optimize logistics in your factory,<br />

refrigerated warehouse or freezer.<br />

HDF model for warehouses<br />

Chillfast model for<br />

refrigerators and freezers<br />

DESCRIPTION<br />

SPECIFICATIONS HDF CHILLFAST<br />

High-performance fast-action roller door,<br />

without springs<br />

Insulated fast-action roller door, capable of withstanding<br />

temperatures between -30 ºC (-22ºF) and +40 ºC (104ºF)<br />

INTEGRATED WINDOW Yes No<br />

INSULATED MATERIAL No Yes<br />

OPENING MECHANISMS AVAILABLE<br />

Push button Pull cord Motion sensor Remote control<br />

24<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

GAS-TIGHT DOORS<br />

FEATURES AND ADVANTAGES<br />

Horizontal (left or right) or vertical configuration<br />

(with a counterweight on the left or right to make<br />

opening easier).<br />

Sturdy rubber joint design with 4 or 6 clamping<br />

handles for maximum seal.<br />

Stainless steel frame, steel plates coated with<br />

baked-on paint, inside door grouting (urethane<br />

40 kg/m 3 - 2.5 lb/ft 3 ) performed in-factory to avoid<br />

manufacturing voids.<br />

Color: Orange (other colors available upon request).<br />

Lockable entry with thermal insulated window.<br />

Fiberglass door frames to avoid thermal bridge.<br />

The chamber’s interior frame is covered with steel<br />

plates coated with baked-on paint.<br />

Lockable 1/2” door valve available for sampling<br />

purposes as well as a 2” lockable valve for nitrogen<br />

injection or pressure testing.<br />

95 mm (3.75”) thick for<br />

maximum insulation!<br />

Urethane injection<br />

(grouting) on site<br />

for framing<br />

Valve installation according to your needs<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

25

HIGH-PURITY NITROGEN GENERATORS<br />

Performance - Innovation - Reliability<br />

Nitrogen is an inexpensive inert gas frequently used to replace oxygen in packaging and<br />

processing where there are risks of oxidation damaging food or liquids (e.g., wine). In<br />

areas without oxygen (anaerobic environments), the growth of bacteria, fungi and microorganisms<br />

is minimized.<br />

Integrated oxygen<br />

purity analyzer<br />

Uses of high-purity nitrogen<br />

Wine industry:<br />

Become your own nitrogen supplier – replace your nitrogen cylinders with a high-purity<br />

nitrogen generator. In winemaking, nitrogen plays a critical role in controlling oxygen<br />

and carbon dioxide that can lead to undesirable effects on the final product.<br />

Nitrogen can be used for:<br />

• Protection against oxidation:<br />

- Protecting harvests and musts<br />

- Pressing, disgorging, transferring, barrel filling, blanketing, bottling<br />

- Physical treatments: filtering, tartaric stabilization (racking off), electrodialysis<br />

• Mixing: settling, flotation separation, pumping-over, blending, fining.<br />

• Stripping: deoxygenation, decarbonation.<br />

Food industry:<br />

Packaging under nitrogen allows food to retain its appearance, texture and nutritional value longer, while reducing the need for added<br />

preserving agents or chemical substances. It extends the shelf life of foods without preservatives or chemicals.<br />

Artwork treatment:<br />

To preserve works of art, it is recommended that they are kept in an oxygen-free environment in order to destroy any micro-organisms<br />

that may be living in or on canvas, fabric, paintings, tapestries, sculptures, etc.<br />

High-purity nitrogen generators can be used in other industries, such as the oil industry.<br />

Nitrogen is also used to fight fires by reducing oxygen content in the air.<br />

