VISAX MV Metal-clad Switchgear - Lindenberg-Anlagen GmbH

VISAX MV Metal-clad Switchgear - Lindenberg-Anlagen GmbH

VISAX MV Metal-clad Switchgear - Lindenberg-Anlagen GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

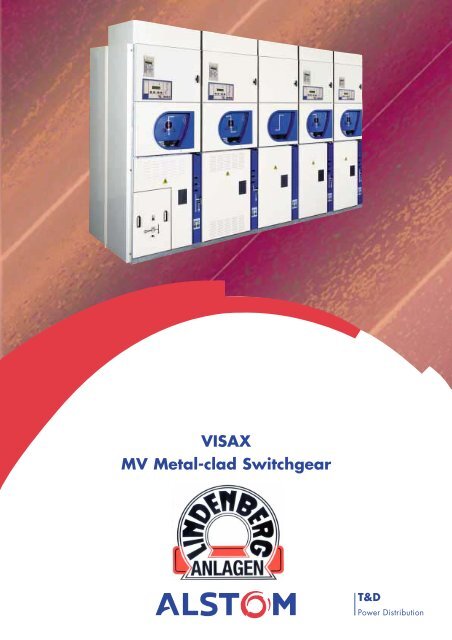

<strong>VISAX</strong><br />

<strong>MV</strong> <strong>Metal</strong>-<strong>clad</strong> <strong>Switchgear</strong><br />

T&D<br />

Power Distribution

<strong>VISAX</strong>: A New Generation of Medium Voltage <strong>Switchgear</strong><br />

