PRESENTATION

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

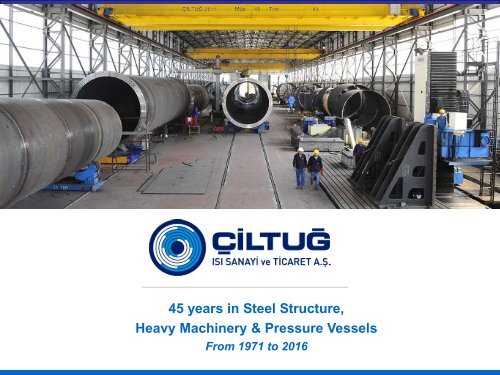

45 years in Steel Structure,<br />

Heavy Machinery & Pressure Vessels<br />

From 1971 to 2016

General Overview<br />

History:<br />

Gaziantep / TURKEY<br />

COLLECTIVE COMPANY<br />

Pressurized Vessels<br />

c<br />

JOINT STOCK COMPANY<br />

Pressurized Vessels&Steel Constructions<br />

c<br />

GROUP COMPANY<br />

Hydromechanical&Electromechanical Works For HEPP,<br />

Heavy Machinery,<br />

Wind Towers Production since-2012<br />

1971<br />

1976<br />

1980<br />

CILTUG<br />

Co.<br />

TEKTUG<br />

Co.<br />

BAYTUG<br />

Co.<br />

TUGCAN<br />

OTEL Co.<br />

TURNA<br />

Co.<br />

ASTUG<br />

Co.<br />

Production:15.000ton<br />

Total:169 MW<br />

Total 186 Room

COMPANIES OF GROUP<br />

CILTUG Heat Industry and Trade Co.<br />

• Design, Fabrication, Erection and Commissioning of Hydro-Mechanical Equipment for Hydro Power Plants and Irrigation Projects.<br />

• Fabrication and Installation of Turbine Electro-Mechanical Accessories.<br />

• Erection and Installation of Turbine-Generator Groups for Hydropower Plants.<br />

• Fabrication, Shipment and Erection works for Wind Towers and Turbine Frames.<br />

• Turn-key projects including Civil and Contracting Works for Hydropower Plants.<br />

• Heavy Machineries of parts having dimension up to (w x L x h) 12,500mm x 12,500mm x 6,000mm and 250,000kg<br />

• Piping with diameter from 600 mm to 10,000 mm and thickness from 5 mm to 110 mm, (Carbon and Stainless Steel)<br />

