Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Construction<br />

Computing<br />

WWW.CONSTRUCTION-COMPUTING.COM<br />

Bringing the tropics to Hampshire<br />

Terence O'Rourke and Vectorworks<br />

bring Marwell Zoo's Tropical House to life<br />

VR4CAD<br />

Virtalis provides a professional VR<br />

CAD solution for the mainstream<br />

Constructioneering<br />

Bentley Systems and Topcon<br />

combine to innovate in the Cloud<br />

NOVEMBER/DECEMBER 2016<br />

VOL 12 NO 06<br />

The Hammers XI<br />

The winners of the 2016 Construction<br />

Computing Awards are here!<br />

Are we there yet?<br />

Reflecting on the BIM journey so far<br />

@CCMagAndAwards

CONTENTS<br />

NOVEMBER/DECEMBER<br />

CONTENTS<br />

CONSTRUCTIONEERING 10<br />

Bentley and Topcon embrace the concept of<br />

"the continuous representation of reality" through<br />

innovating in the cloud and collaborating on<br />

'constructioneering'<br />

MARWELL ZOO TROPICAL HOUSE 12<br />

Its 3D BIM and advanced modelling tools made<br />

Vectorworks the ideal choice for Terence<br />

O'Rourke when designing Marwell Zoo's new<br />

Tropical House<br />

VR4CAD 22<br />

Virtalis, pioneers in virtual reality, have recently<br />

launched VR4CAD, providing engineers and<br />

architects with a serious interest in VR with an<br />

easier entry point<br />

THE HAMMERS XI 24<br />

The eleventh annual Construction Computing<br />

Awards were held in November at the historic<br />

BMA house in London. Discover more about<br />

this year's winners and runners-up in our<br />

special awards round-up!<br />

I NEWS................................................INDUSTRY NEWS....................................................................................................6<br />

• TURNING 3D MODELS INTO INTERACTIVE AR/VR • UK MISSING THE MARK ON HOUSING TARGETS<br />

CASE STUDY...................................LENDLEASE GETS AHEAD IN THE CLOUD.....................................................14<br />

• LENDLEASE DEPLOYS HUMAN RECOGNITION SYSTEMS' CLOUD-BASED MSITE BIOMETRIC SITE ACCESS SYSTEM<br />

SOFTWARE REVIEW........................BOXING CLEVER..............................................................................................16<br />

• GRAPHISOFT ADDS VR SUPPORT TO THE ARCHICAD EXPERIENCE WITH ITS LATEST RELEASE<br />

VIEWPOINT......................................ARE WE THERE YET?..........................................................................................18<br />

• AS 2016 DRAWS TO A CLOSE, JASON RUDDLE OF ELECOSOFT LOOKS AT THE BIM JOURNEY SO FAR<br />

CASE STUDY...................................REBAR PREFABRICATION...................................................................................20<br />

• MIDLAND STEEL HAS MADE CONSIDERABLE SAVINGS IN ALL AREAS OF A PROJECT WITH TEKLA STRUCTURES<br />

VIEWPOINT......................................A LIGHT TOUCH....................................................................................................30<br />

• DOES INCREASED INVESTMENT IN TECHNOLOGY GUARANTEE AN INCREASE IN PROJECT PERFORMANCE?<br />

TRAINING MAP................................AUTODESK TRAINING.........................................................................................32<br />

• YOUR GUIDE TO AUTODESK TRAINING<br />

CASE STUDY....................................FUSION IN PRACTICE........................................................................................34<br />

