Natural News - Winter 2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

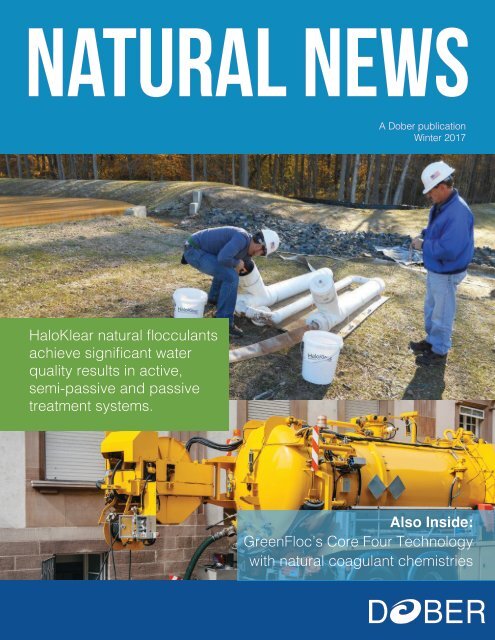

natural news<br />

A Dober publication<br />

<strong>Winter</strong> <strong>2017</strong><br />

HaloKlear natural flocculants<br />

achieve significant water<br />

quality results in active,<br />

semi-passive and passive<br />

treatment systems.<br />

Also Inside:<br />

GreenFloc’s Core Four Technology<br />

with natural coagulant chemistries

Table of Contents:<br />

WORKING GREENER<br />

The Dual Product System...................................3<br />

WHAT’S HAPPENING<br />

IECA Trade Show – Feb. 21-24..........................4<br />

REAL WORLD APPLICATIONS<br />

Significant Savings in Oil and<br />

Water Separation Case Study............................5<br />

PRODUCT SPOTLIGHT<br />

The GreenFloc Core Four...................................7<br />

GET TO KNOW DOBER<br />

Dober-at-a-Glance.............................................8<br />

Letter from the editor<br />

Welcome to the first edition of <strong>Natural</strong> <strong>News</strong>!<br />

This new magazine is designed to deliver the most<br />

important industry developments and featured water<br />

treatment technologies, along with stories of real-world<br />

success with Dober’s portfolio of natural water treatment<br />

chemistries.<br />

We hope you’ll learn something valuable from this and<br />

each upcoming issue – and invite you to share your<br />

questions, comments and success stories with us for<br />

future publication. As always, don’t hesitate to give us a<br />

call to discuss your specific needs. We look forward to<br />

hearing from you!<br />

info@dober.com<br />

800.323.4983<br />

HAVE YOU SEEN OUR NEW WEBSITE?<br />

We launched our website in January with an all new look.<br />

Visit us at dober.com/water_treatment<br />

2

Dual Product<br />

System (DPS)<br />

HaloKlear products are used to treat storm, industrial and<br />

municipal water, including pollutants in construction site runoff,<br />

by reversing the process of water contamination through a<br />

combination of advanced, environmentally friendly, natural<br />

flocculant technologies.<br />

When it comes to handling dirty water, HaloKlear has built its<br />

reputation on creating reliable, effective and safe solutions that<br />

can solve all kinds of sediment control problems. The Dual<br />

Product System has been proven to have zero toxicity.<br />

HaloKlear’s Dual Product System (DPS) uses natural flocculants<br />

that completely biodegrade through simple enzymatic activity,<br />

resulting in no bioaccumulation.<br />

The HaloKlear Residual Test Kit is used to ensure chemical<br />

treatment is operating efficiently and effectively. This knowledge is<br />

comforting for regulators, contractors and the general public, who<br />

can rest assured that the environment is the #1 priority.<br />

Most importantly, HaloKlear’s DPS has a best-in-class<br />

performance and has proven itself under vastly varied conditions<br />

around the world. It is used in systems ranging from active<br />

treatment for mobile water treatment, semi-passive pumped water<br />

incorporating coarse filtration and geotextile bags, and completely<br />

passive models, such as bio-filtration and check dams. HaloKlear<br />

DPS is designed to give contractors and industries in need of<br />

water treatment solutions the essential tool they need to meet<br />

state and national discharge regulations, as well as EPA Effluent<br />

Limitation Guidelines (ELGs).<br />

working greener<br />

A winning equation<br />

lbp-2101 +<br />

liquifloc = dps<br />

LIQUID DPS SYSTEM<br />

LBP-2101<br />

LiquiFloc<br />

Functions in active<br />

treatment systems<br />

DRY DPS SYSTEM<br />

DBP-2100 socks<br />

GelFloc socks<br />

Functions in active<br />

semi-passive and passive<br />

treatment environments<br />

LOOSE DPS SYSTEM<br />

MB Kits<br />

Functions in<br />

passive treatment<br />

environments<br />

For a downloadable copy of our DPS guide,<br />

contact us at info@dober.com or go to<br />

dober.com/water_treatment.<br />

A CLEAR ADVANTAGE FOR YOUR OPERATION<br />

We’ll help you choose from a portfolio of HaloKlear natural flocculants—from 100% biodegradable natural<br />

flocculants to hybrid flocculants—all of which offer a greener alternative to commodity chemicals.<br />