Hydro-Mechanical<br />

Equipment<br />

Turbine<br />

Electro-Mechanical<br />

Equipment<br />

Turbine-Generator<br />

Groups for<br />

Hydropower Plants<br />

Wind Towers<br />

and<br />

Turbine Frames<br />

Civil and Contracting<br />

Works for<br />

Hydropower Plants

TEKTUG Electricity Generation Co.<br />

Works on energy production and sales<br />

KARGILIK HEPP / TURKEY<br />

(2 x 12 MW)<br />

KALEALTI HEPP/TURKEY<br />

(15 MW)<br />

KEBAN HEPP / TURKEY<br />

(5.5 MW)<br />

ERKENEK HEPP/TURKEY<br />

(13 MW)<br />

ANDIRIN HEPP / TURKEY<br />

(1 x 42 MW)<br />

SIRIMTAS HEPP / TURKEY<br />

(1 x 28 MW)<br />

KALEALTI-2 HEPP / TURKEY<br />

(1 x 14,24 MW)<br />

SİNCİK WEPP / TURKEY<br />

(11 x 2,5 MW)<br />

TOTAL<br />

Installed Power<br />

169 MW<br />

Future Investments<br />

• YELLIBEL WIND POWER PLANT / TURKEY…………….. 50 MW<br />

• CAGLAYAN HYDRO POWER PLANT / TURKEY………… 10 MW<br />

• ANDIRIN SOLAR POWER PLANT / TURKEY…………….. 5 MW

Organization Plan<br />

Çiltuğ A.Ş. Organization Chart<br />

Chairman of the Board<br />

(Yönetim Kurulu Başkanı)<br />

İbrahim TUĞSUZ<br />

General Manager<br />

(Genel Müdür)<br />

Zeki UĞUR<br />

Accounting<br />

Manager<br />

(Muhasebe<br />

Müdürü)<br />

Mehmet<br />

YILDIRIM<br />

External<br />

Marketing and<br />

R&D<br />

(Dış Pazarlama<br />

ve AR-GE)<br />

Tunç UĞUR<br />

Project Design<br />

Department<br />

(Proje-Dizayn<br />

Departmanı)<br />

Tamer UÇAR<br />

Contracting<br />

Manager<br />

(Teklif ve<br />

Taah.Müd.)<br />

Şevket<br />

ALACACI<br />

Contracting<br />

Department<br />

(SözleşmelerDept.)<br />

Olcay KAVALA<br />

R. Fatih KURT<br />

Muhittin MİŞE<br />

Purchasing<br />

Department<br />

(Satınalma Dept)<br />

Mehmet<br />

ŞAHİN<br />

Budget and<br />

Planning<br />

Manager<br />

(Bütçe ve<br />

Planlama Müd.)<br />

M.Can TUĞSUZ<br />

Factory-1 Manager<br />

(Fabrika-1 Müdürü)<br />

Levent AYDIN<br />

Manufacturing<br />

Engineer<br />

(İmalat Mühendisi)<br />

Faik Özer UÇAR<br />

Arif Can TEKE<br />

Foreman<br />

(Formen)<br />

Mehmet PALA<br />

OsmanYAĞCI<br />

Murat CİN<br />

Tahir YILAN<br />

Workers<br />

(İşçiler)<br />

Administrative Works<br />

and Management<br />

Systems Manager<br />

(İdari İşler ve Yönetim<br />

Sistemleri Müdürlüğü)<br />

Burçin ÖNAY<br />

Veysel KILINÇ<br />

Finance and<br />

Administrative<br />

Works Responsible<br />

(Finans ve<br />

İdari İşler Amiri)<br />

M.Hüsnü KOZAN<br />

Warehouse and Pay-Roll<br />

(Ambar ve Puantaj İşleri)<br />

Turgut TEKKANAT<br />

Mehmet BAŞAR<br />

EHS<br />

(İSG-İs Sağlığı<br />

ve Güvenliği)<br />

M.Ataman<br />

GÜRSEL<br />

Factory-2<br />

Manager<br />

(Fabrika-2 Müdürü)<br />

…………………<br />

Manufacturing<br />

Engineer<br />

(İmalat Mühendisi)<br />

Erhan Y.ALİOĞLU<br />

Musa E.DOĞANGÜL<br />

Süleyman ÖZKAYA<br />

Foreman<br />

(Formen)<br />

İbrahim ASLAN<br />

M.Sait FIRAT<br />

Emin<br />

B.OCAKOĞLU<br />

Workers<br />

(İşçiler)<br />

QA/QC Manager<br />

(Quality Assurance<br />

and Control)<br />

(Kalite Güvence ve<br />

Kontrol Müdürü)<br />

Uğur ÇALIŞIR<br />

Quality Assurance<br />

&Control Chief<br />

(Kalite Güvence ve<br />

Kontrol Şefi)<br />

Recep GÜNDÜZ<br />

Mustafa HİNTOĞLU<br />

Enes GÜN<br />

Inspector<br />

(İnspektör)<br />

Adem Almas<br />

Adil BALCI<br />

Yunus ALTINTAŞ<br />

Halil İbrahim BARAZİ

Workshop Location<br />

• Total Area 50.000 m 2 .<br />

• Total Closed Area 16.000 m 2 .<br />

• Distance to Mersin Sea Port 305 km<br />

• Distance to Iskenderun Sea Port 215 km<br />

• Distance to Highway 5 km<br />

• Distance to Railway 5 km

Human Sources and Capabilities<br />

FACTORY 1 FACTORY 2<br />

Total<br />

Employees<br />