• BARRATT DEVELOPMENTS EXPERIENCES THE BENEFITS OF MANUFACTURING BUILDING COMPONENTS OFFSITE<br />

November/December 2016 3

COMMENT<br />

Editor:<br />

David Chadwick<br />

(cad.user@btc.co.uk)<br />

News Editor:<br />

Mark Lyward<br />

(mark.lyward@btc.co.uk)<br />

Advertising Sales:<br />

Josh Boulton<br />

(josh.boulton@btc.co.uk)<br />

Production Manager:<br />

Abby Penn<br />

(abby.penn@btc.co.uk)<br />

Design/Layout:<br />

Ian Collis<br />

ian.collis@btc.co.uk<br />

Circulation/Subscriptions:<br />

Christina Willis<br />

(christina.willis@btc.co.uk)<br />

Publisher:<br />

John Jageurs<br />

john.jageurs@btc.co.uk<br />

Published by Barrow &<br />

Thompkins Connexion Ltd.<br />

35 Station Square, Petts Wood,<br />

Kent BR5 1LZ<br />

Tel: +44 (0) 1689 616 000<br />

Fax: +44 (0) 1689 82 66 22<br />

SUBSCRIPTIONS:<br />

UK £35/year, £60/two years,<br />

£80/three years;<br />

Europe:<br />

£48/year, £85 two years,<br />

£127/three years;<br />

R.O.W. £62/year<br />

£115/two years, £168/three years.<br />

Single copies can be bought for £8.50<br />

(includes postage & packaging).<br />

Published 6 times a year.<br />

© 2016 Barrow & Thompkins<br />

Connexion Ltd.<br />

All rights reserved.<br />

No part of the magazine may be<br />

reproduced, without prior consent<br />

in writing, from the publisher<br />

For more magazines from BTC, please visit:<br />

www.btc.co.uk<br />

Articles published reflect the opinions of<br />

the authors and are not necessarily those<br />

of the publisher or his employees. While<br />

every reasonable effort is made to ensure<br />

that the contents of editorial and advertising<br />

are accurate, no responsibility can be<br />

accepted by the publisher for errors, misrepresentations<br />

or any resulting effects<br />

Comment<br />

Waking up to virtual realities<br />

by David Chadwick<br />

Virtual Reality features in several<br />

articles this issue, reflecting the<br />

maturing of the industry. Looked at as<br />

a whole, though, they illustrate the fact that<br />

there is quite a difference between entry<br />

level VR solutions and the features that you<br />

would expect to find at the professional end<br />

of the technology.<br />

The driver, of course, is the evolution of VR<br />

headsets such as the Oculus Rift and HTC<br />

Vive, the peaks that 3D digital technology<br />

can now reach, assisted by powerful gaming<br />

processors, and customer demand seeking<br />

the most lifelike and immersive simulations in<br />

VR worlds. Whilst we are stunned by the<br />

scale of what is possible in these virtual<br />

worlds, mirroring our fantasies and driving<br />

our imaginations, it's easy to forget that VR<br />

can be used for more prosaic purposes, and<br />

some of the advanced techniques employed<br />

owe their existence to more simplistic needs.<br />

Virtalis has been involved in Virtual Reality<br />

for some years, developing solutions for the<br />

manufacturing industry that have<br />

foreshadowed some of the developments in<br />

the gaming industry. Pure speculation here,<br />

but what came first - the ability to select and<br />

grasp a spanner and to apply it to a turnable<br />

nut on the 3D mock-up of a vehicle chassis -<br />

or the ability to select and wield a weapon<br />

before advancing on a digital foe in a VR<br />

game? I watched a demonstration of the<br />

former some 10 years ago, and it seems that<br />

the VR gaming industry has caught up in<br />

leaps and bounds in recent years.<br />

It seems that the fidelity of a VR experience,<br />

the level of detail and interactivity - whether<br />

it's manipulating a virtual model or exploring<br />

a game environment - is largely determined<br />

by how much you are willing to pay for the<br />

experience and what you want to achieve<br />

with it. The HTC Vive, for example, starts at<br />

around £759 whereas Sony’s PSVR is £350 -<br />

and sold out everywhere this Christmas. A<br />

sign of VR things to come?<br />

At a most modest level, Graphisoft has<br />

enabled its users to download an app to a<br />

smartphone which can then be placed in a<br />

Google Cardboard viewer, so that the user<br />

can wander through 3D building models at<br />

will using the BIMx viewer. It allows the user<br />

to take measurements, climb stairs, and view<br />

the model in different modes - a simplified<br />

way for, say, architects to show their designs<br />

to clients in order to give them a sense of<br />

what a project will look like.<br />

And then, at the higher end of the VR scale,<br />

we have Virtalis with its VR4CAD, which gives<br />

users the opportunity to wander through a<br />

building model, but one they can interact<br />

with, opening doors and windows and<br />

changing features, materials and textures. It<br />

provides an ideal collaboration or operational<br />

tool for maintenance staff who can virtually<br />

climb a gantry in a process plant, turn a valve<br />

wheel and watch as pressure in a boiler<br />

mounts or declines.<br />

These are just two examples at different<br />

ends of the VR scale - but not for long, as a<br />

number of new apps are emerging that<br />

bridge this particular virtual gap. WakingApp,<br />

for example, featured in this issue's news<br />

pages, enables Autodesk Revit & Fusion 360<br />

designs to be converted to augmented<br />

reality and virtual reality experiences and<br />

promises a degree of interactivity, such as<br />

altering colours, animating objects etc.<br />

Of course, a lot will depend on how much<br />

effort has gone into preparing a model to<br />

allow viewers to explore it in VR, and interact<br />

with every feature. Virtalis, for example, will<br />

tell you that that is not an easy task - hence<br />

the (to date) limited range of CAD<br />

applications that they have set up for the full<br />

VR experience.<br />

The floodgates have been opened,<br />

though, and the evolution will proceed<br />

apace as companies strive to master this<br />

emerging market. Perhaps we can expect to<br />

see more representation from companies<br />

involved in VR in future Construction<br />

Computing Awards? In the meantime be<br />

sure to check out our special round-up of<br />

the 2016 awards in this issue!<br />

4 November/December 2016

INDUSTRY news<br />

ARCHITECT@WORK 2017 - GO WITH THE FLOW<br />

ARCHITECT@WORK, the<br />

two-day trade fair aimed at<br />

architects, designers and specifiers,<br />

will return to Olympia<br />

National Hall for its 2017 edition<br />

on 25 and 26 January.<br />

120 leading European architectural<br />

suppliers will be showing<br />

innovative new products<br />

and offering the latest innovations<br />

in surface solutions, lighting<br />

technology as well as interior<br />

and exterior fixtures and fittings.<br />

All of these companies<br />

have gone through a rigorous<br />

selection process, with an<br />

external judging panel overseeing<br />

the product selection.<br />

The theme for ARCHI-<br />

TECT@WORK UK 2017 is<br />

water. To this end, the SCIN<br />

GALLERY will present an exhibition<br />

focusing on four aspects:<br />

The Material Source: Materials<br />

that come from Water will<br />

examine the natural elements<br />

that come from water such as<br />

seaweed, shells and Neptune<br />

balls as well as solutions to the<br />

material waste that is floating in<br />

our seas like Bionic Yarn.<br />

The Physical Connection:<br />

Interacting with Water will<br />

explore how water is incorporated<br />

into design from tiles that<br />

redirect water to prevent flooding<br />

to creating a weathered<br />

look by putting materials in<br />

contact with water.<br />

The Chemical Reaction:<br />

Hydrophilic and Hydrophobic<br />

will look at materials that naturally<br />

repel water (hydrophilic)<br />

and materials that absorb<br />

water (hydrophobic).<br />

Hydrophilic materials are often<br />

incorporated into coatings and<br />

paints to protect surfaces while<br />

hydrophobic substances are<br />

used to create meltable bioplastics,<br />

expanding resins and<br />

dissolvable paper.<br />

The Aesthetic Inspiration:<br />

Looking like Water will show<br />

how water's shine, bubbles and<br />

waves are imitated in design<br />

elements from glass and<br />

acrylic to fabric and marble.<br />

Another feature of the 2017 edition<br />

is the exhibition Matière<br />

grise (GREY MATTER, Materials,<br />

Reuse, Architecture) by<br />

Pavillon de l'Arsenal. Architects<br />

Julien Choppin and Nicola<br />

Delon from the Encore Heureux<br />

architectural design agency<br />

explore the reuse of building<br />

materials at a time when architecture<br />

is aspiring to reinvent<br />

itself but restricted by economic<br />

and environmental constraints.<br />

The exhibition urges<br />

the construction trade to use<br />

more "grey matter" so as to use<br />

fewer raw materials.<br />

More information, including<br />

full detals of the event's Talk<br />

programme, are available at<br />

www.architectsdatafile.co.uk<br />

TURNING 3D MODELS INTO INTERACTIVE AR/VR<br />

WakingApp has released<br />

new, innovative add-ins<br />

that allow Autodesk Revit &<br />

Fusion 360 users to transform<br />

their 3D designs into augmented<br />

reality (AR) and virtual reality<br />

(VR) experiences without<br />

AR/VR programming skills or<br />

experience.<br />

WakingApp's Revit add-in and<br />

Fusion 360 add-in support<br />

seamless content generation,<br />

enabling file sharing and file fixing<br />

for their designs prior to the<br />

prototype and printing stage.<br />

With a few mouse clicks, users<br />

can turn CAD into AR or VR,<br />

and share it with clients and<br />

colleagues instantly.<br />

"Autodesk is excited to see<br />

WakingApp delivering our customers<br />

Augmented & Virtual<br />

Reality in just one click," said<br />