PURITY 99.0% PURITY 99.5% PURITY 99.9% GENERATOR ALONE COMPLETE SYSTEM<br />

MODEL<br />

OUTPUT<br />

(m 3 /h) cfm (m 3 /h) cfm (m 3 /h) cfm<br />

Width (in.)<br />

Depth (in.)<br />

Height (in.)<br />

Weight (lb)<br />

Width (in.)<br />

Depth (in.)<br />

Height (in.)<br />

Weight (lb)<br />

w/ air tank and<br />

w/o nitrogen<br />

tank<br />

Compressor<br />

force (hp)<br />

Power (kW)<br />

GENIUS 2<br />

GENIUS 4<br />

GENIUS 6<br />

GENIUS 8<br />

GENIUS 10<br />

GENIUS 12<br />

GENIUS 14<br />

GENIUS 16<br />

GENIUS 18<br />

GENIUS 20<br />

Nitrogen output 9.9 5.8 9.3 5.5 6.4 3.8<br />

Air output required 25.7 15.1 25.9 15.2 23.2 13.7<br />

Nitrogen output 19.8 11.7 18.5 10.9 12.9 7.6<br />

Air output required 51.4 30.3 51.8 30.5 46.4 27.3<br />

Nitrogen output 29.6 17.4 27.8 16.4 19.3 11.4<br />

Air output required 77.0 45.3 77.8 45.8 69.6 41.0<br />

Nitrogen output 39.5 23.2 37.0 21.8 25.8 15.2<br />

Air output required 102.7 60.4 103.7 61.0 92.8 54.6<br />

Nitrogen output 49.4 29.1 46.3 27.3 32.2 19.0<br />

Air output required 128.4 75.6 129.6 76.3 115.9 68.2<br />

Nitrogen output 59.3 34.9 55.5 32.7 38.6 22.7<br />

Air output required 154.1 90.7 155.5 91,5 139.1 81.9<br />

Nitrogen output 69.1 40.7 64.8 38,1 45.1 26.5<br />

Air output required 179.8 105.8 181.4 106,8 162.3 95.5<br />

Nitrogen output 79.0 46.5 74.1 43,6 51.5 30.3<br />

Air output required 205.4 120.9 207.3 122,0 185.5 109.2<br />

Nitrogen output 88.9 52.3 83.3 49,0 58.0 34.1<br />

Air output required 231.1 136.0 233.3 137.3 208.7 122.8<br />

Nitrogen output 98.8 58.2 92.6 54.5 64.4 37.9<br />

Air output required 256.8 151.1 259.2 152.6 231.9 136.5<br />

30 27 69 430<br />

1381 5 4<br />

79 63 79<br />

30 34 69 597 1707 10 7,5<br />

30 41 69 765<br />

2227 15 11<br />

79 79 79<br />

30 48 69 933 2451 20 15<br />

30 55 69 1100<br />

3038 20 15<br />

30 62 69 1268 89 106 87 3398 25 19<br />

30 69 69 1435 3609 30 22<br />

30 76 69 1603<br />

4244 40 30<br />

30 83 69 1770 89 126 91 4083 40 30<br />

30 91 69 1938 5461 50 37<br />

26<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

HUMIDIFICATION SYSTEMS<br />

To manage humidity in your warehouses, look no further than Merlin<br />

humidification systems. No matter the application, we have the right<br />

solution for you to control and manage humidity:<br />

- High pressure humidification<br />

- Air-water humidification<br />

- Ultrasonic humidification<br />

Fruits and vegetables are generally sold by weight; dehydration can<br />

lead to profit loss as well as decreased quality.<br />

Do not hesitate to contact us to discuss your project.<br />

LEAK TESTING EQUIPMENT<br />

To test the air-tightness of your equipment, we offer a leak detection kit<br />

including a rubber bulb and a package of 10 smoke tubes.<br />

DRA/RUBBERP<br />

DRA/SMOKETUBES<br />

Rubber bulb for smoke tubes<br />

Smoke tubes for leak testing (10 per package)<br />

GAS-TIGHT COATINGS<br />

This food-grade product is ideal for sealing fruit and vegetable storage rooms in which<br />

you wish to control certain gas levels (e.g. oxygen, CO 2 , etc.).<br />

The same product can also be used in controlled atmosphere rooms to more<br />

effectively maintain temperature and humidity.<br />

• White in color.<br />

• Adheres easily to urethane.<br />

• Washable.<br />

• Contains an anti-fungal agent to prevent mould.<br />

• Ideal for sealing modular panel joints by applying it in conjunction with fiberglass strips.<br />

