Vol FW+40/0(1) Model Specifications - Lossinweightfeeder.com

Vol FW+40/0(1) Model Specifications - Lossinweightfeeder.com

Vol FW+40/0(1) Model Specifications - Lossinweightfeeder.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

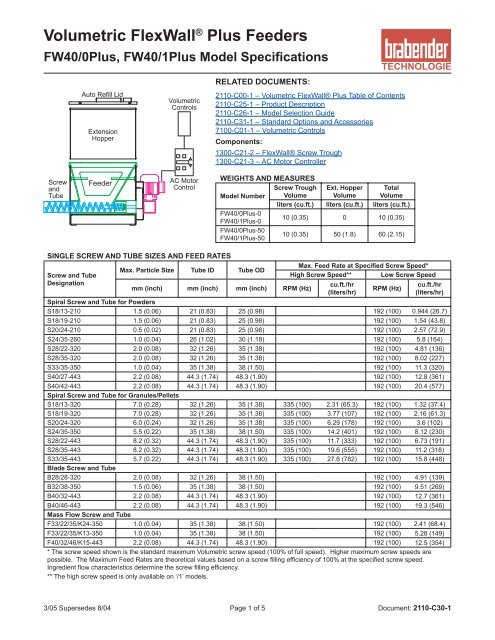

<strong>Vol</strong>umetric FlexWall ® Plus Feeders<br />

FW40/0Plus, FW40/1Plus <strong>Model</strong> <strong>Specifications</strong><br />

Screw<br />

and<br />

Tube<br />

Auto Refill Lid<br />

Extension<br />

Hopper<br />

Feeder<br />

<strong>Vol</strong>umetric<br />

Controls<br />

AC Motor<br />

Control<br />

SINGLE SCREW AND TUBE SIZES AND FEED RATES<br />

Screw and Tube<br />

Designation<br />

RELATED DOCUMENTS:<br />

2110-C00-1 – <strong>Vol</strong>umetric FlexWall® Plus Table of Contents<br />

2110-C25-1 – Product Description<br />

2110-C26-1 – <strong>Model</strong> Selection Guide<br />

2110-C31-1 – Standard Options and Accessories<br />

7100-C01-1 – <strong>Vol</strong>umetric Controls<br />

Components:<br />

Max. Particle Size Tube ID Tube OD<br />

1300-C21-2 – FlexWall® Screw Trough<br />

1300-C21-3 – AC Motor Controller<br />

WEIGHTS AND MEASURES<br />

Screw Trough Ext. Hopper Total<br />

<strong>Model</strong> Number <strong>Vol</strong>ume <strong>Vol</strong>ume <strong>Vol</strong>ume<br />