267<br />

• Engineers 20<br />

• Technicians 8<br />

• Workers 227<br />

• Finance & Account 12<br />

• 4 International Welding Engineer<br />

• 3 NDT Level II acc. to EN ISO 9712 and SNT-TC 1a<br />

• 100 Welder Certification acc. to EN ISO 9606 and<br />

ASME Sec.IX

Management & Process Quality Certification<br />

ISO 9001:2008<br />

Quality Management Systems<br />

by Bureau Veritas<br />

OHSAS 18001:2007<br />

Occupational Health and Safety<br />

Management System<br />

by Bureau Veritas<br />

ISO 14001:2004<br />

Environmental Management System<br />

by Bureau Veritas

Management & Process Quality Certification<br />

EN ISO 3834-2<br />

Quality Requirements of Fusion Welding<br />

of Metalic Materials by Bureau Veritas<br />

EN 1090-1:2009+A1:2011<br />

Load bearing steel components with corrosion protection and structural<br />

design up to EXC 4 acc. EN 1090-2 by TUV Austria

Management & Process Quality Certification<br />

ASME U STAMP<br />

Manufacture of pressure vessels at the above location<br />

and field sites controlled by the above location.<br />

ASME S STAMP<br />

Manufacture and assembly of power boilers at the above<br />

location and field sites controlled by the above location.

Domestic Manufacturing Status Certificate

Employee Qualification<br />

Welder Engineer Certificate<br />

Uğur ÇALIŞIR<br />

Welder Engineer Certificate<br />

Recep GÜNDÜZ

Employee Qualification<br />

NDT Qualification Certificate<br />

RT, PT, MT Level II<br />

Recep GÜNDÜZ<br />

NDE Qualification Certificate<br />

UT, MT, PT Level II<br />

Halil İbrahim BARAZİ

Employee Qualification<br />

NDE Qualification Certificate<br />

LPT Level II<br />

Adil BALCI<br />

Welder Certificate

PRODUCT PORTFOLIO<br />

Fabrication and Erection of:<br />

Penstocks / Pipe Works<br />

Trifurcation Pipes<br />

Atatürk DAM and HEPP / South East Part of TURKEY<br />

26,600 Tons. Penstocks Ø5.5-8mt (8 x 300 MW)<br />

Batman DAM and HEPP / South Eas Partt of TURKEY<br />

700 Tons. Trifurcation Ø9,5 / 5,5Mt. (3 x 63 MW)

Product Portfolio<br />

>> Fabrication and Erection of:<br />

Bifurcation Pipes<br />

Expansion Joints<br />

Akköy II HEPP / North part of TURKEY<br />

Material: S690QL- Th:52-80mm (2 x 116 MW)<br />

Karakaya DAM and HEPP / South of TURKEY<br />

Diameter: 6000mm (6 x 300 MW)

Product Portfolio<br />

>> Fabrication and Erection of:<br />

Transition Part- (Round to Rectangular)<br />

Penstock / Pipe Works<br />

Atatürk DAM and HEPP / TURKEY<br />

(8 x 300 MW)<br />

Batman DAM and HEPP / TURKEY<br />

Diameter: 9,500mm (3 x 63 MW)

Product Portfolio<br />

>> Fabrication and Erection of:<br />

Radial Gates<br />

Stoplog Gates & Lifting Beam<br />

Boyabat HEPP / TURKEY<br />

(3 x 170 MW)<br />

Libya Al-Khalij Power Plant Project / LIBYA<br />

Contractors: GAMA-BECHTEL

Product Portfolio<br />

>> Fabrication and Erection of:<br />

Trashracks<br />

Self Regulating Radial Gates<br />

Kalealtı II HEPP / TURKEY<br />

(14,24 MW)<br />

Şanlıurfa Plain Irrigation Project / TURKEY

Product Portfolio<br />

>> Fabrication and Erection of:<br />

Water Intake Gates<br />

Howell Bungel Valve<br />

Raqqa El-Bab &Tadeff Project / IRAQ<br />

Aksu HEPP / TURKEY<br />

Contractor: KALYON CONS.

Product Portfolio<br />

>> Fabrication and Erection of:<br />

Jet Flow Gates<br />

Sliding Gates<br />

Boyabat HEPP / TURKEY (3 x 170 MW)<br />

Contractor: DOGUS Cons.<br />

Boyabat HEPP / TURKEY (3 x 170 MW)<br />

Contractor: DOGUS Cons.

Product Portfolio<br />

>> Fabrication and Erection of:<br />

Jet Flow Gates<br />

Jet Flow Gates<br />

Artvin HEPP / TURKEY (2 x 166 MW)<br />

Contractor: ALSTOM Hydro.<br />

Artvin HEPP / TURKEY (2 x 166 MW)<br />

Contractor: ALSTOM Hydro.