• Apply with a brush or pressure washer.<br />

PDT/PDL<br />

PDT/CA-TIGHT<br />

PDT/FV-4<br />

PDT/FV-6<br />

5 L (1.32 USG)<br />

pail of metal primer<br />

20 kg tub (44 lb) of<br />

CA-TIGHT SEALANT<br />

Fiberglass strips<br />

(width 10 cm / 4 inches)<br />

Fiberglass strips<br />

(width 15 cm / 6 inches)<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

27

GRADING AND PACKAGING EQUIPMENT FOR PRODUCE<br />

Performance - Innovation - Reliability<br />

A comprehensive solution for quality-sorting<br />

and packaging fruits and vegetables<br />

Emptying bins<br />

with or without water<br />

to transfer your fruits and<br />

vegetables without damaging them<br />

Washing and cleaning<br />

to ensure clean fruits and vegetables<br />

(scrubbing, drying, etc.)<br />

Avoid losses by choosing<br />

an adaptive solution<br />

Ensure client satisfaction<br />

Sizing and highly efficient sorting<br />

in order to separate fruits and vegetables by<br />

size and color, while eliminating those with<br />

internal or external quality defects<br />

Get the best information<br />

and the best quality<br />

28<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

Pre-sorting<br />

to temporarily hold<br />

fruits and vegetables by category<br />

Increase operating flexibility<br />

Labeling: Print your PLUs<br />

directly on labels;<br />

simplify your operations<br />

by having just one type<br />

of label in stock. Print<br />

tracking numbers<br />

on your labels.<br />

Reduce hassles<br />

and costs<br />

Variable packaging lines<br />

equipped with high-performance<br />

conveyors ensure no damage to<br />

fruits and vegetables<br />

Automatic bagging with smart weighing system<br />

limits losses by putting only the required number of<br />

fruits and vegetables in each bag<br />

Meet your clients’<br />

every need<br />

Palletization<br />

allows for uniform and<br />

continuous box stacking<br />

Optimize costs by never exceeding<br />

the required weight for each package<br />

Reduce your labor costs<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

29

Performance - Innovation - Reliability<br />

PLASTIC BINS<br />

Decade Products plastic bins are designed to meet the highest standards. Their high-density polyethylene<br />

construction, compared to polypropylene, gives them integral strength in cold temperatures. Their ventilated<br />

design accelerates the cooling process of your fruits and vegetables to prolong their quality and freshness.<br />

Specifications MACX ACE MACX48 Custom<br />

Exterior dimensions 48” x 40” x 31” (122 cm x 102 cm x 79 cm) 48” x 48” x 28” (122 cm x 122 cm x 71 cm)<br />

Interior dimensions 45” x 37” x 26” (114 cm x 94 cm x 66 cm) 45” x 45” x 24” (114 cm x 114 cm x 61 cm)<br />