liters (cu.ft.) liters (cu.ft.) liters (cu.ft.)<br />

FW40/0Plus-0<br />

FW40/1Plus-0<br />

10 (0.35) 0 10 (0.35)<br />

FW40/0Plus-50<br />

FW40/1Plus-50<br />

10 (0.35) 50 (1.8) 60 (2.15)<br />

mm (inch) mm (inch) mm (inch) RPM (Hz)<br />

Max. Feed Rate at Specified Screw Speed*<br />

High Screw Speed** Low Screw Speed<br />

cu.ft./hr<br />

(liters/hr)<br />

RPM (Hz)<br />

cu.ft./hr<br />

(liters/hr)<br />

Spiral Screw and Tube for Powders<br />

S18/13-210 1.5 (0.06) 21 (0.83) 25 (0.98) 192 (100) 0.944 (26.7)<br />

S18/19-210 1.5 (0.06) 21 (0.83) 25 (0.98) 192 (100) 1.54 (43.8)<br />

S20/24-210 0.5 (0.02) 21 (0.83) 25 (0.98) 192 (100) 2.57 (72.9)<br />

S24/35-260 1.0 (0.04) 26 (1.02) 30 (1.18) 192 (100) 5.8 (164)<br />

S28/22-320 2.0 (0.08) 32 (1.26) 35 (1.38) 192 (100) 4.81 (136)<br />

S28/35-320 2.0 (0.08) 32 (1.26) 35 (1.38) 192 (100) 8.02 (227)<br />

S33/35-350 1.0 (0.04) 35 (1.38) 38 (1.50) 192 (100) 11.3 (320)<br />

S40/27-443 2.2 (0.08) 44.3 (1.74) 48.3 (1.90) 192 (100) 12.8 (361)<br />

S40/42-443 2.2 (0.08) 44.3 (1.74) 48.3 (1.90) 192 (100) 20.4 (577)<br />

Spiral Screw and Tube for Granules/Pellets<br />

S18/13-320 7.0 (0.28) 32 (1.26) 35 (1.38) 335 (100) 2.31 (65.3) 192 (100) 1.32 (37.4)<br />

S18/19-320 7.0 (0.28) 32 (1.26) 35 (1.38) 335 (100) 3.77 (107) 192 (100) 2.16 (61.3)<br />

S20/24-320 6.0 (0.24) 32 (1.26) 35 (1.38) 335 (100) 6.29 (178) 192 (100) 3.6 (102)<br />

S24/35-350 5.5 (0.22) 35 (1.38) 38 (1.50) 335 (100) 14.2 (401) 192 (100) 8.12 (230)<br />

S28/22-443 8.2 (0.32) 44.3 (1.74) 48.3 (1.90) 335 (100) 11.7 (333) 192 (100) 6.73 (191)<br />

S28/35-443 8.2 (0.32) 44.3 (1.74) 48.3 (1.90) 335 (100) 19.6 (555) 192 (100) 11.2 (318)<br />

S33/35-443 5.7 (0.22) 44.3 (1.74) 48.3 (1.90) 335 (100) 27.6 (782) 192 (100) 15.8 (448)<br />

Blade Screw and Tube<br />

B28/28-320 2.0 (0.08) 32 (1.26) 38 (1.50) 192 (100) 4.91 (139)<br />

B32/38-350 1.5 (0.06) 35 (1.38) 38 (1.50) 192 (100) 9.51 (269)<br />

B40/32-443 2.2 (0.08) 44.3 (1.74) 48.3 (1.90) 192 (100) 12.7 (361)<br />

B40/46-443 2.2 (0.08) 44.3 (1.74) 48.3 (1.90) 192 (100) 19.3 (546)<br />

Mass Flow Screw and Tube<br />

F33/22/35/K24-350 1.0 (0.04) 35 (1.38) 38 (1.50) 192 (100) 2.41 (68.4)<br />

F33/22/35/K13-350 1.0 (0.04) 35 (1.38) 38 (1.50) 192 (100) 5.28 (149)<br />

F40/32/46/K15-443 2.2 (0.08) 44.3 (1.74) 48.3 (1.90) 192 (100) 12.5 (354)<br />

* The screw speed shown is the standard maximum <strong>Vol</strong>umetric screw speed (100% of full speed). Higher maximum screw speeds are<br />

possible. The Maximum Feed Rates are theoretical values based on a screw filling efficiency of 100% at the specified screw speed.<br />

Ingredient flow characteristics determine the screw filling efficiency.<br />

** The high screw speed is only available on ‘/1’ models.<br />

3/05 Supersedes 8/04 Page 1 of 5 Document: 2110-C30-1

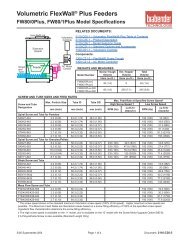

FW40/0Plus, FW40/1Plus <strong>Model</strong> <strong>Specifications</strong><br />

Conversion of FW40/0Plus or FW40/1Plus to a Twin Screw Feeder<br />

TWIN SCREW AND TUBE SIZES AND FEED RATES<br />

Screw and Tube<br />

Designation<br />

Twin Concave Screws and Tube<br />

Max. Particle Size Tube ID<br />

Twin Screw Insert<br />

Easy Change Design Option for FW40Plus Feeders<br />

FlexWall ® Plus feeders with a Swing Motor Mount have the feature of<br />

optionally switching from a single screw to a twin screw mechanism. This<br />

makes the feeder much more flexible when the ingredient being fed changes<br />

and the wiping action of a concave screw is desirable (floodable or cohesive<br />

ingredients). The twin screw drive gearbox is enclosed in the Insert housing!<br />