Jim Quanci, Senior Director<br />

AN AWARD-WINNING EVENT FOR ABVENT<br />

Abvent has won 3 out of 10<br />

categories at the first annual<br />

Digital Transition Plan for<br />

Buildings Awards held in Paris,<br />

France on November 29. Twinmotion<br />

won the top prize in the<br />

"Planning, Visualisation and<br />

Communication" category.<br />

Abvent's ClimaBIM won the<br />

award for best "Energy Performance<br />

and Environmental Protection"<br />

software. ClimaBIM<br />

enables RT2012 thermal calculations<br />

of BIM projects directly<br />

from an architectural model in<br />

both Revit and ARCHICAD.<br />

RT2012 is the national standard<br />

of France.<br />

Graphisoft's ARCHICAD 20,<br />

distributed by Abvent in<br />

France, took home the top<br />

prize in the "Design Tools" category.<br />

The award-winning<br />

firm's focus on IFC interoperability,<br />

real-time photo-realistic<br />

rendering, and an IFC/BCF<br />

collaborative platform made it<br />

Software partner Development.<br />

"When WakingApp's ENTiTi software<br />

is combined with<br />

Autodesk apps, millions of CAD<br />

users and their customers can<br />

experience their designs in augmented<br />

and virtual reality in<br />

near real time."<br />

With the ENTiTi Creator<br />

(WakingApp's cloud-based platform),<br />

CAD users can add interactivity<br />

to their designs, such as<br />

colours, animating objects and<br />

more. The software allows CAD<br />

users to edit existing projects<br />

created by the Revit or Fusion<br />

360 add-in. Once users save<br />

and publish content in ENTiTi,<br />

their AR/VR experience can be<br />

immediately shared and viewed<br />

by clients and colleagues. It's<br />

easy to use and requires no<br />

prior AR or VR experience.<br />

www.wakingapp.com<br />

a clear choice for the jury.<br />

Established by the Government<br />

of France, the Digital Transition<br />

Plan for Buildings (PTNB)<br />

awards recognise software<br />

innovations that help building<br />

design and construction professionals<br />

transition to and work<br />

within a BIM workflow.<br />

"Our objective is to highlight<br />

the digital tools that allow all<br />

building professionals to work<br />

on digital models using BIM,"<br />

said Bertrand Delcambre, President<br />

of the PTNB. "Of the 93<br />

entries, we selected 30 nominees,"<br />

he said.<br />

The jury then selected 11 winners<br />

in 10 categories. Most of<br />

the participating software will be<br />

listed on the French Government's<br />

PTNB website as a<br />

guide for design and construction<br />

professionals to consider<br />

the best BIM software tools<br />

available on the market today.<br />

www.abvent.com<br />

6<br />

November/December 2016

60<br />

50.35<br />

50.35<br />

6.20<br />

7.30<br />

32.40<br />

YOU SEE<br />

THE WORLD<br />

DIFFERENTLY.<br />

ST 17H<br />

TRANSFORM IT.<br />

DESIGN WITH VECTORWORKS 2017.<br />

VECTORWORKS.NET/EXPLORE2017<br />

Our intuitive software enhances your design process,<br />

enabling you to collaborate from inspiration to execution<br />

and explore the possibilities of BIM and beyond.<br />

IN PARTNERSHIP WITH

INDUSTRY news<br />

UK MISSING THE MARK ON HOUSING TARGETS<br />

Nearly 90% of local authorities<br />

believe that the Government's<br />

housing targets will<br />

be impossible to meet due to a<br />

lack of planning resources,<br />

according to a new joint<br />

research report from the Federation<br />

of Master Builders (FMB)<br />

and the Local Government<br />

Information Unit (LGiU).<br />

The report, the first of its kind<br />

to draw upon the experience of<br />

both local authorities and SME<br />

house builders from right<br />

across the UK, also found that:<br />

• 64% of builders and 45% of<br />

local authorities see lack of<br />

planning resources as a barrier<br />

to developing more small sites<br />

• More than half of councils<br />

deliver fewer than 40% of<br />

homes on small sites<br />

• Builders and local authorities<br />

call for councils to be<br />

allowed to raise planning application<br />

fees.<br />

Brian Berry, Chief Executive of<br />

London South Bank University<br />

(LSBU) is has announcing<br />

a £50K award from the<br />

Higher Education Funding<br />

Council for England (HEFCE)<br />

to support a research pilot conducted<br />

by the University’s<br />

School of Architecture and the<br />

Built Environment (BEA), looking<br />

at encouraging students<br />

and staff within the AEC arena<br />

to collaborate and work together<br />

better on joint projects.<br />

The research pilot launches<br />

this month and is set to run<br />

from December 2016 until May<br />

2018 for a period of one and a<br />

half years.<br />

The project is being led by<br />

Jennifer Hardi, Senior Lecturer<br />

at LSBU’s School for Architecture<br />

and the Built Environment,<br />

together with her colleagues<br />

the FMB, said: "The Government<br />

aim to build one million<br />

new homes by 2020 won't be<br />

realised unless more SME<br />

housebuilders can enter the<br />

housing market. That's why the<br />

barriers that SME house<br />

builders currently face need to<br />

be removed. We know that the<br />

availability of suitable small<br />

sites and the difficulty of getting<br />

planning permission on them<br />

are two of the biggest barriers<br />

these firms face. In this<br />

research, both local authorities<br />

and SME builders identify<br />

under-resourcing as a key barrier<br />

to allocating more small<br />

sites and getting planning permissions<br />

in place on them.<br />

Too often small sites are dealt<br />

with entirely by inexperienced<br />

officers. There simply aren't<br />

enough senior and experienced<br />

planners to make the<br />

system work effectively."<br />

www.fmb.org.uk<br />

£50K FUNDING FOR AEC RESEARCH PILOT<br />

Steve Pittard and Professor<br />

Andy Ford, who were both in<br />

the original bidding team.<br />

Jennifer Hardi said, "The culture<br />

within the UK’s construction<br />

industry currently shows a<br />

tendency towards silo working,<br />

where different professionals<br />

working on the same project<br />

often fail to communicate well<br />

with one another about the different<br />

stages of that project. In<br />

the past this has proved<br />

extremely frustrating and even<br />

led to delays in projects being<br />

completed and deadlines<br />

being missed.<br />

This is not a sustainable or<br />

efficient way for the UK’s construction<br />

industry to be working<br />

if it is to retain its competitive<br />

edge in a post-Brexit economy."<br />

www.hefce.ac.uk<br />

NEW WAYS TO DESIGN FOR MEP DISCIPLINES<br />

The new version 2016.11 of<br />

the MEP design software<br />

MagiCAD for Revit and Auto-<br />

CAD introduces new productivity-enhancing<br />

workflows on<br />

top of Revit and AutoCAD<br />

technologies. MagiCAD offers<br />

a comprehensive and<br />

advanced solution for all ventilation,<br />

piping and electrical<br />

BIM, design and calculations<br />

needs. MagiCAD 2016.11 supports<br />

Revit 2017-2016 and<br />

AutoCAD 2017-2013.<br />

The new release offers a<br />

complete MEP calculation<br />

solution on Revit platforms,<br />

with the capability to perform<br />

all of the thorough MagiCAD<br />

calculations now also on<br />

native Revit families. In previous<br />

versions, MagiCAD for<br />

Revit has already offered full<br />

design functions with both<br />

native RFAs and MagiCAD<br />

RFAs, as well as full calculations<br />

with MagiCAD RFAs.<br />

The new version also integrates<br />

consistently with native<br />

Revit units of measurement,<br />

optimises drawing legends for<br />

quantity take-off documents<br />

and bills of materials, and<br />

provides easy functions for<br />

locating potential errors and<br />

failed objects in the model<br />

after IFC export.<br />

www.magicad.com<br />

INTERACTIVE, 3D MODELING PLUG-IN<br />

RDV Systems has released<br />

123BIM Publisher, a 3D<br />

modeling plug-in for Auto-<br />

CAD Civil 3D and Bentley<br />

MicroStation. 123BIM Publisher<br />

enables engineers and<br />

visualisation experts to use<br />

their existing CAD platforms<br />

to democratise their designs<br />

by publishing their models<br />

into a browser-based Google<br />

Earth-like 3D environment<br />

that is fully interactive.<br />

By using 123BIM Publisher<br />

to import external data such<br />

as aerial photographs, GIS<br />

data, SketchUp models and<br />

much more, designers will be<br />

able communicate intent<br />

quickly and inexpensively.<br />

"123BIM Publisher was built<br />

in a way so that actual, complex<br />

project design created in<br />

any industry standard CAD<br />

platform can be seamlessly<br />

converted to 3D digital models<br />

and uploaded to the<br />

cloud for collaboration and<br />

public engagement on the<br />

123BIM platform. This is not<br />

trivial since the 3D digital<br />

documents created by the<br />

engineers are huge and<br />

require dedicated software to<br />

be viewed," said Dolio Kafri,<br />

VP North America Sales with<br />

RDV Systems.<br />

www.rdvsystems.com<br />

8<br />

November/December 2016

From design<br />

to reality<br />

Louis Vuitton Foundation (France)<br />

Tekla Structures is intelligent 3D modelling software at the heart of the digital<br />

construction process. From concept drawing to reality, collaboration between<br />

people and across technologies becomes more efficient and rewarding.<br />

Together we are shaping a smarter future for construction.<br />

www.tekla.com/uk/solutions<br />

TRANSFORMING THE WAY THE WORLD WORKS

INDUSTRYfocus<br />

Innovating in the Cloud<br />

Bentley Systems and Topcon join forces to advance cloud services for 'constructioneering'<br />

