Armor Series Product 2017 Catalog

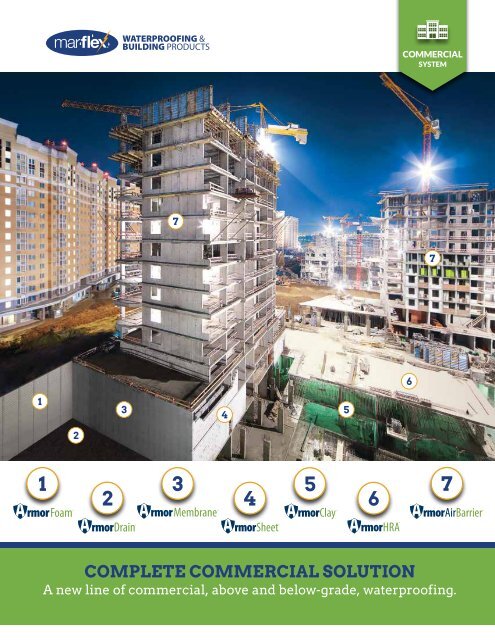

Commercial-grade Waterproofing Solutions from Mar-flex. Introducing the Armor Series.

Commercial-grade Waterproofing Solutions from Mar-flex. Introducing the Armor Series.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WATERPROOFING &<br />

BUILDING PRODUCTS<br />

COMMERCIAL<br />

SYSTEM<br />

7<br />

7<br />

6<br />

1<br />

3<br />

4<br />

5<br />

2<br />

1 3 5<br />

2 4 6<br />

7<br />

COMPLETE COMMERCIAL SOLUTION<br />

A new line of commercial, above and below-grade, waterproofing.

TABLE OF CONTENTS<br />

PRODUCT OVERVIEW<br />

WATERPROOFING & BUILDING PRODUCTS<br />

<strong>Product</strong><br />

Bentonite Clay Waterproofing<br />

Page<br />

600 04 – 05<br />

1000 04 – 05<br />

1500 04 – 05<br />

Accessories 06 – 07<br />

Self-Adhering Sheet Waterproofing<br />

Fluid-Applied Waterproofing<br />

600 / 601 08 – 09<br />

Accessories 08 – 09<br />

363 10 – 11<br />

Accessories 10 – 11<br />

600 / 1000 / 1500 600 / 601<br />

Composite Bentonite Sheet<br />

Ideal for use under structural or<br />

non-structural concrete floor slabs,<br />

on below-grade foundation walls,<br />

between slab applications, zero<br />

property line construction, tunnel<br />

and subways.<br />

363<br />

Water-Based or Solvent-Based Membrane<br />

Self-adhesive Asphalt<br />

Sheet Membrane<br />

Ideal for below-grade<br />

waterproofing of foundation<br />

walls, tunnels, earth shelters,<br />

ICF forms, plaza decks,<br />

balconies and terraces.<br />

A water-based or solvent-based spray applied membrane that can be<br />

applied to parking garages, bridge decks, plaza decks, foundation and<br />

retaining walls.<br />

Drainage Mats<br />

110 12 – 13<br />

150 12 – 13<br />

150P 12 – 13<br />

400 12 – 13<br />

Accessories 12 – 13<br />

110 / 150 / 150P / 400<br />

Three-dimensional, High-flow Drainage Solution<br />

A high-performance, high-strength drainage composite mat consisting<br />

of a high-impact polystyrene core and a high-strength non-woven filter<br />

fabric. For vertical and horizontal applications<br />

Fluid-Applied Dampproofing<br />

Air & Vapor Barriers<br />

361 14 – 15<br />

Accessories 14 – 15<br />

1200p 16 – 17<br />

1800i 16 – 17<br />

Accessories 16 – 17<br />

361<br />

<strong>Armor</strong>Block 361 WB is a commercial<br />

grade heavy bodied emulsion asphalt<br />

protective coating used when<br />

VaporBarrier / dampproofing is required.<br />

1200p / 1800i<br />

Permeable or Impermeable Membrane<br />

A permeable membrane ideal for managing<br />

the flow of air and water vapor through the<br />

buildingenvelope.<br />

An impermeable membrane ideal for<br />

managing the flow of air and water vapor<br />

through the building envelope.<br />

Hot-Applied Waterproofing<br />

800 18 – 19<br />

Accessories 18 – 19<br />

800<br />

Hot Rubberized Asphalt Membrane<br />

Foam Insulation<br />

25 / 40 20 – 21<br />

Accessories 20 – 21<br />

A Hot Rubberized asphalt membrane for bridge, plaza or promenade<br />

decks, tunnels, pedestrian concourses and similar types of construction<br />

where a monolithic waterproofing membrane is needed.<br />

Masonry Sealer<br />

20<br />

Freight Zone 22<br />

Order Form 23<br />

WATERPROOFING &<br />

BUILDING PRODUCTS<br />

25 / 40<br />

An expanded polystyrene board<br />

that has considerably better<br />

thermal insulation capacity than<br />

conventional EPS products with<br />

high compressive resistance.<br />

A single component water-based<br />

emulsion of siloxane that penetrates<br />

into concrete and masonry and<br />

provides true long term weatherproofing<br />

protection.<br />

2<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

3<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.

Exterior Below or Above Grade Commercial Bentonite Waterproofing System<br />

WATERPROOFING & BUILDING PRODUCTS<br />

600<br />

ACBS-30600<br />

Waterproofing membrane combines<br />

the thermal stability and high<br />

performance of a cross-laminated HDPE<br />

sheet with the long-term sealing of bentonite<br />

clay. Installation is fast and efficient - bonding<br />

tightly to the recommended Spray Adhesive. NO NAILING IS REQUIRED.<br />

It is non-toxic, fire resistant, and emits no solvents or VOC’s. <strong>Armor</strong>Clay<br />

600 will have unsurpassed life expectancy and provide waterproof<br />

protection equal to the life of the structure.<br />

Packaging<br />

Rolls of 39" x 37' (0.99 m x 11.2 m) or<br />

120 SqFt (11 m 2 ) per package weight<br />

72 lbs (32.7 kg) .6 lbs per SqFt.<br />

Each or 25 rolls per pallet maximum.<br />

Uses<br />

Waterproofing membrane designed for use<br />

on below- grade or split-slab structures.<br />

It is excellent for use on poured and ICF<br />

foundation walls, tunnels, plaza and parking<br />

decks. It is designed for easy installation<br />

with <strong>Armor</strong>Clay Mastic Adhesive depending<br />

on the project.<br />

Property<br />

Method<br />

Results<br />

Thickness Membrane Puncture-<br />

Propagation<br />

Tear<br />

Resistance<br />

– ASTM<br />

D2582<br />

.09” Black 4-mil<br />

cross<br />

laminated<br />

HDPE<br />

7.7 lbs.<br />

(3,500 gm)<br />

Tensile<br />

Strength:<br />

Membrane<br />

(psi)<br />

ASTM<br />

D882<br />

6,100 psi<br />

(42 MPa)<br />

%<br />

Elongation<br />

at break<br />

ASTM<br />

D882<br />

Bentonite<br />

100% Sodium<br />

Montmorillonite<br />

(>90%)<br />

Overall<br />

Weight<br />

0.6 lb per<br />

sq foot<br />

(2.44 kg/m 2 )<br />

Resistant to<br />

Hydrostatic<br />

head<br />

ASTM<br />

D751<br />

Procedure A<br />

174 ft. (52.9<br />

m) of water<br />

Crack<br />

Bridging<br />

1/8" (0.32<br />

cm) crack<br />

Water Vapor<br />

Permeability:<br />

ASTM E96<br />

0.53 x 10- 13<br />

cm/sec<br />

0.84 ng/<br />

m 2 .s.Pa<br />

0.033 Perms<br />

(grains/ft 2<br />

* hr * inHg)<br />

Installed<br />

System<br />

with<br />

Bitumen<br />

Taped Seams<br />

Puncture<br />

Resistance<br />

Membrane<br />

ASTM-<br />

D-781<br />

Puncture<br />

Resistance of<br />

Composite<br />

Membrane<br />

ASTM-<br />

E-154<br />

Tensile<br />

Strength of<br />

composite<br />

membrane<br />

ASTM<br />

D-412<br />

Modified<br />

Die C<br />

Elongation-<br />

Ultimate<br />

Failure of<br />

Rubberized<br />

Asphalt<br />

ASTM<br />

D-412<br />

Modified<br />

Die C<br />

Water Vapor<br />

Transmission-<br />

Permance<br />

ASTM<br />

E96<br />

Method B<br />

110 Kg/CM 40 Min. Lbs 750 psi Min 400% Min 0.1 Max<br />

Grains/SF/Hr<br />

in HG<br />

1000<br />

ACBS-31000<br />

A multi-layer waterproofing<br />

membrane consisting of bentonite,<br />

virgin high-density polyethylene, and<br />

a protective layer of non-woven<br />

polypropylene. The tough HDPE membrane<br />

provides the primary waterproofing envelope while the expandable<br />

bentonite clay provides the self-sealing reassurance under hydrostatic<br />

conditions. The polypropylene fabric protects the bentonite from<br />

exposure to inclement weather and direct installation of shotcrete.<br />

Packaging<br />

3.5' x 21.5' (1.1 m x 6.6 m) or<br />

75 SF (7 m 2 ) standard rolls.<br />

Each or 20 rolls per pallet maximum.<br />

Uses<br />

Waterproofing membrane is used on structures below<br />

grade and is especially effective where the water-proofing<br />

is applied before the walls or floor are poured. <strong>Armor</strong>Clay<br />

