Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

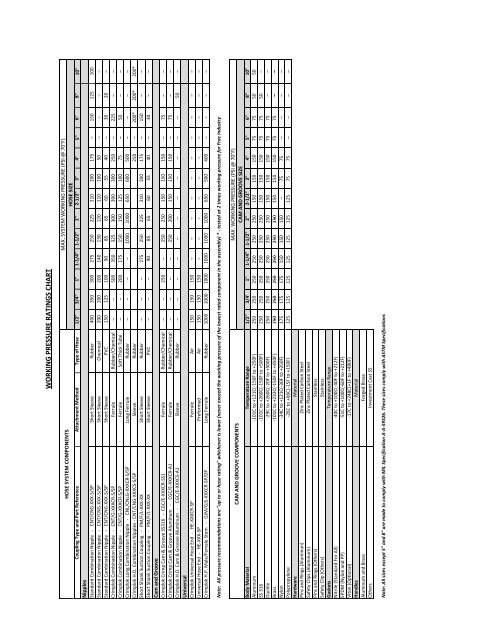

Note: All pressure recommendations are "up to or hose rating" whichever is lower (never exceed the working pressure of the lowest rated component in the assembly) * - tested at 2 times working pressure for Frac Industry<br />

WORKING PRESSURE RATINGS CHART<br />

HOSE SYSTEM COMPONENTS<br />

MAX. SYSTEM WORKING PRESSURE (PSI @ 70°F)<br />

HOSE SIZE<br />

Coupling Type and Part Reference Attachment Method Type of Hose 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 4" 5" 6" 8" 10"<br />

Nipples<br />

Standard Combination Nipple - CNT/CNG-XXX-S/SP Short Sleeve Rubber 400 350 300 275 250 225 210 200 175 – 150 125 100<br />

Standard Combination Nipple - CNT/CNG-XXX-S/SP Short Sleeve Chemical 200 200 200 140 130 120 110 100 50 – – – –<br />

Standard Combination Nipple - CNT/CNG-XXX-S/SP Short Sleeve PVC 150 125 100 90 85 65 60 55 40 – 30 20 –<br />

Crimplok Combination Nipple - CNT/G-XXXCR-S/SP Ferrule Rubber/Chemical – – 500 350 325 300 300 300 250 – 225 – –<br />

Crimplok Combination Nipple - CNT/G-XXXCR-S/SP Ferrule Soft Thick Tube – – 200 175 150 150 125 100 75 – 50 – –<br />

Crimplok Long Combination Nipple - CNL/CNLG-XXXCR-S/SP Long Ferrule Rubber – – – – 1000 1000 650 600 500 – – – –<br />

Crimplok H.D. Combination Nipples - CNT/CNG-XXXCS-S/SP Sleeve Rubber 250 – 200* 200* 200*<br />

Short Shank Suction Coupling - PM/F/L-XXX-XX Short Sleeve Rubber – – – 275 250 225 210 200 175 – 150 – –<br />

Short Shank Suction Coupling - PM/F/L-XXX-XX Short Sleeve PVC – – – 90 85 65 60 55 40 – 30 – –<br />

Cam and Groove<br />

Crimplok Crimp Cam & Groove SS316 - CGC/E-XXXCR-SS1 Ferrule Rubber/Chemical – – 250 – 250 250 150 150 150 – 75 – –<br />

Crimplok Crimp Cam & Groove Aluminum - CGC/E-XXXCR-A1 Ferrule Rubber/Chemical – – – – 250 200 150 150 150 – 75 – –<br />

Crimplok H.D. Cam & Groove Aluminum - CGC/E-XXXCS-A1 Sleeve Rubber – – – – – – – – – – – 50 –<br />

Universal<br />

Crimplok Universal Hose End - HE-XXXCR-SP Ferrule Air 150 150 150 – – – – – – – – – –<br />

Universal Hose End - HE-XXX-SP Preformed Air 150 150 150 – – – – – – – – – –<br />

Crimplok H.P. Male/Female Stem - GJM/GJS-XXXCR-SP/DP Long Ferrule Rubber 1000 1000 1000 1000 1000 1000 650 500 400 – – – –<br />

CAM AND GROOVE COMPONENTS<br />

MAX. WORKING PRESSURE (PSI @ 70°F)<br />

CAM AND GROOVE SIZE<br />

Body Material Temperature Range<br />

1/2" 3/4' 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 4" 5" 6" 8" 10"<br />

Aluminum -101C to +121C(-150F to +250F)<br />

250 250 250 250 250 250 150 150 150 75 75 50 50<br />

SS 316 -101C to +260C(-150F to +500F)<br />

250 250 250 250 250 250 150 150 150 75 75 50 –<br />

Ductile -29C to +260C(-20F to +500F)<br />

250 250 250 250 250 250 150 150 150 75 75 – –<br />

Brass Nylon -101C to +232C(-150F to +450F)<br />

-34C to +121C(-30F to +250F)<br />

250 175 250 175 250 175 250 150 250 150 250 150 150 – 150 75 150 75 75 – 75 – – – –<br />

–<br />

Polypropylene -26C to +66C(-15F to +150F)<br />

125 125 125 125 125 125 125 75 75 – – – –<br />

Hardware<br />

Material<br />

Pins and Rings (Aluminun)<br />

Zinc Plated Carbon Steel<br />

Safety Clips (Aluminum)<br />

Zinc Plated Carbon Steel<br />

Pins and Rings (Others)<br />

Stainless<br />

Safety Clip (Others)<br />

Stainless<br />

Gaskets<br />

Temperature Range<br />

Nitrile (Standard For All)<br />

-40C to +100C(-40F to +212F)<br />

EPDM (Nylon and PP)<br />

-51C to +100C(-60F to +212F)<br />

Viton (Optional)<br />

-17C to +248C(+1F to +480F)<br />

Handles<br />

Material<br />

Aluminum and Brass<br />

Forged Brass<br />

Others<br />

Investment Cast SS<br />

Note: All sizes except 5" and 8" are made to comply with MIL Specification A-A-59326. These sizes comply with ASTM Specifications