MANmagazine Bus edition 1/2017 International

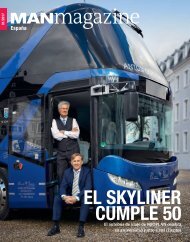

In this issue of MANmagazine, we celebrate the NEOPLAN Skyliner's birthday. It was exactly 50 years ago that NEOPLAN created a new kind of bus, the double-decker coach. Since then, the Skyliner has been delighting customers worldwide as a reliable and stylish companion for holidaymakers. One of the first customers was Anton Götten Reisen from Saarbrücken, for whom the Skyliner has been an integral part of the fleet ever since its market launch. You can also read about why Dubai is relying on gas-fuelled buses from MAN and how the latest model of the NEOPLAN Tourliner proved its abilities on the roads of the Dolomites.

In this issue of MANmagazine, we celebrate the NEOPLAN Skyliner's birthday. It was exactly 50 years ago that NEOPLAN created a new kind of bus, the double-decker coach. Since then, the Skyliner has been delighting customers worldwide as a reliable and stylish companion for holidaymakers. One of the first customers was Anton Götten Reisen from Saarbrücken, for whom the Skyliner has been an integral part of the fleet ever since its market launch.

You can also read about why Dubai is relying on gas-fuelled buses from MAN and how the latest model of the NEOPLAN Tourliner proved its abilities on the roads of the Dolomites.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IMPRESSIVE ALL ALONG THE LINE:<br />

COMPONENTS AND SYSTEMS FROM ZF<br />

<strong>Bus</strong> passengers expect maximum safety and comfort. Transmissions and axles from ZF help fulfill these expectations.<br />

They let passengers get in and out quickly and safely, and ensure a swift and pleasant journey. What’s more,<br />

our products are tailored precisely to one another and are always top quality, providing dynamic acceleration<br />

and quiet running too. That way, you can reduce strain on the vehicle and the environment – not to mention<br />

the life cycle costs. www.zf.com/buses<br />

Final check: At the new customer<br />

centre, MAN employees and<br />

customers give the completed city<br />

buses a careful inspection.<br />

„I was most<br />

impressed by the<br />

cathodic immersion<br />

paint system.”<br />

Horst Noppe, Head of Technology at <strong>Bus</strong>verkehr<br />

Oder-Spree GmbH<br />

about 500 employees changed to the sister<br />

company. Roughly the same number chose to<br />

leave with severance pay and quickly found<br />

other jobs in the Poznan region. The goal<br />

during relocation was “to integrate all Poznan<br />

parameters into the Starachowice processes,<br />

while simultaneously increasing efficiency,<br />

shortening run times and above all maintaining<br />

quality”, enumerates Kobriger. “The fact<br />

that we actually achieved that target was due<br />

to the amazing work of the team.” To some<br />

extent, goals were even exceeded: “During<br />

the two relocation years, for example, we<br />

increased productivity by 14%.” This certainly<br />

serves as a testament to how the knowledge<br />

transfer to the new and extremely committed<br />

employees happened so seamlessly.<br />

WHEN TOURING THE PLANT, customers are<br />

amazed by the modern facilities. “I’m pleasantly<br />

surprised by the cleanliness and the fact<br />

that all logistical workflows take place under<br />

one roof,” emphasises Christian Popp, Head of<br />

Operations for Austria’s bus enterprise ÖBB-<br />

Postbus. In Starachowice, the entire production<br />

process of a bus is made transparent. One<br />

of the highlights for visitors is the projection<br />

room. Here developers work with life-sized<br />

and walk-in 3-D simulations that appear real<br />

enough to give some guests a dose of<br />

dizziness. At another station, the laser cutting<br />

area, staff members are punching out the<br />

sheet metal parts for the bus frame. After stabilising<br />

and erecting the frame, the bus is<br />

dipped into multiple basins of cathodic<br />

immersion paint to ensure optimised<br />

corrosion resistance. MAN’s Starachowice site<br />

is the only bus manufacturer in Poland to<br />

operate such equipment. The measuring and<br />

chemical labs are also ultramodern and facilitate<br />

ecological solutions. In 2012, the plant<br />

also put a thermal exhaust air treatment<br />

system into operation.<br />

In the assembly hall for bus interiors, the<br />

MAN crews work on the individual vehicles<br />

on two levels. The wide diversity of design<br />

variants, due to customer-specific furnishing<br />

choices, poses a major challenge for<br />

employees, such as when installing electronics<br />

– be it for cash register systems or for triggering<br />

traffic lights. Upon completion, the<br />

buses are handed over to the customer in the<br />

delivery centre, where the new owners can<br />

scrutinise their vehicles carefully and sign<br />

off on them. “This plant is just as good as the<br />

one in Poznan, and we’re very satisfied with<br />

our sophisticated new low-floor buses,” says<br />

Christian Studnicka from the technology department<br />

at ÖBB-Postbus, when summarising<br />

his impressions.<br />

© Piotr Malecki<br />

18