1000 is effective for blindside installation such as lagging,<br />

under floors, and elevator pits or standard installations such as<br />

backfilled wall, decks/tunnels. It has outstanding performance<br />

when used under conditions of high water head.<br />

Property<br />

Method<br />

Results<br />

Thickness Membrane Bentonite Weight Puncture<br />

Resistance<br />

– ASTM<br />

E-154-88<br />

Section 10<br />

.16" Green Sodium<br />

20-mil virgin Montmorillonite<br />

resin HDPE<br />

1 lb per sq<br />

foot (4.89<br />

kg/m 2 )<br />

170 LBS<br />

(77.3 kg)<br />

Tensile<br />

Strength:<br />

Membrane<br />

ASTM<br />

D638<br />

MD: 3660<br />

psi (25.2<br />

MPa)<br />

TD; 3650 psi<br />

(25.2 MPa)<br />

%<br />

Elongation<br />

at break<br />

ASTM<br />

D638<br />

Type 1<br />

dogbone<br />

Crack<br />

Bridging<br />

>700% 3/8” (0.95<br />

cm) crack<br />

Resistance<br />

to<br />

Hydrostatic<br />

head<br />

ASTM<br />

D751<br />

Procedure A<br />

174 ft. (52.9<br />

m) of water<br />

Water Vapor<br />

Permeability:<br />

ASTM<br />

E96-80<br />

Resistance<br />

to micro-organisms:<br />

(bacteria,<br />

fungi, mold,<br />

yeast)<br />

ASTM<br />

E154-88<br />

Section 13<br />

0.53 x 10- 13 Unaffected<br />

cm/sec 0.84<br />

ng/ m 2 .s.Pa<br />

0.033 Perms<br />

(grains/ft 2 *<br />

hr * inHg)<br />

Toxicity: Staining: Chemical Freeze/thaw Installation<br />

Resistance: stability Temperatures<br />

Low.<br />

Do not<br />

ingest<br />

No known<br />

incompatibilities<br />

Extremely<br />

high<br />

resistance to<br />

chemicals &<br />

gases.<br />

Contact mfg<br />

for specific<br />

information.<br />

No effect<br />

before or<br />

after<br />

installation.<br />

ASTM<br />

D746<br />

ASTM<br />

D1238<br />

-40˚F to<br />

150˚F<br />

(-40˚C to<br />

65.5˚C)<br />

Life<br />

Expectancy<br />

Both<br />

high-density<br />

polyethylene<br />

and bentonite<br />

have life<br />

expectancy<br />

measurable<br />

in thousandsof-years.<br />

1500<br />

ACBS-31500<br />

The ultimate multi-layered<br />

waterproofing system that has<br />

bentonite clay on both sides<br />

of virgin HDPE membrane and a thin<br />

scrim of polypropylene to protect<br />

the bentonite from exposure to the elements.<br />

This system will form waterproof barriers to both sides of the HDPE.<br />

It combines the swelling properties of Bentonite clay with the strength<br />

and protection of virgin HDPE sheets to form two layers of self-sealing<br />

waterproofing, for the toughest projects even under hydrostatic<br />

conditions. Because both Bentonite and the HDPE membrane are very<br />

stable, <strong>Armor</strong>Clay 1500 waterproofing will provide long-lasting<br />

protection for your building.<br />

Packaging<br />

3.5' x 14.3' (1.1 m x 4.4 m) or<br />

50 sf (4.6 m 2 ) standard rolls.<br />

Each or 20 rolls per pallet maximum.<br />

Uses<br />

Waterproofing membrane is used on structures below grade and is<br />

especially effective where the waterproofing is applied before the<br />

walls or floor are poured such as blindside installation lagging,<br />

under floors, and elevator pits. <strong>Armor</strong>Clay 1500 is also effective<br />

in combination with Mar-flex Neofoam Insulation in preventing<br />

water migration behind the insulation. It has outstanding performance<br />

when used under conditions of high water head pressure. Can be<br />

used as a complete system with many Mar-flex Commercial<br />

Drainage Boards and Mats as well.<br />

Property<br />

Method<br />

Results<br />

Thickness Membrane Membrane<br />

High-Density<br />

Polyethylene<br />

Bentonite<br />

(2 layers)<br />

Weight<br />

Puncture<br />

Resistance<br />

– ASTM<br />

E-154-88<br />

.26” Fabric/<br />

Gray/<br />

Green/<br />

Gray<br />

Green<br />

20-mil<br />

virgin resin<br />

HDPE<br />

Sodium<br />

Montmorillonite<br />

1.5 lb per sq<br />

ft (7.34 kg/<br />

m 2 ) 172<br />

172 LBS<br />

(77.5 kg)<br />

Tensile<br />

Strength:<br />

Membrane<br />

ASTM<br />

D638<br />

MD: 3750<br />

psi (25.9<br />

MPa)<br />

TD; 3780<br />

psi (26.1<br />

MPa)<br />

%<br />

Elongation<br />

at break<br />

ASTM<br />

D638<br />

Type 1<br />

dogbone<br />

Crack<br />

Bridging<br />

567% 3/8” (0.95<br />

cm) crack<br />

Resistance<br />

to<br />

hydrostatic<br />

head<br />

ASTM<br />

D751<br />

Procedure<br />

A<br />

Water<br />

Vapor<br />

Permeability:<br />

ASTM E<br />

9E6-80<br />

Resistance<br />

to microorganisms:<br />

(bacteria,<br />

fungi, mold,<br />

yeast)<br />

ASTM<br />

E154-88<br />

Section 13<br />

169 ft. (51.5 0.39 x 10- 13 Unaffected Low. Do not<br />

m) of water cm/sec 0.61<br />

ingest<br />

ng/ m 2 .s.Pa<br />

0.024<br />

Perms<br />

(grains/ft 2 *<br />

hr * inHg)<br />

Toxicity: Staining: Chemical<br />

Resistance:<br />

No known<br />

incompatibilities<br />

Extremely<br />

high<br />

resistance<br />

to chemicals<br />

& gases.<br />

Contact<br />

mfg for<br />

specific<br />

info.<br />

Freeze/<br />

thaw<br />

stability<br />

No effect<br />

before or<br />

after<br />

installation<br />

Installation<br />

Temperatures<br />

ASTM<br />

D746,<br />

ASTM<br />

D1238<br />

-40˚F to<br />

150˚F<br />

(-40˚C to<br />

65.5˚C)<br />

Life<br />

Expectancy<br />

Both HDPE<br />

and bentonite<br />

have life<br />

expectancy<br />

measureable<br />

in<br />

hundredsof-years.<br />

Features<br />

• Strong cross-laminated HDPE • Self-sealing bentonite layer • Easy installations with <strong>Armor</strong>Clay<br />

Mastic Adhesive on seams<br />

• Adhesion to concrete • Adjustable placement • Longevity: life of the structure • No VOC—solvent free<br />

4<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

5<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.

Accessories<br />

<strong>Armor</strong>Clay<br />

TieBack Cover – ACBS-27278<br />

The <strong>Armor</strong>Clay Tieback Cone is a waterproof assembly made from <strong>Armor</strong>Clay1500, a<br />

20-mil HDPE sheet with bentonite on both sides. The two-piece assembly (cone-shaped<br />

cover and a flange cover) is filled with <strong>Armor</strong>Clay Mastic to complete the waterproofing<br />

detail. The Cone is pre-assembled to provide a simple and quick waterproofing detail<br />

for tie-backs. The cone shape, flange cover, and mastic fill contribute to form a secure<br />

waterproof cover that is strong enough to withstand shotcrete, yet simple enough for field<br />

alterations. The <strong>Armor</strong>Clay Tieback Cone is designed for use with <strong>Armor</strong>Clay1000 and<br />

1500 waterproofing systems. (Sold Individually)<br />

Granular Pack – ACBS-00030<br />

Bentonite is volcanic ash that absorbs several times its weight in water, causing it to<br />

expand, and thus prevent further water penetration. <strong>Armor</strong>Clay Granular Packs are 30<br />

lb. bags of premium granular bentonite for use as fill, a cant along horizontal-to-vertical<br />

transitions, and other loose bentonite applications. The Granular Packs are designed to be<br />

more manageable for the applicator on the job site, with handle on the bag to make the<br />

bentonite easier to carry and apply. (Sold Individually)<br />

Waterstop – 1/2"-ACBS-60550 / 3/4"- ACBS-60575<br />

<strong>Armor</strong>Clay Waterstop is used to seal static construction joints in concrete footings, walls,<br />

floors, tunnels, parking and plaza decks and to prevent water migration. <strong>Armor</strong>Clay<br />