We looked at 'conceptioneering' in<br />

the last issue - now we are being<br />

introduced to<br />

'constructioneering'. Bentley appears to be<br />

pioneering a new method of describing<br />

the bringing together of a number of<br />

different disciplines to make a more<br />

valuable 'whole'.<br />

It's not an uncommon concept, as<br />

traditional construction activities such as<br />

architectural design, structural, MEP and<br />

environmental applications are all well<br />

integrated and capable of sharing models<br />

and data, improving efficiency and<br />

enhancing workflow processes. Bentley is<br />

taking the process one step further,<br />

though, by bringing together construction<br />

workflows that traditionally operate within<br />

their own environment - surveys,<br />

engineering design and construction -<br />

providing benefits not previously<br />

attainable.<br />

The recent Bentley Year in Infrastructure<br />

event in London was the perfect venue for<br />

launching the joint intentions of Bentley<br />

Systems and Topcon Positioning Group to<br />

connect their respective cloud services to<br />

promote the concept of<br />

constructioneering. Topcon is a world<br />

leader in positioning instruments for<br />

survey and construction, and for the use<br />

of GNSS (Global Navigation Satellite<br />

Systems) and robotics in the automatic<br />

positioning of construction equipment like<br />

graders, bulldozers and excavators.<br />

Adopting elements of each other's<br />

software solutions, Bentley Systems will<br />

offer ProjectWise CONNECT Edition users<br />

seamless access to Topcon's MAGNET<br />

Enterprises, whilst Topcon will incorporate<br />

Bentley's ContextCapture image<br />

processing for its mass data collection via<br />

unmanned aerial systems (UAS).<br />

A TWO-WAY PROCESS<br />

The symmetry between the two processes<br />

is quite satisfying. The construction site<br />

survey data - an accurate 3D model of the<br />

current conditions that includes both<br />

terrain and existing structures - is captured<br />

using Topcon UAV photogrammetry and<br />

laser scanners. This is then processed<br />

into engineering ready 3D reality meshes<br />

by ContextCapture software, where it<br />

becomes the basis of further engineering<br />

design and terrain development within<br />

Bentley's numerous applications.<br />

With the connection between Topcon's<br />

MAGNET cloud service and Bentley's<br />

ProjectWise CONNECT Edition Cloud<br />

established, the updated model can then<br />

be automatically conveyed to engineers<br />

engaged in construction processes in the<br />

field, with the digital engineering models<br />

feeding the 3D machine control that<br />

guides the construction machinery.<br />

Greg Bentley, CEO of Bentley Systems,<br />

explained the benefits quite clearly. "To<br />

date," he said, "surveying, engineering,<br />

and construction industries have<br />

separately advanced to 3D technologies.<br />

But unbelievably, until now, 3D models<br />

have been recreated - rather than reused -<br />

at each phase."<br />

He explained further, pointing out that<br />

engineers are now able to start from<br />

reality-captured surveys, and to update<br />

their digital engineering models<br />

throughout the construction process - a<br />

real-time bilateral process that provides<br />

construction workers with the latest<br />

construction model at all times. The joint<br />

cloud service innovations for constructing<br />

and improving roadways, which include<br />

as-built capture, are now enabling the<br />

highest level of workflow automation. This<br />

has to be compared to traditional<br />

workflows between design and<br />

construction in which data from survey<br />

and digital engineering models can be lost<br />

and inefficiently recreated.<br />

Constructioneering empowers engineers<br />

to extend their role within both surveying<br />

and construction.<br />

Actually, constructioneering is just the<br />

start of a whole new way of handling<br />

infrastructure projects, said Greg Bentley,<br />

who believes that Topcon will continue to<br />

pioneer new positioning devices to take<br />

advantage of every emerging opportunity:<br />

"We are enthusiastic about working with<br />

them, enabling us to advance<br />

constructioneering into the mainstream for<br />

infrastructure projects around the world."<br />

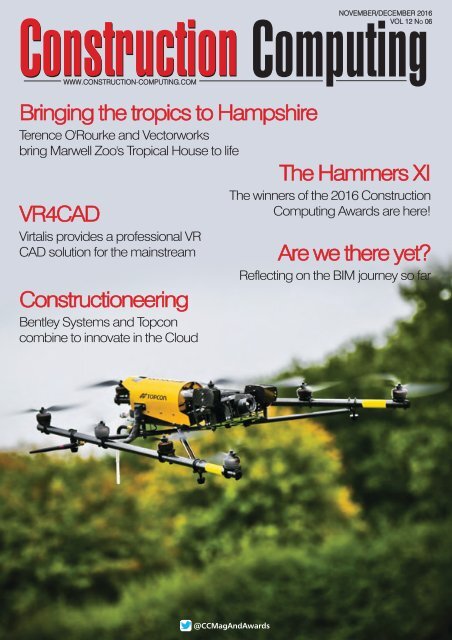

TOPCON UAS<br />

Aerial surveys are certainly the way things<br />

are going with drones, like Topcon's<br />

Falcon 8 rotary winged UAV. Powered by<br />

Ascending Technologies, it’s the latest<br />

addition to the company's line-up of mass<br />

data collection technology (it's also being<br />

used for inspection and monitoring, as<br />

well as surveys and mapping).<br />

According to Charles Rihner, VP of the<br />

Topcon GeoPositioning Solutions Group,<br />

such devices provide perfect solutions for<br />

small-scale sites and projects for which<br />

flexibility of take-off and landing, or oblique<br />

perspectives are required. Drones like<br />

Falcon 8 can manoeuvre in small spaces<br />

and cope with challenging environments,<br />

and can cope with mapping and<br />

modelling projects up to 85 acres in size<br />

that require high-resolution imaging.<br />

The onboard Trinity system makes the<br />

Falcon 8 very efficient and safe in daily<br />

operation. The triple flight controllers<br />

onboard contain a total of 31 sensors,<br />

synchronise all sensing data, and identify<br />

10<br />

November/December 2016

INDUSTRYfocus<br />

signal interference and compensate in<br />

case of trouble. Unmatched position<br />

accuracy can even be guaranteed at high<br />

speeds in highly dynamic flights. Topcon<br />

has two models of the Falcon 8. The<br />

GeoEXPERT is for surveying, modelling<br />

and mapping projects - now mobilised<br />

with ContextCapture - and uses the UAS's<br />

high definition RGB cameras to create<br />

geometrically and visually accurate 3D<br />

representations of both terrain and asbuilt<br />

structures.<br />

The InspectionPRO model is for industrial<br />

inspection and monitoring applications,<br />

and adds infra-red sensors to the payload.<br />

Using established ground control and the<br />

Navigator software for photo-tagging, the<br />

system is able to generate high quality and<br />

easy to edit outputs. The Falcon 8 is not<br />

Topcon's first entry into UAS territory. it<br />

complements the Topcon Sirius Pro, a<br />

fixed wing UAS which is used for larger<br />

area mapping without having to rely on<br />

traditional ground control.<br />

MAGNETIC APPEAL<br />

Topcon also has a full range of optical and<br />

surveying solutions like the GT Total<br />

Station, driven by MAGNET Field software,<br />

which provides users with comprehensive<br />

data collection and surveying solutions.<br />

MAGNET works with a wide range of<br />

industry file formats, and can tackle any<br />

survey task.<br />

At the centre of the MAGNET system is<br />

MAGNET Enterprise, which provides<br />

managers with access to project data via<br />

the cloud, and also to disparate members<br />

of survey teams using MAGNET Enterprise<br />

Mobile on their tablets. This is backed up<br />

further by the MAGNET Office Suite which<br />

serves the whole project, enabling users to<br />

process fieldwork, produce reports<br />

(customisable on-the-fly) and view data<br />

with a satellite image background.<br />

ROBOTICS AND GNSS<br />

Accurate positioning is not just a<br />

requirement for engineering design<br />

purposes; it is also used for stakeout<br />

using Hybrid positioning (combined<br />

Robotic and GNSS) and to control<br />

construction vehicles such as graders.<br />

Topcon's Hybrid solution uses lightweight<br />

GNSS receivers combined with Topcon's<br />

high end Robotic prism-tracking<br />

equipment to provide flexible solutions<br />

with millimetre accuracies. As you move<br />

about the site, the Total Station stays<br />

locked-on and the user can chose to use<br />

data from the Robotic or the GNSS<br />

receiver depending on the environment.<br />

The user can upload or download data to<br />

the cloud-based Enterprise solution as the<br />

job progresses.<br />

Managing bulk earthworks with dozers<br />

and excavators can be challenging, even<br />

for seasoned drivers. Whether you're<br />

grading flat or inclined 3D surfaces,<br />

Topcon allows operators to get the job<br />

done quickly and precisely first time. The<br />

system gives operators real-time cut/fill<br />

data in their cab at all times, making<br />

overcuts and undercuts a thing of the past.<br />

On the stage at the Year in Infrastructure<br />

conference with Greg Bentley was Ray<br />

O'Connor, President and CEO of Topcon<br />

Positioning Group. He spoke about the<br />

vision that both he and Bentley shared.<br />

"With these advancements we can achieve<br />

through what I call the continuous<br />

representation of reality. We also share a<br />

commitment to rolling up our sleeves and<br />

working together to make possible<br />

tangible results and real benefits for our<br />

customers as we advance<br />

constructioneering. I believe that our<br />

strategic collaboration will continue to<br />

integrate surveying, engineering, and<br />

construction, improving outcomes for<br />

project delivery."<br />

www.bentley.com<br />

www.topconpositioning.com/en-gb<br />

November/December 2016 11

CASEstudy<br />

Marwell Tropical House<br />

Its 3D BIM and advanced modelling tools made Vectorworks the ideal choice for Terence O'Rourke<br />

