You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

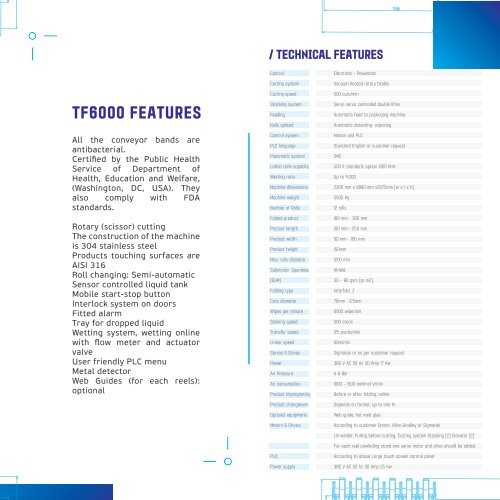

TECHNICAL FEATURES<br />

TF6000 FEATURES<br />

Control<br />

Cutting system<br />

Cutting speed<br />

Stacking system<br />

Feeding<br />

Rolls spliced<br />

Electronic - Pneumatic<br />

Vacuum heated rotary blades<br />

500 cuts/min<br />

Servo servo controlled double lifter<br />

Automatic feed to packaging machine<br />

Automatic detecting- rejecting<br />

All the conveyor bands are<br />

antibacterial.<br />

Certified by the Public Health<br />

Service of Department of<br />

Health, Education and Welfare,<br />

(Washington, DC, USA). They<br />

also comply with FDA<br />

standards.<br />

Rotary (scissor) cutting<br />

The construction of the machine<br />

is 304 stainless steel<br />

Products touching surfaces are<br />

AISI 316<br />

Roll changing: Semi-automatic<br />

Sensor controlled liquid tank<br />

Mobile start-stop button<br />

Interlock system on doors<br />

Fitted alarm<br />

Tray for dropped liquid<br />

Wetting system, wetting online<br />

with flow meter and actuator<br />

valve<br />

User friendly PLC menu<br />

Metal detector<br />

Web Guides (for each reels):<br />

optional<br />

Control system<br />

Motion and PLC<br />

PLC language<br />

Standard English or customer request<br />

Pneumatic system<br />

SMC<br />

Lotion tank capacity 500 lt standard, option 1000 litre<br />

Wetting ratio Up to %300<br />

Machine dimensions 2300 mm x 8900 mm x2075mm (w x l x h)<br />

Machine weight<br />

5900 Kg<br />

Number of Rolls<br />

12 rolls<br />

Folded product<br />

180 mm - 300 mm<br />

Product length<br />

100 mm - 250 mm<br />

Product width<br />

90 mm - 180 mm<br />

Product height<br />

150mm<br />

Max. rolls diameter<br />

1200 mm<br />

Substrate Spunlace, Airlaid,<br />

(GSM)<br />

30 – 80 gsm (gr-m2)<br />

Folding type<br />

Interfold, Z<br />

Core diameter<br />

76mm - 125mm<br />

Wipes per minute<br />

6000 wipe/min<br />

Sacking speed<br />

500 stack<br />

Transfer speed<br />

125 packs/min<br />

Linear speed<br />

60m/min<br />

Servos & Drives<br />

Sigmatek or as per customer request<br />

Power<br />

380 V AC 50 Hz 30 Amp 17 Kw<br />

Air Pressure<br />

6-8 Bar<br />

Air consumption<br />

1000 – 1500 nominal V/min<br />

Product impregnating Before or after folding, online<br />

Product changeover<br />

Optional equipment:<br />

Motors & Drives:<br />

Depends on format, up to one hr<br />

Web guide, hot melt glue<br />

According to customer Omron, Allen Bradley or Sigmatek<br />

Un-winder, Pulling before cutting, Cutting system Stacking (2) Elevator (2)<br />

For each reel unwinding stand one servo motor and drive should be added.<br />

PLC:<br />

Power supply<br />

According to above Large touch screen control panel<br />

380 V AC 50 hz 30 Amp 25 Kw