Product Portfolio<br />

>> Fabrication and Erection of:<br />

LPG Tanks<br />

Horizontal Seperation Tank<br />

Nasiriyah & Dewaniyah-Project / IRAQ<br />

Contractor: Iraq Ministry of Oil.<br />

TPAO Adıyaman & Batman / TURKEY<br />

Contractor: Turkey Petroleums Co.

Product Portfolio<br />

Fabrication of Electro-Mechanical Equipment<br />

(Turbine Auxiliary Parts);<br />

Inlet Parts for Kaplan Turbine<br />

Turbine Inlet Pipes<br />

Ceyhan (Oskan & Berkman) HEPP / TURKEY<br />

Contractor: ALSTOM Hydro.<br />

Akköy HEPP / TURKEY (3 x 34,5 MW)<br />

Contractor: VOITH Hydro.

Product Portfolio<br />

>> Fabrication of Electro-Mechanical Equipment (Turbine Auxiliary Parts);<br />

Draft Tubes<br />

Turbine Housing<br />

Hamzalı HEPP / TURKEY<br />

Contractor: VOITH Hydro<br />

Andırın HEPP / TURKEY (42 MW)<br />

Contractor: TEKTUG Co.

Product Portfolio<br />

>> Fabrication of Electro-Mechanical Equipment (Turbine Auxiliary Parts);<br />

Distributer / Collector Pipes<br />

Draft Tube Elbows<br />

Akköy-II Project / TURKEY<br />

(Pressure Test- 230 Bar / 2 x 116 MW)-Voith Hydro<br />

Yedigöze HEPP / TURKEY (2x158MW)<br />

Contractor: ALSTOM Hydro.

Product Portfolio<br />

>> Fabrication of Electro-Mechanical Equipment (Turbine Auxiliary Parts);<br />

Spiral Case & Stay Ring<br />

Spiral Case & Stay Ring<br />

Yedigöze HEPP / TURKEY<br />

(Total Weight-150 TON / 245 MW)<br />

Yedigöze HEPP<br />

(Total Weight-150 TON / 245 MW)

Product Portfolio<br />

Erection & Installation of Electro-Mechanical<br />

Equipment (Turbine & Generators Parts);<br />

Darıca HEPP / TURKEY (2 x 100 MW)<br />

Contractor: VOITH HYDRO<br />

Sır DAM and HEPP / TURKEY<br />

Contractor: TOSHIBA Co.