Change-over only requires swinging the motor out of the way, removing the<br />

single screw unit, replacing the screw tube and inserting the twin screw unit.<br />

Notes: The Twin Concave Screws are only suitable for powders. Consult<br />

factory before using the Twin Screw Insert in single screw feeders with the<br />

high screw speed.<br />

mm (inch) mm (inch) RPM (Hz)<br />

Removable with Ingredient still in the FlexWall ® Screw Trough!<br />

FlexWall ® 40 Plus feeders are available with a special Easy Change design.<br />

In this design, the outer housing, FlexWall ® screw trough, Screw and Tube<br />

can be removed as a single assembly. This way, the ingredient being<br />

fed can be changed quickly and without having to <strong>com</strong>pletely empty the<br />

ingredient from the screw trough. Or, for applications that require the screw<br />

trough, screw or tube to be cleaned, another assembly can be installed<br />

virtually eliminating downtime during the cleaning procedure!<br />

Change-over only requires releasing two latches at the back of the feeder.<br />

The assembly is then slid forward, then up. The next FlexWall ® Screw<br />

Trough, Screw and Tube assembly is then latched into place and the feeder<br />

is ready to go!<br />

Order Option ST-10.<br />

Max. Feed Rate at Specified Screw Speed*<br />

High Screw Speed** Low Screw Speed<br />

cu.ft./hr<br />

(liters/hr)<br />

RPM (Hz)<br />

cu.ft./hr<br />

(liters/hr)<br />

TC20/12-200T 0.3 (0.01) 20 (0.79) 192 (100) 0.502 (14.2)<br />

TC20/11-223T 0.7 (0.03) 22.3 (0.88) 192 (100) 0.93 (26.3)<br />

TC20/20-223T 0.7 (0.03) 22.3 (0.88) 192 (100) 1.86 (52.7)<br />

* The screw speed shown is the standard maximum <strong>Vol</strong>umetric screw speed (100% of full speed). Higher maximum screw<br />

speeds are possible. The Maximum Feed Rates are theoretical values based on a screw filling efficiency of 100% at the<br />

specified screw speed. Ingredient flow characteristics determine the screw filling efficiency.<br />

** The high screw speed is only available on ‘/1’ models. Consult factory for applications that require high speed twin screws but<br />

do not need agitation.<br />

3/05 Supersedes 8/04 Page 2 of 5 Document: 2110-C30-1

FW40/0Plus, FW40/1Plus <strong>Model</strong> <strong>Specifications</strong><br />

MATERIALS OF CONSTRUCTION<br />

FlexWall ® Flexible Screw Trough White polyurethane, resistant to abrasion, mild acids and alkaline solutions, FDA approvable <strong>com</strong>pound<br />

Feeder Housing 304SS, 2B finish inside, mirror finish outside<br />

Screw and Tube 304SS, 2B finish, electropolished<br />

Screw Drive Shaft 304SS, Polyurethane<br />

Screw Drive Shaft Seals Lip Seals (2)<br />

Extension Hopper and Lid 304SS, 2B finish inside, mirror finish outside<br />

Gaskets Neoprene<br />

MECHANICAL PROCESS CONNECTIONS<br />

Refill (on Lid) Pipe stub connection. See Mechanical Drawing for location and size.<br />

Pipe stub connection. See Mechanical Drawing for location and size. The vent allows dusty air to escape during refill<br />

Vent (on Lid) and atmospheric air to enter during feeding. Brabender offers a vent filter for pellets or non-dusty ingredients. For<br />

powders, dust collector is by others.<br />

Outlet Standard is horizontal from screw tube, optional is vertical outlet.<br />

ENVIRONMENTAL SPECIFICATIONS<br />

Temperature<br />

Ambient<br />

Ingredient<br />

Operating: 0° to 40°C (32° to 104°F), Storage: -40° to 40°C (-40° to 104°F)<br />