Waterstop has superior performance when used under conditions of extreme water head<br />

pressure. Standard rolls sizes are: 1 /2" x 1" x 15' (1.27 cm x 2.54 cm x 4.6 m) & 3/4" x 1" x<br />

15' (1.9 cm x 2.54 cm x 4.6 m) (Sold in 5 rolls per box quantities)<br />

Termination Bar – ACBS-84250<br />

Termination bar is a high strength vinyl/plastic strip designed for attaching and sealing<br />

<strong>Armor</strong>Clay membranes and drainage layers at their termination points. Termination bar<br />

is 2.5" wide, 6'6" long, has pre-drilled holes (8" O.C.) and edging for caulking and sealing.<br />

(Sold 50 per box)<br />

Bitumen Tape – ACBS-04100<br />

<strong>Armor</strong>Clay Bitumen Tape consists of a 4-mil cross laminated HDPE sheet laminated to 26<br />

mils of Butyl Rubber and release liner. Uses include: Protect seams of multiple <strong>Armor</strong>Clay<br />

waterproofing systems from fluid and vapor transmission. <strong>Armor</strong>Clay Bitumen tape may<br />

be used on all grade line termination. (Sold 6 rolls/case)<br />

Seam Tape – ACBS-03180<br />

<strong>Armor</strong>Clay Seam Tape is PVC-backed rubber-adhesive seam tape to protect the joint on<br />

<strong>Armor</strong>Clay waterproofing membranes. It forms a strong bond (25 oz/in) and will<br />

simultaneously cover nail holes along the overlap. The greencolor tape will provide a<br />

contiguous surface after installation. The Seam Tape comes in rolls 3" wide x 36 yards long.<br />

(Sold 16 rolls/case)<br />

Solvent-based Mastic – ACBS-36202/36205<br />

Modified Bentonite Paste. Available in 2 & 5gal pails. (Sold Individually)<br />

Water-based Mastic Adhesive – 2gal pail – ACBC-68002<br />

5gal pail – ACBS-68005<br />

30oz tube – ACBS-68030<br />

Waterbase acrylic mastic adhesive. (Pails sold Individually-Tubes sold 9/case)<br />

WATERPROOFING & BUILDING PRODUCTS<br />

Use <strong>Armor</strong>Clay with Mar-flex commercial grade waterproofing<br />

products for unmatched protection and superior warranties.<br />

Why Bentonite?<br />

<strong>Armor</strong>Clay bentonite products and accessories are a tested and<br />

proven solution for commercial waterproofing applications.<br />

Bentonite clay expands when wet, absorbing several times its weight<br />

in water and makes for a very stable, below-grade solution.<br />

ADVANTAGES:<br />

• Strong cross-laminated HDPE<br />

• Self-sealing bentonite layer<br />

• Easy installations with<br />

<strong>Armor</strong>Clay Adhesive<br />

• Adhesion to concrete<br />

• Adjustable placement<br />

• Longevity: life of the<br />

structure<br />

• No VOC—solvent free<br />

<strong>Armor</strong>Clay <strong>Product</strong>s:<br />

<strong>Armor</strong>Clay 600<br />

<strong>Armor</strong>Clay 1000<br />

<strong>Armor</strong>Clay 1500<br />

<strong>Armor</strong>Clay Bitumen Tape<br />

<strong>Armor</strong>Clay Granular Pack<br />

<strong>Armor</strong>Clay Mastic<br />

<strong>Armor</strong>Clay Mastic Adhesive<br />

<strong>Armor</strong>Clay Seam Tape<br />

<strong>Armor</strong>Clay Termination Bar<br />

<strong>Armor</strong>Clay Tieback Cone<br />

<strong>Armor</strong>Clay WaterStop<br />

<strong>Armor</strong>Drain Mats<br />

(vertical application)*<br />

* For horizontal applications, use “C” Drain 400 Drainage Board<br />

6<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

7<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.

Exterior Above and Below-Grade Commercial Sheet Waterproofing Membrane<br />

WATERPROOFING & BUILDING PRODUCTS<br />

600 – ASSM-39600<br />

601 – ASSM-39601<br />

<strong>Armor</strong>Sheet 600 (summer grade)<br />

Mar-flex <strong>Armor</strong>Sheet is a self-adhering sheet membrane<br />

consisting of 56 mils (1.4 mm) of rubberized asphalt<br />

laminated to 4 mils (0.1 mm) of polyethylene to form a<br />

minimum 60-mil (1.5 mm) membrane. <strong>Armor</strong>Sheet600<br />

Summer Grade membrane is suitable for installations<br />

where the ambient temperature is 40°F (4.4°C) or above.<br />

<strong>Armor</strong>Sheet 601 (winter grade)<br />

Mar-flex <strong>Armor</strong>Sheet is a self-adhering sheet membrane<br />

consisting of 56 mils (1.4 mm) of rubberized asphalt<br />

laminated to 4 mils (0.1 mm) of polyethylene to form a<br />

minimum 60-mil (1.5 mm) membrane. <strong>Armor</strong>Sheet601<br />

Winter Grade is suitable for installations where the ambient<br />

temperature is 20°F-60° F (-6 to -18°C) or above.<br />

Accessories<br />

<strong>Armor</strong>Sheet<br />

600/601<br />

<strong>Armor</strong> 700 Solvent-Based Primer – ASBP-70005<br />

The Mar-flex 700 SB Primer is a solvent based penetration asphalt primer used for the<br />

preparation of all types of surfaces previous to the application of sheet membranes and<br />

hot or cold asphalt where application temperatures of 20°F or more are present.<br />

It is especially designed for use as a prime coat for concrete, gypsum, masonry, brick<br />

and metal surfaces over which waterproofing asphaltic products are to be applied. This<br />

solution readily penetrates pores and seals dusty masonry surfaces to provide a firm<br />

base for such applications.<br />

All surfaces to be primed must be dry and free from dust, dirt, oil, grease and any other<br />

foreign matter.<br />

<strong>Armor</strong> 710 Water-Based Primer – AWBP-70105<br />

Roll sizes=39.37" x 65.5'<br />

The Mar-flex 710 WB Primer is water-based polymer modified primer for self-adhering<br />

membranes. The 710 WB Primer penetrates pores and dries fast to provide a tacky, firm<br />

substrate for adhesion of the membranes.<br />

Uses<br />

<strong>Armor</strong>Sheet membranes are used for<br />

vertical and horizontal waterproofing on<br />

structural foundation walls and decks.<br />

Below-grade foundation walls, tunnels,<br />

split slabs; plaza decks and parking decks<br />

are all areas where <strong>Armor</strong>Sheet may be<br />

applied. <strong>Armor</strong>Sheet may also be used in<br />

interior areas such as mechanical rooms,<br />

laboratories, kitchens and bathrooms The<br />

combination of these two excellent waterproofing<br />

materials provides a highperformance,<br />

extremely durable<br />

waterproofing barrier.<br />

Properties<br />

Property Results Property<br />

Results Method<br />

Color Thickness Tensile<br />

(Membrane)<br />

– ASTM<br />

D3767<br />

Dark<br />

Gray/<br />

Black<br />

Weight per<br />

Gal.<br />

ASTM<br />

D412<br />

Tensile<br />

(Film)<br />

ASTM<br />

D882<br />

Elongation Pereance Low Temp.<br />

Flexibility<br />

ASTM<br />

D412<br />

ASTM<br />

E96<br />

60 mils 796 psi 2243 psi 623% 0.016<br />

perms<br />

Solids by<br />

Weight<br />

7.5 lbs. 45% Dark Gray/<br />

Black<br />

Weight per<br />

Gal.<br />

Solids by<br />

Weight<br />

ASTM<br />

D1970<br />

Crack<br />

Cycling<br />

ASTM<br />

C836<br />

Peel<br />

Strength<br />

ASTM<br />

D903<br />

Lap<br />

Adhesion<br />

ASTM<br />

D1876<br />

Puncture Soil Burial<br />

Resistance at 16 wks<br />

ASTM<br />

E154<br />

GSA-PBS<br />

07121<br />

Water<br />

Absorption<br />

ASTM<br />

D570<br />

Unaffected Unaffected 6.0 lb/in 11.6 lb/in 89 lb (min) No effect 0.18%<br />

by wt<br />

Color Dry Time Cure Time Service<br />

Temp.<br />

60 min<br />

@75°F &<br />

50% RH<br />

2-4 hrs. @<br />

75°F and<br />

50% RH<br />

-40°F and<br />

160°F<br />

Color Dry Time Cure Time Service<br />

Temp.<br />

Coverage<br />

Application<br />

Temp.<br />

150 sqft/gal 20°F and<br />

rising<br />

Coverage<br />

Application<br />

Temp.<br />

VOC<br />

450 g/l<br />

VOC<br />

Hydrostatic<br />

Head<br />

ASTM<br />

D5385<br />

Thickness<br />

ASTM<br />

D3767<br />

Temp.<br />

Application<br />

Range<br />

231 ft 60 mils AS 600<br />

40° +<br />

Roll Size<br />

– –<br />

AS 601<br />

20° +<br />

337'x65.5'<br />

The 710 WB Primer is suitable for use over asphalt, wood, plywood, gypsum board and<br />

concrete surfaces.<br />

All surfaces to be primed must be dry and free from dust, dirt, oil, grease and any other<br />

foreign matter.<br />

Results<br />

8.6 lbs. 37% Milky Blue 25-30 min<br />

@75°F &<br />

50% RH<br />

2 hrs. @ 75°F<br />

and<br />

50% RH<br />

-40°F and<br />

160°F<br />

400 sqft/gal 40°F and<br />

rising<br />

VOC<br />

Compliant<br />

8<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

9<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.