when designing Marwell Zoo's new Tropical House<br />

Designed by award-winning<br />

planning and design<br />

consultants Terence O'Rourke,<br />

Marwell's Tropical House is scheduled<br />

to be completed by February 2018 and<br />

is intended to replace the existing<br />

Tropical World exhibit. It incorporates<br />

an Energy Centre using a sustainable<br />

energy source to power both the<br />

Tropical House and other exhibits within<br />

the park.<br />

Run by Marwell Wildlife, Marwell Zoo<br />

is a well-established, highly respected<br />

and successful zoological park in the<br />

south of England. It has an international<br />

reputation for wildlife conservation as<br />

well as being a very popular visitor<br />

attraction in the South Downs National<br />

Park. Marwell Wildlife is a charity<br />

dedicated to the conservation of<br />

biodiversity and<br />

other natural resources. It undertakes a<br />

broad portfolio of conservation<br />

activities. Marwell Wildlife is also<br />

committed to promoting sustainable<br />

living through initiatives such as<br />

renewable energy generation.<br />

With a strong ethos of involving<br />

people in successful conservation<br />

projects, the charity works closely with<br />

local communities, both at home and<br />

abroad, to find sustainable ways of<br />

living alongside wildlife.<br />

The building features an elongated S-<br />

shaped plan, 1277sq.m in gross<br />

internal floor area, with an elevated<br />

entry and a lower level exit. The<br />

environmentally controlled Tropical<br />

House to the south is separated from<br />

the Energy<br />

Centre to the north by a central<br />

concrete thermal wall. The enclosure of<br />

the building will also serve as the<br />

defining element of its architectural<br />

identity, which is a lightweight curved<br />

roof clad with a translucent ETFE<br />

membrane, supported by an exposed<br />

curved steel structure.<br />

Entering at high level you are taken<br />

along a meandering boardwalk and<br />

path through a tropical themed<br />

environment of vegetation, waterfalls,<br />

rock faces and aquariums populated<br />

by animal species that will interact with<br />

the visitors, such as sloths, monkeys<br />

and lizards. The visitor will feel that they<br />

are in the animals' environment. The<br />

base of the exhibit will be sculpted to<br />

reflect an uneven forest and desert<br />

floor with water features.<br />

12<br />

November/December 2016

CASEstudy<br />

The building is split into several<br />

temperate environments to reflect the<br />

species' living environment. The back<br />

of house area serves as animal housing<br />

and plant areas for animal life support<br />

and the building's environment-friendly<br />

biomass technology.<br />

This complex architectural form (in<br />

terms of the curved roof and S-shaped<br />

plan) suggested early on that using 3D<br />

BIM with Vectorworks 2015 and 2016<br />

was the most rational and efficient<br />

method to document the building. The<br />

initial setting out of the building was<br />

established by a 2D plan grid in a<br />

regular arrangement, dividing the<br />

building into a series of bays, which<br />

meant that it could be easily extended<br />

or reduced through the design process<br />

to meet performance requirements and<br />

cost limits. Breaking the building into a<br />

series of bays to achieve the overall<br />

complex form ensured constructional<br />

efficiency as well as making the design<br />

easier to document.<br />

Due to the bespoke nature of the<br />

structure and envelope, extensive use<br />

of Vectorworks 3D modelling tools was<br />

required instead of standard plug-in<br />

tools. For example, the main structural<br />

elements were formed as curved<br />

circular beams in 3D, using the 'extrude<br />

along path' tool, and the completed<br />

elements converted into a 3D symbol<br />

with IFC data applied.<br />

These symbols were next set out on<br />

the centre point of the set circular grid<br />

and duplicated and rotated to grid. In<br />

order to form the 'pillows' of the ETFE<br />

membrane, a curve was drawn<br />

following the top of beams either side<br />

of a bay, with a third line connecting<br />

them at the base. These were next<br />

converted to spline lines, and using the<br />

surface array tool allowed a curved<br />

pillow shape to be generated that<br />

closely resembles the look of a typical<br />

ETFE installation.<br />

This had the advantage of allowing<br />

easy adjustment of the design by<br />

altering the generating geometry, but<br />

the design team discovered the<br />

importance of adding the right IFC data<br />

so that all information within the model<br />

could be exchanged with other team<br />

members.<br />

The production of a 3D model early on<br />

in the design process also presented<br />

clear advantages for design exploration<br />

and demonstration of the proposals to<br />

the client and design team. The team<br />

was able to quickly produce animated<br />

walkthroughs and 3D views from the<br />

model, but utilised some postprocessing<br />

in other software packages<br />

to achieve the required level of softness<br />

and 'sketchiness' to this early stage of<br />

presentation.<br />

The designers exported IFC data from<br />

a working model and used this to<br />

coordinate with structures and M&E<br />

with relative ease. The new project<br />

sharing facility of Vectorworks 2016<br />

allowed several members of the design<br />

team to work on the project at the same<br />

time, enabling the deadline to be met.<br />

The combined consultant BIM model<br />

was used in design team meetings to<br />

review, coordinate and question the<br />

design, with the knowledge of<br />

outcomes allowing decisions to be<br />

made quickly. With such a highly<br />

themed building Terence O'Rourke<br />

added a 3D model layer of theming to<br />

allow the client to visualise the potential<br />

of the space and show the consultant<br />

team how the structural, mechanical<br />

and electrical designs would be seen<br />

within the space. The theming designer<br />

was able to use the model to take the<br />

project to its next stages, and it also<br />

enabled Terence O'Rourke to efficiently<br />

add an extra bay to the main exhibition<br />

hall late into the tendering process.<br />

Marwell's Tropical House has enabled<br />

Terence O'Rourke to develop an<br />

understanding of complex modelling<br />

techniques and the importance of<br />

collaborative working with BIM models<br />

both in-house and with consultant<br />

teams - David Dexter Associates for the<br />

structural elements, Hoare Lea for MEP<br />

and fire assessment and Main<br />

Contractors Drew Construction Group.<br />

www.torltd.co.uk<br />

November/December 2016 13

CASEstudy<br />

Lendlease gets ahead in the cloud<br />

Meeting Health & Safety requirements prompted Lendlease to<br />

deploy Human Recognition Systems' cloud-based MSite<br />

biometric site access system<br />

Construction sites are notoriously<br />

challenging to manage and keep<br />

safe. Even today they often lack<br />

technical infrastructure or<br />

communications, and hardware has to<br />