Simple architecture<br />

The innovative design of <strong>VISAX</strong> is<br />

based on new metal-<strong>clad</strong><br />

switchgear architecture (fig.1)<br />

where all the functional elements<br />

are mounted in a direct line<br />

between the busbar and the cable<br />

terminals.<br />

Fig. 1 - Direct power line.<br />

<strong>VISAX</strong> combines the advantages of<br />

the most advanced withdrawable<br />

switchgear and the benefits<br />

associated with simplified<br />

architecture: reliability, functional<br />

safety, security.<br />

Fig. 2 - Lateral cross-section of<br />

conventional switchgear.<br />

2<br />

Original architecture<br />

The circuit breaker engages directly<br />

with the busbar, the number of<br />

connections and isolating elements<br />

is significantly reduced.<br />

Low voltage compartment<br />

Busbar compartment<br />

Circuit breaker compartment<br />

Cable compartment<br />

Compartment for the extraction of hot gases<br />

1<br />

2<br />

3 4<br />

Fig. 3 - Lateral cross-section<br />

of <strong>VISAX</strong> switchgear.<br />

1 - Busbar secured to the connection spouts<br />

2 - BLV self-isolating circuit breaker<br />

3 - Multipurpose bushing<br />

4 - Current transformers<br />

5 - Cable terminals<br />

6 - Earthing switch<br />

5<br />

6

The originality of <strong>VISAX</strong> :<br />

an isolating circuit breaker<br />

The circuit breaker is incorporated<br />

in a rotary isolator, thus forming a<br />

dual-purpose module : circuit<br />

breaker and isolator.<br />

This technical innovation has been<br />

made possible by the use of a<br />

vacuum circuit breaker, the poles of<br />

which are arranged longitudinally<br />

(the three poles of the operating<br />

mechanism are aligned along a<br />

single axis).<br />

<strong>VISAX</strong> switchgear concept<br />

Innovation through rotation<br />

The isolation function between the<br />

busbar and the cables is provided<br />

by 90° rotation of the<br />

isolator/circuit breaker (Fig. 5).<br />

Disconnection is thus performed by<br />

rotation of the circuit breaker.<br />

Fig. 5 - Disconnection by rotation.<br />

Description of the 3 positions<br />

• In the "service" position (Fig. 6a),<br />

the poles of the circuit breaker<br />

are in the vertical position. Once<br />

the circuit breaker has been<br />

opened, the poles can rotate to<br />

reach the "disconnected"<br />

position. They therefore withdraw<br />

from the connection spouts to<br />

adopt a horizontal position<br />

(isolated position).<br />

During this rotation, a metal<br />

shutter is automatically drawn<br />

across and obstructs access to the<br />

busbar.<br />

Fig. 6a - “Service” position: circuit breaker<br />

engaged (opening/closure).<br />

3<br />

Fig. 4 - Longitudinal circuit breaker.<br />

• In the "disconnected" position<br />

(Fig. 6b), the front face of the<br />

cubicle may be opened in<br />

complete safety. Tests and checks<br />

may then be carried out.<br />

Fig. 6b - “Disconnected” position or Test :<br />

circuit breaker disengaged through rotation<br />

(isolated position).<br />

• The withdrawal of the circuit<br />

breaker (Fig. 6c) is then possible<br />

after insertion of an isolating<br />

screen between the multipurpose<br />

bushing and the circuit breaker.<br />

Fig. 6c - “Removed” position (the handling<br />

trolley is not shown ) : testing and checking<br />

operations may be performed on the circuit<br />

breaker.

<strong>VISAX</strong>: user safety<br />

(1)<br />

(2)<br />

The circuit breaker compartment after<br />

withdrawal : no access to live sections.<br />

<strong>VISAX</strong> metal-<strong>clad</strong> switchgear<br />

In order to guarantee the safety of<br />

the operator during checking<br />

operations, the circuit breaker<br />

compartment on <strong>VISAX</strong> switchgear<br />

is fitted with an earthed metal<br />

shutter (1). When the circuit breaker<br />

rotates, this shutter is automatically<br />

drawn across to separate the<br />

busbar and circuit breaker<br />

compartments.<br />

When the circuit breaker is in the<br />

isolated position, access to the<br />

connection spouts and the cable<br />

terminals is therefore protected: the<br />

door may be opened in complete<br />

safety.<br />

Prior to withdrawal of the circuit<br />

breaker, an isolating screen (2)<br />

must be inserted so as to prohibit<br />

access to the multipurpose bushings<br />

and thus provide the user with full<br />

protection.<br />

Enhanced interlocks<br />

and safety devices<br />

Apart from the conventional<br />

interlocks, a particularly reliable<br />

chain of interlocks has been<br />

developed. These mechanical<br />

interlocks are simple, robust and<br />

are located, for the most part, on<br />

the front of the unit.<br />

For total reliability, the preassembled<br />

interlock plate has been<br />

designed as an independent subassembly,<br />

requiring no adjustment<br />

during integration into the unit. The<br />

reliability of the interlocks is thus<br />

enhanced for the greater safety of<br />

the personnel.<br />

The optional motorisation of<br />

isolation and earthing operations is<br />

fully integrated into the interlocking<br />

devices. Therefore, in the event of<br />

the loss of the auxiliary power<br />

supply, the manual operations can<br />

be performed without risk to the<br />

operator, as the mechanical<br />

interlocks then take priority.<br />

4<br />

Safety in use<br />

The original architecture of <strong>VISAX</strong>,<br />

combined with the presence of a<br />

gas extraction duct, make it<br />

possible to install the unit flush to<br />

the wall.<br />

In this way, all the steps involved in<br />

switchgear operation are performed<br />

from the front of the unit for<br />

complete user safety.<br />

A unit which allows true wall mounting.<br />

... and space saving<br />

The fact that the unit can be<br />

mounted against a wall allows<br />

space saving in substations,<br />

making it possible to overcome<br />

certain dimensional restrictions.