Commercial Grade Fluid Applied Waterproofing<br />

WATERPROOFING & BUILDING PRODUCTS<br />

363<br />

Solvent-Based – BCC-36315 (55gal)<br />

<strong>Armor</strong>Membrane 363 Solvent-Based Waterproofing<br />

is a tested and proven membrane for<br />

commercial applications.<br />

Features / Benefits<br />

• Creates a seamless membrane<br />

• Effectively coats rough and porous surfaces<br />

• Seals around fasteners<br />

363<br />

Water-Based – BGC-36312 (5gal)<br />

– BGC-36314 (55gal)<br />

– BGC-36316 (330gal)<br />

<strong>Armor</strong>Membrane 363 Water-Based Commercial<br />

Grade Waterproofing is a tested and proven<br />

membrane for commercial applications.<br />

Features / Benefits<br />

• Creates a seamless membrane<br />

• Effectively coats rough and porous surfaces<br />

• Safe, non-flammable and low order<br />

• Seals around fasteners<br />

Packaging<br />

<strong>Armor</strong>Membrane 363 SB is available in 55 gallon drums.<br />

Uses<br />

<strong>Armor</strong>Membrane 363 SB membrane is ideal for new<br />

construction waterproofing of below-grade commercial<br />

walls of poured concrete. In addition, it can be used in<br />

horizontal applications such as parking garages, bridge<br />

decks, and plaza decking as well as retaining wall<br />

applications.<br />

Packaging<br />

<strong>Armor</strong>Membrane 363 WB Waterproofing is<br />

available in 5-Gallon Buckets and 55-Gallon Drums<br />

& 330 gallon totes.<br />

Uses<br />

<strong>Armor</strong>Membrane 363 WB membrane is ideal for new<br />

construction waterproofing of below-grade commercial<br />

walls of poured concrete. In addition, it can be used in<br />

horizontal applications such as parking garages, bridge<br />

decks, and plaza decking as well as retaining wall<br />

applications.<br />

Results Method Property Results Method Property<br />

Color Total Solids Application<br />

Method<br />

Color Total Solids Application<br />

Method<br />

Application<br />

Range<br />

Application<br />

Range<br />

Elongation<br />

@ 70° F<br />

(21°C)<br />

– – – – (AST-<br />

MD-412<br />

Die C)<br />

Black 60 – 70% Spray,<br />

Brush,<br />

Roller<br />

Black 60 – 70% Spray,<br />

Brush,<br />

Roller<br />

20º to<br />

130ºF<br />

Elongation<br />

@ 70° F<br />

(21°C)<br />

– – – – ASTM<br />

D-412<br />

Die C<br />

20º to<br />

130ºF<br />

Crack<br />

Bridging<br />

Ability<br />

(ASTM<br />

C-836<br />

Crack<br />

Bridging<br />

Ability<br />

Resistance<br />

to Hydrostatic<br />

Head<br />

Pressure<br />

1672% min. 10 cycles;<br />

without<br />

bond failure<br />

Water<br />

Leaks:<br />

None<br />

Weight<br />

Gain: None<br />

(ASTMD<br />

C-836<br />

1672% min. 10 cycles;<br />

no failure<br />

(Federal<br />

Spec TT-C-<br />

555B, Par<br />

4.4.7)<br />

Resistance<br />

to Hydrostatic<br />

Head<br />

Pressure<br />

(Federal<br />

Spec TT-C-<br />

555B, Par<br />

4.4.7)<br />

No Water<br />

Infiltration<br />

Total Cure<br />

Time<br />

Total Cure<br />

Time<br />

Weight/<br />

Gallon<br />

Weight/<br />

Gallon<br />

Coverage<br />

Rate<br />

Coverage<br />

Rate<br />

Tensile<br />

Strength<br />

Roll Size<br />

– – – (ASTM<br />

C719)<br />

24 hrs. 7.8 lbs.<br />

(3.4kg)<br />

4-5 gal./100<br />

ft²<br />

24 hrs. 7.6 lbs. 4-5 gal./100<br />

ft²<br />

56.4 psi<br />

(331 kPa)<br />

Tensile<br />

Strength<br />

– – – ASTM-<br />

C719<br />

Water<br />

Vapor<br />

Permeance<br />

(ASTM<br />

E96)<br />

Transmission:<br />

0.11<br />

grains/sf/h<br />

Permeability:<br />

0.23 perms<br />

Water<br />

Vapor<br />

Permeance<br />

ASTM<br />

E96<br />

48 psi 0.12 perm<br />

(grains/<br />

sq.ft/h)<br />

Mold<br />

Growth/<br />

Bacterial<br />

Attack<br />

No<br />

Degradation<br />

Mold<br />

Growth/<br />

Bacterial<br />

Attack<br />

No<br />

Degradation<br />

Membrane/<br />

Vertical<br />

80 mil dry<br />

thickness<br />

Membrane/<br />

Vertical<br />

80 mil dry<br />

thickness<br />

Membrane/ Adhesion to<br />

Horizontal Concrete<br />

– – – –<br />

100 mil dry<br />

thickness<br />

Membrane/ Adhesion to<br />

Horizontal Concrete<br />

100 mil dry<br />

thickness<br />

No<br />

Adhesion<br />

Loss<br />

– – – –<br />

No<br />

Adhesion<br />

Loss<br />

Accessories<br />

<strong>Armor</strong>Membrane<br />

<strong>Armor</strong>Mastic 200 Solvent-Based – ARMT-00200<br />

<strong>Armor</strong>Mastic 200 is a heavy-bodied trowel grade coating.<br />

It is excellent for patching tie holes, filling in honeycombed<br />

areas in both rough and smooth masonry surfaces prior to<br />

application of a variety of Mar-flex Commercial <strong>Product</strong>s.<br />

Uses<br />

<strong>Armor</strong>Mastic 200 is the most versatile heavy-bodied trowel<br />

grade coating available. This product is excellent for patching<br />

tie holes, filling in honeycombed areas in both rough and<br />

smooth masonry surfaces, and surface flaws. <strong>Armor</strong>Mastic<br />

200 remains flexible during freeze-thaw cycles, and can be<br />

applied during any season. You can patch all outside below<br />

grade wall ties with AM200.<br />

Properties<br />

Results<br />

Color<br />

Black<br />

Application<br />

Method<br />

Trowel or<br />

Hand Applied<br />

Can be used with a variety of Mar-flex Commercial <strong>Product</strong>s<br />

including <strong>Armor</strong>Sheet 600/601, <strong>Armor</strong>Block 361 and<br />

<strong>Armor</strong>Membrane 363 and the full <strong>Armor</strong> <strong>Series</strong> line.<br />

Application<br />

Range<br />

0˚ to 120˚ F<br />

<strong>Armor</strong> 700 Solvent-Based Primer – ASBP-70005<br />

<strong>Armor</strong> 700 SB Primer is a solvent-based penetration asphalt<br />

primer used for the preparation of all types of surfaces previous<br />

to the application of sheet membranes and hot or<br />

cold asphalt where application temperatures of<br />

20°F or more are present.<br />

Uses<br />

Designed for use as a prime coat for concrete,<br />

gypsum, masonry, brick and metal surfaces over which<br />

waterproofing asphaltic products are to be applied. This solution<br />

readily penetrates pores and seals dusty masonry surfaces to<br />

provide a firm base for such applications.<br />

<strong>Armor</strong> 710 Water-Based Primer – AWBP-70105<br />

<strong>Armor</strong> 710 WB Primer is water-based polymer<br />

modified primer for self-adhering membranes.<br />

The 710 WB Primer penetrates pores and dries fast<br />

to provide a tacky, firm substrate for adhesion<br />

of the membranes.<br />

Uses<br />

The 710 WB Primer is suitable for use over<br />

asphalt, wood, plywood, gypsum board and<br />

concrete surfaces.<br />

10<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

11<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.

