Vol FW+40/0(1) Model Specifications - Lossinweightfeeder.com

Vol FW+40/0(1) Model Specifications - Lossinweightfeeder.com

Vol FW+40/0(1) Model Specifications - Lossinweightfeeder.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FW40/0Plus, FW40/1Plus <strong>Model</strong> <strong>Specifications</strong><br />

Conversion of FW40/0Plus or FW40/1Plus to a Twin Screw Feeder<br />

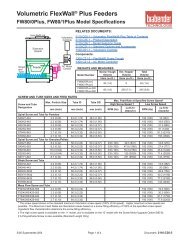

TWIN SCREW AND TUBE SIZES AND FEED RATES<br />

Screw and Tube<br />

Designation<br />

Twin Concave Screws and Tube<br />

Max. Particle Size Tube ID<br />

Twin Screw Insert<br />

Easy Change Design Option for FW40Plus Feeders<br />

FlexWall ® Plus feeders with a Swing Motor Mount have the feature of<br />

optionally switching from a single screw to a twin screw mechanism. This<br />

makes the feeder much more flexible when the ingredient being fed changes<br />

and the wiping action of a concave screw is desirable (floodable or cohesive<br />

ingredients). The twin screw drive gearbox is enclosed in the Insert housing!<br />

Change-over only requires swinging the motor out of the way, removing the<br />

single screw unit, replacing the screw tube and inserting the twin screw unit.<br />

Notes: The Twin Concave Screws are only suitable for powders. Consult<br />

factory before using the Twin Screw Insert in single screw feeders with the<br />

high screw speed.<br />

mm (inch) mm (inch) RPM (Hz)<br />

Removable with Ingredient still in the FlexWall ® Screw Trough!<br />

FlexWall ® 40 Plus feeders are available with a special Easy Change design.<br />

In this design, the outer housing, FlexWall ® screw trough, Screw and Tube<br />

can be removed as a single assembly. This way, the ingredient being<br />

fed can be changed quickly and without having to <strong>com</strong>pletely empty the<br />

ingredient from the screw trough. Or, for applications that require the screw<br />

trough, screw or tube to be cleaned, another assembly can be installed<br />

virtually eliminating downtime during the cleaning procedure!<br />

Change-over only requires releasing two latches at the back of the feeder.<br />

The assembly is then slid forward, then up. The next FlexWall ® Screw<br />

Trough, Screw and Tube assembly is then latched into place and the feeder<br />

is ready to go!<br />

Order Option ST-10.<br />

Max. Feed Rate at Specified Screw Speed*<br />

High Screw Speed** Low Screw Speed<br />

cu.ft./hr<br />

(liters/hr)<br />

RPM (Hz)<br />

cu.ft./hr<br />

(liters/hr)<br />

TC20/12-200T 0.3 (0.01) 20 (0.79) 192 (100) 0.502 (14.2)<br />

TC20/11-223T 0.7 (0.03) 22.3 (0.88) 192 (100) 0.93 (26.3)<br />

TC20/20-223T 0.7 (0.03) 22.3 (0.88) 192 (100) 1.86 (52.7)<br />

* The screw speed shown is the standard maximum <strong>Vol</strong>umetric screw speed (100% of full speed). Higher maximum screw<br />

speeds are possible. The Maximum Feed Rates are theoretical values based on a screw filling efficiency of 100% at the<br />

specified screw speed. Ingredient flow characteristics determine the screw filling efficiency.<br />

** The high screw speed is only available on ‘/1’ models. Consult factory for applications that require high speed twin screws but<br />

do not need agitation.<br />

3/05 Supersedes 8/04 Page 2 of 5 Document: 2110-C30-1