Continuous: 0° to 60°C (32° to 140°F), Intermittent: -20° to 60°C (-4° to 140°F)<br />

Humidity<br />

Ambient<br />

Ingredient<br />

5% to 95% (no condensation)<br />

The ingredient flow characteristics may vary with excessive humidity. The feeder must be dry when feeding.<br />

Pressure<br />

Altitude<br />

Ingredient<br />

To 10,000 feet (3,048 m)<br />

The pressure inside the feeder should be the same as outside the feeder.<br />

Vibration Normal plant vibration does not affect performance.<br />

ACCURACY<br />

Measuring Criteria Data sample time of 1 minute<br />

Feed Range 15:1 screw speed range<br />

Repeatability ± 1% to 5% depending on ingredient flow properties<br />

Linearity ± 0.5% over a screw speed range of 10:1 for each screw type<br />

Standard Options and Accessories (See Document 2110-C31-1 for Details)<br />

Extension Hoppers and Lids<br />

XH-2(A/B) Extension Hopper Lid<br />

Feeder Lid with Integrated<br />

XH-3A Safety Grate (No Extension<br />

Hopper)<br />

Feeder Lid with Inlet and Vent<br />

XH-3B Connection (No Extension<br />

Hopper)<br />

XH-4B Extension Hopper Safety Grate<br />

Flanged Inlet on Extension<br />

XH-6<br />

Hopper Lid<br />

Bag Loading Hopper with<br />

XH-7<br />

Safety Grate and Lid<br />

XH-8 Extension Hopper Handles<br />

Screw and Tube Options<br />

ST-2A Vertical Outlet<br />

ST-2B Outlet Plunger Valve<br />

ST-2C Outboard Screw Bearing<br />

ST-3 Tube Support with Guy Wire<br />

ST-5 Air Purged Seal<br />

Easy Change Screw Trough,<br />

ST-10<br />

Screw and Tube Design<br />

Additional Easy Change<br />

ST-11 Housing, Screw Trough, Screw<br />

and Tube<br />

Optional Materials of Construction<br />

MC-2B<br />

Conductive Polyurethane<br />

FlexWall ® Screw Trough<br />

MC-2C<br />

High Chemical Resistance<br />

FlexWall ® Screw Trough<br />

MC-3A 316SS Ingredient Contact Parts<br />

MC-4A Food Grade Hopper Finish<br />

MC-4B Food Grade Screw Finish<br />

MC-4C Food Grade Tube Finish<br />

Motor and Drive Options<br />

MD-2 (A-L) Screw VFD Options<br />

Flexible Connections<br />

FC-1 Flexible Inlet Connection<br />

FC-2 Flexible Vent Connection<br />

FC-3 Flexible Outlet Connection<br />

Modifications for Hazardous Areas<br />

<strong>Vol</strong>umetric Feeder Suitable<br />

XP-1(A-D)<br />

for Hazardous Areas<br />

Accessories<br />

Level Probe Connection<br />

ACC-3 (Female NPT, Probe not<br />

included.)<br />

ACC-7A Vent Dust Bag<br />

ACC-16A Feeder Lift Station<br />

Extra Parts Ordered with Feeder<br />

EP-1 Extra Screw Trough<br />

EP-2 Extra Screw<br />

EP-3 Extra Tube<br />

3/05 Supersedes 8/04 Page 3 of 5 Document: 2110-C30-1

Mechanical Drawing<br />

ITEM DESCRIPTION<br />

1 FlexWall ® Plus FW40/0Plus Feeder<br />

2 Screw Motor<br />

3 Paddles<br />

4 Extension Hopper - 50L (1.8 cu.ft.)<br />

5 Screw<br />

6 Tube<br />

7 Auto Refill Lid (Optional)<br />

8 Inlet (On Auto Refill Lid)<br />

9 Vent Dust Bag (Optional)<br />

10 Manual Refill Lid (Optional)<br />

Notes:<br />

1) All Dimensions are in Millimeters [Inches]<br />

Description ‘A’ ‘B’<br />

Standard Tube Length 100 [3.9] 285 [11.2]<br />

Standard Extended Tube Length 250 [9.8] 435 [17.1]<br />

Description ‘E’<br />

Standard Inlet Diameter 150 [5.9]<br />

Standard Larger Inlet Diameter 200 [7.9]<br />

FW40/0Plus, FW40/1Plus <strong>Model</strong> <strong>Specifications</strong><br />