REFERENCE PROJECTS<br />

Atatürk DAM and HEPP (8 x 300 MW)<br />

Client: General Directorate of State Hydraulic<br />

Works (DSİ) of Turkey<br />

Location: Şanlıurfa, Turkey<br />

Contractor: Noell GmbH / Germany, Sulzer<br />

Escher Wyss Ltd. & Asea Brown Boveri Co.<br />

/ Switzerland<br />

Sub-Contractor: Noell GmbH and Ciltug Joint<br />

Venture<br />

Scope: Fabrication, blasting, painting,<br />

erection and testing of Penstocks, supports and<br />

expansion joints.<br />

Project Weight: 26,600 tonnes<br />

Total Painting Area: 250,000 m2<br />

Year: 1994<br />

Project Weight.………………….. 26,600 tonnes<br />

Diameter of Pipes………………... 8,000 mm<br />

Material……………………………. St 52-3

Reference Projects<br />

Karakaya DAM and HEPP (6 x 300 MW)<br />

Client: General Directorate of State Hydraulic<br />

Works (DSİ) of Turkey<br />

Location: Diyarbakır, Turkey<br />

Contractor: Italstrade-Recchi SPA/ITALY<br />

Sub-Contractor: Noell GmbH and Çiltuğ Joint<br />

Venture<br />

Scope: Fabrication, sandblasting, painting and<br />

erection of all permanent hydro-mechanical<br />

equipment such of Penstocks.<br />

Penstocks: Ø6m L:80mx6 Lines, 5,500 Tons<br />

Spillway Radial Gates: 14mx10m, 1,500 Tons<br />

Water Intake Equipment: 2,700 Tons<br />

Bottom outlet tunnel steel lining and gates: 3,250 Tons<br />

Draft tube gates: 650 Tons<br />

Power house machine hall cranes and other cranes<br />

erections : 1,900 Tons<br />

Project Weight: 15,500 tons<br />

Year: 1989<br />

Project Weight.………………….. 15,500 tonnes<br />

Diameter of Pipes………………... 6,000 mm<br />

Material……………………………. St 52-3

Reference Projects<br />

Batman DAM and HEPP (3 x 63 MW)<br />

Client: General Directorate of State Hydraulic<br />

Works (DSİ) of Turkey<br />

Location: Diyarbakır, Turkey<br />

Contractor: Onar-Gunsayıl İnşaat /Turkey<br />

Scope: Fabrication and erection of all hydromechanical<br />

equipment, Intake Gates, Trashracks,<br />

Penstocks, Tri-Furcation and bifurcation branch<br />

pipes, gantry cranes, slide and conical valves.<br />

Steel Lining and Penstocks : 3,500 tons<br />

Radial gates : 6 no’s, 1,600 tons<br />

Trashracks, stoplogs service gates and other<br />

equipment : 1,900 tons.<br />

Project Weight: 7,000 tons<br />

Year: 2000<br />

Project Weight.………………... 7,000 tonnes<br />

Diameter of Pipes……………... 5,500 & 9,500 mm<br />

Material…………………………. St 52-3

Reference Projects<br />

Jiroft DAM and HEPP (2 x 50 MW)<br />

Client: Iran Ministry of Energy / IRAN<br />

Location: Iran<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope:Sandblasting, painting, erection and<br />

commissioning of all permanent hydro-mechanical<br />

equipment. 2 set of spillway Radial gates in dim. of<br />

12x8m. 2 set of hydraulic operated radial gate in dim. of<br />

7.8x6.2m. Fixed wheel gates in dim. of 7.2x11m. 2 set of<br />

hydraulic operated sliding gates in dim. of 1.2x1.2m. 2 set<br />

of bottom outlet Radial gates with hydraulic operated in<br />

dim. of 1.2x1.2m. 4 set of draft tube gates in dim. of<br />

2.4x1.8m. 1 set of hydraulic operated butterfly valve in<br />

dim. of Ø2600mm. Trashracks in dim. of 5x15m. Stoplog<br />

gates in dim. of 4.8x5.2m. Irrigation service gates with<br />

hydraulic operated in dim. of 4.8x5.2m. Penstocks in dim.<br />

of Ø2600, L=290m. Bifurcation branch pipe in dim. of<br />

Ø2600/2xØ1100) and all electrical control systems of<br />

hydro-mech. Equip.<br />

Project Weight: 2,200 tons<br />

Year: 1992

Reference Projects<br />

Boyabat DAM and HEPP (3x170 MW)<br />

Client: Doğuş İnşaat ve Tic. A.Ş.<br />

Location: Sinop, Turkey<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication and erection of<br />

Hydromechanical Equipments.<br />

Project Weight: 5000 tons<br />

Year: 2011<br />

Project Weight.………………….. 5,000 tonnes<br />

Diameter of Pipes………………. 6,000&5,600 mm<br />

Material…………………………… 490 FG

Reference Projects<br />

Boyabat DAM and HEPP (3x170 MW)<br />

Client: Doğuş İnşaat ve Tic. A.Ş.<br />

Location: Sinop, Turkey<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication and erection of<br />

Hydromechanical Equipments.<br />

Project Weight: 5000 tons<br />

Year: 2011

Reference Projects<br />

ARTVİN HEPP (2x166 MW)<br />

Client: Alstom Power ve Ulaşım A.Ş. / Turkey.<br />

Location: Artvin, Turkey<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication and erection of Bottom Outlet<br />

and Intake Trashracks, Intake Bellmouth, Bottom<br />

Outlet Penstocks, Bottom Outlet Sliding Gate and<br />

Jet Flow Gate, Intake Bulkhead Gate and<br />

Embedded Parts, Bottom Outlet Steel Liner.<br />

Project Weight: 1,574 tons<br />

Year: 2015

Reference Projects<br />

Akköy II HEPP (2 x 116 MW)<br />

Client: Kolin İnşaat Turizm Sanayi ve Tic. A.Ş.<br />

Location: Giresun, Turkey<br />

Contactor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication and erection of<br />