For Heavy Duty Horizontal and Vertical Drainage Applications<br />

CORE<br />

WATERPROOFING & BUILDING PRODUCTS<br />

FABRIC<br />

110<br />

Vertical Mat – DP-48325<br />

<strong>Armor</strong>Drain 110 is an impermeable polymeric sheet<br />

that while under heat and pressure is formed into a<br />

dimpled drainage core. The core is then bonded to<br />

a single layer of non-woven filter fabric. The filter<br />

fabric retains soil and sand particles as well as freshly<br />

placed concrete or grout, allowing water to pass into<br />

the drainage core.<br />

150/ 150PF<br />

Horizontal and Vertical Mat – DP-48350/48355<br />

<strong>Armor</strong>Drain 150 is an impermeable polymeric sheet<br />

that while under heat and pressure is formed into a<br />

dimpled drainage core. The core is then bonded to<br />

a single layer of non-woven filter fabric. The filter<br />

fabric retains soil and sand particles as well as freshly<br />

placed concrete or grout, allowing water to pass into<br />

the drainage core.<br />

The 150 PF is identical to the 150 only with the addition<br />

of a membrane protective film on the backside.<br />

400<br />

Horizontal Mat – DP-48375<br />

<strong>Armor</strong>Drain 400 is a heavy duty, high density<br />

polyethylene geonet drainage core. Its ridges are<br />

heat fused to a layer of non-woven filter fabric with<br />

an added layer of heavy duty grey fabric bonded to<br />

the back.<br />

Accessories<br />

<strong>Armor</strong>Drain<br />

Purpose<br />

<strong>Armor</strong>Drain 110 is engineered to provide ample strength<br />

to protect waterproofing membranes against back fill soil<br />

and sediment and to provide excellent drainage capabilities<br />

providing hydrostatic relief.<br />

AD 110 is ideal for basement foundations, retaining walls,<br />

planters or bridge abutments.<br />

Advantages<br />

• 11,000 psf of protection<br />

• Resistance to hydrostatic pressure<br />

• High flow dimpled drainage core<br />

• Protects foundation waterproofing membrane<br />

• Easy installation<br />

Purpose<br />

<strong>Armor</strong>Drain 150/150 PF is used as a protection and drainage<br />

roll and is engineered to provide ample strength to protect<br />

membranes against back fill soil and sediment and to<br />

provide excellent drainage capabilities.<br />

Advantages<br />

• 15,000 psf of protection<br />

• Higher compressive strength for greater depth<br />

• Strong resistance to hydrostatic pressure<br />

• High flow dimpled drainage core<br />

• Protects waterproofing membrane<br />

• Easy installation<br />

Purpose<br />

<strong>Armor</strong>Drain 400 is ideal under slabs, planters and roof<br />

gardens, retaining walls, foundation walls, and bridge<br />

abutments.<br />

Because of the crush proof nature of the geonet, drainage<br />

composites can be used in the most extreme cases where<br />

heavy loads and/or heavy vehicular traffic are abundant.<br />

Advantages<br />

• 40,000 psf of protection<br />

• Crush resistant<br />

• Strong resistance to hydrostatic pressure<br />

• High flow dimpled drainage core<br />

• Protects waterproofing membrane<br />

• Easy installation<br />

Method <strong>Armor</strong>Drain 400 <strong>Product</strong> Method <strong>Armor</strong>Drain 150 <strong>Product</strong> Method <strong>Armor</strong>Drain 100 <strong>Product</strong><br />

Color Material Dimple<br />

Height<br />

Black<br />

Color Material Dimple<br />

Height<br />

Black<br />

Compressive<br />

Strength<br />

Geocomposite<br />

water flow<br />

rate@hydr.<br />

Grad 0.1<br />

Color Material Compressive<br />

Strength<br />

Black<br />

Drainage<br />

core:<br />

co-polymer<br />

polypropylene<br />

Geotextile:<br />

Polypropylene<br />

Drainage<br />

core:<br />

co-polymer<br />

polypropylene<br />

Geotextile:<br />

Polypropylene<br />

.40"<br />

(10.16mm)<br />

Drainage<br />

core:<br />

co-polymer<br />

polypropylene<br />

Geotextile:<br />

Polypropylene<br />

Compressive<br />

Strength<br />

15,000 psf<br />

(718 kN/<br />

m²)<br />

ASTM ASTM<br />

D1777-96 D6364-06<br />

Geocomposite<br />

water flow<br />

rate@hydr.<br />

Grad 0.1<br />

21 g/min/<br />

ft-260L/<br />

min/M<br />

40,000 psf<br />

(1915 kN/<br />

m²)<br />

ASTM<br />

D1621<br />

ASTM<br />

D4716<br />

Drainage<br />

Core<br />

impact<br />

resistance<br />

Drainage<br />

Core<br />

impact<br />

resistance<br />

Thickness<br />

Drainage<br />

core<br />

maximum<br />

tearing<br />

strength<br />

2.9 J mean MD 550N<br />

failure CD 800N<br />

energy at<br />

5° C<br />

ASTM<br />

D4226-09<br />

CORE<br />

.25in<br />

(6.35mm)<br />

ASTM<br />

D1777<br />

Drainage<br />

core<br />

maximum<br />

tearing<br />

strength<br />

.40" 11,000 psf 18 g/min/ 2.9 J mean MD 550N<br />

(1016mm) (527 kN/<br />

m²)<br />

ft-223L/<br />

min/M<br />

failure<br />

energy at<br />

5° C<br />

CD 800N<br />

ASTM<br />

D1777<br />

ASTM<br />

D1621<br />

CORE<br />

ASTM<br />

D4716<br />

ASTM<br />

D4226-09<br />

ASTM<br />

D5884-04a<br />

Drainage Geotextile<br />

core stress water flow<br />

cracking rate<br />

resistance<br />

504 hrs @<br />

156 kPa<br />

(No cracking<br />

at test<br />

termination)<br />

140 gal/<br />

min/ft²<br />

ASTM<br />

D5884-<br />

04a<br />

Drainage Geotextile Geotextile Geotextile Geotextile<br />

core stress water flow grab tensile elongation trapezoidal<br />

cracking<br />

resistance<br />

rate strength<br />

tear<br />

504 hrs @<br />

156 kPa<br />

(No cracking<br />

at test<br />

termination)<br />

SAGEOS<br />

GD<br />

001-2012<br />

Flow<br />

(Hydraulic<br />

gradient=1)<br />

8.5 g/min/ft<br />

(106L/<br />

min/m)<br />

ASTM<br />

D4716<br />

(5704 L/<br />

min/m²)<br />

SAGEOS<br />

GD<br />

001-2012<br />

140 gal/<br />

min/ft²<br />

(5704 L/<br />

min/m²)<br />

ASTM<br />

D4491<br />

Flow<br />

100 lbs<br />

(.45kN)<br />

110 gal/<br />

min/ft²<br />

(4481 L/<br />

min/m²)<br />

ASTM<br />

D4491<br />

Geotextile<br />

grab<br />

tensile<br />

strength<br />

100 lbs<br />

(.45kN)<br />

ASTM<br />

D4491<br />

ASTM<br />

D4632<br />

Geotextile Geotextile Geotextile Geotextile Geotextile<br />

elongation trapezoidal<br />

tear<br />

puncture<br />

strength<br />

mullen<br />

burst<br />

apparent<br />

opening<br />

size (AOS)<br />

60% 45 lbs.<br />

(200N)<br />

ASTM<br />

D4632<br />

60% 45 lbs.<br />

(200N)<br />

ASTM<br />

D4632<br />

CBR<br />

puncture<br />

450lbs<br />

(2.0kN)<br />

ASTM<br />

D6241<br />

ASTM<br />

D4632<br />

ASTM<br />

D4533<br />

250 lbs<br />

(1.1113<br />

kN)<br />

ASTM<br />

D4533<br />

Geotextile Geotextile Geotextile<br />

puncture<br />

strength<br />

mullen<br />

burst<br />

apparent<br />

opening<br />

size (AOS)<br />

250 lbs<br />

(1.1113<br />

kN)<br />

ASTM<br />

D6241<br />

210 psi<br />

(1446 kPa)<br />

Geotextile<br />

weight<br />

(typical)<br />

70 US 4.0 oz-yd²<br />

Sieve (135 g/m²)<br />

(.212mm)<br />

Geotextile<br />

UV<br />

resistance<br />

70%<br />

strength<br />

retained<br />

Toxicity<br />

Non-toxic,<br />

nonpolluting<br />

AOS (EOS) Grab Tensile Toxicity Roll size/<br />

weight<br />

80 U.S.<br />

Sieve<br />

(.18 mm)<br />

210 psi<br />

(1446<br />

kPa)<br />

ASTM<br />

D6241<br />

FABRIC<br />

ASTM<br />

D3786<br />

FABRIC<br />

160 lbs.<br />

(.712 kN)<br />

ASTM<br />

D4632<br />

70 US<br />

Sieve<br />

(.212mm)<br />

ASTM<br />

D3786<br />

ASTM<br />

D4751<br />

Geotextile<br />

weight<br />

(typical)<br />

4.0 oz-yd²<br />

(135 g/m²)<br />

ASTM<br />

D4751<br />

ASTM<br />

D5261<br />

160 lbs.<br />

(.712 kN)<br />

Geotextile<br />

UV resistance<br />

70%<br />

strength<br />

retained<br />

ASTM<br />

D5261<br />

ASTM<br />

D4355<br />

Toxicity<br />

Non-toxic,<br />

nonpolluting<br />

ASTM<br />

D4355<br />

*4' x 50' (1.2<br />

x 15.25m)<br />

55 lbs.<br />

(24.95kg)<br />

Roll size/<br />

weight<br />

*4' x 50' (1.2<br />

x15.25m)<br />

38 lbs.<br />

(15.87kg)<br />

*6.5' or 8'<br />

widths available<br />

as special<br />

order<br />

Roll size/<br />

weight<br />

*4’ x 50’ (1.2<br />

x15.25m)<br />

39 lbs.<br />

(15.87kg)<br />

*6’ or 8’<br />

widths<br />

available<br />

as special<br />

order<br />

Service life<br />

expectancy<br />

>25 years (at<br />

pH between<br />

4 and 9, and<br />

temperature<br />

below 77°F /<br />

25°C) Do not<br />

expose to UV<br />

light for more<br />

than 30 days.<br />

Service life<br />

expectancy<br />

>25 years (at<br />

pH between<br />

4 and 9, and<br />

temperature<br />

below 77°F<br />

/ 25°C) Do<br />

not expose to<br />

UV light for<br />

more than 30<br />

days.<br />

Service life<br />

expectancy<br />

>30 years (at<br />

pH between<br />

4 and 9, and<br />

temperature<br />

below 77°F /<br />

25°C) Do not<br />

expose to UV<br />

light for more<br />

than 30 days.<br />

12<br />

GeoClip is designed to be used in conjunction<br />

with <strong>Armor</strong> Drain to speed installation. The<br />

Geo Clip’s prongs help distribute weight to<br />

secure board after nail is inserted into<br />

preformed center nail hole.<br />

GM-48277<br />

500/box<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

Termination bars are designed to be used in conjunction with <strong>Armor</strong>Drain.<br />