Internal arc withstand<br />

The rigid construction of the <strong>VISAX</strong><br />

unit, incorporating exhaust flaps on<br />

each compartment, ensures perfect<br />

internal arc withstand.<br />

Designed and tested according to<br />

the latest standard, CEI 298<br />

Appendix AA, each compartment<br />

has an internal arc withstand which<br />

conforms to criteria 1 to 6.<br />

Enhanced personnel safety is<br />

offered as manual operations are<br />

affected with the doors closed.<br />

The gases are channelled in<br />

a special compartment<br />

An advantage specific to <strong>VISAX</strong><br />

architecture is to allow, thanks to a<br />

single duct located at the rear of the<br />

unit, the collection and the<br />

evacuation of the hot gases in the<br />

event of internal arcing.<br />

This duct, a standard component in<br />

<strong>VISAX</strong> units, is designed to collect<br />

the gases from independent flaps,<br />

specific to each of the<br />

3 compartments: cables, circuit<br />

breaker and busbar.<br />

Should a problem arise in one of<br />

the compartments, it does not affect<br />

the others in any way.<br />

A single duct for the extraction of hot<br />

gases.<br />

Operator safety<br />

In this way, the hot gases are<br />

extracted at the back of the unit,<br />

towards the top, as far as possible<br />

from the operator, for improved<br />

safety.<br />

The safety conditions within<br />

substations are thus enhanced. The<br />

hot gases coming from these ducts<br />

can easily be collected from each<br />

unit by a conduit (optional) and<br />

expelled outside the substation.<br />

5

Reliability of information and ease of operation<br />

Operation from the front<br />

panel<br />

The original architecture of <strong>VISAX</strong><br />

provides the user with a new<br />

dimension in reliability and safety,<br />

both in terms of operation and<br />

readings.<br />

<strong>VISAX</strong> architecture allows all<br />

actions associated with the circuit<br />

breaker/isolator and the earthing<br />

switch to be carried out in complete<br />

Operation from the front panel.<br />

safety from the front face of the unit<br />

by direct action on the operating<br />

mechanism.<br />

Actions on the circuit breaker<br />

(opening/closing) while it is at the<br />

service position are performed<br />

directly via the push buttons located<br />

on the front door of the unit,<br />

whereas isolation of the circuit<br />

breaker is performed by inserting<br />

the isolating crank handle through<br />

the door.<br />

6<br />

Certainty of positional<br />

information<br />

The front-to-back layout of all the<br />

elements in the main circuit enables<br />

the operator to see directly the axes<br />

of both the circuit breaker and the<br />

earthing switch.<br />

Status and positions clearly visible, without<br />

intermediate or interface systems.<br />

The operator is left in no doubt, of<br />

the "service" or "disconnected"<br />

positions therefore benefiting from<br />

inherent reliability.<br />

The position of the earthing switch is clearly<br />

visible to the operator.