penstocks/pipes<br />

Project Weight: 9500 tons<br />

Year: 2011<br />

Project Weight.………….. 9,500 tonnes<br />

Diameter of Pipes………. 2,700 & 1,800 mm<br />

Material…………………… S690 QL & S550 ML

Reference Projects<br />

Yedigöze HEPP (2 x 158,5 MW)<br />

Client: Alstom Power Hidroelektrik A.Ş.<br />

Location: Adana, Turkey<br />

Scope: 2 Units Draft Tube, Spiral Case, Stay<br />

Ring, Spiral Case Sleeves and Pit Line fabrication<br />

Project Weight:<br />

433,4 tons<br />

Year:<br />

2009

Reference Projects<br />

Hacınınoğlu HEPP (130 MW)<br />

Client: Andritz Hydro Ltd. Şti., Ankara, Turkey<br />

Location: Kahramanmaraş, Turkey<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication of 2 units Draft Tube, Spiral<br />

Case & Stay Ring and Pit Liner.<br />

Project Weight: 126.61 tons<br />

Year: 2009

Reference Projects<br />

Offshore Sub-Marine Pipeline Project/North Cyprus<br />

Turkish Republic<br />

Client: Sigur-Ros Kalyon Joint Venture/TURKEY<br />

Location: North Cyprus Turkey Republic<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: 132 pcs of Elbow (“Y” Piece)<br />

Manufacturing and Transport for North Cyprus<br />

Turkish Rebuplic Offshore (Sub-Marine) Fresh<br />

Water Supply Project<br />

Project Weight: 1,245 tons<br />

Year: 2015

Reference Projects<br />

Al-Khalij Project / Libya<br />

Client: Gama Endüstri A.Ş. / TURKEY<br />

Location: Libya<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication of Stoplogs Gate, Stoplog<br />

Embedded Structures, Intake Header and test<br />

cover, Manhole Gates and embedded structure<br />

Gates Dimension :<br />

- 2 set - 5.1 x 11.4 mt<br />

- 2 set - 4.9 x 11.4 mt<br />

- 1 set - 5.84 x 11.4 mt<br />

- 1 set - 3.9 x 11.4 mt<br />

- 1 set - 2,34 x 11.4 mt<br />

Project Weight: 400 tons<br />

Year: 2011

Reference Projects<br />

Rajma Ghot Es-Sultan and Benghazi Water Irrigation<br />

Project / Libya<br />

Client: Kolin İnş. Tur. San ve Tic. A.Ş. / TURKEY<br />

Location: Libya<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication and erection of Penstocks.<br />

Project Weight: 608 tons<br />

Year: 2011

Reference Projects<br />

TG01 TYPE Transportation Frame / Areva<br />

Client: Areva Wind Gmbh / GEMRANY<br />

Location: Germany<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: 8 Sets Transportation Frame Fabrication.<br />

Project Weight: 196 tons<br />

Year: 2013

Reference Projects<br />

SENDJE ROTOR SPIDER/RUSSIA<br />

Client: Alstom Hydro France S.A./ FRANCE<br />

Location: Sendje Project / Russia<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: 4 Units Rotor Spider fabrication.<br />

Project Weight: 61.3 tons<br />

Year: 2016

Reference Projects<br />

HARJAVALTA UPPER&LOWER BRACKET/FINLAND<br />

Client: Alstom Hydro Hydro/ SPAIN<br />

Location: Harjavalta Project / Finland<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: 1 Unit Upper&Lower Bracket fabrication.<br />

Project Weight: 32.8 tons<br />

Year: 2016

Reference Projects<br />

Nam Theun 2 Project / Cambodia<br />

Client: GE General Energy / Norway<br />

Location: Cambodia<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication and delivery exworks for ; 8<br />

numbers of Francis Draft Tube Stoplogs (6.35x9<br />

mt) including lifting beams, dogging beams and<br />

spares. 4 numbers of pelton draft tube stoplogs<br />

including lifting beams, dogging beams and<br />

spares. 1 set drainage and dewatering system.<br />

Project Weight: 87 tons<br />

Year: 2007

Reference Projects<br />

Tartous Project / Syria<br />

Client: Tartous Cement&Building Material Co.<br />

Location: Tartous, SYRIA<br />

Contractor: Çiltuğ Heat Industry and Trade Co.<br />

Scope: Fabrication of 4 units of steel cylindrical<br />

links.<br />

Project Weight: 227 tons<br />

Year: 2008

REFERENCE CUSTOMERS

Thank you<br />

for your Attention