The termination bar protects the top edge of the polyethylene at grade<br />

level from soil penetration between roll and wall.<br />

Termination bar has eight pre-drilled nail holes for<br />

ease of installation.<br />

GM-48280<br />

50 (6'6") Termination bar/box<br />

Drainage board fasteners. Fastens board to poured<br />

wall, providing an additional bond until backfilled. May<br />

be installed into concrete with hammer.<br />

AI-28132 (1")<br />

AI-28136 (1.5")<br />

AI-28134 (1-1/4")<br />

AI-28138 (2-1/2")<br />

500/box<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

<strong>Armor</strong>Flash is designed to be used in conjunction with all <strong>Armor</strong> <strong>Series</strong> products.<br />

CETS-0475 (4" x 75') CETS-1875 (18" x 75')<br />

CETS-0675 (6" x 75') CETS-2475 (24" x 75')<br />

CETS-1275 (12" x 75')<br />

Rolls per box varies per size<br />

4"-9 rolls, 6"-6 rolls, 12"-3 rolls, 18"-2 rolls, 24"-1 roll<br />

13

Exterior Commercial VaporBarrier / Dampproofing<br />

WATERPROOFING & BUILDING PRODUCTS<br />

361<br />

Water-Based – CMB-36120 (5gal)<br />

– CMB-36125 (55gal)<br />

– CMB-36127 (330gal)<br />

– CMB-36129 (6000gal bulk)<br />

<strong>Armor</strong>Block 361 WB is a commercial grade heavy<br />

bodied emulsion asphalt protective coating used<br />

when VaporBarrier / dampproofing is required.<br />

Packaging<br />

<strong>Armor</strong>Block 361 WB is available in 5-Gallon Buckets &<br />

55-Gallon Drums, 330gal totes and 6000gal bulk.<br />

Uses<br />

<strong>Armor</strong>Block 361 WB membrane is recommended for<br />

dampproofing below-grade basement walls of poured<br />

concrete or unit masonry construction. It serves as a<br />

vapor retarder on the exterior face of the interior walls of<br />

above-grade exterior masonry cavity walls. It excels as a<br />

utility coating on posts, pilings and other metal surfaces<br />

set into the ground.<br />

<strong>Armor</strong>Block 361 WB can be spray, brush or roll applied to<br />

any vertical or horizontal surface.<br />

Property<br />

Method<br />

Results<br />

Color<br />

Total Solids Application Application Elongation Resistance Total Cure<br />

Method Range @ 70° F<br />

(21°C)<br />

to Hydrostatic<br />

Head<br />

Pressure<br />

Time<br />

– – – – ASTM<br />

D-412<br />

Die C<br />

Black 55 – 60% Spray,<br />

Brush,<br />

Roller<br />

20º to<br />

130ºF<br />

(Federal<br />

Spec TT-<br />

C-555B,<br />

Par 4.4.7)<br />

180% No Water<br />

Infiltration<br />

Weight/<br />

Gallon<br />

Coverage<br />

Rate<br />

Tensile<br />

Strength<br />

– – – ASTM-<br />

C- 719<br />

24 hrs. 7.6 lbs. 2 gal/100<br />

ft 2<br />

Water Film<br />

Vapor Thickness-<br />

Permeance Membrane<br />

Only<br />

ASTM<br />

E-96<br />

32 psi min. 0.20 perm<br />

(grains/sq.<br />

ft/h)<br />

Shelf Life<br />

– –<br />

20 mil dry<br />

thickness<br />

6 mo.<br />

Accessories<br />

<strong>Armor</strong>Block<br />

<strong>Armor</strong>Mastic 200 Solvent-Based – ARMT-00200<br />

<strong>Armor</strong>Mastic 200 is a heavy-bodied trowel<br />

grade coating. It is excellent for patching tie<br />

holes, filling in honeycombed areas in both<br />

rough and smooth masonry surfaces prior<br />

to application of a variety of Mar-flex<br />

Commercial <strong>Product</strong>s.<br />

Uses<br />

Mar-flex’s <strong>Armor</strong>Mastic 200 is the most versatile heavy-bodied trowel grade<br />

coating available. This product is excellent for patching tie holes, filling in<br />

honeycombed areas in both rough and smooth masonry surfaces, and surface<br />

flaws. <strong>Armor</strong>Mastic200 remains flexible during freeze-thaw cycles, and can<br />

be applied during any season. You can patch all outside below grade wall ties<br />

with AM200.<br />

Properties<br />

Results<br />

Color<br />

Black<br />

Application<br />

Method<br />

Trowel or<br />

Hand Applied<br />

Application<br />

Range<br />

0˚ to 120˚ F<br />

Can be used with a variety of Mar-flex Commercial <strong>Product</strong>s including<br />

<strong>Armor</strong>Sheet 600/601, <strong>Armor</strong>Block 361 and <strong>Armor</strong>Membrane 363 and the<br />

full <strong>Armor</strong> <strong>Series</strong> line.<br />

<strong>Armor</strong> 700 Solvent-Based Primer – ASBP-70005<br />

<strong>Armor</strong> 700 SB Primer is a solvent-based penetration asphalt primer used for the preparation<br />

of all types of surfaces previous to the application of sheet membranes and hot or cold asphalt<br />

where application temperatures of 20°F or more are present.<br />

Property<br />

Weight per<br />

Gal.<br />

Solids by<br />

Weight<br />

Color Dry Time Cure Time Service<br />

Temp.<br />

Coverage<br />

Application<br />

Temp.<br />

VOC<br />

Uses<br />

Designed for use as a prime coat for concrete, gypsum, masonry, brick and metal surfaces over<br />

which waterproofing asphaltic products are to be applied. This solution readily penetrates<br />

pores and seals dusty masonry surfaces to provide a firm base for such applications.<br />

<strong>Armor</strong> 710 Water-Based Primer – AWBP-70105<br />

<strong>Armor</strong> 710 WB Primer is water-based polymer modified primer for self-adhering<br />

membranes. The 710 WB Primer penetrates pores and dries fast to provide a tacky,<br />

firm substrate for adhesion of the membranes.<br />

Property Results<br />

7.5 lbs. 45% Dark Gray/<br />

Black<br />

Weight per<br />

Gal.<br />

Solids by<br />

Weight<br />

60 min<br />

@75°F &<br />

50% RH<br />

2-4 hrs. @<br />

75°F and<br />

50% RH<br />

-40°F and<br />

160°F<br />

Color Dry Time Cure Time Service<br />

Temp.<br />

150 sqft/gal 20°F and<br />

rising<br />

Coverage<br />

Application<br />

Temp.<br />

450 g/l<br />

VOC<br />

Uses<br />

The 710 WB Primer is suitable for use over asphalt, wood, plywood, gypsum board<br />

and concrete surfaces.<br />

Results<br />

8.6 lbs. 37% Milky Blue 25-30 min<br />

@75°F &<br />

50% RH<br />

2 hrs. @ 75°F<br />

and<br />

50% RH<br />

-40°F and<br />

160°F<br />

400 sqft/gal 40°F and<br />

rising<br />

VOC<br />

Compliant<br />

14<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

15<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.