survive in harsh environments with<br />

unreliable power provision. Solutions need<br />

to be easy to use but meet an everonerous<br />

list of moral, Health and Safety<br />

and legal requirements. And then there's<br />

the contractor who expects it to simply<br />

work ... and work simply.<br />

These very special requirements were one<br />

reason Human Recognition Systems (HRS)<br />

turned to the cloud when it pioneered a<br />

construction-specific biometric site access<br />

and contractor management product which<br />

uses worker identity and skills information<br />

to manage sites effectively.<br />

Its cloud-based MSite system, which is<br />

now deployed on more than 600 sites, with<br />

more than 1 million workers enrolled to date<br />

and 150,000 entries and exists processed<br />

per day, has captured this requirement so<br />

completely that it has become a main<br />

contractor's virtual site manager, saving one<br />

of them six figures on a single element of a<br />

single project alone.<br />

HRS has worked with Lendlease on<br />

numerous large projects using MSite as the<br />

contractor's preferred access control<br />

system, and a prime example of this is the<br />

10-year regeneration scheme currently<br />

underway at Elephant and Castle in<br />

London. As Southwark Council's<br />

development partner, Lendlease was<br />

selected to carry out the regeneration of<br />

more than 28 acres across three sites in its<br />

initial phase and a total of eight sites for the<br />

life of the project, and needed an access<br />

control system that could cope with crosssite<br />

access rights and a complex set of<br />

reporting requirements.<br />

As part of the project, Lendlease had a<br />

Section 106 requirement from Southwark<br />

Borough Council to demonstrate its<br />

commitment to the development of local<br />

skills and labour, including apprenticeships<br />

and skills training programmes.<br />

Lendlease chose MSite to service up to<br />

3,000 site workers with 100,000 secure<br />

entries/exits per month. The initial delivery<br />

of this was so successful Lendlease asked<br />

HRS to provide an automated solution for<br />

all the required site reporting and<br />

management, including the monthly<br />

automated diversity reporting.<br />

A quarterly report was designed which<br />

provided the exact information required,<br />

reporting on the key groups and the<br />

respective time spent working on site. This<br />

report was automatically produced for the<br />

client and used to show key progress<br />

against diversity and local labour targets.<br />

MSite's comprehensive reporting engine<br />

answered all of Lendlease's reporting<br />

requirements and more. In fact on-site's<br />

Lendlease staff estimate that without MSite<br />

they would require one person per site for<br />

the duration of the project just to create the<br />

diversity reports alone - a cost saving of<br />

over £200,000 on this element alone.<br />

"MSite saves us considerable time in<br />

reporting and allows our on-site project<br />

team to focus on managing projects on<br />

site, while giving our head office instant<br />

visibility to all the data needed in real time,"<br />

said Andy Fulterer, Lendlease's head of<br />

strategic procurement.<br />

Apart from specific sites, HRS has also<br />

worked with Lendlease to improve overall<br />

processes across the entire company, and<br />

for the past 18 months MSite pre-enrolment<br />

has been mandated across all Lendlease<br />

sites. Most recently, HRS has developed an<br />

extensive skills management sub-system of<br />

MSite for Lendlease which effectively<br />

manages and records training sessions<br />

across a multitude of sites.<br />

"What's different about this is its ability to<br />

link seamlessly with our MSite access<br />

control system," said Brian Van<br />

Campenhout, Lendlease's health and<br />

safety director. "This assures us that our<br />

health and safety policies are being<br />

followed on all sites across thousands of<br />

operatives. If they're not, untrained workers<br />

won't be able to enter and we are alerted to<br />

the problem. Simple training attendance<br />

reports also allow us to automate our CITB<br />

grant claims process across all sites and<br />

maximise the financial returns."<br />

Along with the cast-iron guarantee of<br />

biometric identification which eliminates<br />

'ghost' workers and time fraud, the cloudbased<br />

MSite system provides:<br />

CSCS integration and card usage,<br />

where workers use their own cards to<br />

access site - this has been shown to<br />

save £59,000 in purchased cards and<br />

faster induction,<br />

Pre-enrolment and induction booking,<br />

where suppliers enter their workers'<br />

details online prior to the first visit to<br />

site - saving £110,000 in induction time<br />

and errors<br />

Local labour and environmental<br />

reporting, for the logging of workers'<br />

travel-to-site distances to contribute to<br />

a site's CO2 footprint, saving £13,500<br />

on the average half a day per site per<br />

month it usually takes to do this,<br />

Diversity reporting by category, saving<br />

£25,000<br />

Delivery management where suppliers<br />

and contractors book their slots online,<br />

saving £15,000 on a part-time<br />

employee per site.<br />

With a revolutionary fingerprint-enabled<br />

touchscreen display also launched this<br />

year, a system combining sophisticated<br />

workforce management software with<br />

biometric hardware has set the bar in an<br />

industry typically slow to embrace new and<br />

innovative methods of working.<br />

www.hrsid.com<br />

14<br />

November/December 2016

Call 020 3002 8700 or go to www.redskyit.com<br />

A truly Integrated Contract Financial and Operational Solution<br />

RedSky IT’s Summit system is the only truly integrated, construction specific,<br />

enterprise solution for the UK and Middle East markets. Summit covers the complete<br />

process within a single product:<br />

Estimating & Tender Management, Budgeting, Planning, Requisitions, Procurement,<br />

Plant Management, Valuations, CVR, Job Costing Financials, Payroll & HR,<br />

Subcontractor Database & Management, Housebuilding, Service Management,<br />

Mobile Solutions, Document Management, Dashboards, Email Archiving, Forms<br />

Control, Workflow, Approvals, Alerting<br />

Scalability<br />

Whether you are a small growing subcontractor or a top 100 construction business<br />

there is a Summit solution to suit you, and as you grow you can simply add modules<br />

and licenses as required.<br />

IT Choice<br />

Summit gives you freedom of choice to choose the appropriate technology for your<br />

business: Hosted or on premise Microsoft SQL/Oracle Database; Windows or Linux;<br />

scaleable thin client Windows or Web interface.<br />

Pedigree<br />

Over 1,000 clients from your industry have chosen RedSky IT. These secure<br />

partnerships drive an unrivaled depth of functionality into our solutions.<br />

Customer Driven Solutions<br />

As authors of our solutions and not resellers of a 3rd party product, RedSky IT and our<br />

customers make the critical decisions regarding product direction and development.<br />

