D5_GR4_FINAL_DOCUMENTATION_spreads

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

06. CAGE<br />

The cages are submerged to get them<br />

beneath the lize zone, and away from<br />

airborne predators and harsh weather<br />

conditions. An airtight air-bubble with<br />

artificial lighting inside provides a controllable,<br />

simulated water surface. This<br />

supports fish welfare. feeding and creates<br />

a natural habitat for the fish.<br />

016<br />

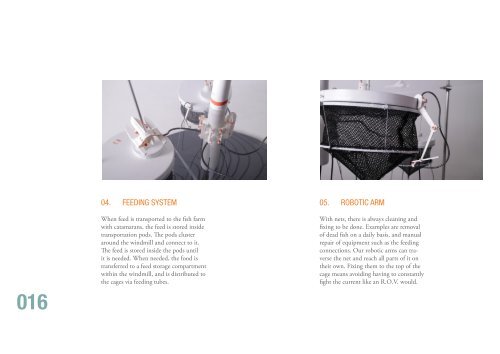

04. FEEDING SYSTEM<br />

When feed is transported to the fish farm<br />

with catamarans, the feed is stored inside<br />

transportation pods. The pods cluster<br />

around the windmill and connect to it.<br />

The feed is stored inside the pods until<br />

it is needed. When needed, the food is<br />

transferred to a feed storage compartment<br />

within the windmill, and is distributed to<br />

the cages via feeding tubes.<br />

05. ROBOTIC ARM<br />

With nets, there is always cleaning and<br />

fixing to be done. Examples are removal<br />

of dead fish on a daily basis, and manual<br />

repair of equipment such as the feeding<br />

connections. Our robotic arms can traverse<br />

the net and reach all parts of it on<br />

their own. Fixing them to the top of the<br />

cage means avoiding having to constantly<br />

fight the current like an R.O.V. would.<br />

We spent quite some time looking at<br />

different cage solutions and decided not<br />

to focus on the netting or cage operations<br />

themselves, but rather to propose a<br />

solution that opens many opportunities<br />

and serves the system as a whole.<br />

1 million fish per cage<br />

5% fish to 95% water<br />

Diameter: 72 metres. Height: 30 metres<br />

Top of cage: 20 metres below the surface<br />

017