Exterior Commercial Air/Vapor Barrier<br />

WATERPROOFING & BUILDING PRODUCTS<br />

CWAB-12005 (5gal)<br />

CWAB-120055 (55gal)<br />

1200p<br />

1200p Vapor Permeable, water-based, Liquid Applied AirBarrier is an<br />

acrylic membrane that cures to form a seamless membrane around the<br />

building envelope.<br />

Uses<br />

1200p is intended as a breathable air barrier for all types of cavity wall construction.<br />

1200p has been formulated to protect the building envelope from air filtration and<br />

exfiltration, while still allowing the transmission of water vapor to prevent<br />

condensation in the wall assembly.<br />

Property<br />

Method<br />

Results<br />

Type<br />

Air Leakage<br />

Rate<br />

– ASTM<br />

E2178<br />

Elastomeric<br />

Emulsion<br />

0.0004 cfm/<br />

ft 2 under a<br />

pressure<br />

differential<br />

of 0.3"<br />

water.<br />

On concrete<br />

block and<br />

drywall.<br />

Elongation<br />

(%)<br />

ASTM<br />

D412<br />

(DieC)<br />

Low-Temperature<br />

Flexibility<br />

ASTM<br />

D1970<br />

1200 % Flexible to<br />

-15°F<br />

Peel<br />

Adhesion<br />

to<br />

Concrete<br />

ASTM<br />

D903<br />

Peel<br />

Adhesion<br />

to<br />

CMU<br />

ASTM<br />

D903<br />

9.1 lbf/in. 20.25 lbf/<br />

in.<br />

Peel<br />

Adhesion<br />

to Ext.<br />

Sheathing<br />

ASTM<br />

D903<br />

Water<br />

Vapor<br />

Permeance<br />

ASTM<br />

E96 (B)<br />

VOC<br />

20 lbf/in. 12 perms

Exterior Commercial Hot Rubberized Applied Waterproofing Membrane<br />

WATERPROOFING & BUILDING PRODUCTS<br />

AHRA-00050<br />

800<br />

Mar-flex <strong>Armor</strong>HRA 800 Hot<br />

Rubberized Applied Waterproofing<br />

Membrane is a single-component,<br />

rubberized asphalt compound that<br />

forms a tough, flexible, thick waterproofing<br />

membrane. <strong>Armor</strong>HRA<br />

800 is comprised of 24% pre-consumer<br />

material and can contribute<br />

toward LEED ® credits in new construction. <strong>Armor</strong>HRA 800 adheres to<br />

virtually any sound vertical or horizontal surface, to ensure water will not<br />

migrate beneath the membrane in the event of physical damage. The fast<br />

setup time speeds the completion of the waterproofing. <strong>Armor</strong>HRA 800<br />

Hot-Applied Liquid Membrane is applied in a thick, monolithic coating<br />

utilizing <strong>Armor</strong>HRA 800 Reinforcing Fabric, which allows for a wide variety<br />

of substrate conditions. <strong>Armor</strong>HRA 800 is used for waterproofing splitslab<br />

construction projects and is especially suited as the waterproofing<br />

membrane on roof decks using the inverted roof membrane assemblies and<br />

green roof systems.<br />

Accessories<br />

<strong>Armor</strong>HRA 800<br />

PACKAGING<br />

<strong>Armor</strong>HRA 800 is packaged in 50-lb. blocks, one block per<br />

carton, 48 cartons per pallet. Each block is sealed in a<br />

polyethylene bag inside the carton. The block, including the<br />

bag, is placed in the kettle, leaving only disposal of the carton.<br />

The HRA 800 Reinforcing Fabric is packaged in rolls of<br />

36"x360'. (1080 sqft). Approximate weight per roll-16lbs.<br />

Sold in Cartons of 4 rolls per Carton.<br />

COVERAGE RATE<br />

The following is a guide to estimate the amount of<br />

materials required for various membrane thicknesses.<br />

Approx: 11.39 lbs/gallon.<br />

215 mils applied = 1.53 lbs/ft2 = 7.5 ft2/gal<br />

125 mils applied = 0.89 lbs/ft2 = 13 ft2/gal<br />

90 mils applied = 0.64 lbs/ft2 = 18 ft2/gal<br />

*Application temperature 350-400˚F<br />

SHELF-LIFE<br />

When stored at temperatures between 40°- 100° shelf life<br />

is 12 months in the original, unopened container.<br />

Property<br />

Method<br />

Typical Value<br />

Solids<br />

Content<br />

ASTM<br />

D1353<br />

Flow<br />

ASTM<br />

D5329<br />

100% Control<br />

60% No effect 0ºF 50%<br />

Sulfuric<br />

Acid w/o<br />

blistering,<br />

deterioration,<br />

delamination<br />

or<br />

reemulsification<br />

Sodium<br />

Chloride<br />

Resistance<br />

ASTM<br />

D896<br />

Passed<br />

20%<br />

Sodium<br />

Chloride<br />

w/o<br />

blistering,<br />

deterioration,<br />

delamination<br />

or<br />

re-emulsification<br />

ASTM<br />

D896<br />

Passed<br />

0/10/10<br />

Fertilizer<br />

w/o<br />

blistering,<br />

deterioration,<br />

delamination<br />

or<br />

re-emulsification<br />

<strong>Armor</strong>HRA Fabric – AHRA-36360<br />

Mar-flex <strong>Armor</strong>HRA 800 Reinforcing Fabric is a 1.35 oz/sq yd spun bonded<br />

polyester, high strength material used to reinforce the Mar-flex HRA<br />

membranes in a variety of applications.<br />

In addition, the 800 Reinforcing Fabric exhibits high resistance to splitting<br />

and cracking from thermal shock, low temperatures, freeze/thaw cycles,<br />

folding/creasing and rough handling. Unlike fiberglass, it is non-irritating to<br />

the skin.<br />

Property<br />

Results<br />

Method<br />

Weight oz/yd 2<br />

ASTM<br />

D1910<br />

Breaking<br />

Strength<br />

ASTM<br />

D2523<br />

Tear<br />

Strength lbs.<br />

ASTM<br />

D2263<br />

Flex Life,<br />

Cycles<br />

ASTM<br />

D813<br />

Ellongation<br />

at Break %<br />

ASTM<br />

D2523<br />

Packaging<br />

1.35 25 8 >1000,000 42 36" x 360' - 4<br />

rolls/carton<br />

–<br />

<strong>Armor</strong> 700 Solvent Based – ASBP-70005<br />

The Mar-flex 700 SB Primer is a solvent based penetration asphalt primer used for the<br />

preparation of all types of surfaces previous to the application of sheet membranes and<br />

hot or cold asphalt where application temperatures of 20°F or more are present.<br />

Property<br />

Weight per<br />

Gal.<br />

Solids by<br />

Weight<br />

Color Dry Time Cure Time Service<br />

Temp.<br />

Coverage<br />

Application<br />

Temp.<br />

VOC<br />

It is especially designed for use as a prime coat for concrete, gypsum, masonry, brick<br />

and metal surfaces over which waterproofing asphaltic products are to be applied. This<br />

solution readily penetrates pores and seals dusty masonry surfaces to provide a firm<br />

base for such applications.<br />

Results<br />

7.5 lbs. 45% Dark Gray/<br />

Black<br />

60 min<br />

@75°F &<br />

50% RH<br />

2-4 hrs. @<br />

75°F and<br />

50% RH<br />

-40°F and<br />

160°F<br />

150 sqft/gal 20°F and<br />

rising<br />

450 g/l<br />

All surfaces to be primed must be dry and free from dust, dirt, oil, grease and any other<br />

foreign matter.<br />

18<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

19<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.

Commercial Foam<br />

WATERPROOFING & BUILDING PRODUCTS<br />

25 / 40<br />

25 – ARFM-24825 (10 pieces per bag)<br />

– ARFM-14825 (20 pieces per bag)<br />

40 – ARFM-24840 (10 pieces per bag)<br />

– ARFM-14840 (20 pieces per bag)<br />

<strong>Armor</strong>Foam Board is constructed of expanded polystyrene and has considerably<br />

better thermal insulation capacity than conventional EPS products.<br />

Uses<br />

The <strong>Armor</strong>Foam 25 and 40 are both expanded polystyrene foam insulation<br />

boards that meet the needs of the commercial foundation and building floor<br />

slab market where a high psi is required (use the <strong>Armor</strong>Foam 40 product where<br />

highest psi is demanded). This insulation can also be used for attics, foundations/<br />

slabs and craw spaces in residential applications. <strong>Armor</strong>Foam Graphite-Enhanced<br />

Expandable Polystyrene Foam (GPS) Insulation has more than 30 years of proven<br />

performance in wet environments. The closed-cell structure of <strong>Armor</strong>Foam<br />