Contact<br />

Management<br />

Workflow/<br />

Approvals<br />

Estimating<br />

& Budget<br />

Production<br />

Time, Mileage<br />

& Expenses<br />

FM/Customer<br />

Care<br />

Post Contract<br />

& Planning<br />

MI/Role Based<br />

Dashboards &<br />

Reporting<br />

Auto-email &<br />

attachments<br />

House Build<br />

Plot Mgmt<br />

CONTRACT MANAGEMENT<br />

Procurement<br />

Excel &<br />

MS Office<br />

Integration<br />

Finance,<br />

Payroll & HR<br />

Vendor/<br />

Subcontractor<br />

Mgmt<br />

Email<br />

Archive<br />

Valuations<br />

& CVR<br />

Costing<br />

Alerting<br />

& Tasks<br />

Database<br />

Management<br />

Documents

SOFTWAREreview<br />

Boxing Clever<br />

Graphisoft adds VR support<br />

to the ARCHICAD experience with the<br />

latest release of the software<br />

If you are old enough, you might<br />

remember getting a View Master for<br />

Christmas, along with half a dozen<br />

discs showing some improbably sunny<br />

landscapes in 3D. I spent hours looking<br />

through them (if you want to know more,<br />

there are loads for sale in vintage toys on<br />

eBay) but, looking back, the distinct<br />

impression wasn't the images seen, but<br />

the technology - and even that had been<br />

superceded by 100 years or so.<br />

I was recently reminded of the View<br />

Master by Google's Carboard VR -fold-up<br />

cardboard boxes that convert into<br />

disposable Virtual Reality viewers when<br />

you insert your smart phone. They are<br />

ideal for handing out to clients who want<br />

to view their properties in virtual 3D<br />

walkthroughs, which is why Graphisoft has<br />

made them available to ARCHICAD users,<br />

who can convert their building models into<br />

viewable 3D, thus enabling users of their<br />

free BIMx viewer to explore models at will.<br />

Aside from enhanced modelling tools like<br />

Rhino and Grasshopper, integrating within<br />

ARCHICAD 20, Graphisoft has<br />

concentrated with the latest revision of the<br />

software on improving usability and the<br />

viewer's experience, with a new Properties<br />

Manager amongst other handy tools.<br />

We seem to have pretty much exhausted<br />

what extra features we can add to<br />

architectural geometry, as the tools we<br />

already have allow us to design anything<br />

we can dream up, thanks to things like<br />

morphing tools and algorithmic or<br />

generative design provided by Rhino and<br />

Grasshopper (covered in the last issue).<br />

Adding freeform modelling and scripting<br />

to parametric 3D modelling applications<br />

adds new dimensions to the concept of<br />

architectural design - not least, the<br />

addition of advanced concept modelling<br />

to ARCHICAD's traditional strengths in<br />

formal design and construction<br />

documentation.<br />

And talking of advanced modelling, there<br />

is a bonus in the latest version of<br />

ARCHICAD, namely the ability to support<br />

more accurate representations of NURBS<br />

(Non-uniform rational Basis spline) curves<br />

and surfaces. As a result, complex Rhino<br />

models can be imported directly into<br />

ARCHICAD 20 as Global GDL objects<br />

using native NURBS definitions, giving<br />

ARCHICAD users better control over them<br />

- of which more later.<br />

IT'S THE HOW, NOT THE WHAT<br />

The bulk of the latest upgrades to<br />

ARCHICAD concentrate on improving the<br />

user experience, making it easier to use<br />

the software and reorganising the way in<br />

which ARCHICAD tools are organised and<br />

how non-geometric information in a BIM<br />

model (such as manufacturers<br />

information, costs, fire ratings, etc.) are<br />

imported, created and used.<br />

Immediately apparent, though, is the<br />

refined user interface. Adding so many<br />

bells and whistles to the software probably<br />

went too far, and tended to detract from<br />

the main element - the model display<br />

Consequently, the toolbars have been<br />

reduced in size and toned down (a more<br />

muted two colour system) to give the<br />

display more prominence, but with the<br />

numerous features of the software still<br />

available in pull-down menus. Graphisoft<br />

has also added a Quick Options toolbar<br />

below the graphics display which gives<br />

quick access to frequently used features<br />

without having to use the Navigator.<br />

And there are now three levels of<br />

resolution available - low, medium and<br />

high - taking advantage of the higher<br />

resolution and retina displays becoming<br />

available to provide sharper resolutions in<br />

complex drawings.<br />

MODEL VIEWS AND FAVOURITES<br />

Rather than reducing the number of<br />

features available, though, a couple of<br />

new ones have been added. View tabs<br />

provides a drop-down list of available<br />

views, which can be used to save model<br />

views directly from the tab, irrespective of<br />

the view on display. If you are showing a<br />

floorplan, for instance, you can create and<br />

save a view from the model in any other<br />

mode. This saves the hassle of switching<br />

to a particular view before it can be saved.<br />

Access to Favourites has also been<br />

enhanced. All of the tools that you have<br />

used in a particular project are stored in<br />

the Favourites palette, supported by 2D<br />

and 3D thumbnail previews, will display<br />

their properties when you hover the<br />

mouse over them. Favourites are also<br />

available from individual element types -<br />

such as walls, doors, windows, etc. - and<br />

16<br />

November/December 2016

SOFTWAREreview<br />

Rhino, Grasshopper and ARCHICAD integration<br />

ARCHICAD 20 Graphical Favourites<br />

can be organised into individual folders to<br />

be used on a project, or exported to be<br />

shared across multiple projects. Once<br />

selected, all tools and components within<br />

Favourites are fully editable.<br />

ELEMENT PROPERTIES<br />

Properties in ARCHICAD are absolutely<br />

any type of information about an element<br />

that isn't geometric information - the 'I' bit<br />

of BIM - and can come from numerous<br />

sources: COBie, IFC, Excel or ARCHICAD<br />

GDL files, or keyed in directly. In earlier<br />

versions of ARCHICAD, property data was<br />

managed within individual property<br />

dialogue boxes - an onerous task when<br />

fire-ratings had to be applied, individually,<br />

to each type of element such as a wall,<br />

door or window. A new Property Manager<br />

dialogue box is also now available and<br />

can be used to define properties and<br />

allocate them to elements within different<br />

groups or categories.<br />

If property data is to be added from a<br />

non-CAD source, or from a different<br />

discipline, the Property import/export<br />

function allows users to export the<br />

property data and element types to project<br />

team members as an Excel file, which they<br />

can fill in, and send back. It’s an ideal tool<br />

for manufacturers to update all of the<br />

information on a full range of products for<br />

incorporation within each BIM model.<br />

GRAPHIC OVERRIDES<br />

Graphic Overrides is used to change the<br />

representation of model views to highlight<br />

different elements. Available in both 2D<br />

and 3D views, rules can be applied to the<br />

graphical parameters of any element. This<br />

is particularly useful for fire ratings, MEP,<br />

space types and usage, MEP elements<br />

and so on, specifying which graphic<br />

elements are to be changed for specific<br />

displays - colours, line types, surfaces etc.<br />

To take an example, using the properties<br />

manager to allocate different levels of fire<br />

resistance to different wall sections, each<br />

of these can be assigned a different<br />

colour using the graphic override. When<br />

selected, the model will display the<br />

appropriate walls with the chosen colour<br />

scheme. The original model will retain its<br />

standard graphic attributes.<br />

RENDERING AND VISUALISATION<br />

ARCHICAD 20 uses the latest Cinema 4D<br />

R16 rendering engine, which provides<br />

more accurate renderings with more<br />

realistic surfaces. The reflectance and<br />

specular levels make it easier to define the<br />

reflective characteristics of surfaces,<br />

together with enhanced backlight shaders<br />

that further enhance surface effects.<br />

The enhanced rendering engine provides<br />

improved global illuminance with highly<br />

realistic contact shadows, thanks to an an<br />

improved physical ray tracing engine<br />

boosting performance.<br />

In 3D perspective views, users can<br />

switch to any two part perspective in any<br />

camera position, which enables verticals<br />

in any 3D model view to remain as vertical<br />

in perspective views<br />

GOOGLE CARDBOARD VR<br />

BIMx is used to navigate 3D models in<br />

real-time. As Virtual Reality is now all the<br />

rage the viewing experience can now<br />

feel old hat unless you have the option to<br />

view the model in 3D. The good news is<br />

that you don't have to invest in an Oculus<br />

Rift or HTC Vive as Google’s Cardboard<br />

VR is cheap and simple enough for you<br />

to send to your client, who can download<br />

the BIMx app and explore your designs<br />

at their leisure. The instructions for<br />

moving around the model are shown on<br />

the smartphone display, and are<br />

activated by a simple, clickable point on<br />

the cardboard devices.<br />

CONCLUSION<br />

The integration of Rhino and<br />

Grasshopper within ARCHICAD 20 is a<br />

significant development. The degree of<br />

integration allows bidirectional links<br />

between all applications in real-time,<br />

providing an apparent native looking<br />

integration. Although algorithmic design<br />

looks complex, its foundation lies in<br />

being able to lay out complete logical<br />

workflows for each element of the<br />

design, and is a joy to use.<br />

The other major new feature - the ability<br />

to add building information to elements<br />

in a much more organised manner using<br />

the Property Manager - together with<br />

improved interoperability for sharing data<br />

throughout the full project team, make<br />

ARCHICAD 20 a very worthwhile update.<br />

www.graphisoft.co.uk<br />

November/December 2016 17

VIEWPOINT<br />

Are we there yet?<br />

As 2016 draws to a close, Jason Ruddle of Elecosoft muses on the BIM journey so far, and what<br />

2017 might hold for contractors who are continuing to transform around digital construction<br />

