Ethylenoxid Sterilisation - Vor- und Nachkonditionierungskammern

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

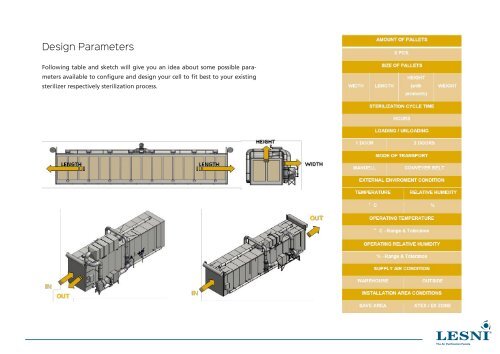

Design Parameters<br />

Following table and sketch will give you an idea about some possible parameters<br />

available to configure and design your cell to fit best to your existing<br />

sterilizer respectively sterilization process.