3<br />

3<br />

3<br />

3<br />

Effective alone or paired with other chemistries<br />

Appropriate for active, semi-passive and passive applications<br />

Use with existing equipment or as part of a customized solution<br />

Ensure regulatory compliance with on-site residual testing in real-time<br />

3

what’s happening<br />

Join us at the world’s largest soil and water event – the <strong>2017</strong> Environmental Connection hosted<br />

by the International Erosion Control Association in Atlanta, GA on February 21 – 24!<br />

Come visit us in Booth 122 to get a peak at our lineup of natural<br />

coagulants and flocculants for <strong>2017</strong>.<br />

Learn about our innovative, all-natural stormwater treatment solutions by picking up a copy of our<br />

new Dual Product System brochure, and talk with one of our Water Treatment Specialists to hear<br />

how you can test out our chemistries for your next project.<br />

we’ve never<br />

killed a fish<br />

Don’t just clean the water, clean the environment<br />

Our chemistries are less toxic when water is returned to its natural<br />

environment. All of HaloKlear’s products exhibit exceptionally low toxicity,<br />

and the Dual Product System has been proven to have zero toxicity.*<br />

No bioaccumulation concerns exist when and where HaloKlear products<br />

are used, and our products are 100% biodegradable through enzymatic<br />

activity.<br />

* Third-party toxicity testing concluded that no fish were killed by the <br />

Dual Product System (DPS) when both parts were used in combination<br />

of following Best Management Practices.<br />

Clean Water.<br />

<strong>Natural</strong>ly.<br />

4

Real World Applications<br />

Significant Savings<br />

in Oil and Water Separation<br />

Oil Refinery<br />

Total Project Benefits<br />

$35,000 savings in monthly spend<br />

20% reduction in Aeration Inlet COD<br />

44% reduction in Aeration Inlet Oil/Grease<br />

Case<br />

Study<br />

The Challenge: A large oil refinery in the<br />

US committed to safety, the environment, and<br />

continuously improving performance began a<br />

cost-cutting initiative in 2013. The Refinery<br />

management team tasked the waterside<br />

chemical supplier, an existing Dober partner, to<br />

reduce chemical spending plant wide and<br />

improve wastewater treatment plant efficiency.<br />

Dober’s partner decided to focus on finding a<br />

new coagulant for treating the oily waste<br />

streams at the PSO and IGF units within the<br />

wastewater treatment plant.<br />

The Refinery’s waterside chemical supplier<br />

spent the first several months bench testing<br />

traditional synthetic and inorganic coagulants<br />

such as, polyDADMAC, polyamine, and alum<br />

blends with little to no improvement over the<br />

existing polyDADMAC/PAC blend being used.<br />

After attempting to find a solution on their own,<br />

the waterside chemical supplier presented this<br />

challenge to its partner Dober, the industry<br />

leader in custom formulated natural coagulant<br />

and flocculant chemistries with over 25 years of<br />

research, innovation, and success.<br />

The Solution: Dober’s Water Treatment<br />

Division treats every partner’s challenge with the<br />

highest level of customer service, close attention<br />

to detail, continuous validation, and custom<br />

formulations of our GreenFloc natural coagulant<br />

product line. The GreenFloc product line<br />

consists of environmentally friendly, natural<br />

coagulants for use in a wide variety of water<br />

treatment applications. GreenFloc natural<br />

coagulants provide better performance, reduce<br />

overall use cost, and are significantly less toxic<br />

to the environment.<br />

Dober’s GreenFloc natural coagulant, GFT<br />

6173, was specifically developed for treating the<br />

oily waste streams at the PSO and IGF units at<br />

this particular refinery. After developing GFT<br />

6173, Dober validated product performance with<br />

in-house bench studies over the course of<br />

several months. In-house bench studies allowed<br />

Dober to validate GFT 6173’s performance on a<br />

multitude of wastewater samples from the<br />

refinery to ensure we had consistent<br />

GreenFl c ®<br />

NATURAL COAGULANTS<br />

5

Real World Applications<br />

performance with every type of oily waste<br />

stream encountered in the full-scale application.<br />

Dober also gauged GFT 6173’s performance<br />

against the existing treatment and all other<br />

traditional synthetic and inorganic coagulant<br />

blends. After validating product performance and<br />

dosage requirements in our world-class<br />

laboratories, the product was brought on-line for<br />

a full-scale, two-month trial period. Improved<br />

product performance and a reduction in<br />

chemical costs were realized during the<br />

two-month trial period.<br />

The Results:<br />

Dober’s GreenFloc natural coagulant<br />

technology successfully reduced Aeration Inlet<br />

COD by 20%, Aeration Inlet Oil/Grease by<br />