Jason Ruddle - Chief Operating<br />

Officer, Elecosoft<br />

The past few years have been<br />

tumultuous for construction<br />

companies. It is five years since<br />

the launch of BIM as a UK directive,<br />

and it only intensified this year. They<br />

have battled their way through a tough<br />

economy and been pushed to start a<br />

process of change which will see their<br />

businesses and modus operandi alter<br />

almost beyond recognition. Even the<br />

truism that construction always involves<br />

laying brick on brick is starting to<br />

change, thanks to huge developments<br />

in new and smart materials, and the<br />

rise and rise of off-site construction and<br />

pre-fabrication.<br />

Now, construction businesses must<br />

also cope with an extreme level of<br />

uncertainty. Not only must they<br />

consider the implications of Brexit,<br />

especially around possible limitation of<br />

labour movement, but now we must<br />

consider the global impact that may<br />

arise from the change of US<br />

administration. Trading may become<br />

less free, more fraught and more<br />

expensive, if signals from incoming<br />

leaders are to be believed. Our<br />

immediate trading environment is sure<br />

to be impacted by Brexit, on a timeline<br />

that is murky, at best. It has never been<br />

more vital for British businesses to be<br />

in the best possible shape, both<br />

operationally and financially, to<br />

navigate such choppy waters.<br />

DIGITAL CONSTRUCTION<br />

MOMENTUM<br />

The digitisation of construction is<br />

already a focus of the discussion<br />

around change, as it is not really a<br />

choice. However, done right, it will play<br />

a significant role in improving<br />

construction businesses' ability to see<br />

ahead, manage risk, drive best<br />

practices, and manage more efficient<br />

and effective operations and projects.<br />

BIM was the starting step on the<br />

digital path for many. A lot of hard work<br />

later, the first key milestone has<br />

passed. Firms which have not yet truly<br />

met their Level 2 BIM goals will be<br />

working hard in 2017 to do so. This will<br />

be the year that losing out on public<br />

sector contracts starts to bite if they do<br />

not, but further impetus will come from<br />

the fact that it is highly likely that we will<br />

see an acceleration of BIM adoption by<br />

private sector clients. It promises them,<br />

too, better visibility and efficiencies -<br />

but, even more vitally, it promises lower<br />

lifecycle costs and easier management,<br />

thanks to the rich data model that they<br />

gain in addition to their asset.<br />

Not only is the Government firmly<br />

standing behind BIM Level 2, it is now<br />

looking ahead at Level 3, and has<br />

outlined a vision of digital data<br />

supporting the entirety of building and<br />

infrastructure lifecycles, enabling the<br />

development of smart cities,<br />

infrastructure and services.<br />

So, the answer to the title question is,<br />

of course, no. We aren't there yet. As<br />

Confucius said, roads were meant for<br />

journeys, not destinations - and that<br />

couldn't be more true of BIM. In fact<br />

we've barely scratched the surface.<br />

SHIFTED WAYS OF THINKING<br />

If BIM was only a step on the road, it<br />

was nonetheless significant. It marked<br />

18<br />

November/December 2016

VIEWPOINT<br />

a paradigm shift for construction: from<br />

thinking in a linear way about the<br />

process of building, to a threedimensional<br />

outlook which was more<br />

connected with the design intentions of<br />

architects, more comprehensible for<br />

clients, and easier to communicate to<br />

sub-contractors.<br />

But that shift hasn't finished yet. 2017<br />

will be, we confidently predict, the year<br />

when the emphasis moves to 5D<br />

thinking. En route, construction<br />

companies must first fully embrace 4D,<br />

but we believe they will move on<br />

rapidly.<br />

4D BIM, which blends BIM data from<br />

3D models with time, has become<br />

familiar. The 4D BIM module of Asta<br />

Powerproject has certainly seen<br />

increasing adoption. Even as<br />

contractors continue to explore how 3D<br />

visualisation can enhance project<br />

management, we believe the focus<br />

should move to 5D planning and the<br />

project delivery as fast as possible.<br />

5D planning is an essential next stage<br />

of the journey. Only with this can<br />

contractors fully integrate project cost<br />

plans with programmes - and keep<br />

them in step throughout the build.<br />

Embracing 5D BIM will deliver benefits<br />

in spades. Contractors will be able to<br />

go beyond cost estimation to achieve<br />

true cost control. They will be able to<br />

manage inevitable supply chain issues<br />

with greater agility, and to project and<br />

plan for the impact of a supplier<br />

collapse, a manufacturing delay, a<br />

missed key delivery, in both cost AND<br />

time terms - and communicate it all to<br />

clients.<br />

5D BIM will not only be a vital step<br />

towards Level 3. The Digital Built Britain<br />

vision not only envisages fully open<br />

BIM, but also its application for better<br />

long-term sustainable, manageable,<br />

and smart built environments. The<br />

information models that construction<br />

companies build today will be critical<br />

for clients, as they look to empower<br />

managers with smart building<br />

management controls, and demand<br />

data-driven FM services. Unless<br />

builders gets to grips with 5D BIM,<br />

there will be a far weaker foundation for<br />

clients to leverage BIM data to support<br />

long-term operations, termed '6D' BIM.<br />

LOOKING FORWARDS<br />

2017 must be a year not only of forward<br />

momentum, but of consolidation. Many<br />

changes were implemented this year:<br />

strategies were developed, BIM<br />

departments established, champions<br />

identified and systems trialled. The next<br />

must be one of driving for stability,<br />

embedding the learnings of the past,<br />

and creating concrete plans for the<br />

future. Newly-minted digital<br />

construction experts must educate and<br />

spread their knowledge to reach every<br />

corner. This will be the year where<br />

many contractors finally start to see<br />

benefits and savings from their first BIM<br />

projects - although only when 5D BIM is<br />

fully embraced do we believe such<br />

savings will hit their peak. As tangible<br />

commercial benefits emerge, it will<br />

further incentivise clients to demand<br />

BIM - and so the cycle will continue.<br />

Digital transformation is not yet<br />

complete - either of projects, or of the<br />

businesses that run them. We also<br />

expect this year to see a greater<br />

emphasis on mobility, with greater<br />

engagement and involvement in the<br />

BIM value chain of managers on site,<br />

subcontractors and suppliers. Whether<br />

it is about uploading site progress<br />

updates seamlessly from mobiles into<br />

the master programme, or better<br />

information gathering to enrich BIM<br />

models, construction will undoubtedly<br />

be a more collaborative sector.<br />

Software developers have a significant<br />

role to play. We are working together<br />

with our customers to meet their needs.<br />

The aim must be for developers to<br />

deliver tools that will enable contractors<br />

to improve their businesses, as well as<br />

their projects, ensuring that systems<br />

can do more than simply exchange<br />

data, integrating in ways that benefit<br />

business, delivering functionality to<br />

drive success.<br />

As we head into 2017, uncertainty<br />

remains the only thing contractors can<br />

rely upon. They must do their utmost to<br />

reduce risk and exert control through<br />

better forward visibility. They need to<br />

embrace digital change to take<br />

advantage of digital data, as well as to<br />

secure business around BIM, and be<br />

part of a smarter and Digitally Built<br />

Britain of the future. We're not there yet<br />

but we've achieved a huge amount<br />

already. Elecosoft wishes every<br />

construction contractor and supplier a<br />

confident and productive New Year -<br />

and we look forward hugely to seeing<br />

what 2017 will bring.<br />

www.astapowerproject.com<br />

Twitter @astapmsoftware<br />

November/December 2016 19

CASEstudy<br />

Rebar Prefabrication<br />

Midland Steel finds that using Tekla Structures to plan Rebar fabrication leads to considerable<br />

savings in all areas of a project<br />

Midland Steel is the fastest<br />

growing reinforcing steel<br />

fabricator in the United Kingdom<br />

and Ireland and offers a diverse range of<br />

reinforcing steel products and<br />

accessories, from accredited cut and<br />

bent reinforcement and standard and<br />

special mesh products, through to<br />

advance 3D detailing and prefabrication<br />

services. The company has the technical<br />

capability and capacity to supply any<br />

reinforced concrete project, regardless<br />

of complexity or size.<br />

REBAR FABRICATIONS<br />

In the top tier of independent fabricators<br />

in the UK and Ireland, Midland Steel's<br />

bent rebar fabricating operation centres<br />

on value engineering and rationalisation.<br />

As such, one of the key drivers to the<br />

business is to promote collaborative<br />

working within its industry.<br />

Tony Woods, Managing Director at<br />

Midland Steel, explained the company's<br />

strategy. "From our experience, within the<br />

construction industry and working on<br />

projects that include a BIM process, we<br />

have discovered that there are many<br />

business benefits that come with<br />

adopting an open and joint approach to<br />

a project. For example, we are currently<br />

trying to get to a stage in the business<br />

where we can collaboratively work with<br />

everybody to reduce delays and costs.<br />

The benefits of everyone involved in a<br />

project using 3D modelling are huge as<br />

it provides a greater understanding of<br />

how the building works during the<br />

construction - which ultimately results in<br />

a smooth process all round."<br />

Midland Steel uses Tekla Structures<br />

because of its ability to precisely build<br />

constructible models to visualise larger<br />

quantities of material and produce<br />

accurate schedules and drawings from<br />