Weight 74 lb - 34 kg 93 lb - 42 kg<br />

Visit our website to see<br />

Capacity 1500 lb - 680 kg 1500 lb - 680 kg<br />

additional models.<br />

Stack height 10 10<br />

Nesting capability Yes No<br />

Wide range<br />

of colors available.<br />

Add your logo<br />

to your bins<br />

to prevent loss/theft.<br />

Add your product<br />

information in the<br />

specially-designed<br />

cardholder.<br />

Track your bins using<br />

integrated RFID tags.<br />

Nest your MACX ACE<br />

bins for optimal storage.<br />

***Select the configuration of the base of your bins according to your needs.<br />

30<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

Sales - Installation - Maintenance - Repairs<br />

BIN WASHERS<br />

Douglas BW-1000 bin washers quickly and efficiently clean<br />

plastic bins. Containers are loaded onto the door and placed<br />

into a special holding bracket that secures it in the machine.<br />

Loading can be done with a pallet jack or a forklift. With this<br />

high-efficiency washer, both the interior and exterior of the<br />

bin receive a thorough cleaning.<br />

Depending on the model, Douglas machines feature a<br />

re-circulating pre-wash tank, a re-circulating detergent<br />

wash tank, and a separate fresh water rinse section.<br />

Cycle times are fully adjustable, but a 1-2 minute pre-wash,<br />

1-2 minute wash and 30-second sanitizing rinse is typical.<br />

The washer can wash 12-18 bins an hour.<br />

The BW-1000C model is designed to wash and disinfect<br />

plastic or stainless steel containers as well as other bins<br />

of a similar weight and size. The BW-1000E model, for use<br />

without caustic detergents, is also available.<br />

LETS washers are high-performance, high-pressure<br />

hot water washing machines that deliver an efficient<br />

wash with low water consumption. Rinse water<br />

is re-circulated during the wash process, allowing for<br />

a total water consumption of 15 L/hour (4 USG/hour).<br />

The unique washing process provides a total cleaning<br />

for your containers.<br />

Optional:<br />

- Automatic loading and unloading mechanism to<br />

facilitate operations.<br />

- Inline dryer.<br />

This equipment is easy to maintain and can wash up<br />

to 100 bins an hour.<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com<br />

31

REUSEABLE PLASTIC CONTAINER (RPC) WASHERS<br />

Performance - Innovation - Fiabilité<br />

Douglas tunnel washers quickly and easily wash plastic and<br />

stainless steel containers of various sizes. Over 40 different<br />

types of washers are available to meet your specific needs.<br />

The ideal model for you will depend on the type of soil to be<br />

cleaned and the desired wash time. The machines are also<br />

adapted to your water and energy usage needs as well as<br />

the space available in your facility.<br />

Douglas washers can be custom designed to meet your<br />

precise requirements.<br />

LETS IMPACT<br />

Reliable and easy to maintain.<br />

LETS plastic container washers are compact and highly<br />

efficient, thanks to their large capacity pumps. They quickly<br />

remove stuck-on, dried-on fruit and vegetable residue.<br />

Washing is done by high-pressure jets affixed to rotating<br />

arms, allowing the machine to thoroughly clean both the<br />

inside and outside of the container. This model is 7 times<br />

more efficient than conventional systems.<br />

Wash temperature is adjustable from 40ºC (104ºF)<br />

to 65ºC (149ºF).<br />

The detergent dosing pump lets you control product<br />

concentration and improve wash performance. Water<br />

is filtered and re-circulated though the system to reduce<br />

water consumption.<br />

PRESTRESSED CONCRETE POSTS AND<br />

COMPLETE ANTI-HAIL SYSTEMS WITH NETS<br />

www.valentepali.com<br />

INNOVATION<br />

AND RELIABILITY<br />

Won’t twist or curve like wooden posts<br />

KONCRETO<br />

Contains carbon and<br />

twisted iron wires<br />

• Easy to install<br />

• High mechanical resistance and flexibility<br />

• Durability over time and in cold temperatures<br />

• Competitive pricing compared to conventional methods<br />

Different pile widths and lengths are available.<br />

Please contact us with your application so we can help you find the best technical solution.<br />

Large selection of<br />

anchors and brackets<br />

32<br />

450 994-4567 • info@producetech.com<br />

www.producetech.com

www.producetech.com<br />

CONVERSION TABLES<br />

Note: Some of the larger numbers have been rounded to facilitate calculations.<br />

For exact figures, please refer to the charts in our literature.<br />

Multiply your original unit (in green) by the number below to obtain the desired unit (in blue).<br />

LENGTH<br />

AREA<br />

WEIGHT<br />

PRESSURE<br />

Original unit Centimeter (cm) Meter (m) Kilometer (km) Inch (in) Foot (ft) Mile (mi)<br />