Empty Feeder Weight Kg (lb)<br />

With no Extension Hopper 30 (66)<br />

With 50L (1.8 cu.ft.) Extension Hopper 48 (106)<br />

Screw Availability<br />

1) All Tubes and standard Spiral Screws are available in Standard<br />

and Standard Extended lengths from stock<br />

2) Whenever possible, use a stocked length screw and tube and<br />

move the inlet location to align the inlet and outlet of the feeder<br />

with the existing equipment<br />

3) All Spiral Screws requiring modifications, all Blade Screws and all<br />

Mass Flow Screws are special order<br />

3/05 Supersedes 8/04 Page 4 of 5 Document: 2110-C30-1<br />

E

Typical Feeder Electrical Connections<br />

FW40/0Plus, FW40/1Plus <strong>Model</strong> <strong>Specifications</strong><br />

Note: The Disconnect, Fuse Holders, Fuses, Motor Thermal Overload and wiring are by others. The AC Motor Controller is<br />

supplied loose with the feeder.<br />

115V, 1Ph<br />

AC Power<br />

Disconnect<br />

Fuse (15A)<br />

(AC Power Wiring, Wiring to the Motor,<br />

Disconnect and Fuses are not<br />

included with the feeder)<br />

FEEDER ELECTRICAL SPECIFICATIONS<br />

Screw and Paddle AC Motor<br />

Controller (A-B VFD)<br />

R/L1<br />

S/L2<br />

Head Office:<br />

6500 Kestrel Road<br />

Mississauga, Ontario<br />

Canada, L5T 1Z6<br />

AC Motor Controller (VFD)<br />

Allen-Bradley PowerFlex 40<br />

<strong>Model</strong> 22B-V2P3N104<br />

115V, Single Phase In<br />

230V, 3 Phase Out (0.5 HP)<br />

(Provides Class 10<br />

overload protection) U/T1<br />

Telephone:<br />

Toll Free:<br />

Facsimile:<br />

Email:<br />

(905) 670-2933<br />

(888) 284-4574<br />

(905) 670-2557<br />

sales@brabenderti.<strong>com</strong><br />

3/05 Supersedes 8/04 Page 5 of 5 Document: 2110-C30-1<br />

Start/<br />

Stop<br />

Input<br />

0-10V<br />

Speed<br />

Input<br />

V/T2<br />

W/T3<br />

Input Power: 115 VAC, 50/60Hz, Single Phase;<br />

Motor Output: 230 VAC, 3 Phase;<br />

Motor Control Input: 0-10V or 4-20ma;<br />

Enclosure: NEMA 1 with Keypad for Speed Control and Run/Stop<br />

Screw and Paddle Motor 1⁄2 HP (0.37 KW), 230/460 VAC, 3 Phase, TEFC<br />

AC Motor Controller (A-B VFD) Dimensions<br />

Note: The AC Motor Controller is supplied loose with the feeder.<br />

Panel Mount (Open Frame)<br />

100 (3.94)<br />

87 (3.43)<br />

5.5 (0.22)<br />

180<br />

(7.09)<br />

168<br />

(6.61)<br />

136 (5.35)<br />

Dimensions are in millimeters (inches)<br />

87.4<br />

(3.44)<br />

Shipping Weight: 2 Kg (4.9 lbs)<br />

With IP30/NEMA 1 Cover Option<br />

33.0<br />

(1.30)<br />

79.1 (3.11)<br />

64.1 (2.52)<br />

40.6 (1.60)<br />

25.6 (1.01)<br />

Motor<br />

Æ 22.2<br />

(0.87)<br />

74.3<br />

(2.93)<br />

109.9<br />

(4.33)