Self evident operation and<br />

indication<br />

The information essential to<br />

operation of the switchgear is laid<br />

out ergonomically and grouped on<br />

the front face, in areas clearly<br />

identified by specific blue<br />

colouring. The operator thus has<br />

access to the main information by<br />

simply reading:<br />

• from the legend plate located on<br />

the door of the circuit<br />

breaker compartment (fig. 1),<br />

• from the band located on the<br />

right hand side of the cable<br />

compartment (fig. 2).<br />

The circuit breaker mimic<br />

diagram<br />

The single line drawing of the unit<br />

and the positions of the circuit<br />

breaker are indicated by the mimic<br />

diagram. The mimic diagram<br />

allows the operator to view, without<br />

Fig. 3 - Circuit breaker status: clear, distinct information.<br />

“Service” position<br />

circuit breaker closed circuit breaker open<br />

the slightest ambiguity, the status of<br />

the circuit breaker: open, closed,<br />

isolated, in operation.<br />

Furthermore, the circuit breaker<br />

rating plate, the operation counter<br />

and the status of the spring of the<br />

operating mechanism are clearly<br />

visible from outside the unit, with<br />

the door closed.<br />

The earthing switch mimic<br />

diagram<br />

The information on its status<br />

correspond to reality without the<br />

slightest risk of error, as the<br />

position indicator forms an integral<br />

part of the axis of the earthing<br />

switch.<br />

Mimic diagrams reflecting<br />

reality in all circumstances<br />

The mimic diagram (fig. 3) of the<br />

single line drawing on the front<br />

face of the unit incorporates the<br />

position indicators directly. This<br />

7<br />

Fig. 1 - Status of the circuit breaker.<br />

Fig. 2 - Status of the earthing switch.<br />

mimic diagram is entirely made up<br />

of mechanical elements which<br />

remain operational even in the<br />

event of loss of power supply to the<br />

switchboard.<br />

The isolation distances and the<br />

position indicators are totally<br />

reliable and are clearly visible from<br />

the front face of the unit.<br />

“Disconnected” and Test position<br />

circuit breaker open circuit breaker closed

A solution suited to your applications<br />

<strong>VISAX</strong> : created for a modern<br />

world of communication<br />

The environment is changing and is<br />

leading to an evolution in needs,<br />

particularly in the fields of<br />

communication and remote control.<br />

The basic design of <strong>VISAX</strong> units<br />

incorporates the features of remote<br />

control and remote signalling.<br />

Motorisation : an easy<br />

solution<br />

The motorisation of the circuit<br />

breaker/isolator and earthing<br />

switch was taken into account from<br />

Rated voltage (kV)<br />

Rated withstand voltage<br />

7.2/12 17.5 24<br />

50/60 Hz - 1 min (kV rms) 28 38 50<br />

Lightning impulse (kVp)<br />

Rated current<br />

75 95 125<br />

Cubicle (A) ≤ 2500 ≤ 2500 ≤ 2500<br />

Busbar (A)<br />

Short time current<br />

≤ 2500 ≤ 2500 ≤ 2500<br />

Rms. value (kA 3s) 16/25/31.5/40* 16/25/31.5 16/25<br />

Peak value (kAp) 40/63/80/125* 40/63/80 40/63<br />

Breaking capacity (kA) 16/25/31,5/40 16/25/31,5 16/25<br />

Internal arc withstand (kA 1s) 25 25 25<br />

(kA 0.15s) 40<br />

Degree of protection of the enclosures IP 3X (1) IP 3X (1) IP 3X (1)<br />

Height with low voltage compartment (mm) 2150/2350 2150/2350 2450/2650<br />

Height of low voltage compartment (mm) 625/825 625/825 750/950<br />

Width (mm) ≤ 1250 A 650 (3) /800 (2) 650 (3) /800 (2) 800/1000 (2)<br />

1600 A 800 800 1000<br />

2000 A 900 900 1000<br />

2500 A (4) Main characteristics<br />

900 900 1100<br />

Depth (mm) 16-25 kA 1260 1420 1550<br />

31.5 kA 1460 1420<br />

40 kA 1460<br />

Approximate weight of a cubicle<br />

excluding voltage transformer (kg)<br />

500 550 600<br />

* Excepted earthing switch 1sec - 100 kAp - (1) for any other degree of protection, please contact us - (2) equipped with withdrawable voltage transformers<br />

(3) short time current ≤ 25 kA - (4) forced ventilation for 2500A - Please contact us.<br />

8<br />

the very start of the development<br />

process.<br />

On the motorised version,<br />

operations can be performed<br />

manually if required, and the<br />

mechanical interlocks take priority<br />

in all circumstances.