Centimeter (cm) 1 0.01 0.00001 0.3937 0.0328 0.0000062137<br />

Meter (m) 100 1 0,001 39.37 3.28 0.00062137<br />

Kilometer (km) 100 000 1 000 1 39 370 3 281 0.62137<br />

Inch (in) 2.54 0.0254 0.0000254 1 0.0833 0.0000157828<br />

Foot (ft) 30.48 0.3048 0.0003048 12 1 0.000189394<br />

Mile (mi) 160 934.4 1 609.344 1.609344 63 360 5 280 1<br />

Original unit<br />

Square meter<br />

(m 2 )<br />

Square kilometer<br />

(km 2 )<br />

Square foot<br />

(ft 2 )<br />

Acre<br />

(a)<br />

Hectare<br />

(ha)<br />

Square mile<br />

(mi 2 )<br />

Square meter (m 2 ) 1 0.000001 10.764 0.000247 0.0001 0.000000386<br />

Square kilometer<br />

(km 2 )<br />

1 000 000 1 10 763 910 247.1 100 0.386<br />

Square foot (ft 2 ) 0.0929 0.0000000929 1 0.00002296 0.00000929 0.00000003587<br />

Acre (a) 4 046.86 0.004047 43 560 1 0.4047 0.0015625<br />

Hectare (ha) 10 000 0.01 107 639 2.471 1 0.00386<br />

Square mile (mi 2 ) 2 589 988 2.59 27 878 400 640 259 1<br />

Original unit<br />

Gram<br />

(g)<br />

Kilogram<br />

(kg)<br />

Ounce<br />

(oz)<br />

Pound<br />

(lb)<br />

Metric tonne<br />

(t)<br />

Ton-short<br />

(US ton)<br />

Gram (g) 1 0.001 0.0353 0.002205 0.000001 0.0000011023<br />

Kilogram (kg) 1000 1 35.274 2.2046 0.001 0.0011023<br />

Ounce (oz) 28.3495 0.0283495 1 0.0625 0.0000283495 0.00003125<br />

Pound (lb) 453.59 0.4536 16 1 0.0004536 0.0005<br />

Metric tonne (t) 1 000 000 1 000 35 273.96 2 204.6 1 1.1023<br />

Ton-short<br />

(US ton)<br />

907 185 907.2 32 000 2 000 0.9072 1<br />

Original unit<br />

KiloPascal<br />

(kPa)<br />

Atmosphere<br />

(atm)<br />

Bar<br />

(bar)<br />

Inches of water<br />

(in H2O)<br />

Pounds per square<br />

inch (psi)<br />

KiloPascal (kPa) 1 0.00987 0.01 4.015 0.145<br />

Atmosphere (atm) 101.3 1 1.0133 406.8 14.7<br />

Bar (bar) 100 0.987 1 401.46 14.5<br />

Inches of water<br />

(in H2O)<br />

0.249 0.00246 0.00249 1 0.036<br />

Pounds per<br />

square inch (psi)<br />

6.895 0.068 0.0689 27.68 1<br />

TEMPERATURE<br />

ºC ºF ºC ºF<br />

-24 -11.2 8 46.4<br />

-22 -7.6 9 48.2<br />

-20 -4.0 10 50.0<br />

-18 -0.4 11 51.8<br />

-16 3.2 12 53.6<br />

-15 5.0 13 55.4<br />

-14 6.8 14 57.2<br />

-13 8.6 15 59.0<br />

-12 10.4 16 60.8<br />

-11 12.2 17 62.6<br />

-10 14.0 18 64.4<br />

-9 15.8 19 66.2<br />

-8 17.6 20 68.0<br />

-7 19.4 21 69.8<br />

-6 21.2 22 71.6<br />

-5 23.0 23 73.4<br />

-4 24.8 24 75.2<br />

-3 26.6 25 77.0<br />

-2 28.4 26 78.8<br />

-1 30.2 27 80.6<br />

0 32.0 28 82.4<br />

1 33.8 29 84.2<br />

2 35.6 30 86.0<br />