44%, and average monthly spend by roughly<br />

$35,000. These results allowed the new<br />

natural coagulant to be put into service<br />

full-time and has continued the same great<br />

sustainable performance day-in and day-out.<br />

When it comes to finding innovative solutions<br />

for the most challenging wastewater treatment<br />

applications, turn to Dober first. Dober’s work,<br />

not only as a supplier but also as an<br />

innovative customer solutions partner, is why<br />

we are the industry leaders in natural<br />

coagulant and flocculant technology.<br />

Area of Improvement Results without Coagulant Results with Coagulant<br />

Coagulant Cost / Month, Avg $96,000 $62,000<br />

Aeration Inlet COD, Avg ppm 511 407<br />

Aeration Inlet Oil / Grease, ppm 32 14<br />

For additional information contact us at: 800.323.4983 • doberinfo@dober.com • www.dober.com<br />

The GreenFloc product line consists of environmentally friendly, natural<br />

coagulants for use in a wide variety of water treatment applications.<br />

GreenFloc natural coagulants provide better performance, reduce overall<br />

use cost, and are significantly less toxic to the environment.<br />

GreenFl c<br />

NATURAL COAGULANTS ®<br />

D<br />

BER<br />

© <strong>2017</strong> | All rights reserved | GFT_01940_3<br />

6

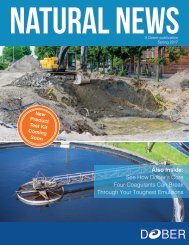

product spotlight – Greenfloc<br />

New Year, New Routine:<br />

Old habits are hard to break, but emulsions aren’t with<br />

Dober’s<br />

Core Four<br />

technology<br />

Your<br />

operator<br />

before the<br />

Core Four<br />

Exercise experts know that strong core muscles<br />

help to stabilize the human body.<br />

Water treatment experts know that Dober Water Treatment’s “core Four”<br />

natural coagulant chemistries, specially formulated for Centralized Waste<br />

Treatment facilities, can bring new stability and efficiency to your water<br />

treatment operation—helping it become greener, cleaner and leaner.<br />

Dober knows that seeing is believing. So think of the “core Four” as<br />

your personal trainer in a box, ready to help you take on your toughest<br />

emulsions with a customized, natural coagulant regimen.<br />

Dober’s natural coagulants can break any emulsion using less heat<br />

and less chemistry—without lowering pH levels—while cost effectively<br />

producing higher oil quality and a cleaner effluent. Test it for yourself<br />

with our Core Four test kit!<br />

We break your emulsion,<br />

not your bank account.<br />

Your<br />

operator<br />

after the<br />

Core Four<br />

Let Us Prove It – We’ll help you find the best<br />

solution so there is no risk to you.<br />

Give us a call at 800.323.4983 to speak with<br />

a Water Treatment Specialist.<br />

7

Get to know Dober<br />

D<br />

BER<br />

FOUNDED<br />

IN 1957<br />

by John F. Dobrez<br />

Soulful dedication to<br />

making our world a better,<br />

cleaner place through<br />

exceptional chemistry<br />

and brilliant technology<br />

OUR CORE<br />

VALUES<br />

OUR<br />

BUSINESS<br />

FORMULATED DETERGENTS<br />

WATER TREATMENT<br />

COOLING TOWER TREATMENT<br />

®<br />

COOLANT ADDITIVES<br />

NOW IN OUR<br />

SECOND<br />

GENERATION<br />

OF LEADERSHIP<br />

OPERATIONS SOFTWARE<br />

Dober is committed to customer service, innovation and<br />

providing exceptional resources for applied research<br />

and development.<br />

This combination is unmatched by any other competitor.<br />

These strengths also make us a valuable partner for<br />

customers with unique challenges in a wide range of<br />

industries.<br />

We create excellent product solutions that work<br />

effectively in the toughest applications while always<br />

putting customers first.<br />

It’s a passion that’s upheld by all employees within all<br />

divisions of our organization. So when we see consistently<br />

high ratings and favorable comments on client satisfaction<br />

surveys—for both our products and services— we couldn’t<br />

be more pleased.<br />

We’ve created a friendly, caring environment where<br />

people stay and make a career with our family.<br />

Of course, treating our own employees well also leads to a<br />

happier, more motivated, service-centric organization.<br />

Our expertise in Chemistry & Technology, coupled with<br />

the drive to continually improve, sets us apart.<br />

Our community of chemists, PhDs and engineers work<br />

to develop solutions that are at the forefront of today’s<br />

emerging technologies.<br />

A family business, we’re here for the long term.<br />

Proud of our heritage and the success we’ve achieved,<br />

we look forward to continued groundbreaking innovation<br />

and product development in the markets we serve, further<br />

expansion into global markets, and to future generations of<br />

leadership from within.<br />

Phone: 630.410.7300 | Toll Free: 800.323.4983<br />

NATURAL FLOCCULANTS ®<br />

11230 Katherine’s Crossing | Woodridge, IL 60517<br />

info@dober.com<br />

www.dober.com D BER<br />

GFT_02014_V3