<strong>VISAX</strong> : a complete range<br />

Load break switch - fuse unit (ISR type load break switch).<br />

Coupling - bus riser unit with withdrawable VT.<br />

Incoming (or outgoing) unit fitted with withdrawable Voltage Transformers (VT) and surge arrester<br />

(fixed VT also available).<br />

Metering/measurement unit with fixed VT and busbar earthing.<br />

9

The essential components of the <strong>VISAX</strong> concept<br />

Multipurpose bushing. (1)<br />

Earthing switch. (2)<br />

Voltage transformer. (3)<br />

Compartment for inter-unit low voltage<br />

cableway, with customer terminal block<br />

accessible.<br />

Busbar compartment<br />

Optional: the compartment may be partitioned<br />

between units and the busbars isolated.<br />

Hot gases extraction duct (standard)<br />

A duct collecting the gases from the ducts of a<br />

series of units is proposed as an option.<br />

Cable compartment<br />

From 1 to 4 single core cable per phase<br />

(according to power handled) may be connected<br />

to the multipurpose bushings.Three-core cables<br />

may also be connected.<br />

The multipurpose bushing performs<br />

the following functions:<br />

• location of ring type current<br />

transformers,<br />

• power connection between circuit<br />

breaker and cable compartments,<br />

• section for the connection of<br />

medium voltage cables,<br />

• capacitor divider for signalling<br />

the presence of voltage on the<br />

cables.<br />

10<br />

(3)<br />

(1)<br />

(2)<br />

Incoming/outgoing and<br />

coupling/bus riser units may be<br />

fitted with voltage transformers, with<br />

or without fuses.<br />

They are available in two formats,<br />

fixed, easy to dismantle, or<br />

withdrawable, which can be<br />

extracted from the front face of the<br />

unit.<br />

<strong>VISAX</strong> is fitted with an earthing<br />

switch with making capacity on<br />

short circuit current.

The isolating circuit breaker<br />

The BLV circuit breaker constitutes<br />

the key element in <strong>VISAX</strong> units.<br />

During isolation, the assembly<br />

comprising the poles and the<br />

operating mechanism rotates. The<br />

circuit breaker is a self-supporting<br />

module which only exerts minimal<br />

forces on the mounting points.<br />

Consequently, the various<br />

operations only require low energy<br />

and the long-term reliability is<br />

further enhanced.<br />

BLV type self-isolating rotative vacuum<br />

circuit breaker<br />

Fig. 1 - Operating mechanism.<br />

Fig. 2 - Pole.<br />

(D)<br />

(C)<br />

Fig. 3 - Vacuum interrupter.<br />

11<br />

(A)<br />

(B)<br />

The elements making up the<br />

BLV circuit breaker<br />

The circuit breaker is fitted with a<br />

spring-loaded mechanical<br />

operating mechanism (fig. 1)<br />

specially developed and optimised<br />

for the specific characteristics of the<br />

vacuum interrupters. Its design<br />

based on a single shaft and spiral<br />

spring for both opening and<br />

closing operations guarantees<br />

exceptional reliability and safety.<br />

The vacuum interrupters are located<br />

in single-pole enclosures (fig. 2).<br />

These enclosures, made of synthetic<br />

resin, provide not only the required<br />

level of insulation, but also the<br />

complete protection of the<br />

interrupters from external damage.<br />

The vacuum interrupters (fig. 3) use<br />

the most advanced technology to<br />

control the arc: the axial magnetic<br />

field. They are essentially made up<br />

of a sealed ceramic enclosure<br />

containing the highly pure copper<br />

contacts. One of these contacts is<br />

fixed (A), the other moving (B) by<br />

means of a metal bellows (C). A<br />

screen (D), located around the<br />

contact zone, collects the metal<br />

vapours created by the arc.

ALSTOM Transmission & Distribution - Appareillage moyenne tension - Boulevard de la Résistance - B.P. 4019 - 71040 Mâcon Cédex 9<br />

Tel. : +33 (0)3 85 29 35 00 - Tlx : 800878 F - Fax : +33 (0)3 85 29 35 01 - www.alstom.com<br />

A067 - AMT - 12/2000 - © - ALSTOM - 2000. ALSTOM 2000 - The logo ALSTOM and their frameworks are trademarks and service trademark applications of ALSTOM. The other names mentioned, registered or not, are the property of their respective companies - COMIMPRESS - 03 85 32 25 40