Expanded Polystyrene Foam (GPS Insulation resists water pickup, enabling it<br />

to retain a high R-value* over time - a necessary property in wet, below-grade<br />

commercial foundation applications).<br />

PACKAGING*:<br />

1.188" x 4' x 8' – (R-5) 20 sheets per bag<br />

2.375" x 4' x 8' – (R-10) 10 sheets per bag<br />

ADVANTAGES:<br />

• Combines high R-value, and superior moisture<br />

protection into one product<br />

(use the <strong>Armor</strong>Foam 40 for highest R-Value)<br />

• Offers a high compression psi rating (25psi and 40psi)<br />

• Protects waterproofing<br />

• Light-weight, Easy to handle and install<br />

• Can be used in any geographical area<br />

• No a food source for insects or other any animals<br />

• Less than.2% water absorption, this maintaining its R-value<br />

• May be used to qualify for LEED credits<br />

Property<br />

Results<br />

ASTM C587<br />

(25 psi)<br />

ASTM C578<br />

(40 psi)<br />

Norminal<br />

Density<br />

N/A<br />

2<br />

PCF<br />

2.5<br />

PCF<br />

Compressive<br />

Resistance 3<br />

Minimum At<br />

10%<br />

Deformation<br />

ASTM<br />

D1621<br />

25<br />

PSI<br />

40<br />

PSI<br />

R-Value<br />

Per Inch<br />

Thickness At<br />

75 F Mean<br />

Temperature<br />

ASTM<br />

C518<br />

4.7<br />

ft 2 •hr •˚F<br />

Btu<br />

4.8<br />

ft 2 •hr •˚F<br />

Btu<br />

Water Vapor<br />

Permeance<br />

ASTM<br />

E96<br />

2.5<br />

Perm<br />

2.5<br />

Perm<br />

Flexural<br />

Strength<br />

Minimum<br />

ASTM<br />

C203<br />

50.0<br />

psi<br />

60.0<br />

psi<br />

Dimensional<br />

Stability<br />

Maximum<br />

ASTM<br />

D2825<br />

2.0<br />

% Linear<br />

Change<br />

2.0<br />

% Linear<br />

Change<br />

Water<br />

Absorption<br />

Maximum<br />

ASTM<br />

C272<br />

2.0<br />

% by Volume<br />

2.0<br />

% by Volume<br />

Oxygen Index<br />

Minimum<br />

ASTM<br />

D2863<br />

24<br />

volume %<br />

24<br />

volume %<br />

Density<br />

Minimum<br />

ASTM<br />

D1622<br />

1.80<br />

PCF<br />

2.40<br />

PCF<br />

Flame Spread<br />

ASTM<br />

E84<br />

5<br />

INDEX<br />

25<br />

INDEX<br />

Smoked<br />

Developed<br />

ASTM<br />

E84<br />

25<br />

INDEX<br />

450<br />

INDEX<br />

*Packaging is the same for <strong>Armor</strong>Foam 25 & 40<br />

Accessories<br />

<strong>Armor</strong>Foam<br />

Board fasteners. Fastens board to poured wall, providing an additional<br />

bond until backfilled. May be installed into concrete with hammer.<br />

AI-28132 (1")<br />

AI-28136 (1.5")<br />

AI-28134 (1-1/4")<br />

AI-28138 (2-1/2")<br />

500/box<br />

<strong>Armor</strong>Flash is designed to be used in conjunction with all <strong>Armor</strong> <strong>Series</strong> products.<br />

CETS-0475 (4" x 75') CETS-1875 (18" x 75')<br />

CETS-0675 (6" x 75') CETS-2475 (24" x 75')<br />

CETS-1275 (12" x 75')<br />

Rolls per box varies per size<br />

4"-9 rolls, 6"-6 rolls, 12"-3 rolls, 18"-2 rolls, 24"-1 roll<br />

<strong>Armor</strong>Masonry Sealer – CWSS-0005<br />

PACKAGING:<br />

5-Gallon Bucket<br />

<strong>Armor</strong>Masonry Sealer is a single component water-based emulsion<br />

of siloxane that penetrates into concrete and masonry and<br />

provides true long term weatherproofing protection.<br />

Uses<br />

The <strong>Armor</strong>Masonry Sealer provides outstanding long term<br />

weatherproofing protection for many types of concrete and<br />

masonry surfaces. Aside from its ability to bead water, it<br />

allows the substrate to breathe due to its moisture vapor<br />

permeability. <strong>Armor</strong>Masonry Sealer is ideal for horizontal concrete<br />

applications and porous concrete block. It protects against deicing<br />

salts and chloride ions and will not change transaction or skid<br />

resistance of a surface. <strong>Armor</strong>Masonry Sealer penetrates the<br />

substrate, and chemically reacts with and bonds to the concrete or<br />

masonry surface. The invisible film will bead water and protect the<br />

substrate many times longer than conventional coatings.<br />

ADVANTAGES:<br />

• Water-based, low odor<br />

• Ready to use<br />

• V.O.C. Compliant<br />

• Outstanding protection against deicing salts<br />

and chloride ions<br />

• Excellent beading for improved aesthetics<br />

• Will not change the traction or skid resistance of a surface<br />

• No color change; will not darken surface<br />

• Strong chemical bond to the substrate<br />

• Excellent vapor transmission<br />

• Dries quickly, re-open to traffic in 1-2 hours<br />

• Excellent alkali resistance<br />

Sponsored by:<br />

WATERPROOFING &<br />

BUILDING PRODUCTS<br />

20<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

Order Today! Contact Mar-flex for the dealer nearest you. 800-498-1411 | 513-422-7285 | Fax 513-422-7282 | Mar-flex.com<br />

21<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.<br />

©<strong>2017</strong> Mar-flex Waterproofing & Building <strong>Product</strong>s. All rights reserved.

Mar-flex Freight Zones<br />

Order Form<br />

WATERPROOFING & BUILDING PRODUCTS<br />

Washington<br />

ZONE 4<br />

*$1,100<br />

Freight Allowance<br />

ZONE 3<br />

*$1,000<br />

Freight Allowance<br />

ZONE 1<br />

*$1,400<br />

Freight Allowance<br />

Maine<br />

Office Hours: Monday-Friday 8:00a.m. - 5:00p.m. E.S.T.<br />

Shipping Hours: Monday-Friday 8:00a.m. - 4:00p.m. E.S.T.<br />

COPY AND FAX/EMAIL TO:<br />

513-422-7282 or email: info@mar-flex.com<br />

OR CALL TOLL FREE 1-800-498-1411<br />

1. SOLD TO: 2. SHIP TO: (If different than #1)<br />

Company Name:<br />

Company Name:<br />

Montana<br />

North Dakota<br />

Minnesota<br />

VT<br />

NH<br />

Street Address:<br />

Street Address:<br />

Oregon<br />

Idaho<br />

South Dakota<br />

Wisconsin<br />

Michigan<br />

New<br />

York<br />

MA<br />

RI<br />

City/State/Zip:<br />

Phone:<br />

City/State/Zip:<br />

Phone:<br />

Nevada<br />

Wyoming<br />

Nebraska<br />

Iowa<br />

Indiana<br />

Ohio<br />

Pennsylvania<br />

MD<br />

NJ<br />

DE<br />

CT<br />

Buyers Name/Title:<br />

California<br />

ZONE 5<br />

*$1,400<br />

Freight Allowance<br />

Utah<br />

Arizona<br />

Arizona<br />

Colorado<br />

New Mexico<br />

Kansas<br />

Oklahoma<br />

Texas<br />

Missouri<br />

Arkansas<br />

Illinois<br />

Mississippi<br />

Tennessee KY<br />

Alabama<br />

Kentucky<br />

Georgia<br />

WV<br />

Virginia<br />

North<br />

Carolina<br />

South<br />

Carolina<br />

ZONE 2<br />

*$800<br />

Freight Allowance<br />

Quantity Item # Item Description Unit Price Total Price<br />

ZONE 6<br />

Hawaii & Canada<br />

Call for current rates<br />

* Regardless of order size, we will always locate the best shipping terms to meet your<br />

timing and delivery requirements. If your total order exceeds $24,000 and fits on a single<br />

truckload, the freight allowance will be given toward the actual cost of the shipment.<br />

Louisiana<br />

Florida<br />

SHIPPING POLICY<br />

Your order is shipped from the nearest Mar-flex location or dealer. UPS is used<br />

whenever possible. However, should your order exceed UPS size or weight limits,<br />

“Common Carrier” (LTL) will be selected and generally has a 48hr turnaround. Back<br />

ordered items to ship F.O.B. from origin at customer's expense.<br />

RUSH SHIPMENTS/SPECIAL INSTRUCTIONS<br />

Please request UPS Next Day Air, 2nd or 3rd Day, preferred truck line, or<br />

special instructions. We will promptly take care of your needs.<br />

Subtotal<br />

Tax<br />

Shipping<br />

Total Amount<br />

Call for<br />

options &<br />

amounts<br />

Credit Terms & Conditions<br />

Credit Terms are Net 30 subject to approval (unless otherwise<br />

noted). Any amount remaining unpaid after such date will<br />

incur a service charge of 1.5% (monthly) on the unpaid<br />

balance, until paid in full, plus any and all collections costs and<br />

attorney fees incurred to collect unpaid balances.<br />

Sales and/or use taxes will be collected in the following<br />

states: Illinois, Indiana, Ohio, Pennsylvania and Tennessee. For<br />

purchases shipped to other states, taxes are the responsibility<br />

of the purchaser. The collection of sales and/or use taxes is<br />

subject to change in order to comply with state regulations. All<br />

orders are subject to acceptance.<br />

Every effort has been made to ensure the accuracy of the<br />

information contained in this catalog. Because of our constant<br />

efforts to offer the very best products, we reserve the right to<br />

change product specifications and/or prices without notice.<br />

All credit card transactions, including payments on<br />

accounts, will incur a 3% service charge.<br />

Return Policy<br />

We will normally accept returned products under the<br />

following conditions:<br />

• Prior written authorization including RGA number from<br />

Mar-flex Waterproofing <strong>Product</strong>s is obtained.<br />

• <strong>Product</strong>s must be returned within 30 days from the original<br />

date of the invoice.<br />

• <strong>Product</strong>s must be in new and saleable condition.<br />

• <strong>Product</strong>s must be normal stock for us<br />

(not special or custom order).<br />